Custom Connectors with Pogo Pins Boost Device Performance by 30%, Enhance Efficiency, Reliability, Connectivity. Essential Read for Engineers!

Introduction: Custom connectors revolutionize your device performance, increasing it by 30%!

With rapid development of connectivity, improving equipment performance has become a core challenge that engineers urgently need to solve. Faced with constantly growing performance demands, it brings huge challenges to R&D engineers. How to improve overall efficiency and reliability of equipment through precise custom connectors has also become an important issue.

So, how can you achieve a 30% performance improvement? The answer lies in choosing Johoty’s appropriate custom connectors. Pogo pins, as a flexible connectivity technology, play a crucial role in improving device performance with their excellent stability and accuracy.

Johoty will delve into how customized pogo pin connector can help you overcome performance bottlenecks and achieve significant device improvements. Let’s explore infinite possibilities that custom connectors bring to devices behind this groundbreaking solution.

High-performance design custom connectors: beyond the limits of standard connectors

In the design of modern high-performance devices, standard connectors often fail to meet increasingly stringent requirements. Especially in equipment that requires high-frequency transmission, low contact impedance, and high reliability, traditional connection schemes have shortcomings that cannot be ignored. For engineers, how to choose suitable connectors to ensure the stability and high efficiency of equipment is the core issue of every design scheme.

Why can’t standard connectors meet the needs of high-performance devices?

High frequency transmission problem: In many high-performance devices, the frequency requirements are very high, especially in industries such as communication, healthcare, and aviation. Standard connectors often cannot handle such high-frequency signals, resulting in distortion or attenuation of the transmitted signal, which in turn affects the overall performance of the device.

Excessive contact impedance: Contact impedance is one of very key factors affecting connector’s transmission performance. Standard connectors often have high contact impedance due to material and design limitations. This can lead to signal loss, increased power consumption, and even unstable device operation.

Reliability issue: In harsh environments, the reliability of standard connectors is difficult to guarantee. For example, in vibration or impact, high temperature and high humidity, traditional connectors may experience poor contact or failure, thereby affecting the long-term use of the equipment.

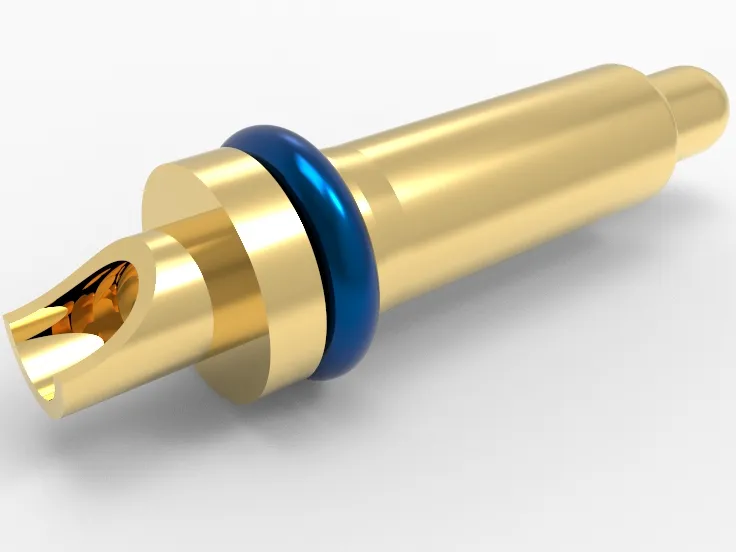

Custom connectors: The advantages of Pogo Pins

Custom connectors, especially pogo pins or pogo pin connectors, provide engineers with an ideal solution. The application of these connectors in high-performance devices can overcome various limitations of standard connectors and has significant advantages:

High frequency transmission performance: Pogo pins can carry higher frequency signal transmission, and data transmission is fast and stable. It is crucial for 5G communication, medical equipment, and intelligent hardware that require high-speed data exchange.

Low contact impedance: Pogo pins use high-quality materials and precision design to provide low contact impedance connection performance. This means smaller signal attenuation and higher energy efficiency, ensuring high efficiency and low energy consumption of the equipment during operation.

High reliability: The design structure of Pogo pins is very robust and can maintain long-term stability performance under extreme conditions. Pogo pins can ensure stable connection in harsh environments, including high temperature, vibration, low temperature, impact, and humidity. It will not experience performance degradation due to external factors.

Customized design: Pogo pins have excellent technical performance and can be customized according to customer needs, fully adapting to various special requirements. Custom connectors can perfectly meet the specific requirements of different devices in terms of size, contact points, arrangement, and material selection.

