5 Innovative Uses of High Density Connectors in Cutting-edge Electronics. Solutions Optimize Performance in Industry: 5G, Automotive. Read Now

Introduction: High density connectors, the cornerstone of future electronic engineering

With increasing demand for miniaturization and device performance, traditional connections can’t meet efficiency and reliability requirements again. High density connectors, as core technology to solve this problem, are rapidly becoming an indispensable key component in electronic design. They can significantly optimize space utilization, stably transmit high-speed signals, and greatly improve system performance and reliability. From 5G communication network to autonomous vehicle, medical equipment and industrial automation, high density connectors are breaking through traditional boundaries. They are leading the technological innovation of the electronic industry.

In this article, Johoty will delve into high density connectors in 5 innovative electronic applications. Reveal how it drives the future development of electronic engineering and showcase Johoty’s advanced technological solutions. Assist engineers in obtaining more efficient and reliable design solutions in complex projects. By analyzing these cutting-edge applications, you will see how high density connectors have become the cornerstone of modern electronic systems. They are meeting increasingly demanding design requirements.

Read: 14~598 pin connector

Technical details and highlights of High Density Connectors

High pin count design

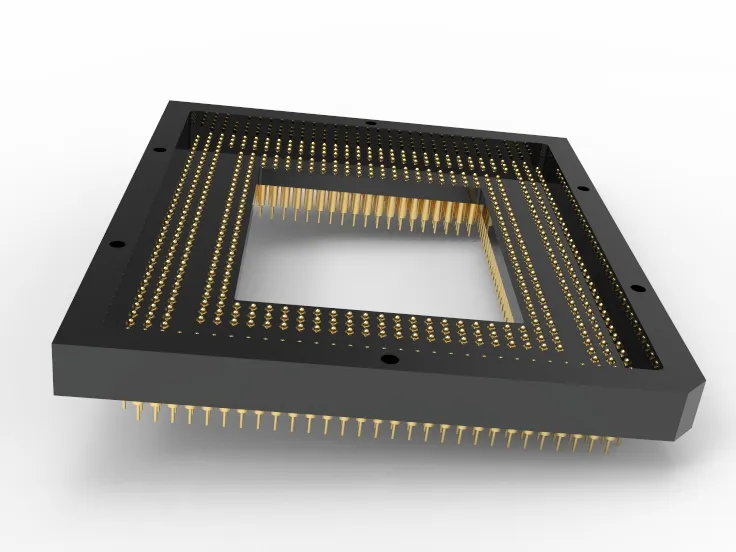

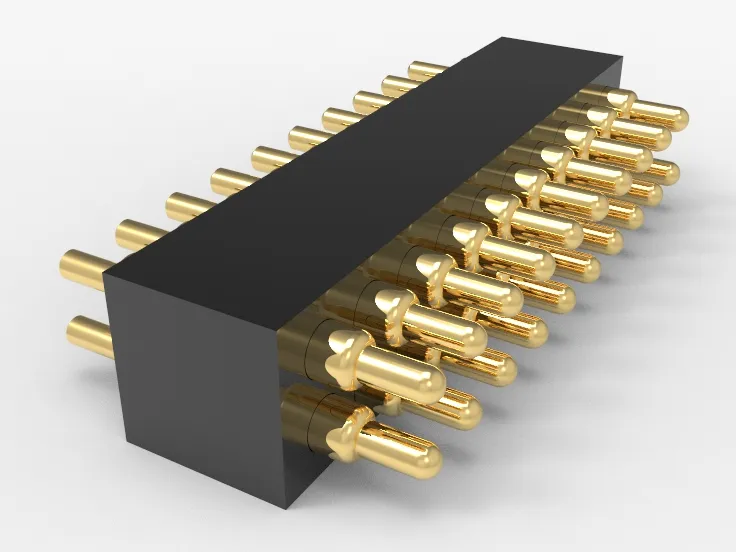

Johoty’s high density connectors utilize cutting-edge micro pin technology. Each connector module can support extremely high pin density, reaching a level that traditional designs cannot match. Our latest pogo pin connector supports nearly 40% more pins per cubic centimeter than conventional products. Significantly improved space utilization.

For electronic products with limited space and high functional integration, it is crucial. Very useful in embedded systems, aerospace, automotive electronics, and high-performance computing devices. Johoty’s high density connectors can provide up to 598 signal transmission channels in extremely small spaces. We can meet the dual demands of high performance and miniaturization for the latest technological products.

