How Do Pogo Pins Work? Insights Into Everything You Need to Know About Pogo Pins and Their Functionality, Operational Mechanism, Applications

1. Introduction

Pogo Pins are small electrical connectors commonly used in electronic devices. They consist of a spring-loaded metal pin and a fixed metal shell that establishes electrical connections through pressure contacts.

This article aims to explain in-depth the working principles of Pogo Pins and their significance across various applications. With their unique spring design, Pogo Pins provide convenient connections during device assembly and testing. They are widely used in fields such as testing, programming, device debugging, charging interfaces, and data transmission, playing a crucial role in product reliability and efficiency.

Next, we will delve into the mechanics of Pogo Pins, including their internal structure and principles, as well as the specific uses and advantages of different types of Pogo Pins in various application scenarios.

2. Basic Components of Pogo Pins

Pogo Pins, commonly used connectors in electronic devices, have a highly precise and specialized design for electrical connectivity. Here’s a detailed breakdown:

2.1 Tip Section:

- Material: Typically made of highly elastic alloys like copper or stainless steel for good resilience and electrical conductivity.

- Design: Tips are usually sharp to penetrate oxide layers or surface contaminants during connections, ensuring reliable electrical contact. Some are semi-circular and customizable in shape.

- Surface Treatment: May undergo special treatments like gold-plating, silver-plating, palladium-plating, platinum-plating, or rhodium-plating to enhance conductivity and oxidation resistance.

2.2 Spring Section:

- Spring Material: The core component of Pogo Pins, made from elastic alloy materials such as steel springs or precious metal spring alloys.

- Design: Typically spiral or compression spring designs allow for rebound under pressure, ensuring reliable electrical connections.

- Pressure Rating: Springs are designed to withstand specific pressures to maintain electrical contact during connections.

2.3 Shell Section:

- Material Selection: Usually metal shells like stainless steel or copper alloys, used to secure and protect the internal spring structure.

- Design: Shell designs balance insertion stability and fixture performance within devices.

2.4 Connector Section:

- Connection Type: Can be direct insertion or socket designs with fixing devices for easy device assembly and disassembly.

- Electrical Interface: Ensures stable and reliable transmission of electrical or power signals during connections.

2.5 Additional Features:

- Protective Measures: Some Pogo Pins include dust and waterproof features to enhance device reliability and durability.

- Temperature Range: Advanced designs operate across wide temperature ranges to meet diverse environmental needs.

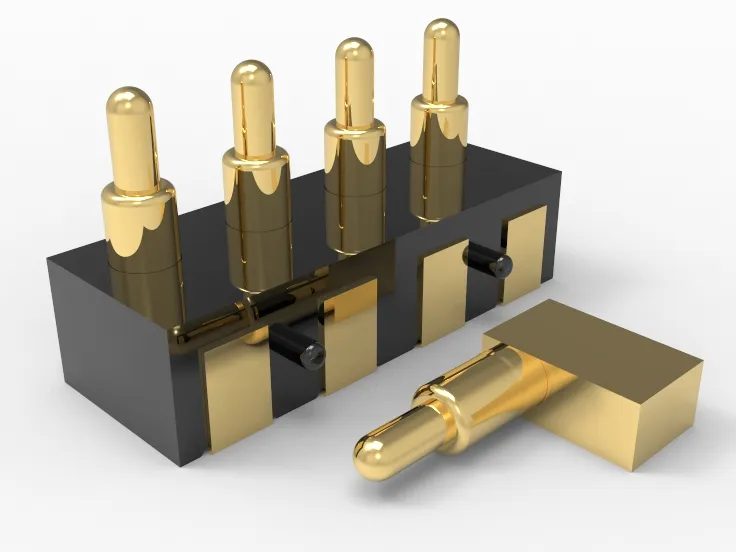

2.6 Illustration of Pogo Pins

Pogo Pins are frequent in electronic devices and testing tools requiring frequent insertion and removal. They consist of multiple components:

- Spring Body: Typically a spring-shaped metal component providing connector elasticity for stable electrical connections.

- Head: The top of the spring pin, usually metal for conductivity, contacting other connectors or conductors.

- Base: The bottom of the spring pin, soldered or fixed to circuit boards or connector bases, stabilizing the spring pin’s position and providing electrical connections.

