Working Height: Explore How it Shapes Pogo Pin Design and Performance. Key Considerations and Essential Insights for Engineers and Designers

Introduction

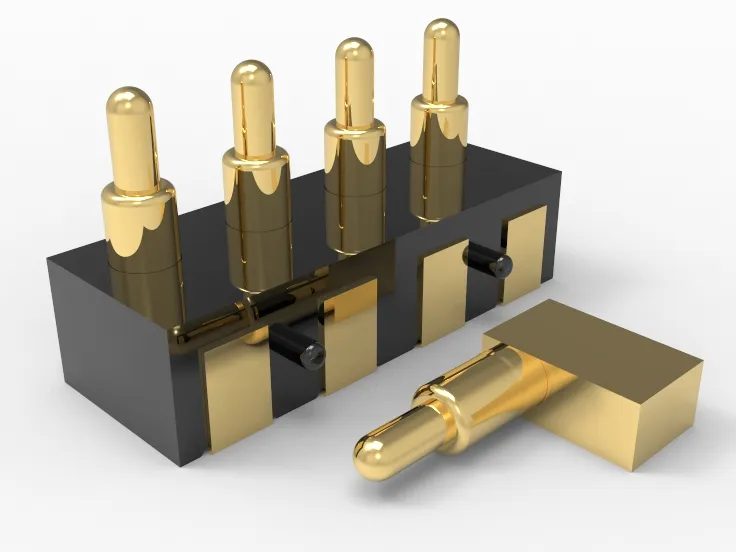

Pogo pins are crucial in electronic connections. They are used widely in various electronic devices and testing systems to ensure reliable electrical connections. Their unique design allows for flexible and stable contact between connectors, making them vital in the electronics industry.

One key factor is the pogo pin’s working height. This height directly affects the reliability and stability of its contact, and determines its suitability for different applications. Therefore, understanding and designing the appropriate working height is essential for optimal pogo pin performance.

This article will explore how the working height impacts pogo pin performance and why it’s a critical design element.

1. What Are Pogo Pins?

Pogo pins are specialized connectors used for electronic connections. They consist of a pin, spring, and barrel, providing stable electrical contact through the compression and recovery of the spring.

Design Features:

- Spring Design: Made with top-notch materials for long-lasting strength and reliability. The spring’s pressure and rebound affect the pin’s contact reliability.

- Plunger Tip Shape: Available in different shapes—pointed, rounded, and flat—to fit various contact surfaces for optimal electrical connections.

- Barrel Material: Made from high-strength metals like brass or stainless steel, often plated to enhance conductivity and wear resistance.

- Size and Spacing: Precisely designed to meet different application needs, with pin diameters ranging from 0.3mm to 1.5mm and customizable spacing.

- Working Height: The length of the pin when compressed, affecting its performance and lifespan. Proper working height ensures stable operation in various environments.

2. Working Height: Definition and Importance

2.1 The Working Height of a pogo pin is the length it compresses when in use.

It shows the range from the pin fully extended to fully compressed, ensuring effective contact and current flow during connections.

2.1.1 Definition:

- Working Height: The distance the Pogo pin compresses from its fully extended to fully compressed state, measured in millimeters.

2.1.2 Importance:

- Contact Stability: Ensures stable contact pressure for reliable electrical connections.

- Mechanical Lifespan: Prevents fatigue and wear by avoiding excessive or insufficient compression.

- Electrical Performance: Influences the ease of electrical flow and connection quality, vital for getting the best results in different settings.

2.1.3 Measurement:

- Free Height: Length of the pin in its uncompressed state.

- Full Compression Height: Length when fully compressed.

- Working Height: An intermediate length ensuring good contact, usually with some compression margin to avoid over-compression.

2.1.4 Applications:

- Electronics: Used in devices like smartphones and tablets for battery, power, and signal connections.

- Test Equipment: Ensures proper contact in PCB testing fixtures.

- Medical Devices: Connects sensors and transmits signals with precision.

2.1.5 Selection Criteria:

- Choose working height based on reliability and lifespan needs.

- Consider environmental factors like temperature and vibration.

- Ensure compatibility with other components.

Understanding and selecting the right working height for Pogo pins can greatly enhance connection performance and reliability across various applications.

2.2 Why Working Height Matters?

- Contact Stability: The working height of Pogo pins affects how stable the electrical contact is. If the height isn’t right, pins may not make good contact during insertion and removal, leading to potential signal loss or connection issues. Proper working height ensures reliable contact with boards or components.

- Lifespan and Durability: The right working height extends the pin’s lifespan. Too high or too low a height can cause uneven wear over time. Correct height ensures proper spring compression and extension, enhancing durability.

- Electrical Performance: Working height impacts electrical performance by affecting contact resistance and conductivity. Proper working height makes sure connections are firm, lowering resistance and enhancing performance. Incorrect height can lead to unstable electrical performance or poor current flow.

- Insertion and Removal Force: Working height also influences how easy it is to insert or remove the pins. If the height is off, it can make the process too difficult or too easy, affecting usability. Correct height ensures moderate force, making operation smoother.

- Design Compatibility: Working height must align with other components and structures, like PCB thickness and enclosure design. Proper height ensures pins fit well after assembly, avoiding compatibility issues.

In summary, working height is crucial for the functionality, reliability, and durability of Pogo pins. Setting the correct working height ensures excellent functionality in real-world scenarios.

3. The Impact of Working Height on Pogo Pin Performance

Pogo pins are widely used in electronics, particularly where detachable connections are needed. Working height, or the vertical distance when the pin contacts the surface, significantly affects performance. Here’s a simplified overview:

3.1 Definition

- Working height is the distance between the Pogo pin and the contact surface. It affects contact pressure and stability.

