Show You How Johoty’s Innovative Pogo Pins Slash Batch Production Costs by 30%. Learn Key Engineering Insights to Boost Design Efficiency Now!

Introduction: Why 72% of Engineers Regret Their Connector Choices After Batch Production?

In engineering manufacturing, selecting appropriate connectors is crucial for product performance and production costs. However, research shows that up to 72% of engineers regret their connector choices after batch production. This regret is not aimless, as there are technical challenges and cost pressures hidden behind it.

So, what causes so many engineers to make mistakes when choosing connectors? Why do seemingly perfect designs expose defects during batch production? It’s time to re-examine the selection criteria for connectors. You need to find a balance between 3 key factors of cost, reliability, and scalability.

In this article, Johoty will show you how to reduce these common errors by carefully designing and selecting appropriate pogo pins. How to reduce batch production costs by up to 30% through Johoty’s pogo pin technology. With the technology advancement, connectors are no longer simple parts. Their performance directly affects engineers’ work efficiency and product quality. Johoty will reveal how to avoid those common pitfalls. Provide engineers with a more cost-effective and reliable solution.

Read: 8 Types of Pogo Pins

How Johoty’s Pogo Pin Design Cuts Costs Before Batch Production?

Reduced contact resistance and improved performance stability

In traditional pogo pin designs with high frequency and low voltage, contact resistance is an important factor that cannot be ignored. Johoty can significantly reduce contact resistance through precise internal structure, surface coating, and spring contact design. This design can improve the efficiency of current transfer, reduce heat accumulation and component aging caused by high resistance. By reducing contact resistance, frequent product testing and rework are no longer required in batch production, saving a significant amount of testing and adjustment costs. Reduce contact resistance by 30%, improve transfer efficiency, and reduce energy loss.

