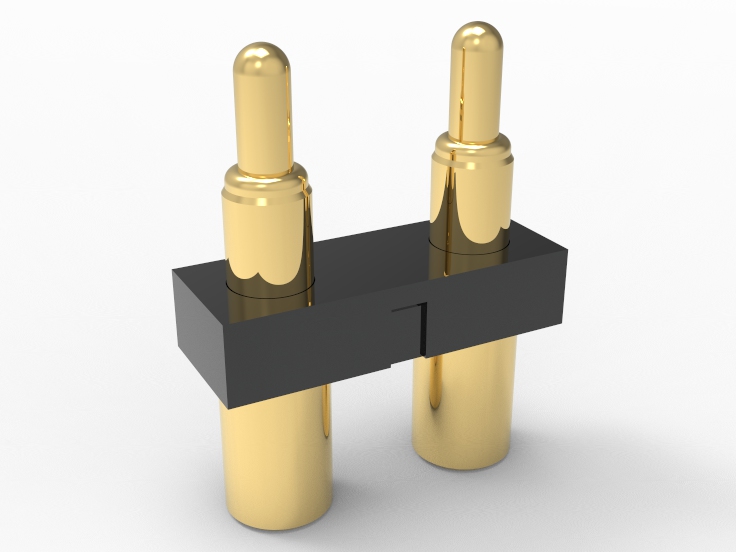

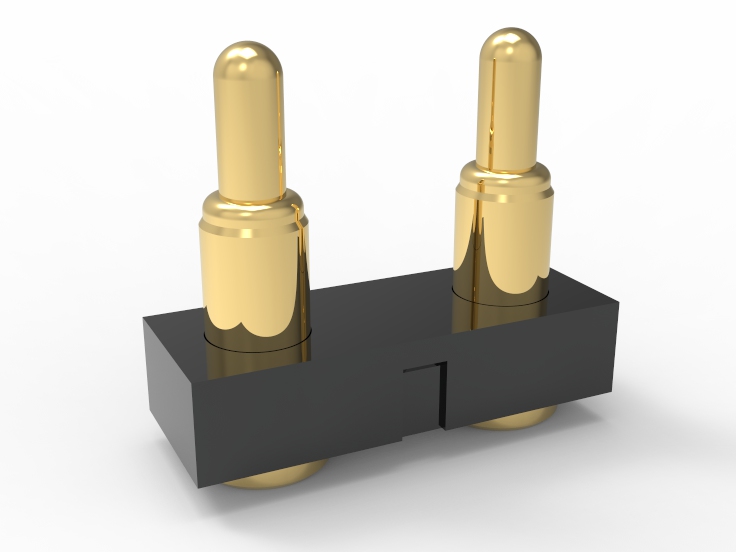

Advantages of 2 Pin Automotive Connector, Pitch 4.00~4.99

Ultra high conductivity

The high conductivity material of 2 pin automotive connector ensures that current passes quickly without generating excess heat. High conductivity can reduce voltage drop and improve the overall efficiency of the system. during high-power transfer, Johoty’s pogo pin connector can maintain low temperatures to avoid overheating issues. Excellent conductivity helps improve the stability of various electronic systems in automobiles. It ensures that the current transfer of 2 pin automotive connector is not affected and maintains stability after long-term use.

