Advanced Equipment at Johoty Ensures High-precision Pogo Pin | Connector at the Best Price, Delivering Top Quality with Cutting-edge Technology

Introduction

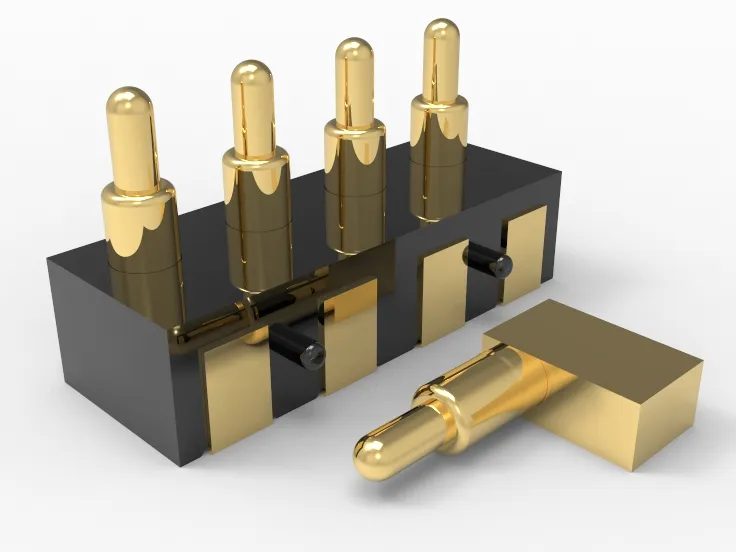

In modern electronics, Pogo Pins and Pogo Pin Connectors are crucial components that play an essential role. At Johoty, we use state-of-the-art machinery and the latest tech to make top-notch Pogo Pins and Pogo Pin Connector with pinpoint accuracy. Our production facilities feature industry-leading technology, including automated precision machinery, fully CNC laser cutting systems, and high-efficiency testing equipment, all working together to ensure exceptional product quality.

- Our automated precision machinery operates at a micrometer level, guaranteeing that every detail of the Pogo Pins meets perfection. The fully CNC laser cutting system provides extremely high cutting accuracy, ensuring that each Pogo Pin Connector’s contact points align perfectly. Our high-efficiency testing equipment rigorously tests every product before it leaves the factory, ensuring its reliability and stability in real-world applications.

- Johoty’s production line focuses not only on modernizing technology but also on innovating materials and manufacturing processes. We strive to offer the best products at the most competitive prices, thanks to our ongoing investments in advanced equipment and process optimization. Whether it’s stability under high pressure or precision in high-frequency signal transmission, our products meet customer needs flawlessly.

Choosing Johoty means selecting not only high-precision Pogo Pins and Pogo Pin Connectors but also the industry’s leading technology and the highest quality product experience.

Johoty’s Technical Background

- Johoty produces high-precision, cost-effective Pogo Pins and Pogo Pin Connectors using the latest advanced equipment. Our strong technical background includes state-of-the-art equipment such as ultra-high-precision CNC machining centers, laser welding systems, and automated assembly lines. These technologies ensure both product accuracy and production efficiency.

- Notably, Johoty’s advanced equipment can perform nanometer-level precision machining, achieving the highest international standards in size and performance for each Pogo Pin and Pogo Pin Connector. Additionally, we use advanced quality control techniques, including real-time monitoring and automatic testing systems, to ensure every batch meets strict quality standards.

- In the Pogo Pins industry, Johoty has set a benchmark with its exceptional technical capabilities and innovative approach. We continuously innovate in technology and offer personalized customization based on customer needs, providing solutions that best meet market demands. Johoty’s Pogo Pins and Pogo Pin Connectors are widely used in electronic devices, communication equipment, and medical devices, earning praise from customers both domestically and internationally.

Detailed Analysis of Advanced Equipment

1. Types of Advanced Equipment

Automated Production Line

- Function: This is Johoty’s main advanced equipment for boosting production efficiency and precision. It includes robotic arms, conveyor belts, and automatic feeding systems.

