What is CCD? See How CCD Maintains High Dimensional Precision and Consistency in Pogo Pins, Ensuring Top-notch Quality for Your Applications

1. Introduction: What is CCD?

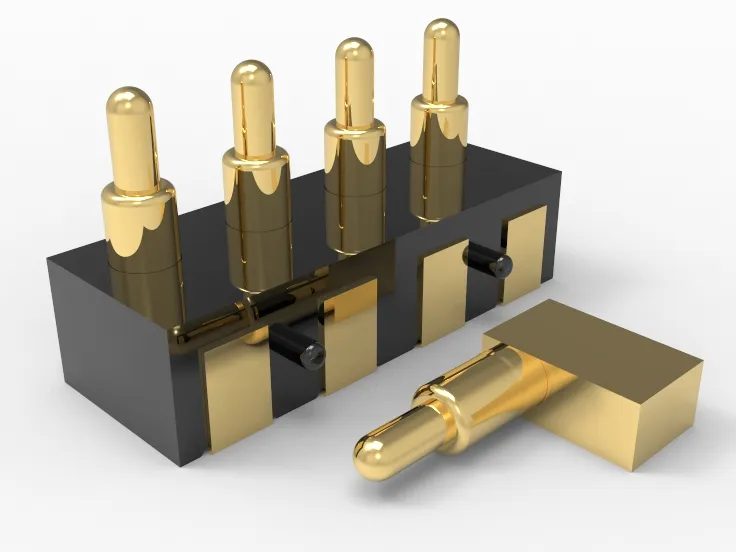

In high-precision manufacturing, even tiny errors can jeopardize a project. The size accuracy and consistency of Pogo Pins are crucial for ensuring device stability and performance. CCD, an advanced detection tool, captures and analyzes every detail with precision, offering unmatched quality assurance. Learn how CCD technology ensures the exceptional quality of Pogo Pins, paving the way for your project’s success.

2. What is CCD? Basic Principles

CCD is a widely used technology in image sensors. It converts light signals into electrical signals, enabling high-precision detection of small objects. For measuring Pogo Pins, CCD plays an irreplaceable role. It uses high-resolution imaging to precisely measure details like length, diameter, and surface defects.

2.1 How CCD Accurately Captures Pogo Pins’ Dimensions

- The core principle of CCD lies in its pixel array. When light hits the CCD sensor’s pixels, each pixel captures photons and converts them into charge. Over time, this charge accumulates, forming an accurate electrical signal. The CCD sends these signals to a processor, which analyzes the intensity and distribution to generate high-precision image data.

- This means every tiny size deviation in Pogo Pins can be precisely captured and identified, ensuring the product meets stringent standards.

2.2 How CCD Remains Ahead in Precision Measurement

- CCD maintains its leading position in measuring Pogo Pins due to its excellent sensitivity and high resolution. Even in low light, CCD provides clear images, ensuring reliable results.

- Its stability and longevity make it the preferred tool for industrial inspection, especially for high-precision Pogo Pins detection, where it offers consistent and reliable results.

2.3 Unique Feature: Innovative Use of CCD in Pogo Pin Inspection

- Compared to traditional size measurement methods, CCD technology boosts both the speed and accuracy of Pogo Pin inspections. By using multi-angle detection, CCD can measure Pogo Pins in detail and identify tiny defects invisible to the naked eye. This innovation improves quality control, reduces human error, and increases production efficiency.

- CCD ensures precise size control at the micron level for each connector. Its high-precision optical imaging detects minute size differences, avoiding issues like poor connections or performance drops due to size inconsistencies. This tech speeds up inspections and cuts down on human mistakes, keeping product quality steady. For manufacturers of high-demand electronics, CCD size inspection is essential.

- In making Pogo Pins, checking sizes accurately is key to ensuring they work well. CCD systems allow for real-time, detailed measurement of each Pogo Pin on the production line. With automatic calibration, CCD can detect and measure tiny size variations, ensuring all Pogo Pins meet strict quality standards. Using CCD technology not only boosts production efficiency but also guarantees that every Pogo Pin matches design specifications, ensuring the final product’s reliability and durability.

- While traditional methods face accuracy and efficiency limits, CCD technology revolutionizes Pogo Pin inspection. With high-resolution imaging and smart algorithms, CCD quickly and accurately measures Pogo Pins, providing real-time feedback and adjustments during production. This technology reduces manual errors and significantly speeds up inspections, ensuring every Pogo Pin in large-scale production meets standards for high performance and longevity.

3. What is CCD? How Does CCD Ensure High Size Precision and Consistency for Pogo Pins?

CCD technology improves the size precision and consistency of Pogo Pins in several ways:

- High-Resolution Imaging: CCD sensors capture detailed, high-resolution images of Pogo Pins. By comparing the standard size with actual measurements, CCD ensures each Pogo Pin’s size is within the required range.

- Real-Time Detection: CCD systems monitor and analyze sizes in real time, quickly spotting any deviations. This allows for immediate adjustments during production, reducing defects and ensuring consistency.

- Automated Processing: Combining CCD with automation allows for fully automated size checks. The system uses preset standards and algorithms to automatically identify and discard defective Pogo Pins, improving efficiency and reliability.

- Non-Contact Measurement: CCD uses non-contact methods, avoiding errors and wear that can occur with contact-based measurements. This extends the equipment’s lifespan and enhances precision and consistency.

- Data Recording and Analysis: CCD systems record data from each inspection, creating reports and charts for quality control and process improvement. This data also helps track product quality and improve consistency.