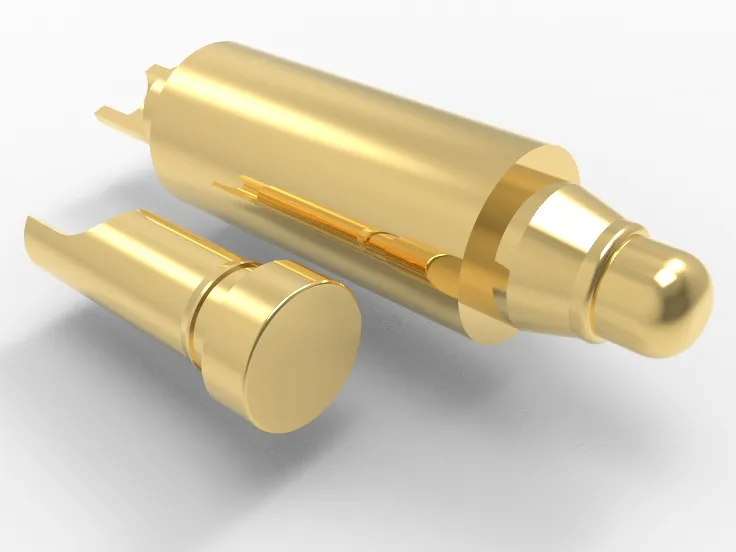

Read: Through Hole Pogo Pins

Improve connection stability and reduce defect rate

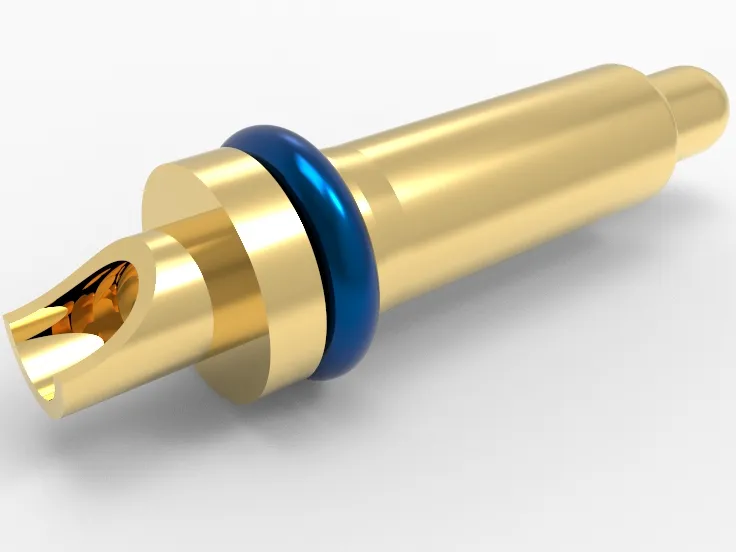

In engineering, the stability of connections directly affects the reliability of products. Johoty’s 10 contact designs can provide stable current conduction. Compared to traditional contact designs, it can significantly improve the stability of the connection. This stability makes the product less prone to poor contact and looseness during mass production. Improved connection stability by 40% and reduced defect rate by 25%. Reduced defective product rate significantly and minimized the costs of repair and scrapping.

Read: SMT Pogo Pins

More uniform force distribution, extending product lifespan

Traditional pogo pin designs often focus on a single contact point. During the contact process, it is easy to cause excessive local wear and reduce the service life of the connector. Johoty’s multi-point contact design evenly distributes the force, reducing the pressure of single point wear. By optimizing the distribution of force, Johoty’s pogo pins can maintain excellent performance even after prolonged use. The uniformity of force distribution has been improved by 50%, and the service life has been extended by 30%. Reduce additional costs incurred due to frequent replacement of damaged connectors.

Read: High Curren Pogo Pins

Reduce the complexity of assembly and maintenance

Johoty’s contact design brings performance advantages, simplifies the structure, and makes the assembly process more efficient. In batch production, the reduction in assembly complexity directly leads to savings in labor costs. Reduce assembly time by 25% and maintenance costs by 20%. Due to product itself durability, maintenance frequency is also reduced. Customers can focus their resources more on research and innovation, rather than repetitive assembly and repair.

Read: Double Ended Pogo Pin

The compatibility of automated production is higher

Automated production has become a trend in industrial manufacturing, and the design of connector components must have higher automation compatibility. Johoty optimizes shape and structure to better fit automated production lines which can further reduce labor costs, improve production efficiency. Importantly, it reduces various quality issues caused by human error. Automation compatibility increased by 35% and production efficiency increased by 30%.

Read: Solder Cup Pogo Pin

Competitive Comparison of Batch Production Visualization

Production efficiency: reduce manufacturing time

Adopting high-precision automated production processes, the quality of each pogo pin is stable, reducing manual operation errors and product defect rates. Johoty’s pogo pins’ streamlined design and efficient processing technology significantly shorten the production cycle. The overall production efficiency can be improved.

Many traditional competitors rely heavily on manual intervention and complex manual operations in the production process. This will result in longer production cycles and lower production efficiency. Due to unstable quality control and high defect rates, many manufacturers require multiple rounds of rework and inspection. It is clear that this can increase production time and costs.

