Mass Production Expertise at Johoty Delivers High-quality Pogo Pin and Cuts Your Procurement Costs. Learn How Our Methods Benefit Your Business

Introduction

- Today, many clients face the dual challenge of improving product quality while reducing production costs. Johoty, with its extensive expertise and experience in mass production, offers an efficient approach to enhancing the quality of Pogo Pins while significantly lowering procurement costs. We use cutting-edge technology, streamline our production, and enforce strict quality checks to make sure every Pogo Pin is top-notch.

- Our innovative strategies not only improve the consistency and reliability of Pogo Pins but also effectively reduce production waste, helping clients lower their overall procurement costs. Discover how Johoty achieves these goals through precise mass production and how it can benefit your business.

Definition and Benefits of Mass Production

1. Mass Production Defined:

Johoty’s mass production of Pogo Pins involves highly automated and precise manufacturing processes to ensure consistency and high quality in large quantities:

- Precision Craftsmanship: Advanced manufacturing equipment and strict process controls ensure each Pogo Pin meets design specifications.

- Efficient Production: Streamlined production lines reduce cycle times and lower per-unit costs.

- Quality Monitoring: Comprehensive quality checks from raw materials to finished products ensure each item meets high standards.

- Flexible Customization: Production processes can be adjusted based on customer needs, offering personalized product solutions.

2. Johoty’s Approach Includes:

- Automated Equipment: Utilizing the latest automation lines to boost production efficiency and product consistency.

- Detailed Management: Employing advanced data analysis and production management systems to monitor processes in real-time and reduce defect rates.

- Continuous Improvement: Ongoing optimization of production methods and material selection to enhance product performance and cost-effectiveness.

3. Advantages Analysis of Mass Production:

- High Precision Manufacturing: Johoty’s Pogo Pins maintain exceptional precision in mass production. This is achieved through advanced manufacturing technologies and a rigorous quality control system, ensuring each Pogo Pin meets design specifications and minimizing errors in the production process.

- Stability and Durability: By using high-quality materials and optimized designs, Johoty’s Pogo Pins are known for their durability and stability. They perform consistently well even with prolonged use and frequent insertions and removals, reducing the risk of failures due to wear and tear.

- Efficient Production Capability: Johoty’s production lines are optimized for efficiency. The use of automation and streamlined processes allows for the rapid completion of large production volumes, improving both production speed and delivery times.

- Cost Control: Johoty effectively manages production costs in large-scale manufacturing. Bulk purchasing of raw materials and optimized production processes help lower unit costs, allowing the company to offer competitive pricing to clients.

- Customizable Services: Johoty offers flexible customization options, adjusting the design and specifications of Pogo Pins according to specific client needs. This customization capability enhances market adaptability and meets diverse customer requirements in mass production.

- Strict Quality Testing: Johoty keeps a close eye on quality at every step of making our products. Each batch of Pogo Pins undergoes multiple tests and inspections to ensure the final products meet high quality and reliability standards.

- Eco-Friendly Production: Johoty is committed to environmentally friendly manufacturing practices. The company uses materials and processes that comply with environmental standards, minimizing the environmental impact of production and supporting sustainable development in large-scale manufacturing.

Pogo Pin Production Process of Mass Production

- Precise Material Selection and Inspection: Johoty meticulously selects high-quality raw materials for Pogo Pin production and conducts a series of rigorous inspections to ensure each material meets purity and conductivity standards, laying a solid foundation for the subsequent processes.

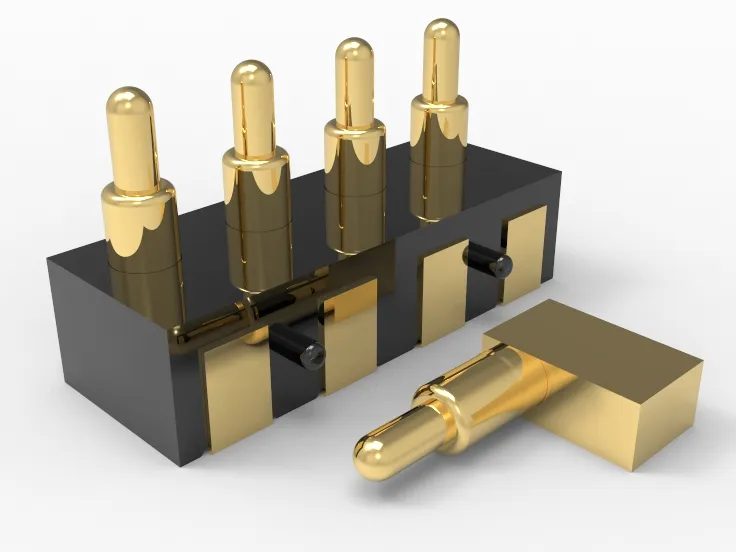

- Automated Lathe Machining Technology: Using advanced CNC automated lathes, Johoty precisely machines each Pogo Pin component, ensuring dimensional accuracy and surface smoothness to micron-level precision, which guarantees high product consistency.