CCD technology excels in maintaining high size precision and consistency for Pogo Pins, ensuring the production of high-quality components.

4. What is CCD, How is CCD Used?

CCD technology excels in measuring Pogo Pins with high precision. It uses high-resolution sensors to capture tiny size changes, ensuring each Pogo Pin meets strict tolerance standards. This is crucial for reliable electronic devices, especially those requiring precise connections.

4.1 Comprehensive Detection

- CCD can measure various parameters of Pogo Pins, including length, diameter, and curvature. It detects tiny defects that traditional methods might miss, improving overall product quality and consistency.

4.2 Automated Detection

- CCD can be integrated with automated systems for full automation of size checks. This boosts efficiency and reduces human error by inspecting Pogo Pins in real time on the production line, ensuring only quality products are passed.

4.3 High-Speed Detection

- The fast imaging capability of CCD allows it to inspect many Pogo Pins quickly, essential for large-scale production. It meets the high-speed demands of production lines, ensuring all Pins meet specifications.

4.4 Data Analysis and Traceability

- CCD technology provides detailed data analysis and tracking, aiding in process management. If size issues arise, it helps pinpoint the production batch and stage, allowing for quick adjustments and improved management.

Overall, CCD technology offers high precision, comprehensive, automated, and fast detection capabilities, ensuring top-quality Pogo Pins and advancing the electronic connector industry.

5. What is CCD? The Importance of Using High-Quality Pogo Pins

- In high-end projects, precision and consistency are crucial. Pogo Pins are key components in connectors, and their accuracy directly impacts project quality. To meet these high standards, we use CCD inspection technology.

- CCD technology offers exceptional precision, allowing real-time monitoring and correction of tiny deviations during production, ensuring each Pogo Pin meets strict specifications. This improves product consistency and significantly reduces defects, saving on production costs.

- High-end projects demand attention to detail, where even minor errors can cause failure. Therefore, choosing Pogo Pins with precise dimensions and high consistency is essential for project success. CCD inspection helps us provide top-quality products, meeting the needs of various high-end projects.

6. What is CCD? What Quality Issues Can CCD Detect in Pogo Pins?

6.1 Surface Defects:

- Scratches and Cracks: CCD detects small scratches and cracks on Pogo Pins that could affect conductivity and lifespan.

- Stains and Foreign Matter: CCD identifies stains and embedded foreign matter that might impact contact quality and stability.

6.2 Size Deviations:

- Length and Diameter: CCD measures the length and diameter of Pogo Pins precisely, ensuring they meet design specifications and avoiding assembly issues due to size deviations.

- Flatness and Curvature: CCD checks the flatness and curvature of Pogo Pins to ensure they meet shape requirements for stability and reliability.

6.3 Coating and Plating Quality:

- Uniformity: CCD inspects the uniformity of coatings or platings on Pogo Pins, ensuring consistent thickness across all parts to prevent performance instability.

- Adhesion: CCD verifies coating adhesion to ensure it doesn’t peel off easily, maintaining long-term performance.

6.4 Assembly Quality:

- Spring Offset: CCD detects if the internal spring in a Pogo Pin is positioned correctly to prevent poor contact.

- Soldering Quality: CCD checks solder joints to ensure no weak or poor soldering, guaranteeing stable electrical connections.

7. How to Determine if Johoty is the Right Pogo Pin Supplier for You

7.1 Evaluate Johoty’s Credentials and Experience:

- Choose Johoty, an experienced Pogo Pin manufacturer with top-notch certifications and quality control. Check our credentials, customer reviews, and case studies to gauge the quality and service of our Pogo Pins.

7.2 Site Visit and Sample Testing:

- Visit our production facility to see our processes and testing firsthand. Request a few samples to assess and validate how well our CCD detection equipment operates.

7.3 Understand CCD Basics:

- CCDs are light-to-electricity converters used for precise measurements. They transform light signals into electrical signals for accurate detection and imaging. In Pogo Pin manufacturing, CCDs help check product dimensions, shapes, and surface quality.

7.4 Choose High-Resolution CCDs:

- Higher resolution CCDs provide clearer and more detailed images, essential for spotting tiny defects. Generally, higher resolution means greater detection accuracy.

7.5 Consider CCD Sensitivity and Dynamic Range:

- CCD sensitivity affects performance in low light, while dynamic range shows how well it adapts to varying light conditions. Opt for CCDs with high sensitivity and wide dynamic range for clear images in all lighting situations.

7.6 Check CCD Noise Levels:

- Low noise CCDs deliver cleaner images and reduce false readings. Select CCDs with low noise for accurate and consistent results.

7.7 Review CCD Speed and Frame Rate:

- For fast-paced production lines, high-speed and high-frame-rate CCDs are crucial. They capture more images quickly, boosting detection efficiency for high-speed production needs.

7.8 Assess CCD’s Environmental Suitability and Durability:

- Different CCDs are suited for different environments. Ensure the CCD can perform reliably in the supplier’s production conditions, considering factors like high temperatures, vibration, and dust resistance.

By understanding these aspects, you can make a scientific choice and find a high-quality Pogo Pin supplier like Johoty.

Conclusion:

- This guide highlights the role of CCD technology in maintaining precise dimensions and consistency in Pogo Pins. Understanding CCD principles helps ensure top-notch Pogo Pin quality for your projects, whether for medical devices, communication equipment, or other high-demand applications.

- For any questions or needs regarding Pogo Pin quality, contact our CFT team. We offer the best solutions to support your project’s success.