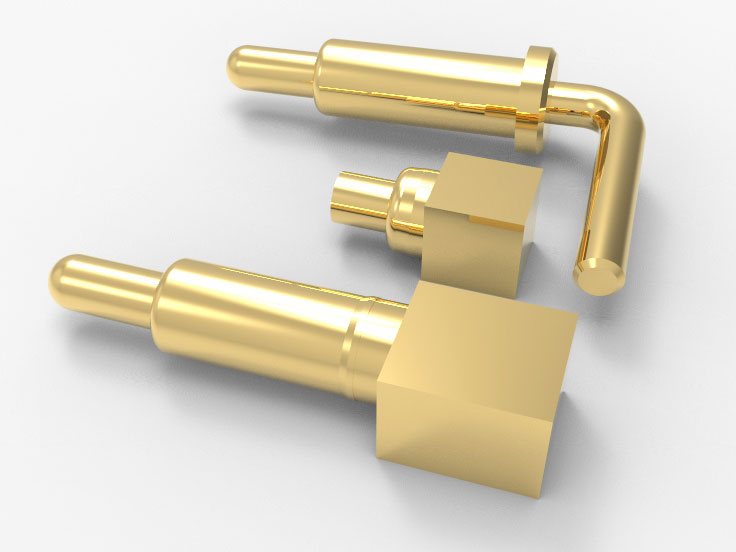

Read: Right Angle Pogo Pin

Cost control: reduce the production cost of individual products

By optimizing materials and precise design, Johoty has reduced the production cost of each pogo pin by approximately 20%. At the same time, improve the durability and reliability of the product. Efficient production processes and strict 23 quality controls can maintain low production costs while ensuring quality.

Some competitors’ pogo pins use more expensive materials, resulting in higher unit costs due to imperfect design and inefficient production. At the same time, the higher rework rate and more non-conforming products further increase the production cost of each pogo pin.

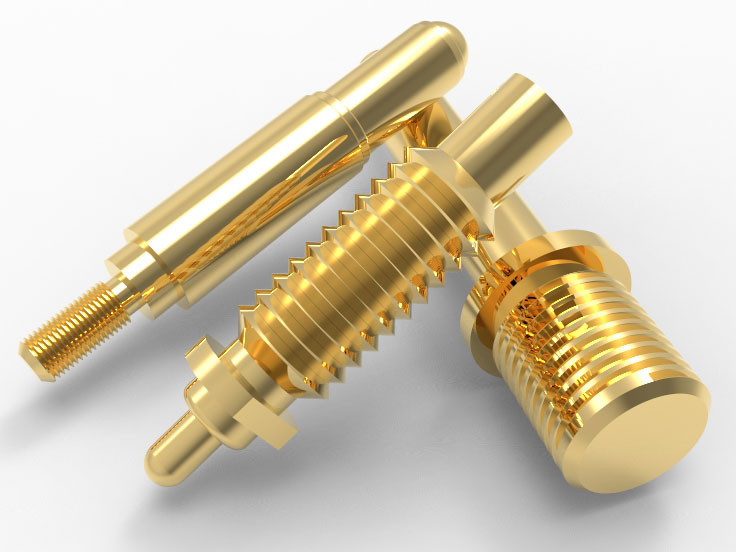

Read: Threaded Pogo Pins

Performance reliability: Improve the stability of the final product

In high-frequency signal transfer, Johoty’s pogo pin design focuses on improving contact reliability. This ensures connection consistency and stability after long-term use. Through meticulous design and strict quality control, Johoty’s pogo pins can operate stably in high temperatures and high humidity. In the automotive environment, it is possible to achieve high-strength protection of stainless steel shells, as well as magnetic contact and stable transfer of current and signals.

Some competitors’ products are prone to poor contact in extreme working environments. In high-frequency applications or high vibrations, the instability of the connection is very obvious, which affects the overall performance of the product.

Read: Pogo Pins or Spring Test Probes for IC Chipset

Flexibility: Meet diverse customization needs

Provide multiple specifications and customization, quickly adjust product design to meet specific requirements. Can design 5gf according to different customer needs, 220 pin connector at pitch 1.27mm, 1,144 pin connector, etc. For batch production, Johoty can provide flexible production plans. We have provided our client with over 50,000 types of pogo pin connector. Ensure delivery within the specified time without additional process modifications.

Many traditional Pogo Pin manufacturers have fixed product designs and poor customization flexibility. Customers need to wait for a long time to obtain the required specifications of connectors. Some competitors can only provide a small number of standardized products and cannot quickly respond to large-scale personalized needs.

Read: Pogo Pins or Spring Test Probe for ICT, FCT, or ATE

Supply Chain Management: Optimizing Inventory and Logistics

Optimized supply chain management, able to quickly respond to customer demands and reduce inventory backlog. We maintain better cash flow and inventory control during mass production. Johoty’s top 4 global logistics networks ensure fast delivery of products and post service support.

Many competitors are lagging behind in supply chain management, resulting in inventory backlog and long delivery waiting times. Due to poor management, some suppliers are unable to guarantee timely delivery, which affects the production cycle of customers.

