Learn How Spring Loaded Connectors Enhances Design, Solves Speed, Space, Soldering, Shape, Current. Optimize Connection With Effective Solution.

Introduction: Why is spring loaded connectors a key component in engineering design?

In engineering design, the selection of connectors often determines the reliability, performance, and cost of the entire system designed by engineers. In automotive electronics, industrial equipment, and consumer electronics, engineers face a series of tricky design challenges every day: how to achieve efficient layout in limited space? How to connect pogo pin connector with USB, Type-C, Molex connector? How to ensure the stability of the connection under vibration, high temperature, or humidity? How to improve production efficiency in budgets?

Although traditional welding or screw connections may perform well in some applications, they often appear inadequate in the face of high engineering design requirements in 2025. At this point, Johoty’s spring loaded connectors, with its unique design and outstanding performance, became a secret weapon for engineers in many of the world’s top 500 companies.

Read: 10 Pin Connector

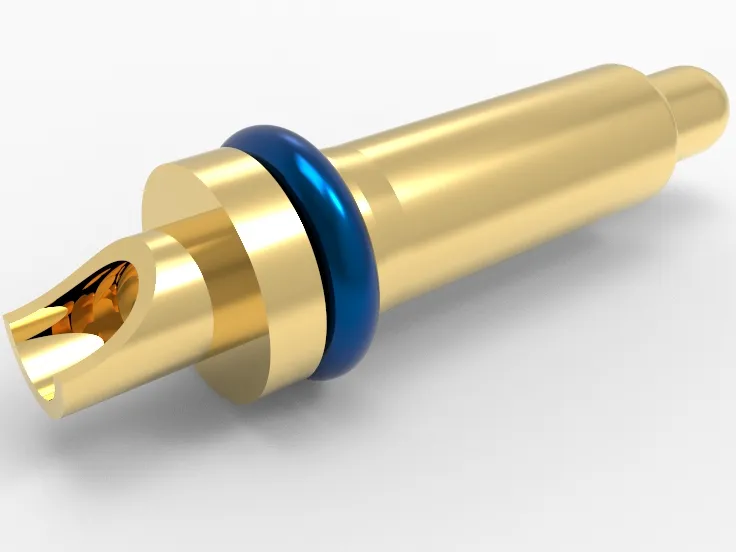

Spring loaded connectors not only solve the common problems of poor contact, space limitations, and maintenance difficulties in traditional connection methods. It also provides higher reliability and environmental adaptability through elastic contact design. Spring loaded connectors can handle harsh industrial environments and meet the demand for miniaturization in consumer electronics with ease.

We will delve into how spring loaded connectors can help engineers optimize designs, reduce costs, and improve system performance through their core advantages. If you are struggling with the choice of connectors, this article will provide you with a brand new solution to take your design to the next level!

Read: Multiple Pin Connectors

Core advantages of spring loaded connectors: how to improve engineering design efficiency?

Automatically adjust pressure

Imagine that when you are making connections, excessive pressure can cause things to break, while less pressure may not be strong enough. The spring loaded connectors can automatically adjust the pressure to ensure stable connection in different situations. In this way, you don’t need to manually adjust the pressure every time, saving time and effort.

Shock absorption protection

Spring loaded connectors are like putting a protective layer on the device. It can absorb external vibrations and impacts, reducing equipment damage. Engineers often encounter problems with equipment malfunctioning during vibration or collision, and pogo pin connector can effectively prevent such situations, making the equipment more durable.

Read: 4 Pin Connector

Long service life

The spring material is very wear-resistant and is not easily damaged even after long-term use. Ordinary connectors may become loose due to long-term use, leading to unstable equipment operation, but spring loaded connectors can maintain stability for a long time, reducing maintenance troubles.

Easy to assemble and disassemble

If you need to frequently replace parts or maintain equipment, spring loaded connectors are convenient. It is easily install without complex tools, saving a lot of time. Engineers often face assembly or disassembly difficulties, and spring loaded connectors can solve these problems.

Read: 7 Pin Connector Male and Female

Adapt to various environments

Spring loaded connectors can work normally in high or low temperature, humid, corrosive environments. Many devices need to operate in harsh environments, and ordinary connectors may experience performance degradation due to environmental factors. However, the design of spring loaded connectors can still work very well under these conditions.

Save space

Spring loaded connector occupy small space and can complete connection tasks in limited space, which is very important for designs with strict space requirements. You don’t need to reserve extra space for the connector, the device can be more compact.

Reduce costs

Although the price of spring loaded connectors may be slightly expensive at first, due to their durability, low failure rate, and long-term use, maintenance and replacement costs will be greatly reduced. For equipment with long-term stability, using pogo pin connector can save a lot of maintenance costs.

Read: 4 Pin Connector Male and Female

Applications of Spring Loaded Connectors in Engineering Design

Automotive industry: shock absorption and stable connection

In cars, many components require frequent vibration, such as suspension systems or engine parts. Spring loaded connectors can help with shock absorption in these areas, as its elastic properties can absorb vibrations and impacts, protecting critical components from damage. Moreover, its automatic pressure adjustment function can also help maintain stable fastening between parts and avoid loosening.

Electronic products: reduce the impact of vibration on circuit boards

Many laptops, mobile phones, and other components, often experience vibrations during use. Spring loaded connectors can be used to secure these components, avoiding internal component loosening or circuit breakage caused by vibration, thereby improving their stability and lifespan.

Read: 3 Pin Connector Male and Female

Robot: Connection module

In robot design, many components require flexible connections and often move in different angles and directions. Spring loaded connectors can provide flexible connections while maintaining stability. It can help robots maintain tight connections between various modules and absorbing impacts generated during movement to avoid looseness or failure.

