What is Pogo Pin? Johoty Shows You Designs | Specs, Performance | Reliability, Electrical Features, Applications, Best Prices | Custom, High Value!

Introduction

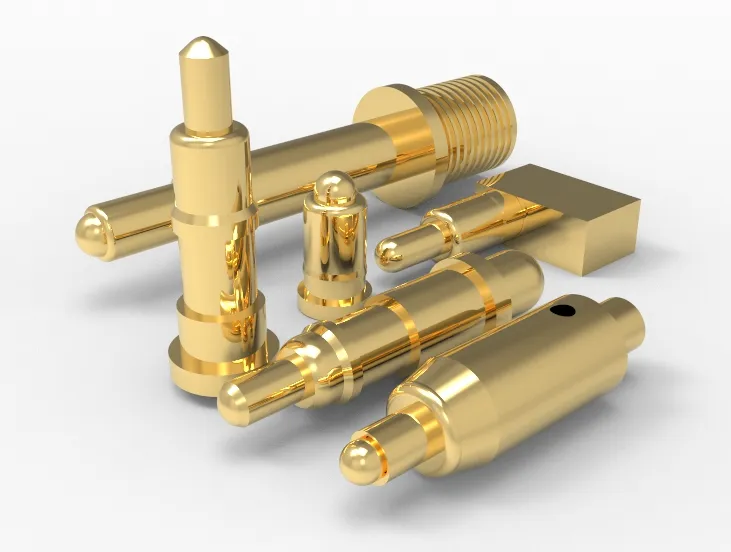

What is pogo pin? Pogo pin is an electronic connector that transmits signals, and power. Common pogo pins contain magnetic or weak magnetic properties, however, non magnetic connectors are customized for high-end devices.

Applied to smart devices, automobiles, medical equipment, etc. As a high-performance connectivity solution, it has unique designs and multiple performances. So, how to choose pogo pins that best suit your needs?

This article will reveal 15 key points to help you make informed decisions when choosing a pogo pin, ensuring the reliability and long-term stability of the connection. Continue reading to learn more important information about the best pogo pins!

Read: Various Pogo Pins

Structural Design to Answer What is Pogo Pin:

The structural design of pogo pin is the key to its efficient operation:

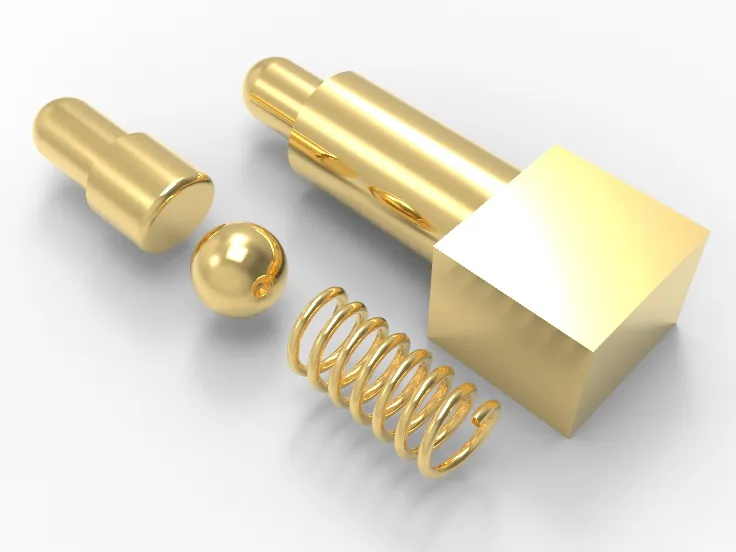

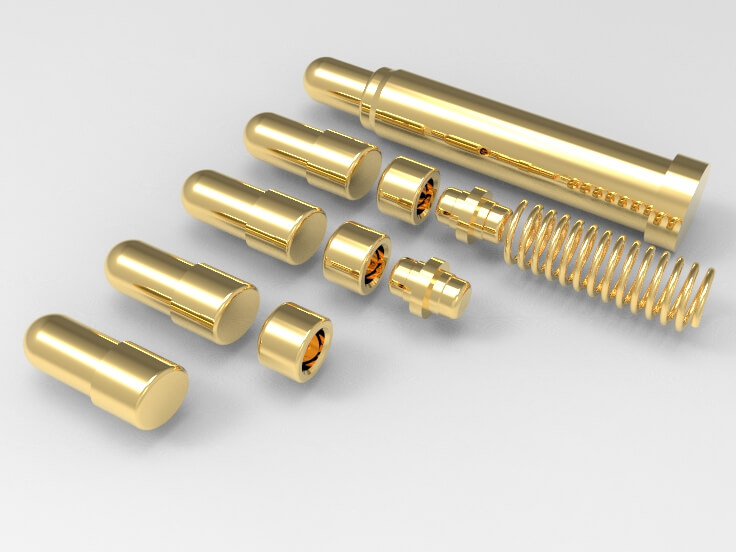

Spring: The pogo pin spring allows it to automatically compress and rebound upon contact, ensuring stable operation in different connections.

Contact point (plunger): This part is responsible for transmitting current and is the most important part of a pogo pin. Conductive materials are usually brass, beryllium, tellurium, SUS316, Stainless steel ensures smooth transfer of signals and electricity.