Use Case: Reduce Batch Production Costs by 30%

Background: Challenges and Opportunities

A US nuclear energy company is facing high mass production costs during the production process. In the testing process of electronic components, traditional connectors and testing equipment are expensive. Due to continuous wear and unstable contact performance, production efficiency is low and costs continue to rise.

Problem analysis

Due to aging or unstable contact, traditional testing equipment cannot maintain long-term stable connections, resulting in frequent maintenance and replacement. Traditional testing equipment not only requires expensive initial investment, but also incurs high costs over the long term due to frequent maintenance. Due to the inefficiency and instability of the testing process, the production cycle is extended and the cost of mass production increases accordingly.

The solution of Johoty pogo pins in mass production

High precision pogo pins

Johoty’s pogo pins design and manufacturing process significantly improve the contact accuracy and stability of each spring pin. High precision contact performance solves the problem of unstable contact in traditional connectors. It can effectively reduce the need for maintenance and rework in production. By using Johoty Pogo Pins, the stability of the testing process has been significantly improved, and the overall efficiency of the production line has been greatly enhanced.

Reduce long-term maintenance costs

Using highly durable stainless steel or piano steel wire can greatly extend the service life of spring needles. The cost of connectors and testing equipment that require frequent replacement and maintenance has been significantly reduced. With the reduction of equipment maintenance costs, overall production costs have been significantly saved, and customers are no longer troubled by frequent equipment replacement and maintenance issues.

Improve production efficiency

The high performance and long lifespan of Johoty’s pogo pins reduce the failure rate of testing equipment and improve the overall work efficiency of the production line. Optimize every link on production line, thereby shortening production cycle. Reduce downtime caused by equipment failures during the production process. The improvement of production efficiency directly promotes the reduction of batch production costs.

Achievement

Applying Johoty’s pogo pins to the production process, American nuclear companies have achieved significant cost savings in just a few months. By reducing equipment maintenance and replacement costs, as well as improving production efficiency, the cost of the entire production process has been reduced by 30%. The efficiency in the testing phase has increased by 20%, resulting in a shortened production cycle and a significant increase in output per unit time. Due to the long lifespan and high stability of pogo pins, the maintenance cost of enterprise equipment has been reduced by 25%.

Why Johoty Pogo Pins is the preferred solution

Many engineers have provided feedback that Johoty’s pogo pins offer a direct, simple, and efficient solution. They meet the requirements of high precision and high stability in technology. It has brought tangible benefits in cost control and production efficiency. Many engineers hope to optimize production flow through innovative technology, and Johoty’s pogo pins are undoubtedly a trustworthy choice.

Core requirements of engineers

As an engineer, ensuring the stability and accuracy of the connection is the top priority, and Johoty’s pogo pins perfectly meet this requirement. Cost control is a factor that every engineer and enterprise must consider, and Johot’s pogo pins have brought significant cost advantages to the enterprise through their long-term low maintenance costs. What engineers need is a solution that can operate stably for a long time, and the durability and reliability of Johoty’s pogo pins perfectly meet this requirement.

Conclusion:

Batch production is constantly seeking cost optimization and production efficiency improvement on a global scale. Johoty’s pogo pins have significant cost-effectiveness and efficient performance, preferred choice for many engineers and procurement decision-makers. By reducing batch production costs by 30%, Johoty can help clients optimize production processes. We can also provide the R&D team with stronger design flexibility and more budget space.

Choosing the appropriate connectors is crucial in batch production for engineering projects that require high precision and reliability. Johoty’s pogo pins have become a core component in multiple industries due to their superior conductivity and long service life. Johoty can provide customized solutions in automation equipment, consumer electronics, and intelligent manufacturing. Assist customers in quickly responding to market changes and maintaining technological leadership.

Now, let Johoty be your key partner for your next innovation project. Contact Johoty to start reducing batch production costs and improving product performance. Join hands with Johoty to start more efficient and intelligent batch production!