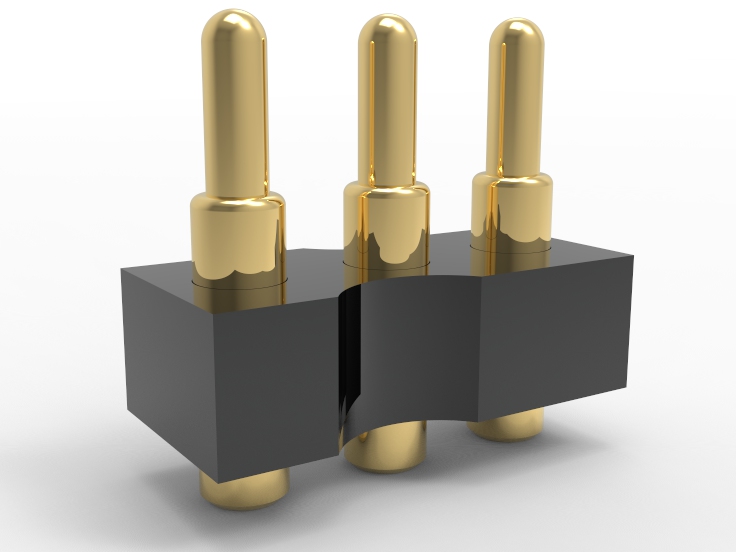

Advantages of 3 Pin Pogo Connector, Pitch 2.00~2.53

Extremely high conductivity

Conductivity is very important because it directly affects the speed and accuracy of signal transfer. The 3 pin pogo connector uses special metal materials and surface electroplating technology to ensure low losses during current flow. It can achieve fast and stable transfer of extreme frequency signals. This superior conductivity also makes it reliable in complex environments.

High precision manufacturing

The high-precision manufacturing ensures that each plunger and housing meet the design standards very closely. Through micrometer level technology, the dimensions of each part are very precise and there will be no errors. This precision ensures smooth insertion and removal, reducing wear and tear. Meanwhile, when in use, it can be firmly fixed without loosening or shifting, making it very suitable for precision instruments.

Super durability

Durability is a major advantage of the 3 pin pogo connector, which uses high-strength metal and elastic materials to withstand repeated insertion and extraction without damage. Even in frequent use, the spring can maintain good elasticity and the plunger is not easily worn. This durability greatly reduces maintenance and replacement costs for users, and can also cope with various complex conditions.

Superior contact performance

Plunger designr has been carefully optimized to ensure a perfect fit with the contact surface of pogo pin connector, resulting in very low contact resistance. This ensures that the loss of electrical energy is minimized and data transfer is more reliable. Especially in high-speed data transfer, this design is important as it can ensure the stability of every connection.

High adaptability

The design of the 3 pin pogo connector is very flexible, as it can adapt to various device interfaces without requiring additional modifications. This adaptability allows it to be used in different types of electronic devices, whether they are large or small devices. Design diversification can also meet users’ personalized needs, and its application scope is very wide.

Strong anti vibration ability

The structure of the 3 pin pogo connector can effectively absorb external vibrations and impacts. The spring allows the plunger to maintain stable contact even during vibration, without causing circuit interruption due to external influences. At the same time, it can also reduce the problem of accidental contact caused by vibration, making it suitable for use in devices that require movement or high vibration.

Optimize thermal management

The 3 pin pogo connector adopts optimized thermal management design to ensure that excessive heat does not accumulate during use. Even under high current, it can maintain low-temperature operation to prevent damage caused by overheating. This design improves product safety and allows it to maintain good performance.

Accurate insertion and extraction force

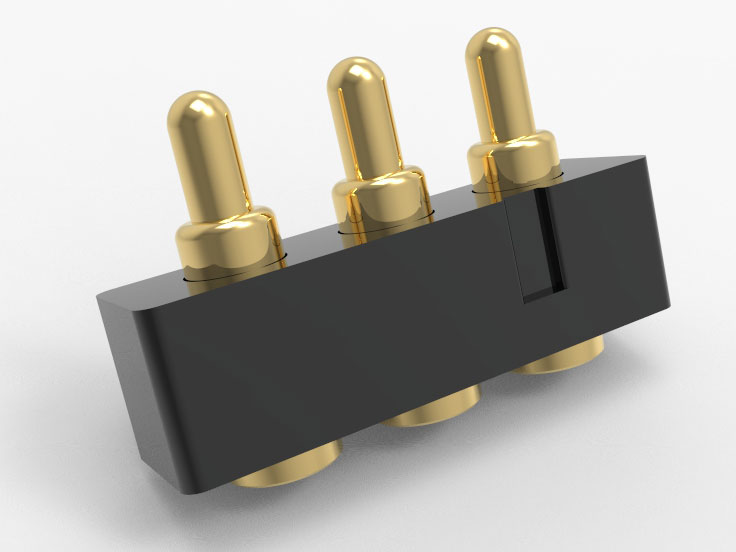

The insertion and extraction force is a major feature of 3 pin pogo connector. We always take into account user’s operating experience, with right force control. The insertion and removal is very smooth, without any lagging or being too tight. At the same time, this 3 pin connector can effectively protect device interfaces and avoid damage. This makes it very suitable for frequent plugging and unplugging.