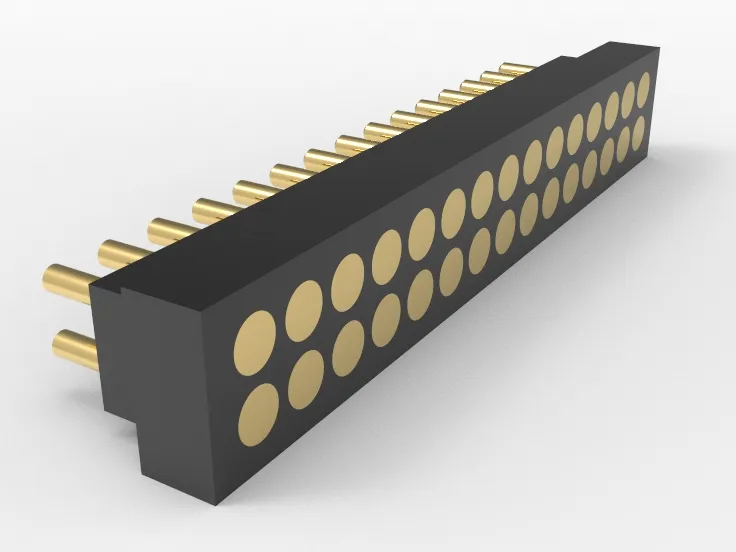

Miniaturization structure and reliability enhancement

Advanced miniaturization materials and manufacturing processes enable pogo pin connectors to maintain ultra-high signal transmission rates and extremely low EMI while being miniaturized. Johoty’s pogo pin connector supports stable transmission of high-frequency signals and maintains high reliability in high temperatures, humidity, and vibration. Johoty’s high density connectors can provide long-lasting and stable performance in automotive intelligence, 5G communication devices, and drone systems.

Precise design to meet demanding applications

Johoty’s high density connectors have strong adaptability and can operate efficiently in complex industrial applications. Our pogo pin connector has undergone rigorous 23 tests and is capable of long-term stable operation in military, aerospace, and medical equipment. Thanks to its unique anti-interference design, the Johoty connector can effectively reduce high-frequency noise. Providing clear and accurate data transmission is critical for modern electronic systems.

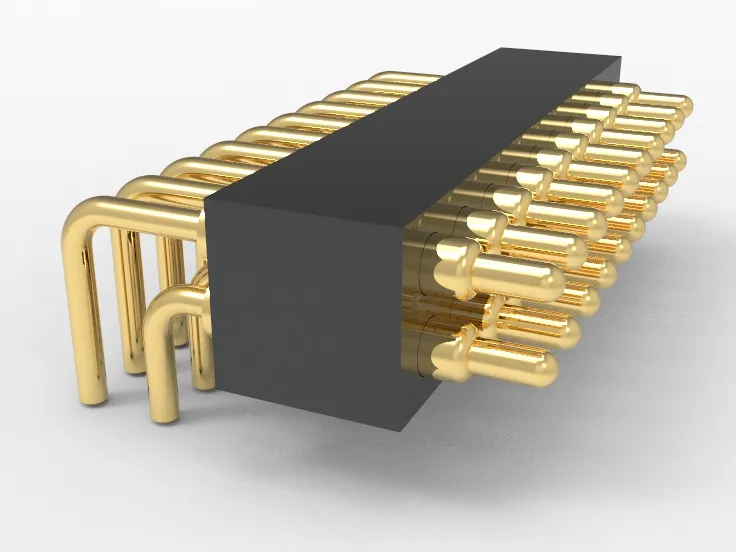

Innovative locking connection

Johoty’s high density connectors use the latest intelligent locking technology to ensure stability and safety during the connection process. Our designed automatic docking locking system can automatically adjust the locking force based on the insertion status of the pogo pin connector. This can reduce the complexity of human operation and improve assembly efficiency.

Environmental protection and efficient manufacturing processes

The manufacturing process of Johoty connectors uses environmentally friendly materials and has passed multiple international certifications. Our factory uses efficient automated production lines to ensure that every pogo pin connector can be completed with high quality in the shortest possible period of time. Innovative design and manufacturing processes to maximize product performance and reduce resource waste in the production process.

Read: Multiple Pin Connectors

5 Innovative Applications of High Density Connectors

Building a High Density Connected Ultra High Speed 5G Network

In 5G and future communication technologies, signal transfer speed and data bandwidth requirements far exceed the capabilities of traditional connectors. Meanwhile, customers are more inclined towards high-density distribution of pogo pins, ultra-low 5gf spring force and ultra-low impedance, and at least 1Gbps high speed. Johoty’s high density connectors are designed with high pogo pin density, which can support higher frequencies and data traffic. They have become essential core components for 5G base stations and terminal devices. The miniaturized design and excellent anti-interference ability of this pogo pin connector can effectively reduce signal loss. Stable transfer of high-frequency data has laid the foundation for the smooth deployment of 5G networks.

