Automotive Connectors: Why 82% of Contact Issues? Johoty’s 5 Magnetic Connector Hacks Boost 40% Wiring Efficiency, Slash 27% Warranty Claims.

Introduction: Why do 82% of automotive electrical failures originate from automotive connectors?

With the acceleration of automotive electronicization, the automotive electrical system has gradually become a key factor affecting the overall performance of the vehicle. However, it is shocking that 82% of automotive electrical failures are caused by the failure of Automotive Connectors. Whether it is high temperature, vibration, moisture, or poor contact, the limitations of traditional connectors often become the root cause of automotive electrical failures. To overcome this issue, Tesla pioneered the use of magnetic connector technology in its latest Cybertruck model, setting a new trend in the industry.

As a leading innovation in the industry, magnetic connector greatly improves the reliability of connections. Meanwhile, it can reduce the wear and tear of traditional plug-in connectors during use. The Johoty engineering team has conducted in-depth research and summarized 5 hacking techniques for magnetic connector. Intended to assist engineers in achieving higher efficiency and lower failure rates during the assembly process of automotive wiring harnesses. These techniques can improve the efficiency of wire harness assembly by up to 40%, reduce the incidence of warranty claims, and decrease after-sales costs by up to 27%.

This article will provide a detailed explanation of these techniques and reveal how magnetic connectors can improve the performance of automotive electrical systems. Meanwhile, how it brings higher production efficiency and lower maintenance costs. If you are an automotive engineer or a professional engaged in automotive electrical design, this article will provide you with valuable technical insights. Help you seize the opportunity in the increasingly competitive automotive industry.

Automotive Connectors for Stable and Rapid Connection in Vibration and High Temperatures

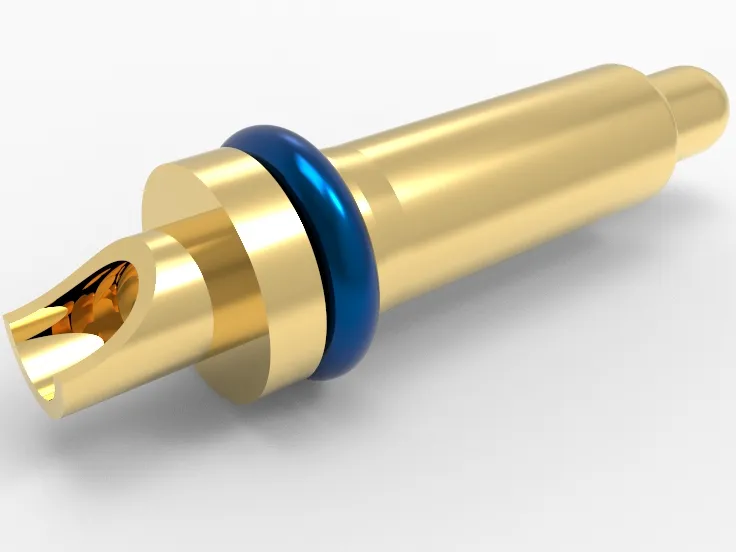

Powerful magnetic connector: perfect combination of stability and fast connection

The most significant advantage of magnetic connector is that it can maintain stable connections even in high vibration and high temperatures. In high-temperature and high vibration engine compartments or chassis, magnetic connector can ensure that the connection between cables and ports is not affected by external interference. When the car is driving on rough roads or highways, the strong magnetic connector ensures the stable operation of the electrical system. The automotive connectors can avoid poor contact effectively caused by vibration.

Improve disassembly efficiency and avoid damage

Traditional mechanical automotive connectors are prone to wear and tear on cables or connection ports during frequent disassembly and installation. It is very inconvenient to adapt to automotive applications with high sealing performance. Magnetic connectors have a simple adsorption design, making the disassembly and installation process very convenient. Meanwhile, it can effectively reduce physical damage to cables and connection ports. This feature is extremely important in electric vehicles and F1 racing cars, as it can accelerate the assembly process and greatly facilitate maintenance efficiency.

Durability under high temperature environment

When cars operate in high-temperature environments, traditional metal automotive connectors may experience oxidation of contact points or aging of plastic components due to high temperatures. This can easily lead to poor connection. Magnetic connector has significant advantages in this regard, as its magnetic connections are not as susceptible to temperature changes as traditional metal contacts. Through reasonable design, magnetic connector can effectively improve its high temperature resistance. Ensure that automotive connectors maintain reliability even at high engine temperatures.

Vibration adaptability: Adapting to dynamically changing environments

During the operation of a car, the body and electrical system are constantly subjected to vibrations from the road surface, engine, and other parts. Magnetic connector, due to its unique adsorption properties, can maintain stable connections in these constantly changing vibration environments. Avoid loosening, poor or intermittent contact caused by vibration in traditional plug connectors. This makes magnetic connector suitable for vibration sensitive power transmission systems, BMS, and other automotive connectors.

