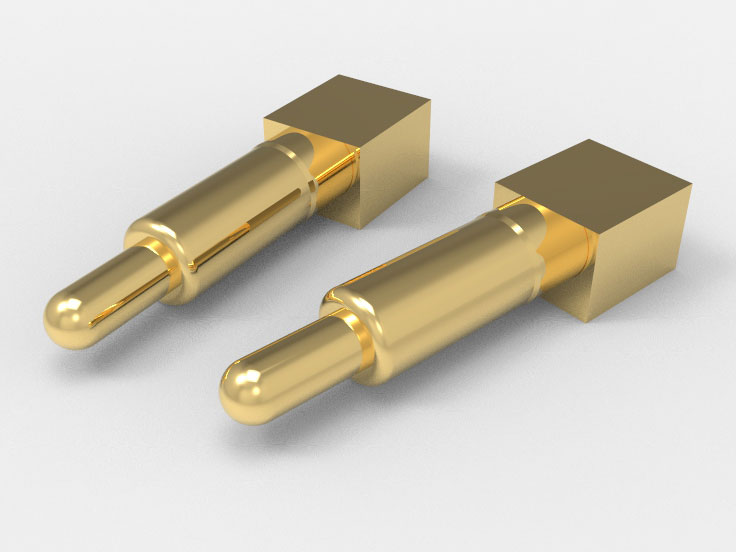

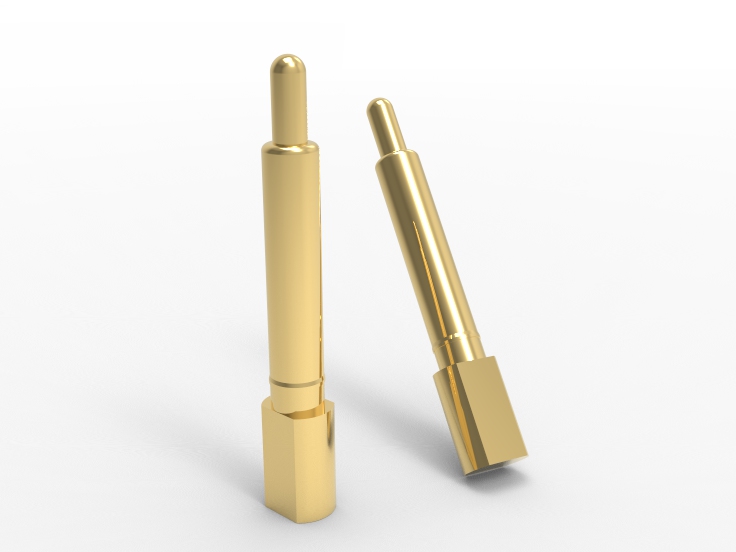

Advantages of Mini Pogo Pins, L: 6.00~26.00 mm

Compact design saves space:

Compact design of mini pogo pins can save space on PCBs. They have a small volume, but strong connection performance. Suitable for high-density circuit board design, helping devices to be more compact. Reduced unnecessary connecting components and optimized layout. Fit miniaturized electronic devices, improve overall design efficiency.

High reliability ensures stable connection:

Right angle mini pogo pins are made of high-quality materials to ensure stable connections during long-term use. Under high-frequency connections, they can still maintain reliable contact. Precise contact point design effectively avoids poor contact issues. Its sturdy and durability reduce maintenance frequency. Provide longer life cycles, reduce maintenance costs.

High precision contact performance:

The design of Johoty’s mini pogo pins emphasizes precision, ensuring consistent current transfer every time. Accurate contact points avoid signal loss or unstable power. By optimizing metal contact surface, the transfer speed has been improved. Ensuring efficient power, data, signal transfer. Perfectly fit high-precision equipment.