Promote the reliability and integration of autonomous driving technology in automobiles

The demand for high density connectors is rapidly increasing due to the autonomous driving of automobiles and the continuous development of intelligent in vehicle systems. Johoty high-density connectors can integrate hundreds of signal channels in a very small space. They can meet the requirements of auto drive system for fast response and high-precision signal transfer. Johot’s pogo pin connector can provide excellent electrical performance and high reliability in vehicle radar, LiDAR sensors, and vehicle computing platforms. It can ensure efficient operation in the car environment.

Read: 12 Pin Connector

High performance connectivity solutions for harsh aerospace environments

In the aerospace industry, the performance requirements for connectors are extremely demanding. High temperature, radiation, vibration, and extreme weather conditions can all affect the stability of connectors. Johoty high density connectors often use special materials that are resistant to high temperatures and radiation, as well as innovative locking structures. They can maintain efficient signal transfer in extreme environments. Can withstand the challenges of high-frequency signals and work stably in highly vibrating environments. Johoty’s pogo pin connector is widely used in satellite communication, spacecraft systems, and unmanned aerial vehicle equipment.

Improve the signal transfer efficiency of precision medical devices

The precision medical equipment in the medical industry has very high requirements for connectors in terms of signal transfer accuracy and stability. Johoty’s high density connectors can support efficient connections of complex sensors and signal processing units. High density integration of multiple signal channels can be achieved in ultra small spaces. It can ensure real-time monitoring and rapid transfer of precise medical data. In intelligent diagnostic devices, endoscopes, and implantable devices, the high performance of Johoty’s pogo pin connector ensures error free signal transfer, improving diagnostic efficiency and accuracy.

Read: 10 Pin Connector

Provide a solid hardware foundation for high-performance computing

In ultra large scale computing systems, high-performance computing has high requirements for data transfer and computational efficiency. Johoty high density connectors provide thousands of parallel signal channels in a very small space. This can support efficient connections of complex hardware in quantum computers and supercomputers. They have the advantages of low latency and high reliability while supporting extremely high-speed data streams. Becoming an ideal choice for supporting quantum bit operations and HPC computing core hardware.

Read: 8 Pin Connector

Johoty’s High Density Connectors Solution: The Perfect Combination of Innovation and Reliability

Dual guarantee of stability and high-speed transfer

In industrial automation, including new network companies in the United States, high-speed and stable data transfer is often required by engineers to be achieved by Johoty. The shielding technology and anti-interference ability of Johoty’s high density connectors demonstrate excellent performance in industrial robots and intelligent manufacturing equipment. Our pogo pin connector has high contact reliability, patented pin technology, and signal attenuation of less than 1%. High speed transfer support, with up to 10 Gbps data transfer, it can easily handle complex data streams.

Reliability performance under aerospace conditions

Designing connectors to achieve excellent performance under high vibration, extreme temperature, and low air pressure is a common requirement for Johoty’s aerospace clients. Johoty’s high density connectors are made of high-temperature resistant PEEK with multiple sealing designs, which remain stable in temperatures ranging from -55 ° C to+250 ° C. Anti vibration design, patented rotating double lock or four lock structure, does not loosen under vibration environment. Its anti-corrosion performance, special coating, and salt spray corrosion resistance exceed 1,000 hours.

Read: 12 Pin Connector

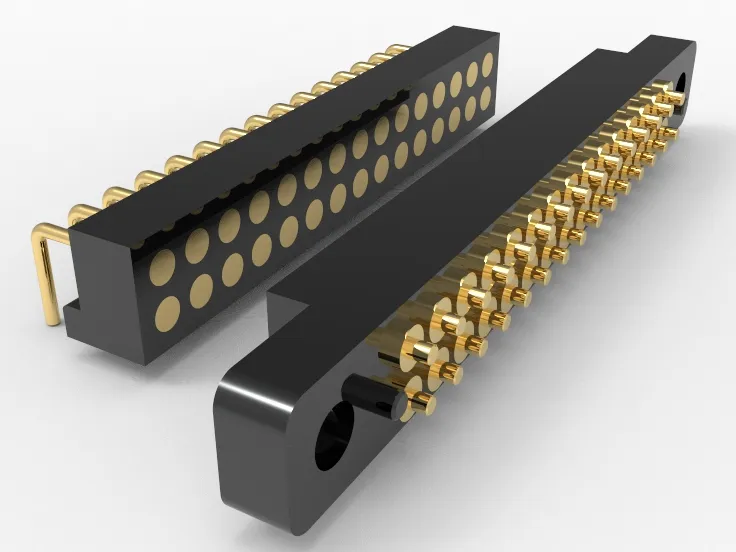

The perfect balance between miniaturization and stable transfer

Space utilization and signal stability have become the key to the development of miniaturization and multifunctionality of medical equipment. Johoty’s high density connectors can be designed with ultra small spacing and multiple pins to achieve the space constraints and signal stability that customers expect. They can minimize the occupied space while ensuring signal integrity. For this high-density pogo pin connector, we can achieve a micro spacing design of ≥ 1.0mm, and the spacing supports compact device integration. A low contact resistance of 20 milliohms ensures signal stability and avoids interference and data loss.

