What Is Magnetic Connector? Learn to Revolutionize Your Design Now, Show Strong Power of Johoty’s Magnetic Pogo Pin Connector in Your Projects

Introduction: What Is Magnetic Connector?

Magnetic connector is crucial in engineering projects today, it can significantly enhance the reliability and convenience of modern technological solutions. Then, what is magnetic connector? what benefits is it to give engineers and clients? In brief, the pogo pin connector uses magnets to achieve quick and secure connections. It is suitable for various electronic devices, medical instruments, and automotive industries, etc.

One of the advantages of Johoty’s magnetic connectors is their convenient plug-and-play operation. Unlike traditional plug connections, Johoty’s magnetic connector can be connected and disconnected simply by approaching and pulling apart. During engagement, they have good fool-proof without error-alignment. And, It can eliminate complex procedures and greatly improve device usability and operational efficiency.

Read: 8 pin connector

Magnetic connectors offer excellent durability and stability. Since there is no physical contact during connection, they can greatly reduce the risk of plug wear and poor contact. Many times, Johoty can customize their life cycles of 200,000 times for some clients. Then, they can extend equipment’s lifespan and reduce maintenance costs significantly.

Johoty’s magnetic connector provides efficient electrical transfer and mechanical connection. It’s well-designed to effectively transmit power and signals while ensuring stability and safety during high-frequency and high-speed operations. Top importance, it is convenient for our clients and end users during designs and uses. This can make it suitable for high transfer quality.

Overall, Johoty’s magnetic connector can simplify engineering design and equipment maintenance, enhance system reliability and operational efficiency. With advancing technology and expanding application areas, our magnetic connectors are getting better and more important in engineering design. Many clients feedback that they can demonstrate their strong advantages across more fields in the future.

Read: 5 pin connector

What is a Magnetic Connector?

Read: 5 pin connector

Working Principle of Magnetic Connector, What Is Magnetic Connector?