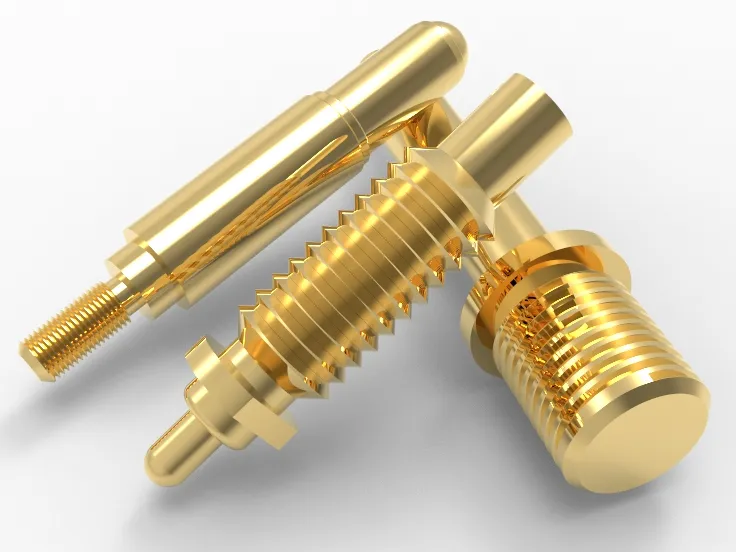

Metal casing (barrel): The casing protects the internal spring and conductive contact point, ensures pogo pin is not easily damaged.

Compact structure: The pogo pin design is very compact, it has a small volume but powerful functions, and work in limited space.

Durability: The pogo pin structure is very durable, it can withstand multiple insertions and mechanical pressures, and not easily damaged.

Electrical performance: Each part of the structure is closely related to electrical performance, ensuring that current is not lost, resistance is low, and signal transmission is clear.

Stability: The spring design ensures pogo pin can maintain a stable connection, avoiding operational failures, few looseness or poor contact.

Read: 4 Pin Connector

Size and Shape to Answer What is Pogo Pin

The pogo pin size and shape are key to fit different applications. It is also critical discussion during double confirming between Johoty CFT team and clients.

Diameter and length: They are selected based on your designs and space requirements. Larger diameter pogo pins are used for high current, while smaller pogo pins are suitable for more precise electronic devices. The length determines the depth at which it can be inserted into the device, affecting the stability of the connection.

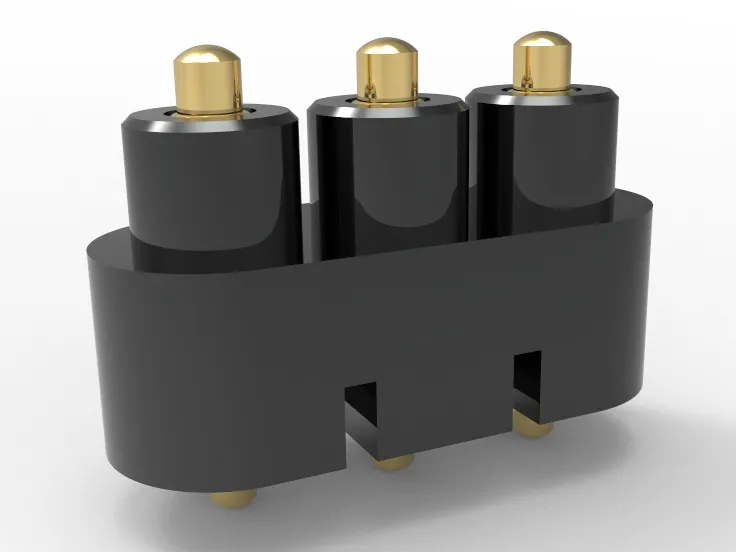

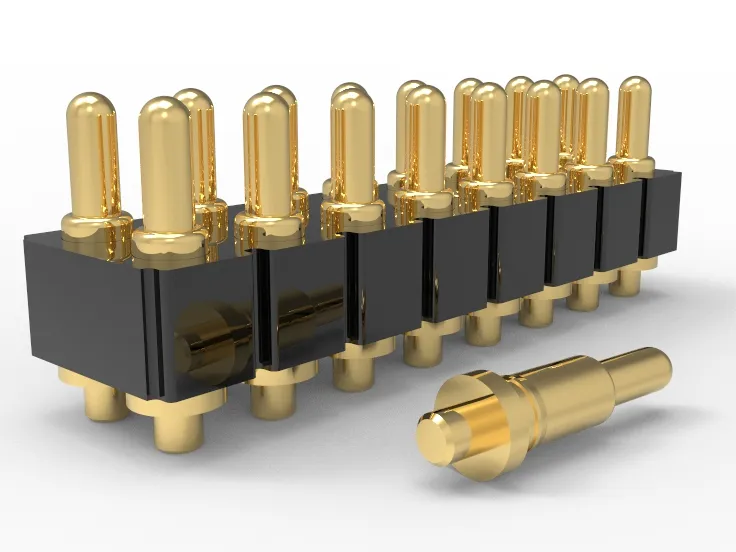

Pin quantity: Johoty surely customs pin number. For multiple connection points, pogo pins can be designed as a pogo pin connector, transmitting multiple signals simultaneously.

Shape variation: Pogo pin shape has cylindrical, square, rectangular, etc. These different shapes can better adapt to different connections and space requirements.

Barrel size: The barrel size is also closely related to their performance. A larger barrel can provide better support and protection for high-frequency plugging and movement. A smaller barrel can make pogo pins more suitable for compact spaces.