- Efficient Plating Process: Johoty employs environmentally friendly and efficient plating techniques to apply metal coatings to the contact surfaces of Pogo Pins. This boosts their ability to conduct electricity, resist wear, and fend off corrosion, making them last longer and stay reliable.

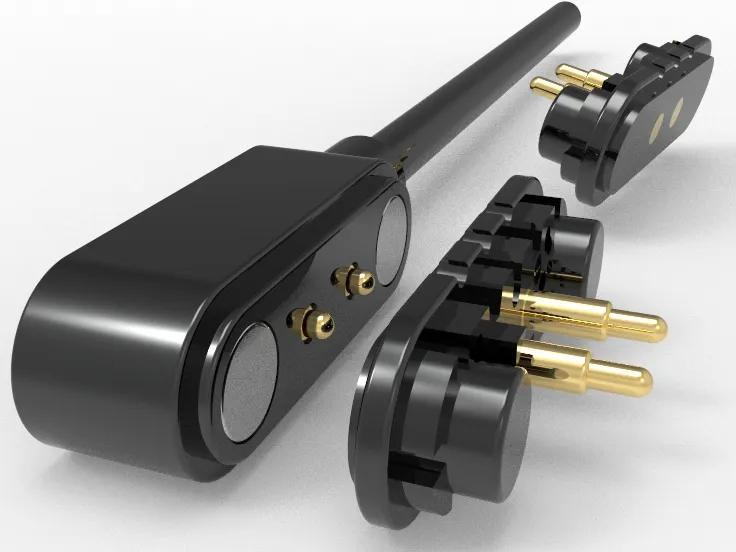

- Precision Spring Design and Manufacturing: Johoty integrates specialized pressure control techniques in the design and manufacturing of springs, ensuring each Pogo Pin’s spring provides stable contact force for reliable long-term connectivity.

- Comprehensive Quality Control System: Johoty uses fully automated quality control systems at every stage of mass production to continuously monitor the parameters of Pogo Pins, ensuring that every product meets standards and preventing defective items from reaching the market.

- Innovative Welding Technology: Johoty’s welding process combines ultrasonic and laser welding techniques to ensure secure connections between Pogo Pin components, enhancing the product’s tensile strength and durability.

- Cleanroom Assembly and Testing: In a dust-free environment, Johoty performs precise assembly and functional testing of each Pogo Pin, ensuring stability and reliability in various operating conditions before final delivery.

Features of High-Quality Pogo Pins Under Mass Production

- Precision Manufacturing: Johoty uses advanced precision machining techniques to ensure that each Pogo Pin’s contact point error is controlled to the micron level, guaranteeing stable and consistent signal transmission.

- Exceptional Durability: Johoty’s Pogo Pins are manufactured under strict quality control, with each pin designed to endure over 100,000 insertions and removals without failure.

- Outstanding Corrosion Resistance: Made with premium materials and advanced plating technology, Johoty’s Pogo Pins offer excellent oxidation and corrosion resistance, making them suitable for long-term use in harsh environments.

- Stable Contact Resistance: The precision-engineered spring structure and high-quality gold plating ensure that Johoty’s Pogo Pins maintain stable contact resistance even after prolonged use, ensuring efficient current transfer.

- High Temperature Tolerance: Special heat treatment processes allow the Pogo Pins to retain their mechanical properties without deformation in high-temperature conditions, making them ideal for hot environments.

- Excellent Current Carrying Capacity: Rigorous testing confirms that Johoty’s Pogo Pins can handle high currents, making them suitable for applications with high current density.

- Even Coating Thickness: Advanced plating techniques ensure that each Pogo Pin has a uniform and thick coating, enhancing contact reliability and wear resistance.

- Precise Spring Rebound Control: Johoty meticulously adjusts the spring’s rebound force during mass production to ensure that each Pogo Pin maintains good contact force during insertion and removal.

- Ultra-Low Contact Resistance: Optimized contact surface design reduces resistance, ensuring efficient electrical performance.