- Benefits: The automated production line reduces manual errors, speeds up production, and ensures the precision and quality of every Pogo Pin and connector.

High-Precision CNC Machine Tools

- Function: CNC machines cut, mill, and drill the metal parts of Pogo Pins, making sure each piece meets strict size and shape tolerances.

- Benefits: High-precision CNC machines allow for complex shapes and accurate machining, ensuring product stability and reliability.

Laser Welding Equipment

- Function: Laser welding devices precisely join different parts of Pogo Pins using high-energy laser beams for seamless welding.

- Benefits: Laser welding offers strong connections, minimizes heat impact, and maintains the material’s original properties.

Optical Inspection Systems

- Function: Optical inspection systems check the appearance, size accuracy, and surface defects of Pogo Pins and connectors.

- Benefits: Optical inspections provide fast, non-contact quality checks to ensure every product meets design standards.

Environmental Simulation Testing Equipment

- Function: This advanced equipment tests the performance of Pogo Pins under extreme conditions like high/low temperatures, humidity, and vibration.

- Benefits: Environmental testing ensures the product’s reliability and durability in real-world use, meeting high-quality standards.

2. Overall Advantages:

- High Precision: Advanced equipment ensures that every detail of the product meets design specifications, enhancing consistency and performance.

- Increased Efficiency: Automated production lines and efficient machining significantly boost production rates and shorten cycles.

- Quality Control: Precise inspection and testing of advanced equipment quickly identifies potential quality issues, maintaining high standards.

- Innovation: Utilizing the latest technology and advanced equipment helps Johoty stay competitive, drive innovation, and develop products.

With these advanced tools and technologies, Johoty produces Pogo Pins and Pogo Pin Connectors that meet the highest quality standards, ensuring excellent performance across various applications.

3. Technical Details:

Automated Precision Stamping Machine

- Function: Produces high-precision metal contact points with high automation and accuracy even at high speeds.

- Technical Details: Uses servo motors and a closed-loop feedback system for precise stamping depth and positioning. It features advanced molds and punches to handle various Pogo Pin specifications.

High-Precision CNC Lathe

- Function: Shapes and details Pogo Pins, including precise pin grinding and cutting.

- Technical Details: Equipped with high-resolution CNC controls and real-time monitoring for micron-level machining. Made from high-rigidity materials to minimize vibration and errors during processing.

Vacuum Coating Advanced Equipment

- Function: Coats Pogo Pins and connectors with a conductive film to improve corrosion resistance and electrical conductivity.

- Technical Details: Utilizes Physical Vapor Deposition (PVD) technology in a high-vacuum environment for even coating and strong adhesion. It controls film thickness and composition to meet various application needs.

High-Precision Measurement Instruments

- Function: Measures the dimensions and tolerances of produced Pogo Pins and connectors.

- Technical Details: Includes laser distance meters, coordinate measuring machines, and optical microscopes. These instruments offer high resolution and repeatability, detecting minute size variations.

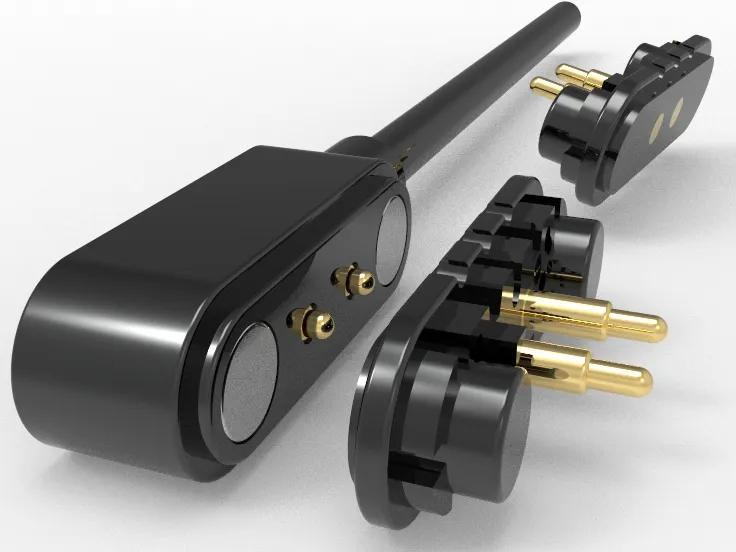

Automated Assembly Line

- Function: Automates the assembly of Pogo Pins and connector components to boost efficiency and consistency.