Spring length and strength: The spring length and strength affect their size and shape. Longer springs can provide greater compression space, suitable for longer working strokes, while shorter spring is suitable for smaller stroke.

Customization: Johoty can fully customize the size and shape according to customer needs, ensuring a perfect fit for specific applications. Some industries may require smaller and more precise pogo pins, while some applications may require larger and more robust pogo pins.

Read: Solder Cup Pogo Pin

Raw Materials Selection to Answer What is Pogo Pin

Material Selection for Pogo Pin:

Plunger to answer what is pogo pin.

- Tungsten steel: Super wear-resistant, suitable for high-frequency use.

- Stainless steel: It is durable, rust-proof, high hardness, corrosion-resistant.

- Brass: Good conductivity and easy processing.

- Beryllium copper: It has both conductivity and elasticity.

- Copper telluride: high conductivity, high hardness.

- Silver alloy: Excellent conductivity.

- Titanium alloy: lightweight and high-strength material.

- Carbon steel: Low price, suitable for basic needs.

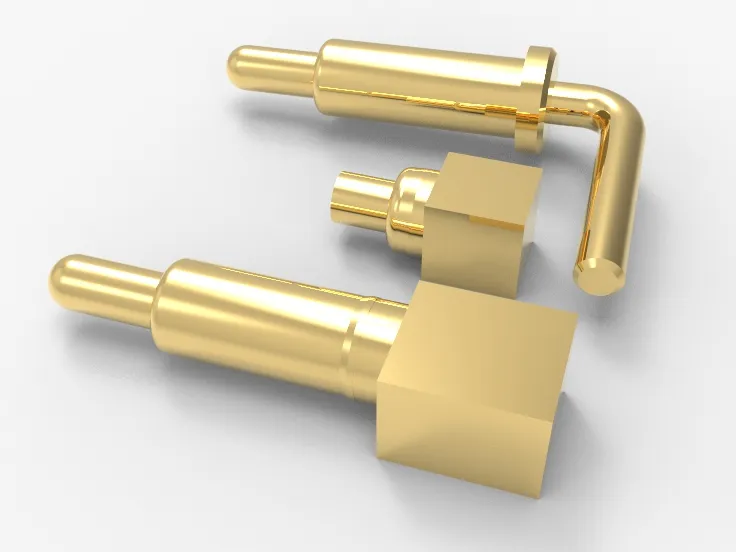

Read: Right Angle Pogo Pin

Barrel to answer what is pogo pin.

- Brass: High cost-effectiveness, fit large-scale production.

- Stainless steel: corrosion-resistant, high-temp resistant.

- Nickel silver alloy: high oxidation resistance.

- Bronze: High hardness, suitable for complex processes.

- Carbon steel: cost-effective and durable.

- Titanium alloy: used for high-end demand.

- Silver plated copper: enhances conductivity.

- Composite materials: lightweight and durable.

Read: Spring Loaded Pin

Spring to answer what is pogo pin.

- High carbon steel: Strong elasticity and long service life.

- Stainless steel: corrosion-resistant and fatigue resistant.

- Beryllium copper: good elasticity and conductivity.

- Nickel alloy: Strong high temperature resistance.

- Phosphorus green copper: wear-resistant and fatigue resistant.

- Tungsten steel: resistant to high pressure and high temperature.

- Silicon manganese steel: high-strength material.

- Copper plated silver: superior conductivity.

Read: High Current Pogo Pins

Ball to answer what is pogo pin.

- Stainless steel: wear-resistant and long-lasting.

- Beryllium copper: Good conductivity.

- Ceramics: high temperature resistance and good insulation.

- Titanium alloy: suitable for high-end products.

Housing to answer what is pogo pin.

- PA66 (nylon): High strength and strong wear resistance.

- POM (polyoxymethylene): Excellent sliding performance.

- PC (polycarbonate): High impact strength.

- PBT (polybutylene terephthalate): Good stability.

- PP (polypropylene): Strong chemical resistance.

- PEEK (polyetheretherketone): High strength and high temperature resistance.

- LCP (Liquid Crystal Polymer): High temperature resistance and high stability.

- ABS: economical material, easy to process.

- TPU (thermoplastic polyurethane): Strong flexibility.

- Silicone: It combines elasticity and durability.

Read: Thread Pogo Pins

Coating to answer what is pogo pin.

- Gold: It has the best conductivity and antioxidant properties.

- Silver: Highly conductive but prone to oxidation.

- Nickel: Good corrosion & wear resistance.

- Palladium: It has strong conductivity and oxidation resistance.

- Copper: Excellent conductivity.

- Platinum: extremely strong corrosion resistance and oxidation resistance.

- Tin: Good soldering performance.

- Chromium: It has good wear resistance and corrosion resistance.

- Cobalt: resistant to high temperatures and wear.

Read: 3 Pin Connector

Composite Electroplating to answer what is pogo pin.

- Gold-nickel-copper-silver-chromium: Gold provides excellent conductivity and oxidation resistance, nickel increases corrosion resistance, copper provides good conductivity, silver enhances electrical contact performance, chromium improves surface hardness, wear resistance, and aesthetics, used in high-end electronic products and precision connectors.

- Nickel-palladium-gold-chromium-copper: Nickel provides excellent corrosion resistance, palladium enhances oxidation resistance, gold ensures electrical contact stability, chromium enhances hardness and glossiness, and copper improves conductivity, making it suitable for electronic components, connectors, and high-frequency equipment.