The combination of high-density wiring and high reliability

High density cabling and efficient heat dissipation are the basic requirements of every customer from Johoty’s data center. The Johoty connector adopts an innovative cooling groove structure, which effectively reduces overheating. The modular design is easy to replace and upgrade quickly. We can design ventilation ducts or double-layer ventilation ducts, which can efficiently dissipate heat and improve overall stability. Modular maintenance reduces downtime and makes it easier for online engineers to maintain. In server clusters, Johot’s high density connectors significantly reduce temperature accumulation issues and improve operational reliability.

The ultimate combination of high density and flexibility

High density connectivity and flexible layout are what customers often require us to achieve in IoT applications. The flexible connector series launched by Johoty supports multi-directional rotation and bending, perfectly adapting to the diverse wiring needs. Flexible connector, connecting FPC with special adapters required by customers, with 360 ° rotation, can adapt to complex wiring scenarios. Lightweight design reduces device load and achieves unprecedented layout optimization in smart home products.

Read: Multiple Pin Connectors

Why choose Johot’s high density connectors?

Compact design, performance not discounted

Customers’ devices are becoming smaller and more powerful, requiring more compact and sturdy connectors. Johoty’s high density connectors achieve an unparalleled balance between size and performance. By focusing on miniaturization design, our pogo pin connector enables engineers to design lighter, more efficient devices while maintaining functionality. Assist in achieving up to 40% wiring optimization for industrial automation, embedded systems, and aerospace applications. Whether you are developing wearable technology or IoT devices, Johoty can ensure that your designs are always at the forefront of technology.

High reliability, adaptable to harsh environments

Johoty’s high density connectors are made of high-quality materials, advanced manufacturing processes, and 23 inspection procedures. Commonly used aviation grade alloys and anti-corrosion coatings can operate stably under extreme temperatures, high vibrations, and humidity. This reliability makes it an ideal choice for automotive electronics, marine engineering,aerospace, and industrial automation. Engineers can confidently integrate Johoty’s pogo pin connector into critical systems. Ensure the signal integrity and long-term stable operation of equipment in harsh industrial and military environments.

High speed data transfer meets the requirements

With the popularization of 5G, various video data transfer, and the Internet of Things, high-speed data transfer has become a core requirement for electronic design. Johoty’s high density connectors support high-speed signal transfer at 5Gbps, 10Gbps data flows seamlessly between devices. Effectively addressing EMI and signal attenuation, the double-layer shielding structure and high-precision contact surface significantly reduce signal crosstalk and energy loss. For medical equipment, communication infrastructure, and consumer electronics, Johoty can meet high bandwidth requirements. Effectively isolate noise, ensure low-power operation, and adapt to high-speed communication.

Read: 10 Pin Connector

Flexible design, simplified integration

Johoty offers a variety of customizations, including different pin configurations, spacing, high/low elasticity, low resistance, material selection, and housing materials. Based on our high density connectors, many engineers can easily integrate connectors into complex designs. Whether it’s a strong protective stainless steel shell or a multi pogo pin shaped structure with magnets nested between the rubber core and the shell. As long as customers make precise requirements, we can achieve them, greatly reducing the development cycle and lowering costs.

Reduce development risks

Engineers are most concerned about long lead times and high risks in product development, and Johoty has significantly shortened the development and validation cycle through rapid sample supply and batch consistency control. Whether it is small-scale testing or large-scale production, consistency and stability can be guaranteed. Quickly obtain 3D models and technical information, increase sample supply speed by 50%, conduct batch consistency testing, and eliminate quality differences. Johoty’s high density connectors use high-temperature resistant polymers and gold-plated contact materials, which can work stably from -55℃ to+200℃. Dense layout, optimized space utilization, modular configuration, and quick adaptation to project changes.

Read: 8 Pin Connector

Conclusion:High density connectors, the cornerstone of future technology

In high-end electronic technology, high density connectors are the core components of IoT equipment, autonomous vehicle, aerospace systems, medical electronics and industrial automation. It is also an indispensable technological cornerstone for promoting future innovation. Their high performance, miniaturization, and reliability are accelerating the development of various industries in unprecedented ways.

Engineers often face the challenges of technological upgrades and equipment integration, and choosing the appropriate high density connectors is a crucial step in determining the success or failure of a project. Johoty high density connectors have won widespread acclaim worldwide for their excellent design and performance. Now it’s time for you to take innovative steps!

Visit Johoty’s official website immediately and contact Johoty’s CFT team to know perfect solution of high density connectors. It will definitely inject strong momentum into your next generation electronic project. The future belongs to those engineers who dare to break through, and Johoty will always walk alongside you.