Aerospace: Stable Connection in High Altitude and High Pressure Environments

In aerospace, equipment often operates in extreme temperature and pressure. Johoty’s pogo pin connector can adapt to these environments, maintain connection stability. And, it can avoid connection loosening or failure caused by high voltage or temperature differences. In the assembly of aircraft and satellites, spring loaded connectors can ensure each component remains sturdy in harsh environments.

Mechanical equipment: reduce vibration, extend lifespan

Many mechanical equipment generate significant vibrations during operation, such as machines on production lines and heavy equipment. Spring loaded connectors can effectively absorb these vibrations, reduce friction between parts, extend equipment’s lifespan, and avoid safety hazards caused by vibrations.

Home appliances: solving looseness during long-term use

Home appliances such as refrigerators, washing machines, air conditioners, etc. are prone to loose parts after prolonged use. This problem often occurs on components with high vibration. Spring loaded connectors can effectively avoid this problem, help these parts stay tight during long-term operation, reduce maintenance and replacement.

Construction project: Connecting fastening systems

In some construction projects, spring loaded connectors can connect steel bars or other structural components to ensure their stability under stress. Especially in earthquake prone areas, Johoty’s pogo pin connector can provide shock absorption, enhance buildings’ seismic resistance, and improve their safety.

Read: 8 Pin Connector Male and Female

Engineering design issues and effective solutions for spring loaded connectors

Unreliable connection, easy to loosen:

Many engineers know that certain connectors are prone to loosening or disconnecting when subjected to external vibration or tension, causing equipment failure. Johoty designs spring loaded connectors with built-in springs that can automatically adjust the connection pressure. Under vibration or external force, the spring can keep stable without loosen too. It can also automatically adjust the spring stroke on uneven surfaces, fully adapting and ensuring a secure connection.

Poor contact at the connection point leads to power loss:

Poor contact is a common problem in electrical equipment. Uneven contact force can cause poor current transfer, even overheating, and waste of energy. The springs inside spring loaded connectors can continuously provide uniform contact force, ensuring that each contact point is always stable. This pogo pin connector can achieve a contact impedance as low as 15mΩ and a single pin current of up to 50A. Whether it’s pogo pins or spring loaded connectors, they can effectively reduce power loss and allow current to flow smoothly.

Installation is troublesome and time-consuming:

Some connectors require complex installation steps and may require special tools or precise operation. In places with limited space, installation is very complicated. Spring loaded connectors are designed to be simple and efficient, with 8 installation methods that can flexibly match the customer’s application to complete the connection. Engineers can quickly complete installation tasks without additional tools, saving time.

Read: 6 Pin Connector Male and Female

Affected by the environment, the connection effect decreases:

Some connectors are prone to aging in environments with high temperatures, high humidity, or corrosive gases, leading to poor contact or connection failure. Johoty uses special materials to design and manufacture spring loaded connectors that are resistant to high temperatures and corrosion. This pogo pin connector can achieve IP67 waterproof, of course, it is usually a female connector. Please note that the pogo pin itself cannot achieve IP67 waterproof At the same time, it also has advantages in anti-EMI and 5Gbps to maintain good connectivity in extreme environments to ensure device’s long-term stability.

Short service life, requiring frequent replacement:

Many connectors are prone to wear and oxidation on their contact surfaces after long-term use, leading to decreased performance and even disconnection or failure. The spring part of Johoty’s spring loaded connectors are wear-resistant and anti-oxidation based on high-quality material. Our specially designed pogo pin connector has a lifespan of up to 200,000 cycles. It can keep long-term function perfect without deformation and avoid frequent replacement.

Read: 5 Pin Connector Male and Female

Use Cases: how can spring loaded connectors change engineering design?

Adjustable power connection for drones

Drones require lightweight and efficient design, but the stability of battery and circuit connections is a major issue. During flight, UAVs experience many severe vibrations and rapid directional changes. Traditional battery connection methods are prone to poor contact between the battery and circuit board due to vibrations or looseness. This can easily lead to power supply interruptions and affect flight safety.

Spring loaded connectors can utilize springs to automatically adjust connection pressure during drone vibration or flight. In this way, it can ensure the contact between battery and circuit board is always stable. Drones vibrate or accelerate at high altitudes, and this pogo pin connector can maintain a stable power supply. Because springs can effectively adapt to vibrations and impacts, avoiding poor contact or loose batteries.

Efficient electrical connection, battery interface for wearable devices

Smart watches or fitness trackers typically require a stable and reliable electrical connection between battery and circuit board. However, due to their small size, these devices require frequent contact with external environment or quick disassembly. Traditional battery interfaces often suffer from poor contact or damage due to frequent plugging or external forces.

Spring loaded connectors can achieve efficient battery connections in these wearable devices. They ensure good contact between battery and circuit board through spring force, regardless of frequent disassembly or external pressure. This pogo pin connector can automatically adjust connection pressure to avoid excessive compression or loosening, ensuring the stability of electrical signal transfer. In addition, spring’s self-healing can ensure the connection can remain reliable after multiple insertions.

Read: 10 Pin Connector Male and Female

Conclusion:

Spring loaded connectors can effectively solve common problems encountered by engineers in design, such as poor contact, limited space, and poor durability. It can also become key component in modern engineering design through high reliability, simplified design, improved overall performance.

If you are facing these design challenges, exploring the application of spring loaded connectors will be an effective investment. To gain a deeper understanding of how to incorporate this innovative component into your design, contact Johoty immediately. Let our spring loaded connectors provide expert solutions for your engineering design, becoming your trusted assistant in your designs.