- Palladium-nickel-gold-copper-silver: Palladium improves high temperature resistance and corrosion resistance, nickel enhances oxidation resistance, gold provides stable electrical contact, copper enhances conductivity, silver enhances conductivity and electrical contact, suitable for high-end electronic connectors and sensors.

- Copper-gold-silver-palladium-chromium: Copper provides excellent conductivity, gold enhances electrical contact performance, silver enhances conductivity, palladium improves corrosion resistance, chromium increases wear resistance and appearance gloss, used for precision electronic components and high-end connectors.

Read: 8 Pin Connector

Conductivity to Answer What is Pogo Pin

Good conductivity ensures smooth current: Pogo pin ensures smooth current transfer in electronic devices. It usually uses copper, gold, or palladium, which can make the current more smoothly without causing high resistance or unstable current.

Low contact resistance, reducing energy loss: Pogo pins with good conductivity have very low contact resistance, so there is not too much energy waste, and there will be no heating or low efficiency caused by excessive resistance.

Antioxidant, long-term stability: Johoty’s pogo pin has long-term performance. If the plunger is prone to oxidation, its conductivity will decrease. High quality pogo pins usually come with gold / silver plating, etc., which can prevent oxidation and keep the contact points clean and stable.

Transfer high-frequency signals: Pogo pin can transmit both regular current and high-frequency signals. In communication equipment or testing instruments, if pogo pin conductivity is poor, high-frequency signals are easily lost or become unstable.

Durable, not easily worn: Pogo pins can withstand >10,000 times plug and unplug, while Johoty can design pogo pins for >200,000 reliable connections. If plunger is severely worn, the contact performance will decrease and the efficiency of current transfer will also deteriorate. So choosing wear-resistant materials and designs is crucial.

Low impact of temperature changes: In some special environments, pogo pin needs to work in significant temperature changes. Johoty’s pogo pin can adapt to temperature changes, maintain stable current transfer, and will not cause poor contact due to high/low temperature.

Read: High Current Pogo Pins

Elasticity and Compressibility to Answer What is Pogo Pin

High quality springs: The pogo pin contains important small springs made of piano steel, stainless steel, or beryllium copper, which can withstand up to 10,000 presses without deformation. Johoty can design pogo pins up to 300,000 or 400,000 times without losing elasticity during frequent connections.

The feeling when pressed down is smooth: the spring is designed very precisely, and there will be no jamming or loosening sensation when pressed down. This linear compression feel is very popular among engineers because the test results are more stable.

Wide compression range: The pogo pin compression range can reach 0.3mm to 20mm or wider. This range ensures good contact regardless of whether the contact point is slightly higher or lower.

Long term pressing will not damage: Johoty can design pogo pins to be fatigue resistant, which can maintain pressure for a long time without spring failure. This performance is very suitable for industrial testing that requires continuous contact.

Adjustable spring force: Different projects require different pressures, some pogo pin springs have higher force, while others are lighter. This selectivity makes it suitable for various precision applications.

Read: Through Hole Pogo Pins

Mechanical Durability to Answer What is Pogo Pin

Ultra-high usage frequency: Pogo pin is very durable and can withstand 10,000 or even 100,000 presses without breaking. This is because its materials and structural design are particularly sturdy, very suitable for repeated testing.

Strong wear resistance: Pogo pin plunger is usually plated with gold, palladium, platinum, rhodium, ruthenium, etc, which prevents rusting and reduces friction, less prone to wear and tear during constant contact and movement.

Strong connection: even after long-term use, pogo pin spring can still maintain stable elasticity and will not loosen or break. This is very important for engineers, as some dirty connections in aviation must be stable and reliable.

Anti-vibration design: The pogo pin structure can resist the influence of vibration and external forces, and it can also maintain good contact in moving or shaking devices without easy disconnection.

Adapt to various environments: The pogo pin material can withstand high & low temps, be waterproof and dustproof. Johoty’s high-end models can work normally in lab high-temp testing or outdoor humid environments.

Read: Solder-Cup Pogo Pin

Rated Current to Answer What is Pogo Pin

Stable transfer of high current: The pogo pin designs can stably transmit current, with a rated current generally ranging from 1A to 5A. Johoty’s high-end models can reach 1,200A. This can meet all engineers’ needs, the more stable the current, the more accurate the results.

Low resistance, high efficiency: The contact resistance of pogo pin is very low, as low as 15 mΩ, and can maintain just over 15 mΩ after 200,000 compressions, Johoty can achieve a low impedance of 1 mΩ for some high current pogo pins. When current through pogo pin, there is almost no loss, saving energy and maintaining the accuracy of signals and data.

Adapt to different currents: Different projects require different current carrying. Johoty can design pogo pins with different specs according to requirements, transmitting low current signals and supporting high-power currents. It is very flexible.

Low heat and high safety: Due to its low resistance, Johoty’s pogo pins generate very little heat when transmitting current, with a common temperature rise <20 ℃. This can extend pogo pin lifespan, avoid equipment failures caused by overheating, and ensure high safety.

Long term reliability: Johoty’s pogo pin can withstand rated current for a long time without any decrease in performance. For example, 200A high current pogo pins can continually work at 25℃ for 2 hours, temp-rise is <20℃,continually work without damage at 120℃ for 2 years , Johoty uses high-purity beryllium copper, gold or silver plating, which can ensure transmission efficiency and prevent oxidation.

