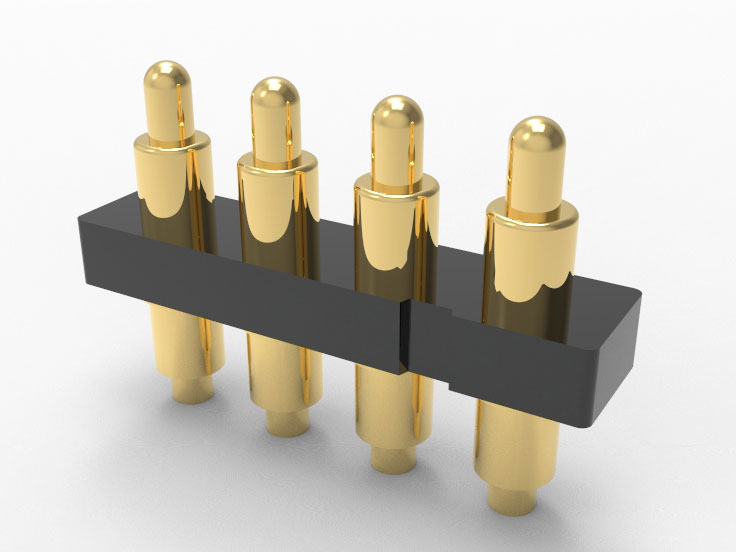

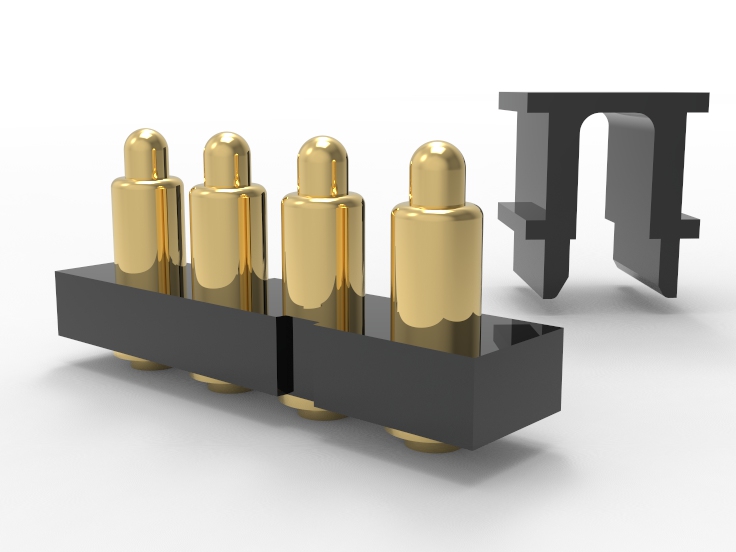

Advantages of 4 pin pogo connector, pitch: 1.27~1.99

High reliability and stability

Johoty’s 4 pin pogo connector has high reliability and stability, it can work properly in complex environments. Johoty commonly uses high-quality brass plated with gold, which has strong corrosion resistance to fit humidity and high temperatures. Connection part of this 4 pin connector is precision, which can avoid poor contact, stabilize current transfer, and reduce electrical faults. Its spring loaded pin has a stable internal structure, effectively preventing vibration impact. Strict CNC machining, manufacturing, CCD detection ensures the consistency of each pogo pin connector, avoiding malfunctions caused by quality issues.

High density design saves space

4 pin pogo connector features a high-density design, greatly saving space for your products. The fine miniaturized structure allows device to be more compact. The 4pin layout ensures functionality is not reduced while maintaining diversity. 4 pin connector offers flexibility for both single and double row layouts, catering to various design needs. High density design improves signal efficiency and reduces circuit boards’s footprint. Compact structure of pogo pin connector makes installation very convenient and suitable for miniaturized devices.

Precise signal transfer

This 4 pin pogo connector transmits high-precision signals and stably transmits high-speed data. The metal pogo pin is precision, which can reduce signal loss. The contact surface of pogo pin connector has been specially treated to improve conductivity. The good contact force of pogo pins ensures signal stability and reduces disconnection. This spring loaded pin has low contact resistance to avoid signal interference. It is specially designed with 200,000 cycles and durability to improve transfer quality during long-term use.

Strong anti vibration ability

The 4 pin pogo connector can operate stably in high vibration and has strong spring force. The fine mechanical design of spring loaded pin can withstand strong vibrations. Built in spring can provide stable contact force. The elastic components in this pogo pin connector can reduce the circuit vibration impact. Our 4 pin connector’s housing is sturdy and can effectively prevent external physical impacts. This pogo pin connector undergoes vibration testing to ensure stability in various devices, it is suitable for use in high-end electronic devices.

Strong adaptability and wide application

This 4 pin pogo connector has strong adaptability and can use in various electronic devices. This pogo pin connector can adapt to different interface and has high flexibility. It is suitable for consumer electronics, medical equipment, industrial automation, etc. This 4 pin connector can withstand high temperatures, dust, moisture, etc. Johoty’s pogo pin connector can be customized according to customer needs to meet special applications. Its compatibility makes it the preferred connection solution for high-end devices.

