Automatic Production by Johoty: Significantly Cut Pogo Pin Costs for Giving You Competitive Prices to Meet Project’s Rigorous Budget Demands

Introduction:

In today’s fast-evolving tech world, controlling costs accurately is crucial for project success. Engineers and procurement managers face the challenge of managing project budgets effectively. Johoty’s automatic production focuses on significantly reducing the manufacturing costs of Pogo Pins through innovative processes.

This blog will explore how Johoty uses advanced automation technology to cut production costs while maintaining high quality.

We’ll delve into how our production process combines cutting-edge technology and meticulous management to deliver high-quality, cost-effective Pogo Pin solutions. Our mission is to provide you with great prices, making it easier to complete your project within your budget.

Advantages of Automatic Production Technology

1. Efficient Production Process:

Behind the technology, Johoty’s Pogo Pin manufacturing is a marvel of modern manufacturing. Our automatic production line is both fast and precise, with micron-level accuracy to ensure every Pogo Pin meets exceptional quality standards. Key aspects of the production process include:

- High-Precision Material Handling: We use the latest laser cutting technology to precisely shape raw materials, ensuring every component meets strict specifications.

- Smart Automated Assembly: Advanced robotic arms and vision systems automatically assemble Pogo Pins. This step features a precision control system that accurately positions and connects each component, minimizing human error.

- Real-Time Quality Monitoring: During production, high-resolution cameras and sensors are used for real-time quality checks. Any tiny defects are immediately detected, and the system automatically adjusts production parameters to ensure each product meets the standards.

- Automated Testing: Each production batch undergoes rigorous automated electrical testing to ensure the stability and reliability of the Pogo Pins. Test data is recorded and analyzed in real-time to ensure continuous improvement in product quality.

- Precise Packaging and Shipping: An automated packaging system ensures that inspected Pogo Pins are packed accurately to prevent damage during transport. Additionally, the system automatically generates shipping reports and performs barcode scans for efficient logistics management.

2. Precision Control and Consistency:

Johoty is at the forefront of automatic production technology, demonstrating exceptional precision and consistency in Pogo Pin manufacturing. With advanced automated equipment, Johoty achieves the following key features:

- Precision Machining: Johoty’s automatic production system is equipped with high-precision robotic arms and laser positioning technology, ensuring that each Pogo Pin maintains perfect size and shape during production. This precision machining keeps batch tolerances to a minimum, greatly enhancing reliability and consistency.

- Smart Inspection: Johoty uses intelligent vision inspection systems to monitor the quality of each Pogo Pin in real-time. This system quickly identifies any tiny defects and automatically adjusts or rejects non-compliant Pogo Pins, ensuring every Pogo Pin meets strict quality standards.

- Automatic Calibration: Johoty’s automatic production line features automatic calibration, allowing real-time adjustments based on actual production conditions. This adaptability ensures stable performance in both speed and precision, improving overall production efficiency.

- Consistency Assurance: Johoty ensures that every batch of Pogo Pins has consistent performance and appearance through a fully automatic production process. This consistency enhances user experience and reduces the rate of rework and customer complaints due to variations in Pogo Pins.

- Data Tracking and Analysis: Johoty’s production system integrates advanced data tracking and analysis tools, allowing real-time recording and analysis of production data. This data helps engineers identify potential issues and make improvements, further enhancing production accuracy and consistency.

3. Long-Term Cost Savings:

- Smart Automatic production: Johoty’s automatic production system uses advanced smart technology to enable a fully automated manufacturing process. By reducing manual intervention, automatic production increases efficiency and minimizes human error, thereby lowering production costs.

- Precise Production Control: With high-precision sensors and control systems, Johoty’s production technology monitors various parameters in real-time. This precise control ensures consistency and high quality of Pogo Pins, reduces defect rates, and lowers overall production costs.

- Optimized Production Layout: Johoty’s production line layout is carefully designed to minimize waste and downtime. The optimized layout improves equipment utilization, ensuring that every machine operates efficiently, which reduces unit production costs.

- Efficient Resource Management: Johoty’s technology also includes an intelligent resource management system that effectively allocates and uses raw materials and energy. By making the most of resources, we save on materials and cut down on energy use, which saves money in Pogo Pin production.

- Data-Driven Production Decisions: By leveraging big data analytics, Johoty deeply analyzes the production process to identify and eliminate potential bottlenecks and inefficiencies. This data-driven approach makes the production process more efficient, further lowering unit costs.

- Continuous Improvement and Innovation: Johoty is all about keeping its production technology fresh and cutting-edge through continuous innovation. By regularly updating and optimizing equipment and processes, Johoty maintains competitiveness and continuously boosts production efficiency, ensuring long-term cost-effectiveness.