Durable, adaptable to harsh environments:

Mini pogo pins can maintain high efficiency in extreme conditions. They are resistant to temperatures and vibrations for various industrial and automotive electronic devices. Metal materials make them wear-resistant and prevent damage during long-term use. Under frequent use or harsh conditions, contact point can remain stable and reliable. Improved equipment overall reliability.

Low contact force enhances user experience:

The low contact force design of our mini pogo pins makes connection smoother. This advantage reduces damage to the device during contact. Compared to traditional connectors, it is easier to operate. The design conforms to ergonomics, making equipment easier to operate. Reduced losses caused by improper connection.

Adapt to various connectivity:

Right angle mini pogo pins support multiple connectivity, allowing for both power and data. They are suitable for traditional devices and high-end smart devices. Can adapt to various PCBs’ dimensions, shapes, or sizes. Can provide stable support in complex circuit design. Its multifunctionality greatly expands applications.

Rapid assembly reduces production costs:

The right angle design of mini pogo pins can simplify PCBs’ soldering process. Through automated production equipment, installation can be quickly completed, reducing manual operation time. Simplified production process and improved production efficiency. Reduced error possibility during production process. Effectively reduced overall production costs.

Powerful compatibility:

Mini pogo pins have strong compatibility to connect various devices. They can be applied in smart devices, robots, medical equipment, etc. In complex systems, stable connections can still be provided. Good compatibility with different hardware. Provide designers with more flexible solutions.

FAQ:

How to avoid PCBs’ thermal expansion issues with mini pogo pins?

Mini pogo pins are designed with elastic materials that can adapt to thermal expansion of circuit boards. With significant temperature changes, stable connections can be maintained. Flexible contact points reduce solder stress. The spring structure absorbs the displacement caused by thermal expansion and contraction. The special coating improves temperature resistance performance.

Why is right angle installation more suitable for compact devices than direct insertion design?

Right angle installation saves vertical space and makes PCB design more compact. It can arrange other components more flexibly. Suitable for narrow spaces, optimize equipment appearance. Reduce equipment internal complexity and facilitate maintenance. Maintain connection stability without affecting performance.

How mini pogo pins cope with the challenges of mechanical vibration?

Spring design can absorb mechanical vibrations and protect contact points. Contact surface design is tight, effectively reducing the risk of looseness. High quality materials increase wear resistance and impact resistance. Coating protection reduces wear caused by vibration. Suitable for electronic devices in vibration.

How to handle the performance of mini pogo pins in high humidity?

Special coatings can prevent moisture erosion and improve oxidation resistance. Contact point design reduces the possibility of moisture entering. Mini pogo pins have a high sealing structure to protect internal springs. With high humidity, stable electrical connection can still be maintained. Suitable for equipment use in humid.

Will mini pogo pins cause delays in high-speed signal transfer?

The contact points are designed with low resistance to ensure fast signal transfer. Material selection optimizes conductivity and reduces latency. High precision structure avoids signal loss. Design to support high-frequency transfer. Johoty’s mini pogo pins are suitable for devices of high signal transfer speed.

Is it possible to customize length and shape of mini pogo pins?

Mini pogo pins support customization of length, shape, and current, etc, for customer needs. Adjustable spring strength to adapt to different applications. We can optimize installation design of right angle according to requirements. Provide multiple connector options to meet special equipment. Customized services ensure the best match between products and equipment.

Will mini pogo pins overheat during high current?

Low resistance material design effectively reduces heat generation. Spring structure disperses current load and reduces temperature rise. Optimization design of contact points ensures uniform conductivity. Mini pogo pins have strong heat dissipation and can work normally under high currents. Suitable for connecting high current devices.

How to determine if mini pogo pins are suitable for my device?

Select appropriate mini pogo pins specifications and sizes based on device requirements. Consult with Johoty’s CFT team for professional suggestions. Check design document to match installation requirements. Choose a compact design based on space constraints. Ensure it can meet power and signal transfer requirements. Johoty’s right angle mini pogo pins, when made into connectors, can simultaneously transmit data and signals, power.