Advantages of 3 Pin Waterproof Connector, Pitch 3.00~11.00

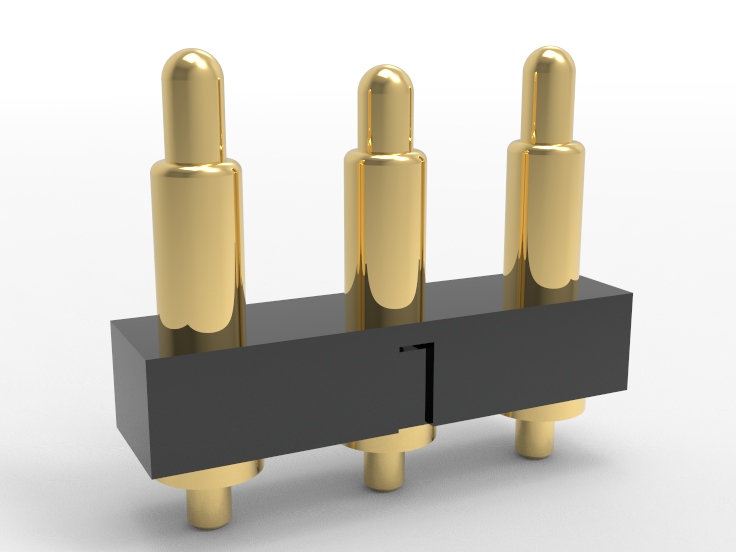

Accurate connection performance

Our 3 pin waterproof connector provides precise contact, it can ensure efficient transfer of data and power while reducing signal interference. Its precise design ensures each plunger contact is uniform, connection is stable and not easy to loosen. Special electroplating process significantly reduces contact resistance and improves current carrying. Support ultra-high frequency transfer and adapt to various complex devices. The plug-in life is >10,000 times, durable and long-lasting.

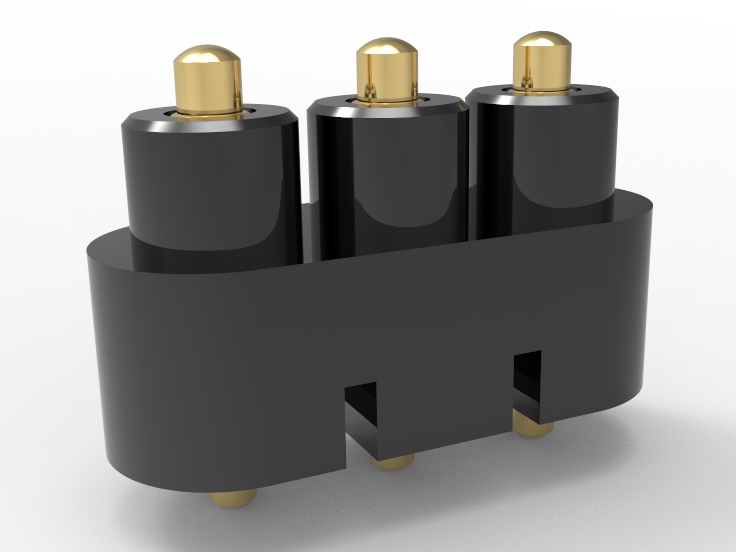

Super waterproof ability

Unique sealing structure endows 3 pin waterproof connector with excellent waterproof performance, fully meeting outdoor or humid. This pogo pin connector uses advanced waterproof materials and design inside to prevent water vapor and affecting performance. The seams of pogo pins are tightly fitted, effectively preventing liquid leakage. They can maintain normal operation in various weather, withstand high humidity, rain, and splashing liquids. After prolonged immersion, our 3 pin connector can also maintain its highly stable electrical performance.

Efficient seismic design

Specially designed for high vibration, 3 pin waterproof connector has super seismic resistance. The high elasticity pogo pins and precision fitting provide excellent seismic resistance, and pogo pins willn’t be interrupted during intense movement. Modular design of this pogo pin connector reduces impact of external forces and maintains stable connections. Our 3 pin connector is suitable for high dynamic load mechanical equipment, automotive, and aviation applications. This can avoid performance loss or wear caused by vibration.

Excellent conductivity performance

Selected high conductivity metal materials, 3 pin waterproof connector significantly improves current transfer efficiency. This pogo pin connector precision process ensures smooth surface of conductive components and low contact resistance to the limit. The spring loaded pins inside can carry high currents and meet high-power devices. Under low voltage, 3 pin connector still maintains good electrical signal transfer. It can reduce energy loss and optimize equipment performance.