Read: Thread Pogo Pins

Contact Resistance to Answer What is Pogo Pin

How much does contact resistance affect the performance of pogo pins?

What is contact resistance? It is the resistance experienced by the current passing through the pogo pin and connection point, just like a small notch in a water pipe. If the contact resistance is too high, the current will become squeezed, resulting in slower power and signal transmission.

Why is contact resistance important? Imagine a pogo pin as a bridge, through which current must pass to the other end. If the bridge is not smooth enough or there are obstacles in the middle (such as high contact resistance), the traffic (current) will be blocked or even have problems. So low contact resistance can make current flow more smoothly.

Influence on high-frequency signal: High frequency signals are like runners who need to quickly transmit information. If the contact resistance is too high, it will interfere with signal transfer, just like when an athlete suddenly trips while running and their rhythm is completely disrupted.

Relationship between contact resistance and heat generation: A high contact resistance will generate more heat, just like shoe sole heats up during running. If there is too much heat, it will damage pogo pin itself and affect connected device lifespan.

Impact on equipment efficiency: If contact resistance is too high, the equipment requires more energy to overcome this resistance, resulting in an efficiency decrease. This is a great challenge for modern devices pursuing energy efficiency.

Read: Right Angle Pogo Pin

What are factors affecting contact resistance?

Material influence: Pogo pins are made of brass, tellurium copper, copper alloys, and gold plating, which can effectively reduce contact resistance. Gold plating has good conductivity, prevents corrosion, and maintains long-term stability.

Contact pressure effect: The greater pressure on pogo pin contact point, the tighter the contact, and the smaller resistance. But if the pressure is too high, it may wear out the contact surface or damage the connector, so a reasonable design is needed.

Relationship between contact point shape and resistance: The contact points are designed to be smooth and flat, which can increase the contact area and reduce resistance. If the contact point is uneven or damaged, the resistance will increase.

Environmental influence: Moisture, dust, and oxidation all increase contact resistance. To prevent these issues, Johoty’s high-end pogo pins will be coated with gold plating, to maintain stability.

Temperature changes effect: Temperature changes can cause metal to expand or contract, thereby changing contact tightness. If temperature fluctuates too much, contact resistance will also change accordingly, Johoty always selects materials with good temp resistance.

Read: 6 Pin Connector

Why is low contact resistance advantageous for pogo pins?

Reduce energy loss: When current passes through a pogo pin with low contact resistance, less energy is lost, which helps the device work more efficiently and fits electronic devices for energy conservation.

Reduce heat generation: Low contact resistance can reduce the heat generated, thereby protecting the equipment and pogo pin itself and extending its service life.

Improving signal stability: In high-speed data transfer, low contact resistance can maintain signal integrity, avoid signal loss or delay, which is highly needed in 5G communication.

Enhancing product reliability: A pogo pin with low contact resistance can maintain stability in harsh, this is crucial in industries and automotives.

Improving overall device performance: Whether it is current or signal transfer, low contact resistance can help achieve higher performance, making terminal items more competitive.

Read: High Current Pogo Pins

Working Temp-range to Answer What is Pogo Pin

The ability of pogo pins to function properly at different temperatures directly determines their reliability and stability in various applications:

Performance guarantee in low temperatures: At – 40℃, some ordinary metals may become brittle even break, while Johoty’s high-quality pogo pins use special alloy to maintain elasticity and conductivity, ensuring stable operation in cold outdoor or high-altitude

.

Stability in high temperatures: High temperatures may cause metal softening or oxidation, but Johoty’s excellent pogo pins use beryllium copper or stainless steel with a gold plated surface to prevent oxidation. Even at 200℃, its mechanical properties and conductivity will not be significantly affected.

Control thermal expansion coefficient: When temperature changes dramatically, thermal expansion coefficient between different materials may lead to loose or poor contact of the contact surface. Johoty’s pogo pins always use materials with similar thermal expansion coefficients to maintain high stability.

Corrosion resistance in humid and hot: Metal contact points are more susceptible to corrosion in high-temp & humidity. High end pogo pins always use gold plating of >0.3 microns, or adopt composite electroplating, which can effectively resist the performance damage of humid and hot, and extend their service life.

Adaptability to rapid temp changes: Some customer’s equipment needs to pass rapid temp changes in a short time, moving from cold storage to room temperature. Johoty considers this thermal shock when designing pogo pins to ensure our spring doesn’t fail due to frequent thermal changes.

Read: Solder-Cup Pogo Pins

Corrosion Resistance to Answer What is Pogo Pin

Maintain stability in easily corrosive environments. Many electronic devices need to work in humid, salty, or harmful gases.

Surface gold plating protection: The pogo pin surface is often coated with thick gold, which can prevent metal oxidation and prevent contact points from rusting. The gold plating layer usually reaches 0.3 microns or more, which can extend the lifespan and smoothly transmit current.

Salt spray resistance: In coastal areas or shipbuilding industries, equipment is often exposed to salt spray. This salt can quickly corrode ordinary metals, while pogo pins are made of stainless steel or plated with thick nickel and gold, which can maintain corrosion resistance for more than three years in high salt, suitable for marine environments.

Anti acid and alkali corrosion design: In industrial production, acid and alkali gases/liquids can corrode equipment. Johoty’s pogo pin is electroplated or chemically finishing to form a protective film that is resistant to acid and alkali. By using gold plating or palladium nickel plating, pogo pins can work for a long time in laboratories or factory workshops.

