Pogo Pins and Pogo Pin Connector China Provider, Manufacturer & Supplier

Johoty offers flexible solutions and on-demand manufacturing for ultra-precise, affordable Pogo Pins and Pogo Pin Connector.

Products Categories

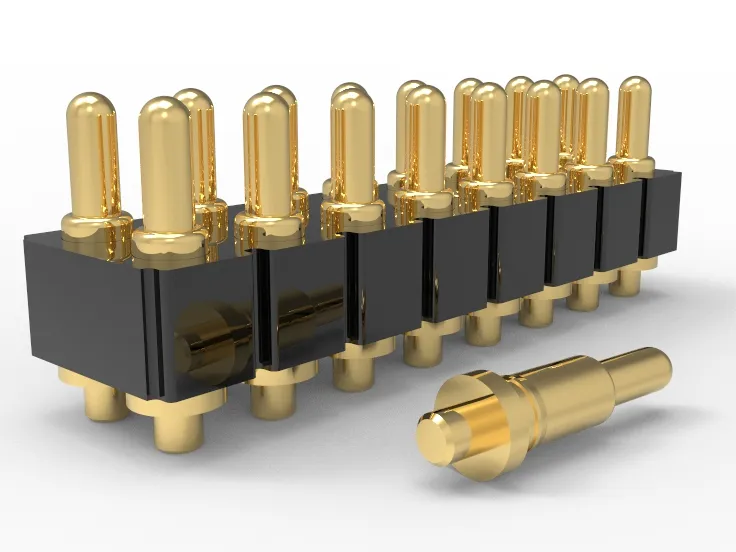

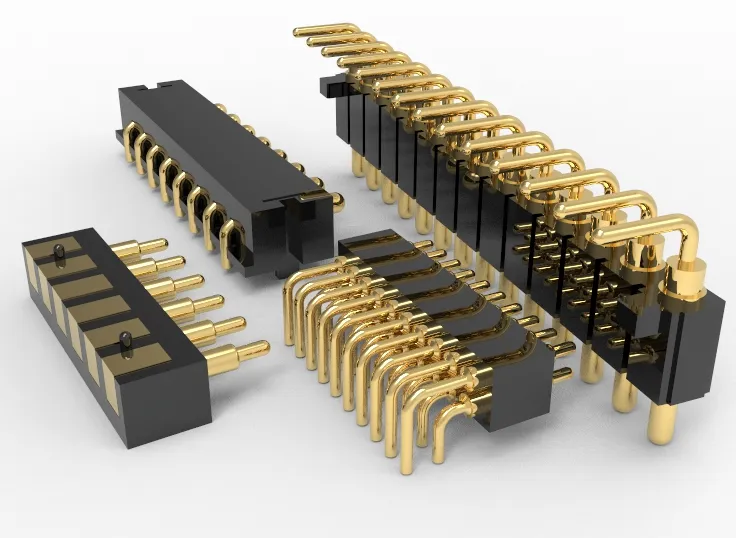

Johoty offers diverse precision parts including pogo pins and pogo pin connector in standard and custom specs. Over 20 installation methods and over 50,000 types. we offer you more choices.