- Technical Details: Uses robotic arms and automatic feeding systems for efficient insertion, welding, and inspection. The line includes fault detection and self-repair features for high reliability.

Environmental Control System

- Function: Keep the production environment in check with the proper temperature, humidity, and cleanliness standards.

- Technical Details: Features air filtration systems, temperature and humidity control units, and cleanroom controls. It monitors and adjusts the environment in real-time to prevent quality issues from external factors.

Product Quality Assurance from Advanced Equipment

Quality Control Process:

- Material Testing Equipment: Johoty uses advanced equipment to rigorously test all incoming materials. These tools analyze the composition, strength, and durability of materials to ensure the final products are reliable and stable.

- Raw Material Inspection: We thoroughly check all incoming raw materials to make sure they meet our standards before they hit the production line.

- Process Monitoring: During production, Johoty employs real-time monitoring systems to track various advanced equipment status and production parameters, promptly identifying and correcting potential issues.

- Finished Product Inspection: Every batch of Pogo Pins and Pogo Pin Connectors undergoes comprehensive functionality and performance tests to verify they meet design requirements.

- Quality Traceability: Johoty has a full system for tracking and tracing quality throughout our processes. Each product can be traced back to its specific production process and raw material sources, ensuring transparency and traceability of product quality.

- Automated Assembly Lines: Johoty uses highly automated assembly lines to ensure precision and consistency in assembling each Pogo Pin and Pogo Pin Connector. These lines are equipped with high-precision sensors and automatic calibration systems that monitor and adjust small errors in the production process.

- High-Precision CNC Machines: Advanced CNC machines are used, capable of extremely precise cutting and processing to ensure each product meets strict size and shape standards.

- Optical Inspection Systems: Johoty employs advanced optical inspection systems for thorough visual checks of each product. These systems automatically detect surface defects and non-conforming details, ensuring each product meets the highest quality standards.

- Environmental Control Systems: Johoty keeps production conditions just right with exact temperature and humidity controls, so environmental factors don’t affect our product quality.

Technological Innovation:

- High-Precision CNC Machines: Johoty’s production line features the latest CNC machines with nano-level precision, ensuring each Pogo Pin’s accuracy and consistency.

- Automated Production Systems: The company uses fully automated systems for every production step, from raw material handling to final assembly, boosting efficiency and reducing human error.

- Laser Marking Technology: Johoty uses laser marking equipment for high-precision labeling on Pogo Pins and connectors, providing clear, durable markings without affecting product quality.

- Advanced Testing Equipment: Johoty employs various high-precision testing devices, including electron microscopes, laser rangefinders, and optical scanners, for detailed inspection of minor defects, ensuring each component meets the highest standards.

- Environmental Control Systems: The production facility is equipped with advanced environmental control systems, including temperature and humidity regulation and air filtration, to maintain a stable environment and reduce external impacts on product quality.

- Real-Time Data Monitoring Systems: Johoty uses real-time data monitoring to track and adjust production parameters, quickly identifying potential issues to ensure consistency and high quality of products.

Cost Advantages Of Advanced Equipment

Johoty leverages a range of cutting-edge production and testing equipment to offer customers high-precision Pogo Pins and Pogo Pin Connectors at the most competitive prices:

- Automated Production Lines: Johoty uses fully automated production lines that ensure each production step is efficient and stable. These lines are powered by high-precision robots and computer control systems, reducing the need for manual intervention. This lowers production costs and enhances product consistency.