Johoty’s automatic production technology—through smart automation, precise control, optimized layout, efficient resource management, data-driven decisions, and continuous innovation—significantly reduces the unit cost of Pogo Pins and enhances production economics. These advanced methods not only improve efficiency but also offer substantial cost savings and a competitive edge in the market.

Cost Analysis and Comparison:

1. Comparing Cost Structures to Traditional Production:

Production Efficiency:

- Automatic production: Automation significantly boosts efficiency by reducing manual intervention and increasing production speed, lowering the cost per unit.

- Traditional Production: Requires more manual labor, resulting in lower efficiency, higher labor costs, and longer production cycles.

Labor Costs:

- Automatic production: Reduces how much manual work is needed, cutting overall labor costs.

- Traditional Production: High labor costs due to a significant portion of manual operations, including wages, training, and related benefits.

Equipment Maintenance and Repair Costs:

- Automatic production: Although initial equipment costs are high, automated systems have lower maintenance and breakdown rates over time.

- Traditional Production: Older equipment often requires more maintenance and repair, leading to higher failure rates and extra costs.

Production Consistency and Quality Control:

- Automatic production: Automation makes products more consistent and better quality, cutting down on defects and waste, which lowers the cost of fixing mistakes.

- Traditional Production: Manual operations can lead to inconsistent quality and more defects, increasing rework and associated costs.

Economies of Scale:

- Automatic production: Automation allows for economies of scale, decreasing per-unit production costs as production volume increases.

- Traditional Production: Limited economies of scale mean production costs don’t drop significantly with higher volumes.

2. Cost Advantages of Automatic production:

- Automatic production Processes: Johoty’s highly automatic production line reduces the need for manual labor, cutting labor costs and boosting efficiency and consistency. Precise control speeds up production and reduces unit costs.

- Reduced Production Waste: Automation minimizes waste by optimizing every production step. For example, precise cutting and assembly of Pogo Pins reduces material waste, cutting down raw material costs.

- Efficient Quality Control: Automated lines have advanced quality checks that monitor every step of production in real-time. This helps spot and fix defects quickly, reducing the number of defective products and cutting down on rework and repair costs.

- Stable Production Capacity: Automation allows Johoty to maintain consistent production levels without human interference. This flexibility helps manage inventory better and avoids excess stock or shortages, optimizing production costs.

- Energy Efficiency: Automated equipment is often more energy-efficient than traditional methods. Johoty’s technology features efficient motors and advanced controls to save on energy costs and minimize its impact on the environment.

- Shorter Production Cycles: High efficiency and precision in automation significantly shorten production cycles. Johoty’s processes streamline production and reduce downtime, cutting costs associated with long production times.

- Lower Labor Costs: Automation cuts down on the need for hands-on work, saving on labor costs and reducing expenses tied to hiring and training.

- Increased Production Flexibility: Automated systems can quickly adjust production settings to meet changing product demands, enhancing flexibility. This allows Johoty to respond swiftly to market shifts, reducing costs associated with fluctuating demand.

Customer Case Studies and Successful Applications

1. Electronics Manufacturer’s Automation Upgrade

- Background: A leading Slovenian electronics manufacturer focusing on smartphones and wearable devices.

- Application: Introduced Johoty’s Pogo Pins and automation technology for frequent connections and disconnections on their production line.

- Results:

- Increased Efficiency: Production efficiency rose by 35%.

- Reduced Failure Rate: Connection failures dropped by 50% due to Pogo Pins’ high reliability.

- Cost Savings: Automation saved about $200,000 annually in labor costs.

2. Automotive Electronics System Optimization

- Background: A global leader in automotive electronics, providing advanced in-car entertainment and navigation systems.

- Application: Used Johoty’s Pogo Pins for automated testing and connection to ensure high-quality in-car electronics.

- Results:

- Shortened Production Time: Production time halved from 24 hours to 12 hours, doubling efficiency.

- Improved Quality: Product quality improved by 40% due to reduced manual intervention and better connection stability.

- Increased Capacity: Production capacity grew by approximately 60% with the automated line.

3. Automation Upgrades for a Medical Device Manufacturer

- Background: A German company specializing in high-precision medical devices, including pacemakers and diagnostic equipment.

- Application: The client integrated Johoty’s Pogo Pins into their automatic production line to connect sensitive medical electronic components.

- Results:

- Increased Production Accuracy: Automation technology improved the assembly precision of components, reducing the device failure rate by 45%.

- Enhanced Production Efficiency: The automation upgrade increased monthly production capacity by 30%.

- Labor Cost Savings: Automation technology saved the client approximately $150,000 annually in labor costs and minimized human errors during production.