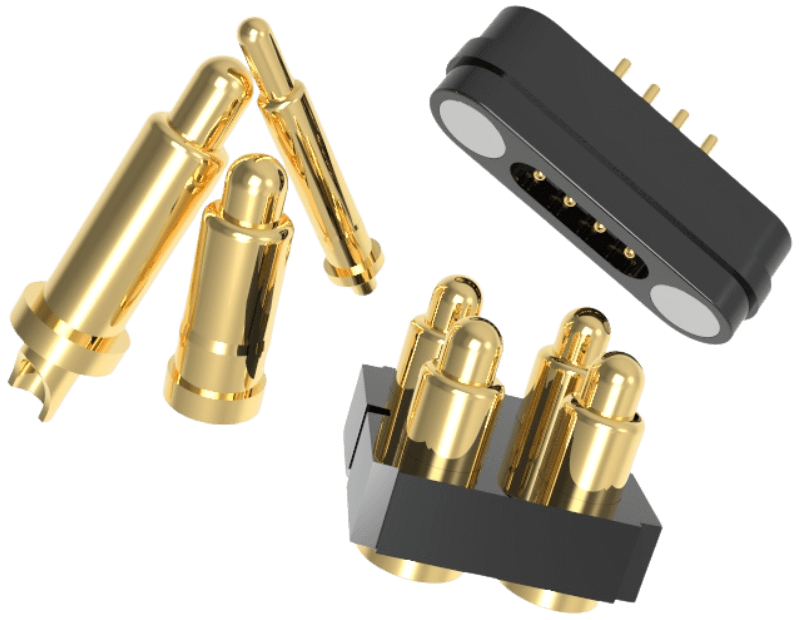

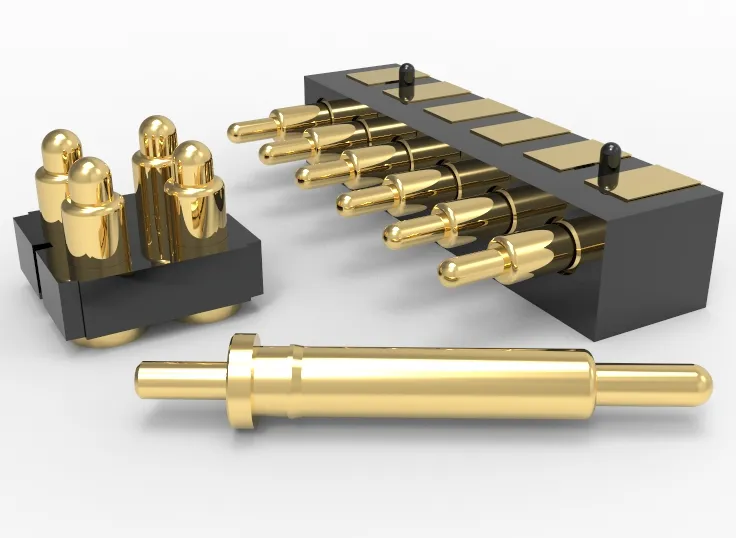

Pogo Pins

Ultra-precise, supremely flexible, cost-effective, long-lasting durability, optimal contact, enhancing product reliability, stability.

Pogo Pin Connector

Precision design, Diverse sizes, affordable, highly reliable electrical connections, ensure user experience for clients’ products.

About Jonoty Technology

Why Choose Us

50,000+ connector types, 20+ installation methods, over 20 years of R&D and production, best price highest quality! Often inquiries and orders from Phd, professors, founders, engineers, and managers.

Utilize five-axis and six-axis CNC machines with TPM quality control.

Flexible solutions with professional technical answers and clarification.

Automated production lines with CNC and 2D/3D CMM

ISO9001, RoHS, REACH, ASTM, guaranteeing connector excellence.

Johoty always offers competitive prices and exceptional value.

Professional Services

CNC machining accuracy at the micrometer level, excellent surface smoothness, 2D/3D CMM, coating thickness tester, customization of diverse specs, shapes, materials for diverse applications, over 20 years of expertise and accumulation.

45-person R&D team, based on materials, electrical, size, shape, and application, produces in 5-axis CNC, confirms right tolerances through 2D CMM and diverse testing, shortens cycle through Johoty's rapid custom, samples, mass production.

Johoty's fast delivery is based on mature production processes and technology accumulated over 20 years, a 45-person R&D team, CNC machining, automation package, 2D/3D CMM, 100% CCD inspection, TQM, SIP, SOP, and stable SCM.

Johoty offers over 50,000 connector types with 20 install methods, customs 2~598 pins, brass, SUS or AISI materials. Supports RF, EMI, IP67/IP68, magnetic connector, and ≤1,200A current. Provide professional selection suggestions, proposals, or solutions.

Follow ISO, RoHS, REACH, ASTM based on advanced coating thickness tester, 2D/3D CMM, CCD, CNC machines, spring force & resistance tester, 23 QC inspection. Strictly select quality brass, stainless steel, copper alloy. Perfect structure design for high quality.

Provide customization, initial drawings within 48 hours, 20 years of pogo pin connector expertise of core engineers in high current, magnetic connector, waterproof IP67, high durability and reliability. Professional technical support to relieve your worries

Strict quality control and high-precision tests reduce production costs. From customized R&D to connector solutions, reduce intermediate steps. Automated assembly and high-precision CNC improve efficiency and reduce costs. Optimize designs for high cost-effectiveness.

High-purity copper alloy, eco-friendly gold-plated and H/F plastic with transparent compliance reports for ASTM, SGS, RoHS, REACH. Strict physical performance and chemical composition tests. Uniform gold-plated ultrafine blind holes inside and outside.

Meet Client Needs

Johoty offers solutions in 2 days, samples within 2 weeks, and high-precision testing instruments to ensure connector quality. Continuously develop new materials and optimize structural design. A complete solution without intermediate steps. Advanced production processes and automated assembly lines can reduce cost and price for you.

Client Background

A German automotive manufacturer required Johoty’s high current pogo pins to maintain stable power connections in high-vibration, temperatures.