Reliability under high humidity: Wet environments can accelerate metal electrochemical corrosion. When designing high-end pogo pins, Johoty will add moisture-proof coatings or choose moisture resistant beryllium copper. This material is corrosion-resistant and maintains good mechanical elasticity and electrical conductivity.

Preventing electrochemical corrosion: When pogo pins contact with different metals, electrochemical reactions may occur, leading to plunger tip corrosion. Johoty engineers always use coating designs that match the contact materials to ensure stable contact for a long time in different devices, without being affected by electrochemical corrosion.

Read: Flat Bottom SMT Pogo Pins

Packaging and Tolerances to Answer What is Pogo pin

It is key to accurately embed devices and maintain long-term stable connections:

Micron machining accuracy: Pogo pin sub-parts undergo high-precision CNC machining, dimensional tolerance can be controlled within ± 0.02 mm. So, pogo pin can perfectly dock when inserted into the connector, neither loose nor too tight, ensuring reliable current transfer.

Different packaging: With varied internal space and designs, pogo pins come in circular, square, and rectangular. Through its flexible shape, pogo pins can easily adapt to various devices, especially achieving efficient connections in smartphones, automotive electronics, and medical equipment.

Spring accuracy and lifespan: Pogo pin spring needs to accurately match package size and pressure. If the spring pressure is too high, it will damage the contact point, and if the pressure is too low, it may loosen. Johoty strictly controls spring dimensional tolerances and conducts fatigue testing to ensure pogo pins can withstand >10,000 times of presses without failure.

Adaptability of connector tolerances: The device connector accuracy may vary slightly, and pogo pins can adapt to these dimensional deviations through spring compression and self adjustment. Even if connector insertion hole is slightly larger or smaller, pogo pins can still achieve stable connection and uniform contact.

Housing protection and connection stability: The pogo pin housing usually uses materials that are resistant to high temperatures, dust, and water, such as PPS or LCP. Protect the internal structure, prevent external environment from interfering, and maintain long-term connection stability. In humid or dusty, it can effectively block pollutants and extend their service life.

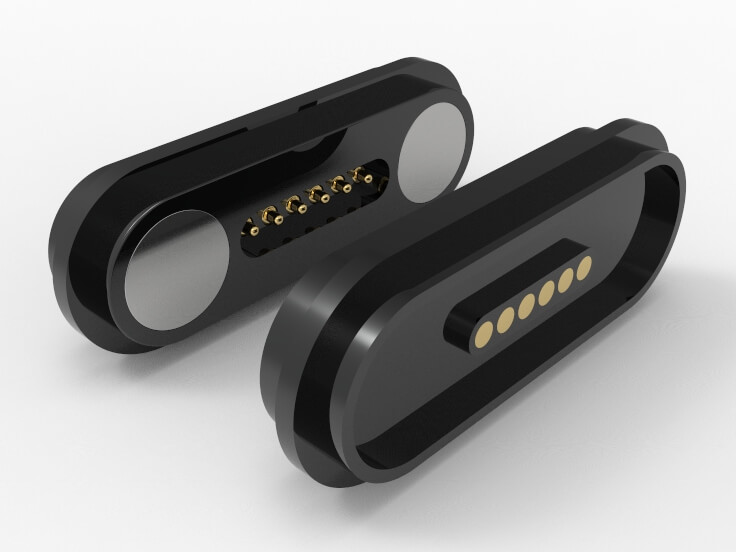

Read: Magnetic Connector

Sealing to Answer What is Pogo Pin

It can effectively prevent moisture, dust, and other impurities from entering the internal structure, maintain good performance in harsh:

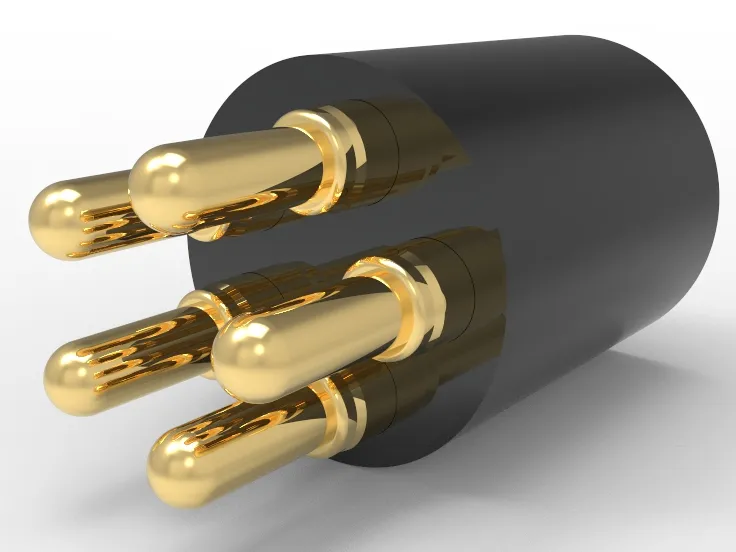

Waterproof up to IP68: High-end pogo pin can reach IP68, completely preventing dust from entering, place it under >1m water without damage. Suitable for outdoor, diving equipment, or industrial equipment contacting with liquids.

Precision designed sealing: Pogo pin barrel and spring parts are precisely designed and sealed with rubber or sealing rings. The transition area between the spring chamber and the contact surface will be sealed with special materials, which will not affect the spring movement and completely prevent external pollutants from entering the interior.