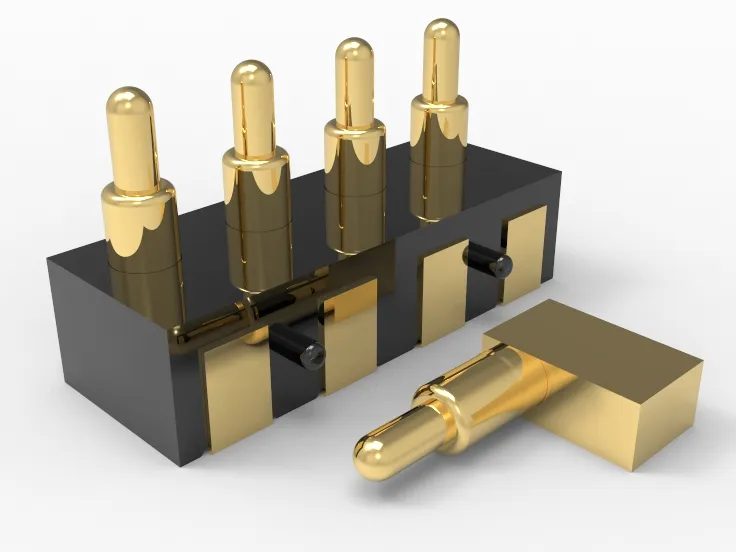

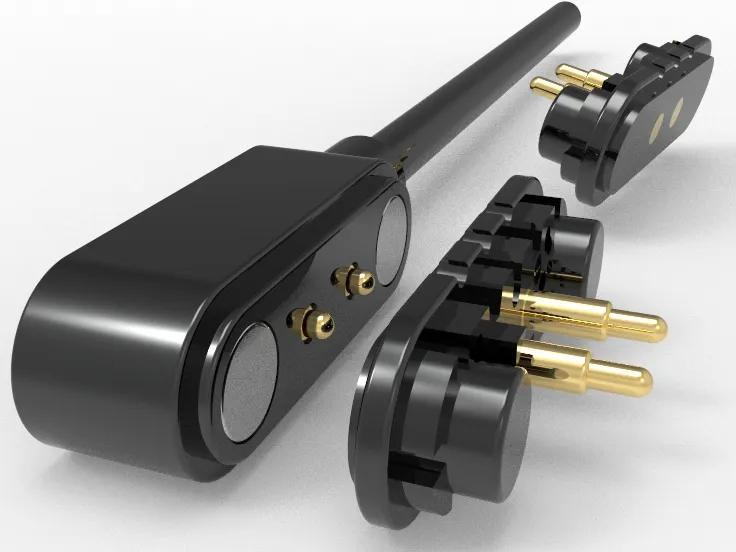

Why Choose Our Pogo Pins?

When looking for high-quality Pogo Pins, Johoty’s automatically produced Pogo Pins are your best choice. We combine advanced technology with stringent quality control to provide Pogo Pins with exceptional performance and great value, ensuring your electronic devices operate reliably and steadily:

- Unmatched Precision: Johoty uses a fully automatic production line, ensuring each Pogo Pin is manufactured with a precision of ±0.02mm. Our production process has ISO 9001 certification, so you can count on our products for top-notch accuracy and reliability.

- Strong Durability: Using high-quality metal materials and rigorously tested surface treatments, our Pogo Pins maintain excellent electrical performance after 10,000 insertion cycles. They are resistant to wear and corrosion, ensuring long-term, stable use.

- High Conductivity: Johoty Pogo Pins have been professionally tested for conductivity, with each pin’s contact resistance as low as 0.015Ω. This ensures stable current transmission, reduces signal interference, and improves the overall performance of your devices.

- Fast Delivery: Thanks to our robust automation production line and efficient manufacturing processes, Johoty can deliver orders quickly, usually within 7-10 business days. This significantly shortens your product’s time-to-market.

- High Customer Satisfaction: According to our latest customer feedback, 95% of customers are very satisfied with Johoty’s Pogo Pins, particularly praising their high quality, affordable pricing, and responsive service. Our goal is to provide top-notch after-sales service, so we can promptly take care of any issues or requests from our customers.

Choosing Johoty’s automated Pogo Pins means opting for high performance and reliability, along with trust and assurance. No matter how complex your application, our Pogo Pins offer the best solution.

Conclusion:

- To maximize your project budget, Johoty’s automatic production technology not only lowers the cost of Pogo Pin Connector and Pogo Pins but also ensures their high quality and precision. With our innovative production processes, we manage to keep prices low without giving up on high performance.

- Whether you’re a major enterprise or a small new business, Johoty is a trusted partner you can count on. Contact us now to experience industry-leading solutions and achieve the best value and quality for your project.