FAQ

Why are plunger lengths of 3 pin pogo connector not exactly the same?

This design is to protect circuit safety of connectors and equipment. If 3 plungers come into contact at the same time, it may cause an instantaneous current surge and damage electronic components. By sequentially contacting plungers of different lengths, a stable current path can be gradually established to ensure safer equipment. Meanwhile, 3 pin pogo connector can also reduce interference during signal transfer, making data more accurate and reliable. Moreover, the length difference also helps to reduce wear and tear and extend pogo pin connector lifespan.

Why does spring force of 3 pin pogo connector vary?

The difference in spring force can adapt to different needs of various devices. Some devices require lighter contact force to protect precision components, while others require greater force to ensure stable connections. This design can effectively reduce wear and tear of 3 pin pogo connector and devices, extending their service life. In addition, spring force difference can also reduce the risk of plunger misalignment. This can transfer signal more stable and reliable in high vibration.

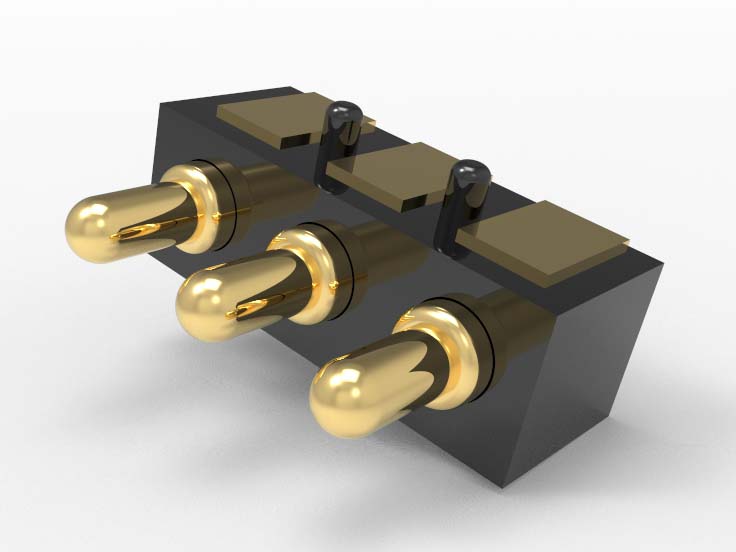

Will plunger in 3 pin pogo connector be rotatable?

Yes, plunger is designed to be rotatable to reduce wear and tear during frequent insertion and removal. When rotating, the contact point of plunger will constantly change. This can effectively eliminate lateral force and reduce damage to pogo pin. This way, the same position will not wear out continuously, greatly extending 3 pin pogo connector lifespan. The rotatable plunger can also avoid signal interference caused by friction, ensuring data transfer quality. Moreover, this design is suitable for industrial automation equipment and medical devices that require quick and multiple connections.

Does plunger tip shape of 3 pin pogo connector affect performance?

Yes, plunger tip shape of 3 pin pogo connector directly determines contact effect and signal transfer quality. Optimizing plunger tip can reduce contact impedance and improve current transfer efficiency. Specific shapes can increase contact area and avoid displacement. The streamlined design reduces wear and improves lifespan, while adapting to different equipment interface.

Why does housing of 3 pin pogo connector have specific pattern?

The pattern on housing of 3 pin pogo connector isn’t just for its appearance, it actually has many practical uses. Firstly, these patterns can enhance tactile feel, easier to grip 3 pin pogo connector when there is sweat or oil on hand. At the same time, such housing can effectively disperse external pressure. This can avoid deformation of the housing due to pressure concentration. In addition, the pattern on the housing can increase overall structural strength. This can prevent damage to equipment in case of accidental dropping.

What special electroplating materials are compatible with 3 pin pogo connector?

The selection of special electroplating materials is to enable 3 pin pogo connector to function properly in harsh environments. These materials can effectively prevent oxidation and corrosion in damp or chemical environments. In addition, electroplating can make the conductivity more stable and signal transfer faster and more accurate. The special coating can also prevent the accumulation of static electricity and protect equipment safety. This design has stronger adaptability and can be used in industrial, medical, and aviation fields.

Will springs force lose after frequent use?

Whether a spring will lose its force depends on our designs and raw materials. High quality springs are usually made of special piano steel or stainless steel, which have strong fatigue resistance. It can withstand compression of up to 200,000 cycles or clients’ required 300,000 cycles. Johoty also considers spring usage environment when designing 3 pin pogo connector. We can ensure 3 pin pogo connector can maintain spring force under high temperature, vibration. By optimizing structure and materials, this spring will be very stable and high performance for a long time.

Why does 3 pin pogo connector require special sealing?

The special sealing is to protect precision structure inside 3 pin pogo connector from external influences. Sealing can prevent dust, small particles, or liquids from entering, thereby avoiding internal short circuits or poor contact. In humid environments, sealing can also isolate moisture, prevent corrosion, and reduce electrical performance. This design of 3 pin pogo connector is suitable for medical equipment and outdoor communication devices.