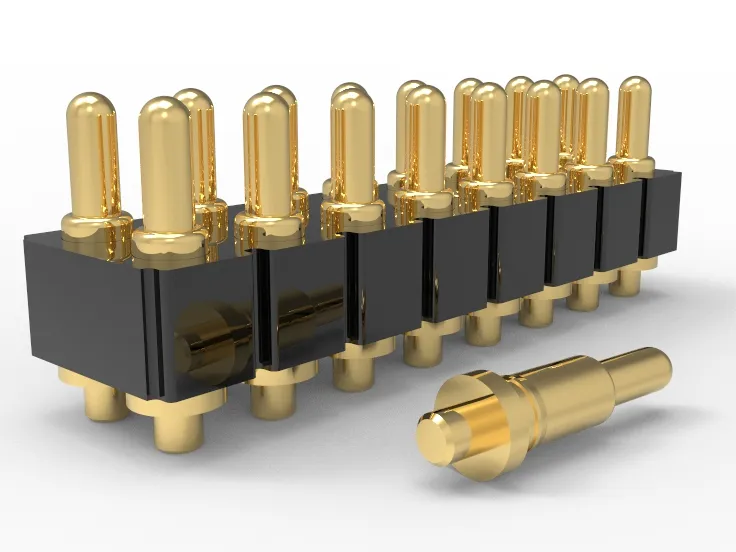

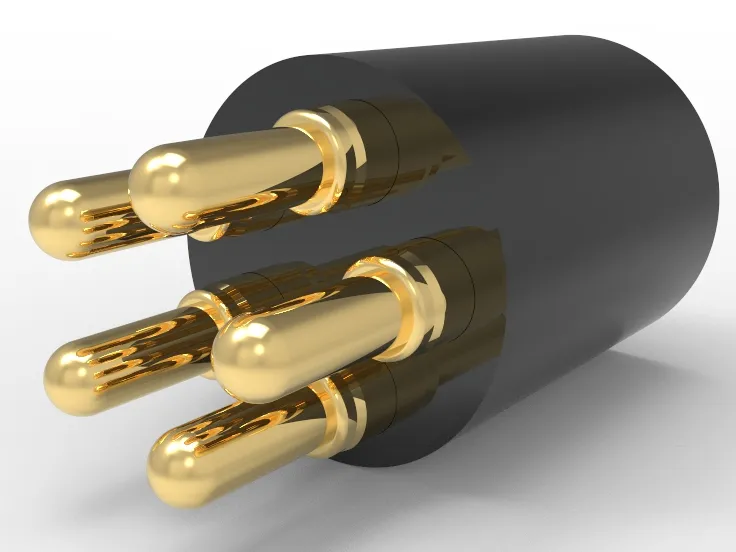

A magnetic connector uses magnetic force to establish and break connections. It consists primarily of two parts: a magnetic plug and a magnetic socket with common cylindrical, rectangular, and runway shapes. Waterproof magnetic connector is commonly used in electronic devices, chargers, and data transfer cables.

How it works:

The magnetic connector operates based on two key components: magnetic male and magnetic female. These parts include magnetic materials, Johoty often uses neodymium magnets with N52. It can always generate strong enough magnetic force to maintain stable connections while keeping stable self-alignment.

Read: 4 pin connector

Read: 4 pin connector

Applications of Magnetic Connectors,What Is Magnetic Connector?

Magnetic connector uses in smart hardware, as it can easily connect devices to power or data ports through magnetic connections. During wireless charging and data transfer, plugging or unplugging aren’t needed. This can avoid wear and tear of traditional sockets and extends your devices’ lifespan. More importantly, magnetic connector provides users with a more intuitive and secure operating experience. It can make high-tech products more convenient and efficient.

In medical equipment, Johoty’s magnetic connector has become important connecting components due to its high stability and safety. In life monitoring instruments, diagnostic and treatment equipment, connectors not only require precision and efficiency, and emergency equipment, always require precision and efficiency and waterproof, dustproof, and anti-interference. Magnetic connector help medical personnel quickly and accurately connect equipment through simple docking. It can reduce operation time and improving response speed, stability, safety, reliability in emergency situations.

Read: 7 pin connector

The demand for magnetic connector in wireless charging and data synchronization, is also increasing day by day. Magnetic connector provides a simple and safe charging method for smartphones, headphones, tablets, and other devices. At the same time, Johoty’s magnetic connector can avoid damage to traditional sockets caused by frequent plugging. Its design is lighter and more exquisite, enhancing product appearance and bringing users a new and convenient experience.

In electric and intelligent vehicles of automotive industry, magnetic connector widely uses for electrical connections in vehicles. It is due to their excellent shock resistance and durability. Electric vehicles require efficient power transfer and multiple data exchange systems. Johoty’s magnetic connector can ensure stability during high-speed driving and bumpy road surfaces. It provides safe and reliable electrical support for vehicles. Its quick disconnection function is very important in ensuring security.

Industrial automation also benefits from magnetic connector. In robot systems, automated production lines, and intelligent devices, magnetic connector can achieve high-frequency connection without complex manual operations. Its durability, anti-interference ability, and high-precision docking ensure equipment stability in harsh industrial environments. At the same time, the simplified method greatly improves maintenance efficiency, reduces human errors and repair costs.

Read: 6 pin connector

Design Considerations for What is Magnetic Connector

Stability and durability: Magnetic connector is connected through the magnetic force of N52, which is crucial for stability. Johoty needs to ensure that the magnet is strong enough during design to prevent it from loosening or disconnecting due to external interference. Our pogo pin connector guarantees that long-term use will not be affected.

Magnetic strength and matching: Insufficient magnetic strength may result in weak connections and easy disconnection. And if the magnetic force is too strong, it may cause difficulty in insertion and removal, and even damage the device. Therefore, appropriate magnetic balance is necessary to ensure stable connection, high performance, and convenient operation. This can keep your devices’ stability and safety.

Electrical performance: The core of magnetic connector is not only for connection, but also for transmitting electrical signals, power, data, etc. When designing, we often consider the influence of magnetic field on current to ensure that pogo pin connectors can transmit current and signals well. Avoid electrical performance degradation caused by magnetic interference.

Read: 10 pin connector

Anti-interference capability: The magnetic field generated by other electronic devices may affect the stability of the magnetic connector. By using shielding materials or optimizing the arrangement of magnets, this pogo pin connector can effectively resist interference. The other parts of your device are protected from the influence of magnetic force, effectively ensuring the purity and stability of the signal.