Corrosion resistant sealing material: Viton or silicone is used for the sealing part. Wear resistant, prevent corrosion from acid, alkali or chemical solvents, suitable for industrial workshops or laboratory.

Sealing performance at extreme temperatures: Many pogo pins require work at extreme temperatures, and the sealing material can maintain elasticity and sealing within -40℃~+200℃. High-quality sealing ensures not to harden or crack at low temperatures, and will not soften or leak at high temperatures.

Dynamic sealing: Pogo pin spring needs to move frequently, and the sealing must adapt to this dynamic environment. Dynamic sealing allows the spring to freely expand and contract, maintaining complete isolation between the contact point and the outside. Under high-frequency use, the sealing is not affected at all.

Read: Bending Pogo Pins

Installation Methods to Answer What is Pogo Pin

Determine the application flexibility of pogo pins in various devices:

Solder cup wiring installation: A method of connecting cable to pogo pin tail pins. The pogo pin tail is a solder cup, which firmly fixes a cable inside the solder cup through soldering. Suitable for point-to-point or board-to-board connections, without PCBA circuit board, making it easy to achieve electrical connections in limited spaces. Commonly used for industrial equipment and flexible connections. When soldering, pay attention to solder paste amounts to avoid too much causing short circuits or too little causing weak contact.

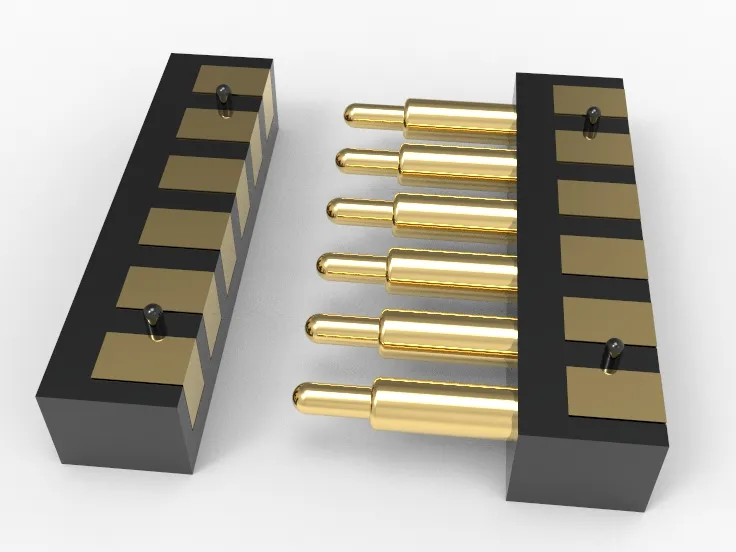

PCB through-hole installation: a classic way to fix pogo pins on a circuit board, There is a small tail pin at the bottom of pogo pin, which is inserted into PCB through-hole and soldered for fixation. The connection is stable and can withstand significant mechanical pressure for long-term use. High strength connectivity for automotive electronics and consumer electronics. Ensure through-hole size matches the pins and prevent overheating from affecting the spring performance during soldering.

SMT surface mount: The pogo pins are directly soldered onto PCB surface by SMT. No need to drill holes, directly solder pogo pin bottom pad to PCB solder pad surface. Space saving, suitable for high-density circuit boards, high installation efficiency. Used for smartphones and wearable devices. Accurate positioning is required during installation, and reflow soldering temperature must comply with standards to protect metal coating.

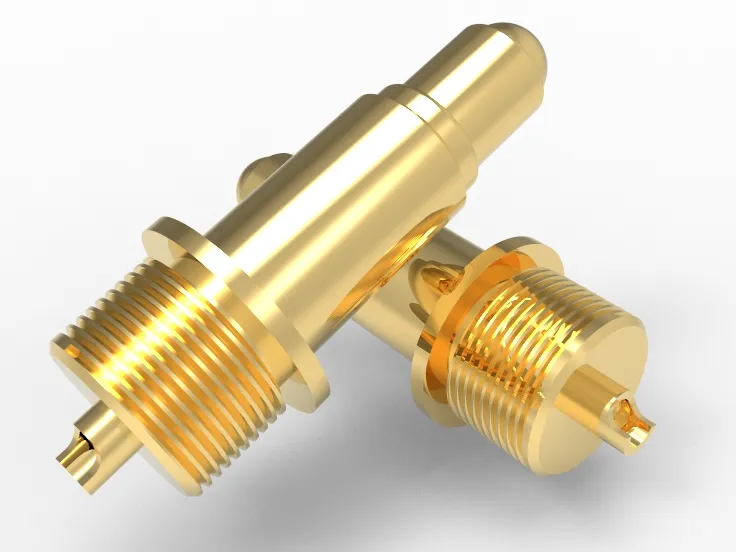

Threaded locking anti rotation installation: Ensure pogo pin stability through the threaded structure. Tail pin and barrel have screw threads, can be fixed in the installation hole with a screwdriver, and also has anti rotation design. Strong anti vibration for mechanical equipment and high dynamic environments. Applied to automotive electronics, aerospace equipment. During installation, need to match screw thread size and use appropriate locking glue to enhance the fixing effect.