Solution

Johoty adopts optimized music steel spring, claw head and blade contact points to ensure stable connection in high vibration. High-temp alloys ensure reliable performance at extreme temperatures. Crown multi-point contact structure enhances conductivity and vibration resistance. The 30u” gold plating process enhances oxidation resistance and longevity. Optimized pogo pin connector size, load capacity, rotating installation, and extended temperature sensor to fully meet professional applications.

Client Background

R&D engineer from an American aerospace company needed our pin pin ponnector to remain highly reliable in extreme environments to ensure the safety and stability of aviation devices.

Solution

Pick up peek housing and 316L pogo pins for stable work of aerospace devices. Gold-plating or AuCo composite electroplating ensures no performance decline for exposure to humid and hot. Bear 120A current to minimize unstable contact risks for high power. Music steel spring, anti-rotation locking, and extending temp. sensor ensures a reliable connection during high vibration. we design a 50,000 cycles lifespan to minimize replacement costs.

Client Background

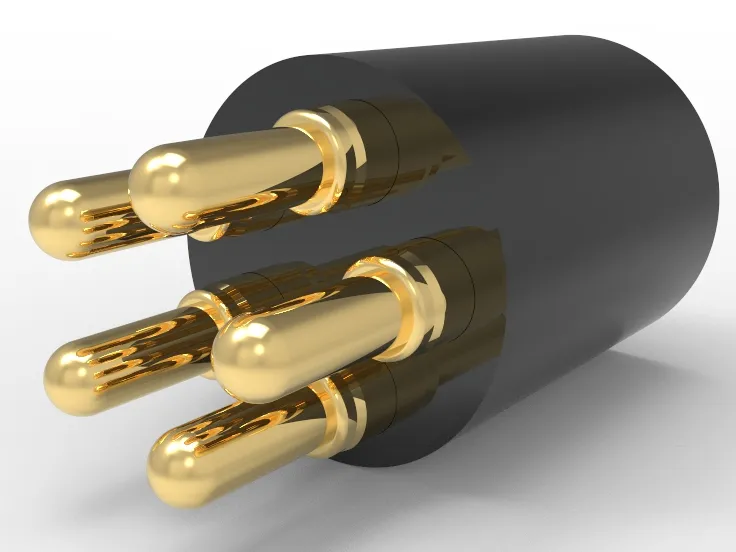

A co-founder from an American medical device manufacturer needed our IP67 magnetic pogo pin connector to provide high precision and stability in EMS system and small and complex medical instruments.

Solution

We use composite coating Copper Zinc Tin+Silver+Gold+Palladium+Gold+Platinum to cope with the environment of the EMS system, and IP67 ensures stability. N52 magnetic 100gf spring force is suitable for reliable connection of complex instruments. 5-axis CNC ensures stable signal and current transfer. Medical-grade raw materials are safe and reliable. Support 50,000 cycles of long lifespan and reduce maintenance costs.

Listen To The True Voice Of Johoty Customers

“As a procurement director, I am highly satisfied with Johoty’s 24-pin pogo pin connector. Mr.Alfred has a very good understanding and expertise. This connector works well in our devices and has high precision, it is very reliable. Its durability and biocompatible materials are impressive and significantly enhance our equipment’s lifespan and safety. We are deeply impressed by Johoty’s strict quality control and CNC production processes, CMM inspection, fully automatic spring force & resistance tester. Johoty allows us to introduce high-quality products to the market confidently. Many thanks to Mr. Alfred.”

“At Tesla, our standards for suppliers are stringent, and Johoty has exceeded our expectations. Their pogo pin can keep stable connections in high vibration and temperature, the 10A pogo pin has accurate sizes I am looking for and is crucial for our electronic systems. I know Johoty utilizes high-strength alloy materials and multi-layer gold plating, the pogo pin has good corrosion resistance and durability after our verification, it is very helpful and useful for product reliability.”

“We highly commend Johoty’s cup-head pogo pins. These connectors have accurate screw threads and work very well in our water heater control systems. they support high reliability in extreme environments after our long-term test. Johoty’s beryllium copper materials and strict tests ensure pogo pins remain stable under high humidity and temp. Johoty is trustworthy, with quality pogo pins, professional support, and technical service.”

“As an R&D engineer, I am impressed with Johoty’s φ6.0 threaded pogo pin. The miniature connector excels in our wireless electronic device, offers high precision and stability and streamlines my development work. I am seeing Johoty’s high-precision CNC machining and laser cutting, I believe this can ensure each of my pogo pins dimensional accuracy. During the project, Mr. Alfred provides professional technical support and fast response, this is very helpful and useful, helping us solve numerous technical challenges. Many thanks!”

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656