Safety: Magnetic connector may sometimes be exposed to high temperatures, heavy rains, or strong electric fields. So, high-quality raw materials can withstand high temperatures and corrosion. This pogo pin connector needs to not experience short circuits or other safety hazards under high load conditions.

Miniaturization and convenience: Nowadays, most customers demand the most exquisite possible design. When using portable devices, customers always emphasize size limitations. Johoty often arranges high-end 5-axis or 6-axis CNC machining when designing magnetic connectors. This ensures that the dimensions meet the customer’s requirements with a tolerance of ± 0.01mm, which is very space saving. Meanwhile, the connection of the magnetic connector is very simple, stable, and convenient, providing good user experience.

Read: 12 pin connector

Compatibility and universality: There are many devices and interface types on the market, and flexible customized magnetic connector isn’t a problem. When designing this pogo pin connector, Johoty considers the compatibility of different devices to ensure that the magnetic connector can adapt to multiple applications. It is usually not limited to various specific devices.

Future Trends and Developments of Magnetic Connectors to Answer What is Magnetic Connector

Stronger suction, more stable connection

Most European and American customers require magnetic connector with stronger magnetic force. Customers often require it to withstand greater tension, maintain a more stable connection, and be less likely to loosen. Johoty is capable of designing magnetic connectors that can operate in even harsher environments, ensuring stable connections in extreme temperatures or humid environments.

Intelligent adaptive connection

High demand engineers require magnetic connector that can automatically detect the type and requirements of equipment, adjust suction and connection methods. During the prototype phase, when engineers insert this pogo pin connector into a device, it automatically adjusts the strength of the connection. It can fully meet the requirements, neither too loose nor too tight, ensuring the best connection.

Read: Multiple pin connector

Wireless power and data transfer

Many company founders require magnetic connector to be used for physical connections, as well as IP67 waterproof for transmitting high voltage and data. A guest of Johoty requested that this water proof magnetic connector be able to be washed repeatedly in the washing machine. It cannot oxidize or peel in laundry detergent yet. Therefore, the connection between devices cannot use traditional plugs and cables, and all signals and electrical energy can be wirelessly transmitted through magnetic connector.

More compact and adaptable to diverse devices

More and more smart engineers are demanding that Johoty design magnetic connector for their increasingly compact devices. Therefore, Johoty’s pogo pin connector will also become smaller and more refined, adapting to a wider range of electronic products. You can definitely see that mobile phones, EMS systems, headphones, smart homes, etc. all use very sophisticated magnetic connector from Johoty.

More environmentally friendly and sustainable

Many EMS systems require Johoty’s magnetic connector to use more eco-friendly materials to reduce the burden on the environment. Of course, many European and American engineers often require ASTM, RoHS, REACH as mandatory requirements. The magnetic connector designed by Johoty can be reused, reducing the generation of electronic waste.

More intelligent error prevention design

Johoty’s magnetic connectors have been designed with error prevention features for many years. Anti reverse insertion can be effectively achieved through the polarity of the magnet, and misplacement can also be achieved through the asymmetry of the rubber core. When you connect a device incorrectly, this pogo pin connector will alert you visually and magnetically through its appearance. Johoty’s magnetic connector can automatically correct the connection and avoid damaging the device due to improper connection.

Expand to more fields

Starting from 2025, many magnetic connectors from Johoty will be used for high-speed visual connections. It is also used for battery charging, as well as in more applications such as medical, automotive, and robotics. In the new type of robot, Johoty’s magnetic connector is used to achieve flexible modular design for easy replacement and maintenance.

Conclusion

Through this article, you can deeply understand working principle, advantages, and applications of magnetic connector. Many clients feedback, it can make your project efficient and stable, saves you time and costs. And, advantages of magnetic connector can’t be underestimated in complex engineering designs. If you are looking for perfect solution, magnetic connector is undoubtedly a worthwhile choice. Because it is to improve your project quality and enhance connection security,

Do you want to improve the reliability and innovation of your project now? It’s time to try now! Choose Johoty magnetic connector to suit your needs. Trust Johoty, we can help you in your next engineering project. You deserve a more efficient, secure, and convenient engineering experience!

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656