SMT right angle mounting: Right angle mounting is an effective mounting method where pogo pins are soldered to PCB solder pad, saving space in the vertical direction. Provide more design possibilities for ultra-thin devices, suitable for thin and light shapes. Applied to smart cards, portable electronic devices, etc. Side welding requires higher welding accuracy for the equipment to avoid poor connections caused by offset.

Non-welding double head connection: Double head connection is a quick installation method, with contact points on both ends of the pogo pin, which can be directly clamped between the two contact surfaces without welding. Easy to install, reusable, suitable for quick replacement or maintenance. Used for board-to-board or point-and-point connections, testing fixtures, detachable modules, etc. Ensure that contact surface is clean and the clamping force is sufficient to avoid affecting electrical performance.

Read: Pogo Pin Connector

High Adaptability to Answer What is Pogo Pin

Extreme Temperatures: Withstand -40℃~125℃. Use beryllium copper, stainless steel, with gold plating to avoid thermal expansion & contraction affecting pogo pin performance. Adapted to extreme high mountains and deserts.

High Humidity: IP68 waterproof, fully resistant to moisture and water. The sealed structure and gold-plated surface ensure stable work in humid without rusting. Applied to marine equipment, outdoor communication, and diving tools.

Vibration and Impact: The spring with a tight structure can effectively buffer vibration and impact forces. Ensure electrical contact to prevent looseness and make connections more stable. Applied automotive electronics, railway signal equipment, aerospace equipment.

Frequent plug and unplug: The spring has a long lifespan and maintains performance after 200,000 cycles of presses. High frequency use ensures stable spring elasticity and contact force. Apply mobile phone charging and automated testing tools.

Miniaturized devices: Compact in size, diameter ≥0.5 mm, and diverse in packaging. Design small devices for save space, high performance. Applied to smartwatches, Bluetooth earphones, etc.

Diverse installations: Support solder cup wiring, PCB through-hole, SMT surface mount, thread locking, soldering free double heads, etc. Adapt to various device structures and deploy quickly. Applied consumer electronics, industrial automation equipment, and medical devices.

Suitable for multiple contact materials: It can maintain good conductivity with copper, stainless steel, aluminum, etc. Gold plating or palladium nickel plating to prevent electrochemical corrosion and long-term stable connection. Industrial equipment and electronic products using mixed materials.

Adapt to corrosive environments: Coating is corrosion-resistant, and the sealing design can prevent salt spray and acid-base erosion. Long term reliable work in corrosive environments. Apply maritime communication equipment and chemical laboratory equipment.

Dynamic environments: Spring design allows for the adjustment of contact pressure at any time in dynamics. Maintain stable connection during moving, tilting, or shaking. Apply portable devices, mobile robots, and unmanned aerial vehicle.

Adapt to high-precision and EMI: CNC machining has high precision as well as small dimensional tolerances. Custom EMI protection, precise matching of equipment interfaces, efficient conductivity and low resistance losses. Apply medical instruments, EMC equipment, and high-end experimental equipment.

Read: Double-Ended Pogo Pin

High Cost-effectiveness to Answer What is Pogo Pin

Pogo pins have excellent performance and high cost-effectiveness, which is why many European and American engineers favor Johoty:

Long service life, reducing replacement frequency: what is pogo pin?

Johoty’s pogo pin can withstand >200,000 presses and maintain stability. The device hardly needs to replace parts during use, saving costs. Applied industrial equipment, testing fixtures, and consumer electronics. One investment, long-term returns, significantly reducing overall costs.

Adapt to multiple environments and reduce additional design costs: what is pogo pin?

Pogo pins are waterproof, heat-resistant, corrosion-resistant for extreme environments. You can directly choose ready-made models without extra customization, saving R&D time and resources. Easy application of outdoor communication, chemical laboratory equipment, etc. A universal pogo pin can reduce your design costs separately for each environment.

Cost advantage from mass production: what is pogo pin?

The production process is mature and suitable for large-scale automated production. Reduce the cost of individual components while ensuring quality consistency. Applied consumer electronics, automotive electronics, and cost sensitive industries. Large scale production achieves high cost-effectiveness.

Easy maintenance, reduced labor costs: what is pogo pin?

Easy to install, easy to disassemble, with Johoty’s simple structure. Equipment maintenance has become faster, and engineers only need to replace damaged components without dismantling your entire system. Application modular equipment, industrial automation devices, etc. High maintenance efficiency, reducing labor input and downtime.

Flexible design reduces customized development costs

Diverse packaging options, supporting soldering, thread locking, SMT, and more. It can be directly integrated into existing designs without the need to customize new connectors. Apply medical equipment and portable electronics. Flexibly adapt to existing designs and reduce customized R&D investment.

High performance, low loss, improving overall efficiency

Low contact resistance and high conductivity, efficient energy transmission. Reducing energy loss, improving overall equipment efficiency, and indirectly reducing usage costs. Apply electric vehicle charging, high-frequency communication equipment, etc. Efficient performance brings long-term energy-saving effects, indirectly improving cost-effectiveness.

Read: Bending Pogo Pin or Right Angle Pogo Pin

Conclusions:

By reading 15 key points of pogo pins, you should have a clearer understanding of choosing the appropriate pogo pins and be able to accurately identify what is pogo pin. If you are looking for a high-quality and reliable pogo pin solution, Johoty would be your ideal partner.

Our pogo pins are well-designed and have excellent performance praised by many engineers, meeting various industrial needs. Contact Johoty immediately for professional advice and customized solutions to make your project more successful!

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656