- Precision Machining Equipment: To achieve high precision in Pogo Pins and Pogo Pin Connectors, Johoty employs advanced CNC machines that work at the micron level. This ensures that every part meets strict size and tolerance standards.

- Efficient Material Testing Instruments: Johoty uses efficient material testing instruments to rigorously check raw materials, ensuring they meet production requirements. This testing helps catch material problems early, cut down on waste, and keep production costs lower.

- Advanced Quality Inspection Systems: Every stage of production is equipped with high-precision quality inspection systems, including automated visual inspections and measurement devices. These systems monitor production in real-time, quickly identifying and correcting issues, which boosts efficiency and product quality.

- Smart Production Management Systems: Johoty employs advanced production management systems that track production data in real-time and optimize processes. These systems analyze production data to predict and adjust workload, helping the company reduce operating costs while maintaining product quality.

By using these advanced devices and technologies, Johoty has not only increased production efficiency but also effectively reduced costs, ensuring that its products remain competitively priced while maintaining high quality.

Customer Reviews and Case Studies

1. High-Precision Production Line Application:

Background:

- Johoty has invested in the latest automated production lines, including high-precision CNC machines, laser cutting equipment, and robotic assembly systems. These tools achieve micron-level precision, ensuring that every part of the Pogo Pins meets strict quality standards.

Technical Highlights:

- CNC Machines: Use high-precision control to cut and process Pogo Pins parts, greatly improving production accuracy and efficiency.

- Laser Cutting Equipment: Provides extremely precise cuts for small dimensions, ensuring uniform pin consistency in every Pogo Pin.

- Robotic Assembly Systems: Reduces human error through automation, enhancing consistency and reliability in production

Customer Feedback:

- “Johoty’s high-precision production line gives us consistent, high-quality Pogo Pins that significantly boost our product performance and market competitiveness.” — Operations Manager at a leading electronics manufacturer

2. Advanced Testing Technology Application

Background:

- To ensure product quality, Johoty has introduced advanced testing equipment, including 3D scanners, automated visual inspection systems, and electronic testers. These devices enforce strict quality control at every production stage.

Technical Highlights:

- 3D Scanners: Quickly capture 3D data of Pogo Pins for comprehensive checks on size and shape, ensuring compliance with design standards.

Automated Visual Inspection Systems: Use high-resolution cameras and smart algorithms to detect surface defects, eliminating subpar products.

Electronic Testers: Check the electrical performance of every Pogo Pin to make sure they work reliably and stably in real-world use.

Customer Feedback:

- “Johoty’s advanced testing technology gives us confidence in the quality of every batch, significantly reducing rework and after-sales issues.” — Quality Director at a high-tech company

3. Innovative Production Process Optimization

Background:

- Johoty has implemented various production process optimizations, including lean manufacturing and smart scheduling systems. These strategies have enhanced production efficiency and reduced costs.

Technical Highlights:

- Lean Manufacturing: Optimizes processes, reduces waste, and improves resource use, leading to lower production costs.

Smart Scheduling Systems: Use advanced data analysis and forecasting to optimize production schedules, minimizing downtime and bottlenecks.

Customer Feedback:

- “Johoty’s process optimization cut our procurement costs by 20% while ensuring product quality.” — Procurement Head at a major electronics supplier

Johoty’s advanced production and testing equipment has achieved high precision and cost-effectiveness in Pogo Pin production. The case studies show that Johoty not only enhances product quality but also lowers production costs through innovative technologies, providing highly competitive solutions. Johoty will continue to focus on technological innovation and quality improvement, delivering superior products and services to customers.

Conclusion

- Johoty, with its state-of-the-art equipment, is committed to producing the most cost-effective and high-precision Pogo Pins and Pogo Pin Connector. Our production lines are equipped with leading technologies, including high-precision automated assembly systems, precise laser measurement tools, and advanced material handling facilities.

- These devices ensure product consistency and high standards, significantly boosting production efficiency and maintaining top industry levels. By continuously adapting and updating cutting-edge technologies, Johoty remains at the forefront of the industry, dedicated to providing the best solutions and services to our customers.