Improve the safety and reliability of electrical systems

Magnetic connector can effectively avoid operational errors such as excessive insertion and incorrect insertion in structural design. By relying on N52 strong magnets, these automotive connectors can greatly improve the safety of electrical systems. The automatic docking function of magnetic connector can reduce human error and ensure precise completion of each connection. This feature is very important for complex electric drive systems and sensor networks in modern automobiles.

Strong Magnetic Automotive Connectors with Anti-Vibration and Anti-loosening

Powerful magnetic connector: Utilizing the attractive force generated by a magnetic field to achieve efficient electrical connection and maintain stability under high vibration and strong impact. Compared with traditional mechanical automotive connectors, magnetic connector is less prone to loosening due to long-term vibration or external forces. It widely fits high stability automotive electronic systems, ADAS, and autonomous driving technology.

Anti vibration capability: Cars will experience varying degrees of vibration during driving, which poses a serious challenge to connector stability. The strong magnetic connector effectively reduces poor electrical contact through the stability of the magnetic field. This type of automotive connector ensures continuous stability in data transmission and current supply. The impact of vibration on connectors is particularly prominent in key components such as automotive power systems, chassis control, and power battery management systems. Magnetic connectors can provide higher vibration resistance and reduce the failure rate caused by vibration.

Anti loosening design: Traditional connectors are susceptible to external temperature changes, mechanical vibrations, and thermal expansion and contraction. This can easily lead to the gradual loosening or even detachment of automotive connectors. And the strong magnetic connector can ensure that the connectors are firmly attached together through magnetic action, resisting looseness caused by external forces. This anti loosening design is very suitable for high-speed driving, rapid acceleration, and sudden braking of automobiles. It can effectively avoid various safety hazards caused by loose connectors.

Magnetic connector in automotive applications:

Battery Management System (BMS): One of the core electronic systems in electric vehicles, requiring its connectors to have extremely high stability and vibration resistance. The strong magnetic connector can ensure a stable electrical connection under the dynamic load of the battery pack. The automotive connectors can prevent battery system failures due to poor connections.

Car entertainment and information systems: Magnetic connector is also extremely important in car data transfer and audio and video signal transfer. Such automotive connectors can provide fast and stable connections, avoiding system failure caused by vibrations in the vehicle environment.

Sensors and auto drive system: the core of autopilot technology depends on accurate data input and processing. Magnetic connector can ensure stable electrical connections in systems such as sensors, cameras, and radars. In the extreme vibration environment, the automotive connectors maintain reliable signal transfer to ensure the accurate operation of the auto drive system.

Automotive Connectors for reducing energy loss and efficient power transmission

The rise of magnetic connector

Magnetic connector, as an emerging technology, have shown great potential in automotive connectors. Its working principle is to connect two electrical ports through magnetic attraction, improve connection stability, and effectively reduce mechanical wear and corrosion. Compared to traditional plug-in automotive connectors, magnetic connector has significant advantages in reducing energy loss during the connection process and improving power transfer efficiency.

Optimizing magnetic field design: improving transfer efficiency

The performance of magnetic connector is closely related to their magnetic field design. Optimize the design of magnetic cores, Johoty chooses high permeability materials and adjusts the magnetic field distribution. It is to maximize the conduction efficiency of magnetic lines and reduce energy loss. Common high permeability materials such as neodymium iron boron (NdFeB), ferrite, etc. can provide strong magnetic fields and effectively reduce energy loss during transfer. Johoty can also ensure maximum energy transfer efficiency by simulating and optimizing magnetic field distribution.

Intelligent current management system: dynamically adjusting load

As the demand for electricity changes, the current load in automotive electronic systems will constantly fluctuate. To ensure efficient power transfer, magnetic connector can integrate intelligent current management systems. Real time monitoring of current changes and dynamic adjustment of current paths through built-in sensors and control units. Intelligent management can effectively avoid problems such as current overload and overheating. Thus, automotive connectors improve power transfer efficiency and reduce unnecessary energy losses.

High integration and multifunctional design

The requirements for connectors in modern automotive electronic systems are becoming increasingly high, requiring higher integration in limited space. The magnetic connector can transmit power and integrate various functions, such as data and signal transmission. Johoty integrates power, regular signals, and high-frequency signals into a 20 pin magnetic connector for Japanese clients. It can reduce the number of traditional automotive connectors, decrease space occupation, and improve system efficiency. The multifunctional integrated design enables magnetic connector to meet efficient power transfer while also taking into account the needs of other electronic systems.

Automotive Connectors of Enhancing High Temperature Resistance and Waterproof Capability

Enhancement of high temperature resistance

In the automotive industry, many connectors need to withstand high temperature environments, especially in high-temperature BMS, engine compartments, exhaust systems. Traditional automotive connectors are often susceptible to deformation, poor contact, or failure due to material limitations and high temperature effects. Magnetic connector can effectively improve their high temperature resistance through the following methods:

Material selection: Magnetic connector uses high-temperature resistant magnetic materials and high-performance plastics, such as polyamide (PA), polyester (PET), etc. They can keep stability in high temperatures.