strong seismic resistance

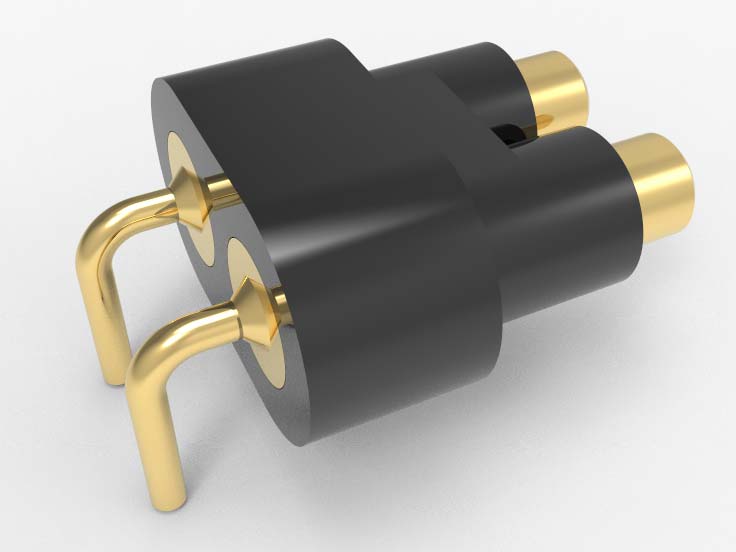

2 pin automotive connector adopts a specially designed spring, which can effectively resist the vibration generated by car during driving. On high-speed or rough roads, this pogo pin connector can maintain a secure connection. The seismic performance ensures that vehicle electronic system operates normally under various road conditions. Our 2 pin connector is not easily loosened or damaged under severe vibration. In long-term use, the seismic resistance of Johoty’s pogo pin inside greatly improves reliability of this 2 pin connector.

Long life design

This 2 pin automotive connector has been carefully designed to withstand high-frequency connection, with a long service life. The contact material and protective housing of this pogo pin connector can effectively prevent oxidation and ensure long-term use. Its spring loaded pin durable design allows this 2 pin connector to work for long time. Each component has been precisely polished and tested, enhancing connector durability. Its stable performance ensures car’s long-term efficient operation.

High temperature tolerance

2 pin automotive connector can operate in high temperatures and adapt to car engines. Johoty took into account thermal expansion and contraction at high temperatures during design. It is to avoid loosening of this pogo pin connector due to temperature changes. The connector performance remains stable after prolonged exposure to high temperatures. High temperature resistance of its pogo pin ensures excellent performance in hot weather or engine high temperatures. The housing material of this 2 pin connector can effectively isolate high temperatures and protect internal circuit from being affected.

Precise contact design

This 2 pin automotive connector adopts a precise contact design, making current more stable and smooth. Each pogo pin is finely polished to ensure perfect contact and reduce resistance. The contact precision greatly improves signal transfer speed and accuracy. Due to the design ensuring that each contact point is error-free, this 2 pin connector can also function properly under high current. It can maintain stable current conduction after long-term use.

Compact design and high-density connectivity

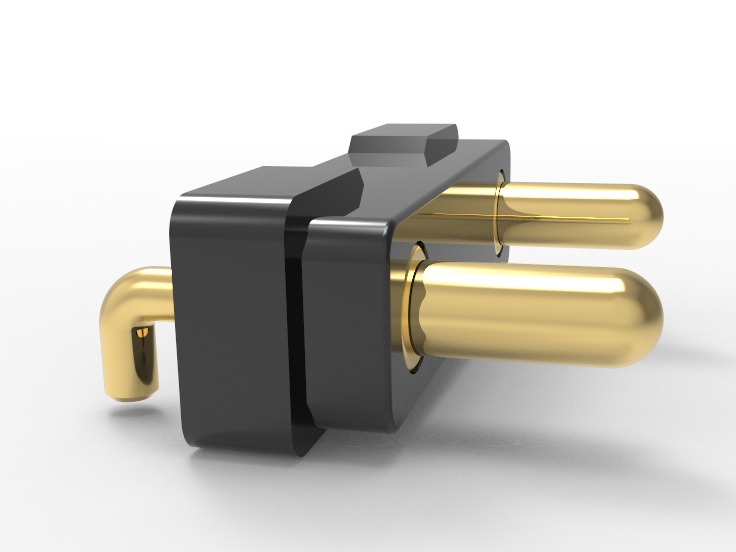

2 pin automotive connector has compact design that enables high-density connections within limited space. This 2 pin connector can effectively save valuable space in car, and more electronic devices can be integrated into car. The exquisite size design of pogo pins can save spaceand improve connection accuracy. Despite its small size, this pogo pin connector can provide powerful power. Compact design, this 2 pin connector is used in modern cars.

Waterproof and dustproof ability

The waterproof and dustproof of Johoty’s 2 pin automotive connector is suitable for complex in car environments. It is not easily affected by moisture, water, or dirt. The special sealing ring and housing design effectively prevent moisture and dust from entering connector interior. Driving on rainy days or on muddy roads, this 2 pin connector can still maintain efficient operation. It has high waterproof rating and can fit challenges of different climatic conditions. In extreme weather, Johoty’s pogo pin connector can still stably transmit power and signals.