Pogo Pins and Custom Connectors: The Secret to Improving Device Performance by 30%

Design accuracy: perfect connection in tiny spaces

The design accuracy of Pogo pin connector is one of its major advantages. Each connection point can achieve precise connection at the smallest contact point, ensuring the stability and accuracy of data transmission. This accuracy is suitable for mobile devices, medical instruments, and portable tools with limited space.

In a medical device design in Germany, Johoty’s pogo pins were used for circuit connections in pacemakers. They successfully ensure the stable operation of the device in complex environments, far exceeding the performance of traditional connectors.

High density design: integrating more functions

With the continuous advancement of technology, the functional requirements of various high-end devices are increasing day by day. Pogo pins provide a unique solution in high-density design. They allow for the integration of more functions within a limited space through extremely small contact points. Compared to traditional connectors, pogo pins can achieve more connections in a smaller area, greatly improving the overall performance of the device.

In a smartphone design project for a Polish client, pogo pins’ custom connectors were used instead of traditional connectors. The performance of the device has been improved by over 30%, while reducing the design volume and enhancing the user experience.

Durability and reliability: Long term stable operation

The durability and reliability of connectors are crucial in harsh environments. Pogo pins can withstand high temperature, high humidity, and vibration, and work stably for a long time. Compared to other types of connectors, pogo pins perform more prominently in aviation, automotive, and medical environments.

In the automotive electronics of Italian clients, the system using Johoty’s pogo pins has improved long-term stability by over 50% compared to traditional connectors. And, at high temperatures, the performance of these custom connectors can remain stable.

Fast response and low latency: the ideal choice for high-frequency devices

High frequency devices have higher requirements for data transmission rate and latency. Pogo Pins have become an ideal choice for these devices due to their fast response and low latency characteristics. They ensure real-time data transmission in wireless communication, testing instruments, and high-frequency signal transmission.

Johoty’s pogo pins are used as custom connectors in the high-frequency testing equipment of American clients. They significantly reduced data transmission latency and improved testing efficiency by 40%.

Precision custom connectors: How does Johoty meet engineers and improve equipment performance?

In high-tech equipment, connector’s accuracy and stability are key to ensuring system’s reliable operation. Johoty, as a leading provider of custom connector solutions, we have excellent engineering technology and customer support. We are committed to providing global customers with flexible custom connectors based on pogo pins, helping to improve device performance.

Johoty’s custom connectors: meet your every need

Johoty’s advantage lies not only in the supply of standard connectors, but also in providing customers with comprehensive customized services. From design to production, each pogo pin connector is tailored to customers. Johoty’s CFT team works closely with clients to ensure every project solution meets high design standards and performance requirements.

We have customized connectors based pogo pins for French airlines to help optimize their charging systems. By precise electrical contact design, charging efficiency and stability under long-term use are significantly improved. Customer feedback shows improving device’s charging stability by 30% and reducing maintenance costs through Johoty’s custom connectors.

Accurate Design and Efficient Performance: Engineering Cases

In the industrial field, Johoty also provides custom connectors for numerous enterprises. Assist customers in improving the connectivity performance and equipment reliability of their products. In a project to provide connectors for automation equipment, Johoty designed customized 6-pin double ended connectors for American clients. Through precise electrical design and high-quality materials, our pogo pin connector ensures stable connection performance of the device under extreme temperature and humidity conditions. This effectively avoids equipment malfunctions and delays.

Customer Case: Successful Collaboration Across Industries

Johoty’s customized connectors have performed outstandingly in the field of consumer electronics. We also provide solutions for medical equipment, automotive industry, and military equipment. The needs of each industry are different, but Johoty’s CFT team is able to quickly understand customer needs. We provide innovative technical support to design customized connectors that are suitable for different environments, workloads, and usage cycles.

Our customized Pogo Pins connector for the medical industry has successfully solved the challenge of high-precision connection of medical instruments. Helping customers improve medical equipment’s accuracy and reliability, providing patients with a more stable treatment experience.

Johoty’s Commitment: Engineering Team and Technical Support

Johoty is committed to maintaining close cooperation with clients, with our CFT team and engineers fully involved in every project. From the customer’s design phase to production implementation, ensure that every customer requirement is accurately met. We are able to deliver high-quality custom connectors and showcase Johoty’s technical strength and innovation capabilities in every detail.

Precise Design and Seamless Integration: Technical Details of Johoty’s Custom Connectors

The design and manufacturing of pogo pin connectors is not just a simple component, it directly affects the performance and stability of the entire device. As a leading provider of customized connector solutions, Johoty has precise engineering design and high-quality manufacturing capabilities. We can help customers provide seamless integrated pogo pin connector solutions.