Efficient power management

Johoty’s 4 pin pogo connector performs well in power management, ensuring device’s stable power supply. We use high conductivity brass or stainless steel plated with gold to ensure efficient current transfer. This pogo pin connector can reduce power loss and extend device lifespan based on design optimizaion. Good electrical contact can effectively reduce current fluctuations. Our 4 pin connector can support high current transfer, meeting device’s high power requirements. Its stable power management makes device operation safer and more reliable.

Quick insertion and easy operation

This 4 pin pogo connector features fast insertion and removal, making it more convenient to operate. Its unique design makes plug-in connections very smooth. Too much force isn’t needed, which can minimize human operation. Elastic design can enhance the durability of this pogo pin connector and avoid damage. Quick plugging and unplugging can improve device efficiency that require frequent disassembly. The unique positioning design of this 4 pin connector avoids insertion errors, greatly improving operation accuracy.

Long service life

The 4 pin pogo connector has long lifespan, and Johoty can specially design it to achieve 200,000 lifespan, it is suitable for long-term applications. Using high-quality brass gold-plated pogo pins, it has strong wear resistance. The internal spring of this pogo pin connector is made of durable piano steel stainless steel to prevent fatigue damage. Johoty has undergone precision manufacturing, which greatly extend this 4 pin connector lifespan, prevent plunger oxidation, and improve durability. After long-term verification, this pogo pin can maintain excellent performance for high-end devices with high requirements.

FAQ

What are features of 4 pin pogo connector?

The 4 pin pogo connector has a small size and 4 contact points, making it suitable for limited space. This 4 pin connector ensures high-density connections while maintaining reliable signals. Its contact pressure is relatively light, and it can still provide stable connection after long-term use. This pogo pin connector has a simple internal structure, ensuring easy installation in mobile phones, headphones, portable devices, etc.

What is difference between 4 pin pogo connector and traditional plug connector?

4 pin pogo connectors often adopt a spring design, which can easily adapt to uneven surfaces and enhance stability. Traditional plug connectors are sturdy, but lack adaptability. This 4 pin connector can plug in and out frequently, while traditional connectors are more durable but difficult to connection frequently. This pogo pin connector has small size and occupies less space. Their contact methods are different. The 4 pin connector is crimped by a spring, while traditional connectors rely more on metal slots.

How to reduce poor contact of 4 pin pogo connector?

Ensure 4 pin connector is clean and dust-free to avoid dust or debris affecting contact effect. Avoid excessive force to prevent spring inside. Regularly check contact points of this 4 pin pogo connector to ensure there is no corrosion or wear. When used in humid, it is best to choose moisture resistant design of Johoty’s 4 pin pogo connector. Keeping contact surface between it and the circuit board slot can help reduce poor contact.

What is difference between single row and double row?

Single row 4 pin pogo connector has only one column of pogo pins, while double row 4 pin pogo connector has two columns of pogo pins. It can provides more connection functions. The single row pogo pin connector is suitable for limited space but low connection requirements. The dual row pogo pin connector fits high number of connections. The installation of a dual row 4 pin connector is relatively complex, but its connection is more stable. The single row 4 pin connector has a small volume and is suitable for simple devices.

What are applications of 4 pin pogo connector?

4 pin design is used for simple electrical connections minimal signal transfer. including wireless headphone charging, sensors, etc. This 4 pin connector can achieve power and data transfer through different combinations. The biggest advantage of 4 pin design is its simplicity and ease of use, convenient installation. It has suitability for small space occupation and low connection requirements.

How to determine 4 pin pogo connector quality?

High-quality 4 pin pogo connector are made of smooth metal material, which is not easy to rust and does not loosen, maintaining stability. The spring design of this 4 pin connector should be uniform to ensure appropriate contact pressure. Its housing is very sturdy, protecting built-in components from damage. This pogo pin connector should continue to provide stable connections without poor contact after long-term use.

What is lifespan of 4 pin pogo connector?

Lifespan of pogo pin connector is mainly affected by contact number. A well-designed pogo pin connector can support over 10,000 insertions. The lifespan of this 4 pin pogo connector is related to working environment, and if environment is too harsh, its service life may be shortened. The correct usage can extend the lifespan of this 4 pin pogo connector. After long-term use, this pogo pin connector may experience poor contact and needs to be replaced timely.

How to choose 4 pin pogo connector?

When choosing a 4 pin pogo connector, it’s better to refer to device’s space size, insertion and removal frequency, and electrical requirements. For small devices, Johoty can provide a miniaturized 4 pin pogo connector. For high-frequency contact, durable and stable contact types should be selected. Choose single row or double row according to expected contact points. Considering the carrying capacity of the 4 pin pogo connector, Johoty can support you right current and voltage.