Quick plug and unplug design

This 2 pin automotive connector has quick connections, it is easy tp repair and replace. Its pogo pin insertion and removal design is very precise, making it less prone to accidental insertion or damage. The operation can also be carried out smoothly in narrow interior space of car. The optimization of this pogo pin connector is more flexible and time-saving, reducing wear and tear. The fast connection of this 2 pin connector improves efficiency of repairing and updating electronic systems, avoiding complex operations.

FAQ

Why does 2 pin automotive connector need to use pogo pins?

Pogo pins are designed with elasticity to provide better contact force and ensure a more secure connection. This spring loaded pin is suitable for automotive electronic systems. Compared to traditional connectors, pogo pins can effectively reduce contact resistance and achieve higher transfer efficiency. Its small volume makes it easy to install in confined spaces. The 2 pin automotive connector with pogo pins can improve system reliability, it can also greatly extend service life.

How to ensure 2 pin automotive connector stability?

This 2 pin automotive connector ensures connection stability through precise design and brass stainless steel. Its pogo pins are made of brass, reducing resistance and heat generation. Precision machining ensures that each spring loaded pin can make close contact with contact surface. Its housing has shock resistance and can maintain stability in high vibrations. After long-term use, this pogo pin connector can maintain excellent conductivity.

Does 2 pin automotive connector work properly at extreme temperatures?

The 2 pin automotive connector can stably operate at extreme temperatures. The pogo pin material inside can effectively cope with temperature changes and prevent loosening caused by thermal expansion or contraction. The design of this spring loaded pin optimizes thermal conductivity and avoids faults caused by overheating. In both hot and cold weather, the 2 pin connector can maintain good performance. Its high temperature tolerance is suitable for automotive engines in high-temperatures.

Why is it difficult for 2 pin automotive connector to loosen?

The design of 2 pin automotive connector adopts a high-precision plug-in structure and strong contact. It can effectively prevent loosening. It uses a spring or locking system internally to ensure tight contact between plug and socket. After prolonged use, this pogo pin connector can maintain secure connection. The seismic performance of spring loaded pins also makes the connection less loosening during driving. in strong vibrations, Johoty can guarantee 2 pin connector stability.

Can a 2 pin automotive connector prevent electrical short circuits?

The 2 pin automotive connector specially optimize for electrical short circuit protection. There is a specialized isolation layer inside to prevent accidental contact of current with other components. Its pogo pins have been reinforced during design to reduce arcing caused by poor contact. High quality materials can effectively isolate potential current leaks. Housing design also provides a certain protection to prevent external objects from causing short circuits.

Is 2 pin automotive connector suitable for frequent plugging?

2 pin automotive connector is suitable for power seat adjustment and in car device maintenance that require frequent plugging. Pogo pins allow for high-frequency insertion and removal without damage. The elastic design of pogo pins ensures reliable electrical contact. The durability of 2 pin connector ensures that frequent operation will not lose contact effect. Through precise design, Johoty’s pogo pin connector can guarantee excellent performance after long-term use.

How does 2 pin automotive connector resist external factors?

Johoty’s 2 pin connector features a special housing that effectively resists moisture, dust, salt spray, and more. The sealing design prevents moisture from entering connector interior for stable operation. The dust-proof design of pogo pins prevents dust and sand particles from affecting current transfer. Housing’s corrosion resistance enables 2 pin automotive connector to adapt to various harsh environments. In high humidity and temperature, nothing affect our pogo pin connector.

Why can 2 pin automotive connector effectively reduce EMI?

This 2 pin automotive connector features specially designed contact surfaces and shielding materials, effectively reducing EMI. High quality conductive materials can ensure uninterrupted signal transfer. Pogo pins and wiring structures have been precisely optimized to reduce the impact of electrical noise. Through precise shielding design, Johoty’s 2 pin automotive connector can effectively shield external EMI. Its anti-interference is suitable for complex electronic systems in modern automobiles.