Precise design: the core of Custom Connectors meeting personalized needs

Johoty’s custom connector solution begins with a deep understanding of customer needs. Our CFT team works closely with clients to accurately analyze the specific requirements of each project. We need to ensure that the design of the pogo pin connector can perfectly match the working conditions and usage scenarios of the device. Johoty is well aware that different devices have different requirements for connectors, so Johoty’s custom connectors will optimize the following main technical details:

Contact surface design: The Pogo pin connector contact surface is the key to ensuring electrical performance. Johoty conducts precise calculations and electrical simulations to optimize the shape of the contact surface. This ensures stable electrical contact and low contact resistance, greatly improving the stability and long-term service life of the equipment.

Pressure and elasticity design: In order to ensure that custom connectors can work stably in various environments, we will finely adjust the pressure and elasticity of pogo pins. Ensure that it has a suitable tactile sensation when connected and disconnected, while reducing the risk of wear and poor contact.

Packaging and protection design: In some applications that require waterproof and dustproof, Johoty provides customized packaging solutions for pogo pin connectors. We use injection molding, combined with high-temperature peek or strong N52, Custom connectors can achieve IP67 water proof and high vibration use. This pogo pin connector can maintain good performance in harsh environments and avoid malfunctions.

Precision Manufacturing: Perfect Control from Raw Materials to Finished Products Custom Connectors

Precise manufacturing processes are another key factor in the success of Johoty’s customized connectors. We strictly control every manufacturing detail and ensure 23 steps meet the highest connection standards. 23 inspection processes ensure that from selecting the raw materials for custom connectors to the final production of pogo pin connectors.

High quality materials: Johoty only selects high-quality materials with high conductivity, durability, and corrosion resistance. This includes metals used in high-temperature environments, as well as plastics that require flexibility and durability. Johoty always ensures that materials perfectly match the design, maximizing the performance of custom connectors.

Advanced manufacturing processes: Johoty always uses 5-axis or 6-axis CNC and CMM, laser welding, and automated assembly. This ensures that the tolerances and dimensions of each pogo pin connector achieve the ultimate precision. Our production process is rigorous and efficient, able to meet the demand for fast delivery while ensuring quality.

Quality control: Johoty conducts 23 strict quality inspection and control on each pogo pin connector during our production process. Ensure that each pogo pin complies with international standards. Johoty conducts comprehensive tests on mechanical strength, electrical performance, and environmental adaptability. We can ensure the long-term stability and reliability of our customers when using our custom connectors.

Seamless integration: Perfect fit between Custom Connectors and devices

An excellent customized connector not only needs to achieve precise design at the physical level, but also needs to achieve seamless integration during the device integration process. Johoty ensures perfect integration between custom connectors and devices through the following technical details:

Electrical compatibility design: We design connectors based on the electrical requirements of the customer’s equipment to ensure electrical compatibility between the connectors and the equipment. By accurately matching parameters such as voltage, current, and signal transmission, Johoty can ensure the optimal performance of custom connectors in devices.

Mechanical matching and packaging: Customers have different requirements for the appearance and interface of different devices. Johoty ensures that custom connectors can seamlessly match the physical structure of the device through precise 3D modeling and simulation. We can provide perfect solutions for both compact connectors for small spaces and connectors that require high strength and pressure resistance.

Thermal management design: For devices that require long-term high load operation, thermal management is crucial. Johoty often uses efficient heat dissipation materials and structures when designing pogo pin connectors. This ensures that custom connectors can maintain a suitable temperature during operation, avoiding performance degradation caused by overheating.

Johoty’s technological advantages: precise design+precision manufacturing

Multi domain applications: Johoty can provide custom connectors in consumer electronics, medical devices, automotive industry, and industrial automation. Help customers improve device performance and ensure reliable connection quality.

Flexible customization services: Johoty provides customers with flexible customization services, offering full support from design to production. Meet customers’ requirements and ensure clients’ every project can proceed and complete smoothly.

Global Support and Service: Johoty provides high-quality customized connectors to customers worldwide and offers comprehensive technical support. No matter which stage of the project you encounter problems with, our CFT team is always ready to provide professional support for you.

Conclusions:Why choose Johoty’s custom connectors?

In fierce market competition, improving equipment performance is core goal of every engineer. Johoty’s custom connectors, especially pogo pin connector based on pogo pins, can effectively improve device performance by up to 30%. We are well aware of each project’s uniqueness and therefore provide custom connectors to meet stringent requirements of different applications.

By collaborating with Johoty, you can obtain high-precision and highly reliable custom connectors, enjoy leading technical support and innovation. With our custom connectors, you can gain an advantage in technological competition and achieve new heights in device performance.

Contact us immediately, make Johoty your reliable technology partner to drive device innovation and enhance overall performance together!