- Fixing Structure: Used to secure the spring body and base, often made of metal or plastic to prevent loosening or displacement during use.

- Shield: Some Pogo Pins feature a protective shield around the head to prevent damage or contamination, ensuring connection stability and longevity.

- Plating: The surface of Pogo Pins typically undergoes plating for enhanced conductivity, corrosion resistance, and wear resistance, common platings include nickel, gold, silver, etc.

These components work together to form a complete spring pin connector suitable for reliable electrical connections in various applications such as testing fixtures, charging equipment, and electronic device interfaces.

3. Working Principles of Pogo Pins

3.1 How do Pogo Pins achieve elastic contact through spring design?

- Pogo Pins require frequent connections and disconnections, such as in mobile devices, testing equipment, and industrial machinery. They achieve stable electrical connections through spring design, ensuring reliable performance even during device movement or vibration.

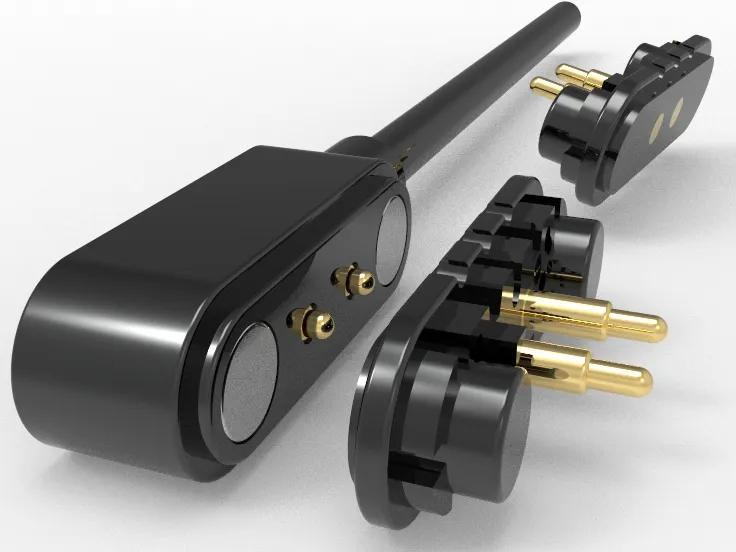

3.2 Structure and Principles

The main components of Pogo Pins include:

- Spring Body: Typically made of stainless steel with good elasticity and conductivity. The spring body’s design provides sufficient force during compression while maintaining good rebound properties.

- Male and Female Connectors: The male connector connects to one side of the circuit board or device, while the female connector connects to the other side. The male connector has a protruding spring body at the bottom, and the female connector is a groove that accommodates the spring body.

- Connection Method: When the male connector is inserted into the female connector, the spring body compresses, generating enough contact force to connect the male and female connectors. This design ensures stable electrical connections even when the device moves or vibrates, thereby improving device reliability and durability.

Pogo Pins achieve stability and reliability during frequent connections and disconnections through their special spring design, making them essential components in many high-end electronic devices and industrial applications. They’re carefully designed to keep working in tough conditions, making them popular in jobs where reliability and durability are key.

3.3 Discussing the Impact of Spring Material Selection on Performance

The choice of spring material significantly affects Pogo Pins’ performance, influencing their electrical characteristics, mechanical performance, and lifespan.

3.3.1 Factors to Consider in Spring Material Selection

3.3.1.1 Electrical Conductivity:

- Spring materials must have good conductivity to ensure reliable electrical connections. Commonly used materials include stainless steel (e.g., SUS301, SUS304), copper alloys (e.g., brass), and sometimes even molybdenum alloys, all known for their excellent conductivity.

3.3.1.2 Elasticity and Rebound:

- Springs must provide sufficient pressure to maintain good contact performance during insertion and withdrawal. Material elasticity determines the force changes during compression and rebound, crucial for equipment reliability.

3.3.1.3 Corrosion Resistance:

- For Pogo Pins used in harsh environments or external applications, materials need good corrosion resistance to prevent failure or reduce lifespan in humid or chemically corrosive conditions. Stainless steel typically excels in this regard.

3.3.1.4 Temperature Stability:

- In specific applications, Pogo Pins must work consistently even in extreme temperatures, be it hot or cold. Material selection considers temperature stability and the coefficient of thermal expansion.