3.2 Effects on Performance

- Contact Pressure: Higher working height may reduce contact pressure, causing poor connection or unstable signals. Too low a height may over-compress the pin, affecting its lifespan.

- Electrical Performance: Proper height ensures stable electrical connections. Too much height can increase contact resistance, while the right height maintains low resistance and reliable signals.

- Durability: High working heights cause more wear with each connection, shortening lifespan. Optimal height balances elasticity and durability.

- Mechanical Stability: Incorrect height can cause movement during insertion/removal, affecting connection reliability. Correct height ensures stability.

3.3 Industry Practices

- Manual Application: Tools and gauges ensure accurate working height during manual installation.

- Automation: Automated systems like laser measurements ensure consistent working height in large-scale production.

3.4 Extreme Conditions

- Temperature & Vibration: Use heat-resistant materials and robust designs to maintain performance under extreme conditions.

4. Considerations for Designing Pogo Pins

4.1 Design Requirements Choose working height based on application needs to ensure reliable electrical connections.

4.2 Influencing Factors

- Contact Pressure: Higher height might need stronger springs, affecting stability.

- Assembly Tolerance: Precise height control is essential to avoid poor connections.

- Temperature Variations: Design should account for thermal expansion or contraction.

- Vibration and Impact: Ensure stable contact under these conditions.

4.3 Industry Standards Adhere to specific standards for fields like medical or high-precision electronics.

4.4 Material and Structure The choice of materials and design affects working height. Select suitable materials and design for stability.

4.5 Testing and Verification Conduct thorough tests to ensure working height meets design specifications.

4.6 Production and Assembly Maintain strict control over working height during production and assembly to ensure reliability and consistency.

5. Designing Pogo Pins: Ensuring Optimal Working Height

5.1 Measuring Working Height

5.1.1 Tools:

- Digital Caliper: Provides precise height measurements.

- Micrometer: For extremely accurate measurements, especially at the micron level.

- Height Gauge: Offers fast, automated measurements.

5.1.2 Steps:

- Setup: Mount the Pogo Pin securely on a test fixture.

- Calibration: Zero the measurement tool for accuracy.

- Measurement: Measure the vertical distance from the base to the contact point, considering initial pin

- state and spring compression.

- Data Recording: Document multiple samples for analysis.

5.2 Testing Working Height

5.2.1 Equipment:

- Height Gauge: Measures vertical height to ensure design compliance.

- Pressure Tester: Checks spring force and contact pressure, indirectly validating height.

- Environmental Chamber: Simulates various conditions (temperature, humidity) to assess height stability.

5.2.2 Steps:

- Initial Check: Inspect for physical damage or deformation.

- Environmental Testing: Assess height stability under different conditions.

- Pressure Testing: Measure height variations under different pressures.

- Reproducibility: Perform multiple tests to ensure consistent results.

5.3 Controlling and Adjusting Working Height

5.3.1 Adjustment Methods:

- Spring Tension: Adjust the spring preload to change working height.

- Base Adjustment: Fine-tune the base to ensure good contact with the mating component.

5.3.2 Control Strategies:

- Production Control: Regularly check and adjust height during manufacturing.

- Quality Control: Implement strict standards and testing processes.

5.4 Common Issues and Solutions

5.4.1 Height Deviations:

- Cause: Spring deformation or material changes during production.

- Solution: Improve quality control and use stable materials and springs.

5.4.2 Environmental Impact:

- Cause: Temperature and humidity affect spring performance.

- Solution: Consider environmental factors in design and testing to ensure stable height.

5.5 Data Analysis and Improvement

- Statistical Analysis: Analyze data to identify issues and trends.

- Feedback Loop: Change your design and manufacturing processes based on results to keep improving.

These methods ensure that Pogo Pins meet design requirements and maintain reliability and performance in actual use.

6. Case Study on Working Height

6.1 Key Design Points:

- Spring Design: The spring’s material and design are crucial for Pogo Pin performance. Proper springs offer the right pressure for good contact without excessive wear or instability. You’ll find stainless steel and nickel-titanium alloys everywhere due to their great stretchiness and ability to resist corrosion.

- Pin Material: Pins need good conductivity and wear resistance. Typically, gold- or nickel-plated copper alloys are used to enhance conductivity and prevent oxidation.

- Size and Spacing: The dimensions and spacing of Pogo Pins should be tailored to the application. Accurate sizing ensures a proper fit with contact surfaces and meets mechanical and electrical connection needs.

- Thermal Management: Effective thermal management is essential in high-power applications. Consider the thermal expansion of pins and springs to avoid connection issues due to temperature changes.

- Manufacturing Process: Precise manufacturing ensures consistency and reliability of Pogo Pins. High-quality processes reduce defects and enhance product lifespan and performance.

6.2 Design Lessons:

- Poor Contact: Ensure contact surfaces are smooth and clean to avoid poor connections. Use precise equipment and regular maintenance to address this.

- Spring Fatigue: Springs may weaken over time, affecting stability. Use high-quality materials and design for durability to mitigate this.

- Oxidation and Corrosion: Pogo pins can fail to connect properly if they get oxidized or corroded. Employ corrosion-resistant materials and surface treatments to prevent this.

- Size Tolerance: For high-precision applications, size tolerance can impact connection quality. Control manufacturing and inspection standards strictly.

- Thermal Expansion: Material expansion at high temperatures can cause connection failure. Consider the thermal expansion coefficient in design and perform thermal tests.

Conclusion:

Precise working height in Pogo Pin design is crucial for connection stability and device performance. Strict control and comprehensive testing are needed to ensure optimal fit with connections. Prioritize accurate design and testing. For professional support and advice, contact us anytime.