Cost Reduction Strategies Based on Mass Production

Procurement Strategies of Mass Production:

- Supplier Management: Build long-term partnerships to ensure suppliers consistently provide high-quality materials.

- Bulk Purchasing: Lower per-unit material costs by buying in large quantities.

- Supply Chain Integration: Simplify the supply chain by removing middlemen to lower expenses.

- Cost Transparency: Require suppliers to provide a clear breakdown of costs for better cost control.

- Regular Evaluations: Periodically assess suppliers to ensure they meet quality and cost standards.

- Technology Upgrades: Invest in advanced technology to boost mass production efficiency and lower costs.

- Inventory Management: Manage your inventory better to avoid spending too much on surplus goods.

- Demand Forecasting: Use accurate forecasts to refine mass production schedules and purchasing volumes.

- Logistics Optimization: Improve logistics management to reduce transportation and storage costs.

- Quality Control: Strengthen quality control to minimize rework and returns, thereby cutting overall costs.

Production Optimization of Mass Production:

- Automated Production Lines: Integrate automation and efficiency into large-scale Pogo Pin production.

- Precise Material Management: Improve how you use materials and reduce waste to cut down on production costs.

- End-to-End Digital Control: Keep an eye on production and quality as it happens to cut down on mistakes.

- Process Optimization: Shorten production cycles and increase line flexibility to handle different specifications.

- Economies of Scale: Reduce the cost of making each Pogo Pin by ramping up production in bulk.

- Efficient Equipment: Use energy-efficient and low-maintenance equipment for greener production.

- Total Quality Management (TQM): Optimize mass production efficiency while maintaining high-quality standards for Pogo Pins.

- Strategic Supply Chain Integration: Collaborate with upstream suppliers to lower procurement costs.

- Continuous Improvement Plan (CIP): Keep improving your processes to make things run smoother and save money.

Customer Success Stories Based on Mass Production

Reducing Part Waste:

- For a globally renowned smartphone manufacturer, Johoty’s high-quality Pogo Pins significantly cut down on part waste during production. Thanks to their consistent contact force and low failure rate, the manufacturer reduced part replacement costs by 10%, ensuring smooth and stable production lines while boosting overall efficiency.

Boosting Production Efficiency:

- A leading electric vehicle maker achieved a 30% increase in production efficiency using Johoty’s Pogo Pins on their large-scale assembly line. The durability and easy integration of these pins helped the manufacturer cut down on downtime and repair costs, allowing them to quickly meet market demands and enhance market share.

Optimizing Supply Chain Management:

- Johoty’s Pogo Pins helped a top global medical device company streamline their supply chain with custom designs and bulk production support. With superior quality and high delivery accuracy, the company reduced procurement costs by 15%, shortened product time-to-market, and improved market competitiveness.

Future Outlook of Mass Production

- Innovative Manufacturing Technology to Cut Costs: Johoty’s advanced Pogo Pins technology effectively lowers production costs per part while maintaining quality, greatly enhancing your production efficiency.

- Precise Design and Outstanding Performance for Mass Production: Johoty’s Pogo Pins excel in large-scale manufacturing with their precise design and top-notch performance. They reduce downtime caused by component failures, which helps lower overall mass production costs.

- Durable and Cost-Effective for Long-Term Maintenance: Thanks to their durability and high reliability, Johoty’s Pogo Pins minimize equipment maintenance frequency, reducing long-term operational costs and boosting economic benefits for businesses.

- One-Time Investment for Long-Term Savings: Investing in Johoty’s high-quality Pogo Pins is a smart move for the future. Their exceptional performance not only saves initial costs but also delivers ongoing savings over time, enhancing your competitive edge.

- Boosting Future Production Efficiency and Gaining Market Advantage: Johoty’s Pogo Pins support efficient mass production, reduce waste and resource consumption, helping you stay ahead in the competitive market and quickly respond to demand, maximizing profits.

- An Ideal Choice for Lean Manufacturing: By choosing Johoty’s Pogo Pins, businesses can streamline production processes, eliminate unnecessary steps, cut production costs, and move towards more efficient and sustainable manufacturing practices.

Conclusion:

- Johoty understands that reliable components are essential for efficient mass production. Our Pogo Pins not only meet industry-leading quality standards but also offer unparalleled cost control advantages. With optimized mass production processes and strict quality control, we help you significantly reduce procurement costs while maintaining excellent quality.

- Our approach goes beyond technology and incorporates a deep understanding of market needs. Through precise mass production planning and large-scale material procurement strategies, we ensure each batch of Pogo Pins meets the highest standards.