3.3.2 Common Spring Materials and Their Effects

3.3.2.1 Stainless Steel:

- SUS301: Offers good elasticity and corrosion resistance, suitable for most general applications.

- SUS304: More elastic and higher tensile strength than SUS301, ideal for long-term and high-reliability applications.

3.3.2.2 Copper Alloys:

- Brass: Good conductivity and elasticity, though slightly less corrosion-resistant compared to stainless steel.

3.3.2.3 Molybdenum Alloy:

- Used in high-temperature environments with excellent heat resistance and chemical stability.

The choice of spring material profoundly impacts Pogo Pins’ performance, directly affecting their electrical connection stability, mechanical elasticity, and lifespan metrics. When selecting materials, it’s essential to consider the operating environment, electrical requirements, and expected lifespan to ensure the final product meets design specifications with optimal reliability and durability.

3.4 How to Ensure Stable Electrical Connections When Connecting Electronic Devices with Pogo Pins?

Ensuring stable electrical connections when connecting electronic devices with Pogo Pins is a key design goal, involving various engineering principles and technical considerations.

3.4.1 Design Principles and Engineering Considerations

3.4.1.1 Spring Design:

- The core of Pogo Pins lies in their spring design, engineered to provide adequate pressure during compression for reliable contact with target points (e.g., circuit boards or other connectors). Springs are typically made from stainless steel or other high-elasticity alloys, offering excellent rebound and durability.

3.4.1.2 Contact Force Control:

- Precise control of spring compression and strength ensures sufficient contact force during connection, effectively transmitting current or data signals. Design factors typically include spring hardness, shape, and length.

3.4.1.3 Material Selection:

- Springs are manufactured from materials with good conductivity (such as stainless steel or copper alloys) to ensure reliable electrical connections. These materials not only require good conductivity but also elasticity and corrosion resistance to adapt to different environmental conditions.

3.4.1.4 Mechanical Stability:

- Pogo Pins are designed to withstand frequent operations of connection and disconnection without losing elasticity or causing connection failures due to increased use.

3.4.1.5 Environmental Adaptability:

- Considering Pogo Pins’ potential use in different environmental conditions (e.g., temperature changes, vibration), designs must ensure stability and reliability. Proper design minimizes electrical connection issues caused by environmental factors.

3.4.2 Use Cases

- Pogo Pins are widely used in mobile devices, test equipment, and industrial control devices. They are designed as reliable connectors, maintaining stable electrical connections over extended periods to enhance device reliability and performance.

Through precise spring design, appropriate material selection, and consideration of environmental adaptability, Pogo Pins ensure stable electrical connections when connecting electronic devices. These engineering considerations make Pogo Pins an indispensable part of many high-end electronic devices and industrial applications, enhancing equipment reliability and lifespan.

4. Applications of Pogo Pins

4.1. Electronics Device Connection and Testing

- Pogo Pins are widely used in electronics for reliable electrical connections and high-frequency testing. For instance, in battery connection tests for smartphones, tablets, and other portable devices, Pogo Pins ensure stable electrical connections, ensuring device performance and reliability.

4.2. Medical Devices and Biomedical Field

- In medical equipment and biomedical applications, Pogo Pins are used for connecting and transmitting data in devices like ECG machines and glucose meters. Their small size and reliable connection technology allow precise data collection and transmission, ensuring accurate medical diagnostics and treatment efficiency.

4.3. Automotive Electronics and Automation Control Systems

- In automotive electronics and automation, Pogo Pins are commonly used for connecting and testing electronic components like ECUs and sensors. They maintain stable connections in harsh conditions, adapting to high temperatures, humidity, and mechanical stress, ensuring reliability and safety of automotive electronic systems.

4.4. Industrial Automation and Robotics

- In industrial automation and robotics, Pogo Pins are widely used for electrical connections and data transmission in robot joints. They support high-frequency operations while maintaining stable electrical performance, crucial for efficient industrial robot operations.

4.5. Consumer Electronics and Smart Home Devices

- Pogo Pins are essential in consumer electronics and smart home gadgets, such as charging docks, smartwatches, and other portable device chargers. Their compact design and reliable electrical connection technology enable faster and more convenient device charging, enhancing user experience and product competitiveness.