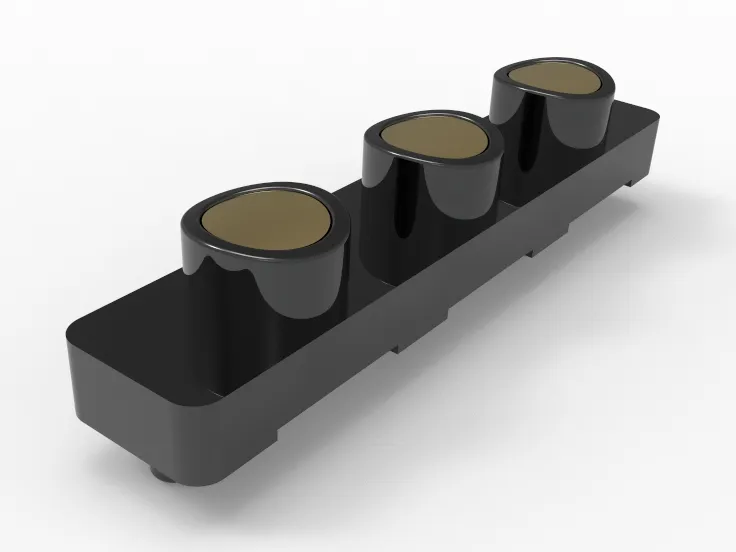

Minimalist and lightweight design

Adopting a compact and lightweight design, 3 pin waterproof connector is small in size but excellent in performance, making it ideal for space saving. A streamlined housing is lightweight without compromising strength and durability. The flexible design of this pogo pin connector is adaptable to multiple devices, making it easy to install and maintain. The elegant appearance design of 3 pin connector balances aesthetics and practicality, making it suitable for modern high-end device. It can optimize internal space utilization and adapt to diverse uses.

High and low temperature resistance

The 3 pin waterproof connector has excellent temperature resistance and can operate stably in extreme environments. Raw materials and design have been optimized to withstand up to 250 ℃ and extreme cold. Johoty’s 3 pin waterproof connector maintains stable performance at high temperatures. At temperatures as low as -55 ℃, there will be no brittle fracture or performance degradation. This pogo pin connector is suitable for industrial and outdoor applications.

High strength durability

Selected high-strength metals and wear-resistant materials ensure durability of 3 pin waterproof connector. Male and female pogo pins have been optimized to reduce wear and extend their lifespan. This pogo pin connector anti impact structure is not easily deformed, no-function, or damaged under various external forces. The surface treatment of pogo pins has excellent corrosion resistance for complex and changing usage. With frequent long-term use, the performance of this 3 pin connector will not decrease.

Flexible customization capability

The 3 pin waterproof connector has extremely high flexibility and can be easily customized according to needs. The number of pins, size, and shape of pogo pin connector can be adjusted to meet specific applications. 3 pin connector has multiple options based on housing color, material, and connection method, suitable for different product designs. Johoty is able to design modularly and support multiple combinations, quickly responding to customer. Our flexible customization helps achieve rapid iteration and upgrading.

FAQ

Can 3 pin waterproof connector work in high vibration?

Johoty often designes it for high vibration applications, and 3 pin waterproof connector remains stable in strong earthquakes. Spring loaded pin can absorb vibration energy and avoid contact point displacement. The overall structure of this pogo pin connector uses shock-absorbing materials to reduce impact force. The internal components of the 3 pin connector are precisely matched to reduce vibration losses. Our 3 pin waterproof connector can be used for high dynamic working conditions in industrial machinery and automobiles.

Does3 pin waterproof connector support fast charging?

Of course, 3 pin waterproof connector supports fast charging, with very high transfer efficiency, suitable for modern device. The pogo pins are designed with low resistance, which can minimize power loss. Pogo pins can also carry high currents, ensuring high-speed charging. The contact point conductivity of this pogo pin connector is superior, ensuring smooth power flow. It can adapt to multiple fast charging protocols and has strong compatibility.

Can3 pin waterproof connector work in high salt environments?

Yes, this pogo pin connector can work reliably in high salt environments and is suitable for marine and coastal equipment. The special coating on 3 pin waterproof connector can keep perfect performance in salt spray. The pogo pin is produced of anti-oxidation metal, which has long-term stability. Sealing prevents salt from entering 3 pin connector interior. It highly fits offshore equipment and ship electronic systems.

Can 3 pin waterproof connector work properly in cold?

At -40℃, 3 pin waterproof connector still has excellent performance. Spring loaded pin can maintain flexibility and don’t fail due to low temperatures. Its housing is resistant to low temperatures and avoids brittle cracking. The structural optimization of this pogo pin connector ensures that thermal expansion and contraction have no impact on performance. Johoty’s 3 pin connector is commonly used for Arctic scientific research and high-altitude equipment.

How does 3 pin waterproof connector transfer data?

3 pin waterproof connector supports simultaneous transfer of data and power, with extremely low signal interference. Our 3 pin connector‘s high-speed data transfer interface can meet modern communication needs. Shielding design of this pogo pin connector can reduce external EMI. Design optimization of spring loaded pin to ensure signal integrity. It is applied to communication equipment and industrial automation.

Does 3 pin waterproof connector support miniaturization design?

Of course, Johoty provides miniaturized versions according to demand to meet space limitations. The 3 pin waterproof connector’s housing and internal accessories are very compact and smaller in size. Spring loaded pin maintains stable performance while reducing size. The optimized structure of this pogo pin connector maximizes the utilization of installation space. It is suitable for smart wearable devices and precision electronic products.

How deep can 3 pin waterproof connector work underwater?

Our 3 pin waterproof connector can work continuously at 5M underwater and has stable performance. Its special sealing effectively prevents influence of water pressure and ensures reliable connection. This pogo pin connector uses high-quality waterproof materials to prevent liquid penetration. Multiple protective structures ensure long-term use in deep water. The 3 pin connector is suitable for various underwater diving lights and robots.

How many times can 3 pin waterproof connector withstand contact?

The 3 pin waterproof connector can withstand up to 300,000 operations while maintaining consistent performance. The built-in spring uses high elasticity metal to ensure spring loaded pin doesn’t break during long-term use. The contact surface of the pogo pin has undergone special finishing to reduce friction loss. Structural optimization ensures pogo pin connector remains stable under high-frequency connections. Our 3 pin waterproof connector is suitable for medical instruments, smart devices, and portable electronics.