Magnetic stability: The magnetic material of magnetic connector is often designed to be high-temperature stable. It can maintain its magnetic force without attenuation even in long-term high-temperature environments, thereby ensuring connection reliability.

Structural optimization: By designing a reasonable structure, reduce heat transfer to the connecting parts. This can effectively avoid damage to internal components of automotive connectors caused by excessive temperature.

Improvement of waterproof ability

In addition to high temperature resistance, the waterproof performance of automotive connectors is equally important. Poor waterproof connectors can cause electrical system failures and even pose safety hazards such as fires when used outside the vehicle or in humid working environments. The magnetic connector designed by Johoty can significantly improve waterproof performance:

Sealing structure design: Magnetic connector are usually designed with a triple sealing structure, which uses magnetic force to tightly adhere the two ends of the connector. At the same time, a second barrier is formed through rubber sealing rings or waterproof film, effectively preventing moisture from entering. Each single needle is designed with a waterproof flange, which is injected and molded into the housing to form an effective seal.

Waterproof rating upgrade: Many magnetic connector is designed to have a higher waterproof rating according to IP standards. Johoty can easily achieve IP67 waterproof or higher IP68 waterproof, which can completely prevent water from entering the interior of automotive connectors.

Corrosion resistance: Waterproof technology not only blocks the penetration of moisture, but also prevents corrosion caused by the reaction between moisture and metal components. Magnetic connector uses anti-corrosion coatings and stainless steel materials to further improve the reliability of automotive connectors in humid environments.

Accurate, efficient, and automated automotive connectors

Fast automatic docking: Through magnetic attraction, the connector can achieve fast automatic docking, avoiding the time waste of traditional manual plugging.

High reliability: Magnetic connector can usually withstand more insertions and removals, reducing system failures caused by poor contact.

Error proof design: Due to magnetic field guidance, the connector docking direction is more precise, avoiding incorrect insertion or incomplete contact.

In BMS of EVs and PHEVs, the performance of automotive connectors directly affects safety and stability of entire system. Magnetic connector can meet these high standard requirements, ensuring reliable connection between various electronic devices and vehicle batteries.

For autonomous vehicle, sensors, laser radars, cameras, etc. also need to transmit data and power through efficient automotive connectors. With its unique design, the magnetic connector makes the connection of these devices more simple and accurate, providing strong support for the auto drive system.

Why choose Johoty’s magnetic connector as the solution for automotive connectors?

Innovative magnetic connections

Johoty’s magnetic connectors use advanced magnetic docking technology to precisely connect using the attractive force of a magnetic field.

Automatic alignment: Magnetic connectors can automatically align during insertion, reducing manual errors and time costs.

Reliable contact: Magnetic connection ensures stable contact and reduces wear or looseness caused by traditional mechanical contact. This has increased the lifespan of the automotive connector.

Quick disassembly: Magnetic connectors are easy to disassemble and replace, especially suitable for automotive applications that require regular maintenance or replacement.

Excellent anti-interference performance

In automotive applications, EMI is critical that can’t be ignored. Johoty’s magnetic connectors have strong electromagnetic interference resistance, which can effectively prevent signal interference and ensure the stability and security of data transmission. In the application of auto drive system and Internet of Vehicles, the anti-interference performance of the automotive connector is particularly important.

High reliability and long life cycle

The design of Johoty magnetic connectors meets the high standards of the automotive industry and can work stably for a long time under high temperature, humidity, and vibration. The high-quality materials used, combined with precise magnetic docking technology, greatly improve the reliability and lifespan of the automotive connector, reducing the frequency of vehicle maintenance and replacement.

Environmental Protection and Energy Efficiency

With the increasing global emphasis on environmental protection, the automotive industry is also paying more attention to green design and energy-saving technologies. Johoty’s magnetic connector has high performance and meet environmental requirements. We always use lead-free and non-toxic raw materials to effectively reduce the impact on the environment. Meanwhile, the efficient power transmission and low power consumption characteristics of automotive connectors contribute to improving the overall energy efficiency of automobiles.

Conclusion: Making the future of automotive connectors within reach

Through these innovative magnetic connector techniques, Johoty can help customers significantly improve the performance and reliability of automotive electronic systems. Our magnetic connector is solid foundation for future intelligent vehicles. It can be used in automotive connectors for more complex electrical systems and for more efficient energy transfer. Johoty’s magnetic connector has shown tremendous potential.

If you are an engineer eager to drive the development of next-generation automotive technology. Or if you are looking for reliable partners who can help you achieve these breakthroughs. So Johoty is definitely a choice you can’t miss. Johoty is committed to providing customized perfect solutions of automotive connectors for every project. 100% guarantee that your design is more efficient, secure, and intelligent.

Don’t hesitate, contact Johoty immediately to initiate cooperation and work together to create the future of automotive connectors!