4.6. Aerospace and Defense

- In aerospace and defense, Pogo Pins are used for connecting and testing critical electronic equipment like satellite communication devices and missile navigation systems. They maintain stable connections and efficient data transmission in extreme conditions, ensuring the reliability and security of aerospace and defense equipment.

4.7. Communication Devices and IoT Technology

- In communication devices and IoT technology, Pogo Pins are widely applied in connecting and testing communication modules such as antennas for smartphones and smart home devices. They provide high-frequency signal transmission and stable electrical performance, ensuring reliable communication and data transmission.

4.8. Scientific Research and Laboratory Equipment

- In scientific research and laboratory equipment, Pogo Pins are used to connect various scientific instruments and experimental devices, such as experimental circuit boards and bioanalytical instruments. Their precise connection and high-reliability help researchers accurately control and collect experimental data, driving advancements in scientific research and technological innovation.

These examples illustrate the extensive applications of Pogo Pins across multiple industries, playing a crucial role in modern technological development with their stable connections and efficient electrical performance.

5. Advantages and Limitations of Pogo Pins

Pogo Pins are small connectors used for electronic connections and testing. Made of high-quality springs, they provide temporary connections between electronic devices. Here’s a detailed overview of the advantages and limitations of Pogo Pins:

5.1 Advantages:

- High Reliability: Pogo Pins use spring designs for stable contact and reliability, suitable for long-term use.

- Versatility: Suitable for various device connection and testing scenarios, such as PCB testing and charging connections, offering high flexibility.

- Space-saving: Small in size, Pogo Pins can be used in limited spaces, enhancing device design compactness and integration.

- Easy Maintenance: Due to their spring connections, Pogo Pins are easy to maintain and replace, reducing repair costs and time.

- Quick Connection: Pogo Pins allow fast electrical connections and disconnections, ideal for frequent plugging scenarios.

5.2 Limitations:

- Limited Lifespan: While durable, frequent plugging may affect their lifespan, especially in high-frequency usage.

- Unstable Contact: Under strong vibrations or extreme temperatures, Pogo Pins’ contact stability may be affected, leading to connection issues.

- Higher Cost: Compared to traditional connectors, manufacturing Pogo Pins can be costly, a consideration for large-scale applications.

- Design Complexity: Designing Pogo Pins connectors requires careful consideration of spring design and material selection, potentially increasing product design complexity and costs.

- Specific Applications: While suitable for various scenarios, Pogo Pins are more suited for temporary connections and testing rather than long-term fixed connections.

These advantages and limitations determine the specific applications and suitability of Pogo Pins in electronic device design, requiring selection and design based on specific needs and environmental conditions.

6. Future Trends of Pogo Pins

Looking ahead, Pogo Pins are poised to expand and innovate in electronic devices, focusing on these key areas:

- Miniaturization and High-density Applications: As electronic products become smaller and more integrated, Pogo Pins will trend towards smaller and denser designs to fit within tight device spaces.

- High-speed Data Transfer: With increasing demands for faster data transfer rates, future Pogo Pins will support higher-speed standards like USB 3.0 and Thunderbolt to meet rapid data transmission needs.

- Durability and Reliability: Future Pogo Pins will prioritize durability and reliability to handle frequent plugging and reduce connectivity issues caused by increased insertion cycles.

- Expanded Application Fields: Beyond traditional consumer electronics, Pogo Pins have promising applications in automotive electronics, medical devices, industrial control, and other fields requiring frequent connections and high reliability.

- Material and Manufacturing Innovation: Advancements in material science and manufacturing technology will lead to Pogo Pins using new materials and advanced processes, enhancing their electrical and mechanical performance.

Overall, Pogo Pins, as a crucial electrical connection technology, will focus on miniaturization, speed, durability, and expanding application areas to meet the increasingly complex and diverse needs of electronic devices.

7. Conclusion

In the meticulous design and precision manufacturing of high-end electronic devices, Pogo Pins play a critical role throughout. Their simple yet effective spring contact mechanism ensures reliable connections and signal transmission between devices. Whether in testing, programming, or charging, Pogo Pins deliver stable and enduring performance. Their compact design allows them to perform well even under high frequencies and pressures.

In essence, Pogo Pins are not only the preferred choice for electronic engineers but also an indispensable part of modern electronic devices. When considering Pogo Pins for your project, contacting Johoty, a top manufacturer, is definitely the right move!