Key Insights Into Pogo Pin Plunger Tip: Shape, Function, Top Benefits. Learn How They Enhance Design Reliability and Precision in Electronics

Introduction: Unlock the power of pogo pins to enhance flexibility and reliability of engineering design

How to ensure efficient and stable electrical connections in engineering design? Why are pogo pins becoming the preferred choice for more and more engineers? What is the profound impact of plunger tip shape on connection quality? How can it enhance your design flexibility and product reliability?

This blog will answer these key questions one by one, delve into the shape and function of pogo pin plunger tip. And, reveal their top advantages in improving testing accuracy, reducing maintenance costs, and enhancing connection stability. Through these in-depth insights, you will master how to fully unleash the potential of pogo pin in engineering design and optimize your design process.

Read: Flat Bottom SMT Pogo Pins

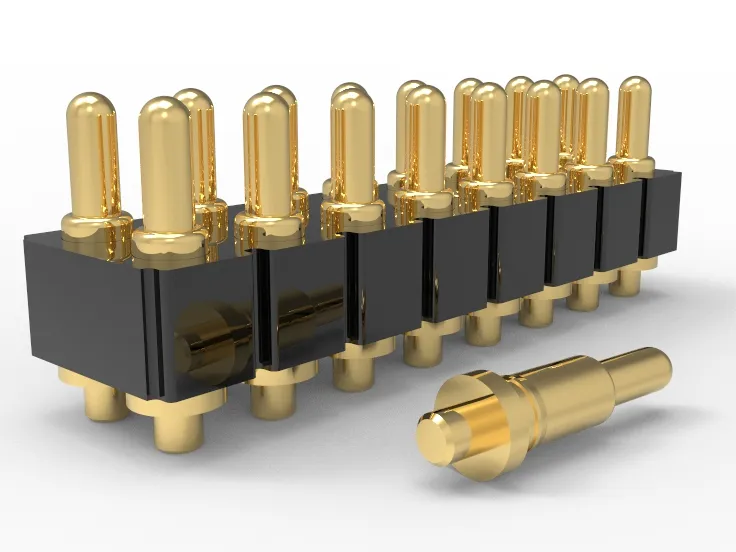

Plunger Tip Shape Designed For Different Performance of Pogo Pins

Circular plunger tip:

The design of the circular plunger tip is simple and the contact surface is uniform, making it suitable for routine circuit connection. It can evenly distribute pressure and is commonly used for smooth connections and good contact performance. It can smoothly contact the soldering point and reduce connection errors caused by improper contact. Electronic devices using circular plunger tips can provide high stability. At the same time, clients can always enjoy reliable super electrical connections in the equipment. It is very good in terms of reliability and stability in connections.

Flat head plunger tip:

Flat head plunger tip has a large horizontal contact surface, which can evenly distribute pressure and is suitable for connecting multiple contact points. In the detection of batteries and capacitors, the contact results are very accurate. It can reduce damage caused by uneven contact, increase contact area, and improve contact stability. Customers can withstand connections with high currents by using flat headed plunger tips. Can improve the consistency and accuracy of connections, applied to industrial equipment.

Read: 12 pin connector

Sharp tip plunger tip:

A pointed tip plunger tip is suitable for small or narrow contact points, which can concentrate pressure and ensure a more stable contact point. It is very effective in connecting micro components and can achieve precise contact in small spaces. Diamond coating or ceramic coating can enhance the wear resistance and corrosion resistance of the tip. The pointed plunger tip can be divided into different angles, commonly including 30°, 60°, 75°, etc. Customers can improve the success rate of microstructure connections, reduce contact errors, and achieve higher accuracy through this type of plunger tip. It can effectively handle applications with fast response and minimal contact area.

Star head plunger tip:

This design has a multi-faceted shape to ensure stronger gripping force and is commonly used for connecting deep holes or small pins. Each contact surface can automatically adjust according to pressure, providing uniform pressure distribution in the case of high-density components or multi-point contact. After using the star tip plunger tip, it can provide good contact force on different contact surfaces simultaneously. It can enhance gripping power, reduce sliding phenomena in connections, and connect high-density circuit boards. Customers can achieve higher connection stability and accuracy through this design. It ensures a more secure contact in applications that require high grip.

Read: High Current Pogo Pins

Concave head plunger tip:

The concave design of this plunger tip concentrates the contact force and can accurately adapt to the target connection point. Johoty can design multi-level concave shapes with different depths and shapes to accommodate contact points of different sizes and heights. Its unique shape helps reduce damage to the contact points and improve the high performance of the connection. Its micro conductive structure can improve the conductivity efficiency of contact, reduce current loss, and is commonly used for high-frequency signal transmission, stable current and signal transmission. By using this plunger tip, customers can ensure higher connection accuracy and reliability. To avoid errors and achieve higher connection stability and quality.

Cone head plunger tip:

This type of plunger tip gradually becomes pointed, which can accurately locate the contact point and reduce errors during contact. It perfectly use in narrow or complex spaces and can accurately enter connection points. Its spiral pattern can effectively increase friction when the tip is in contact with the connection, preventing the plunger tip from slipping. Its ability to withstand lateral forces ensures stable contact, making the connection more accurate. Commonly used for high-precision connections of small holes and uneven surfaces. Customers can improve accuracy in micro connections when using conical head plunger tips. It performs excellently in high-precision applications.

Read: Double Ended Pogo Pin

Claw head plunger tip:

The design of the claw head plunger tip features multiple sharp claws that provide strong grip. Each claw has a small gap, allowing it to finely adapt to pins or components of different sizes. The claw head can also adopt a special spring mechanism, which can automatically adjust the clamping force to prevent excessive pressure from damaging the components. It is suitable for equipment that requires higher mechanical fixation force for vibration or external impact, and can avoid poor contact and sliding. By using pogo pins with claw head plunger tips, customers can achieve higher gripping force and stability, improving the success rate of connections.

Cup head plunger tip:

The design of the cup head plunger tip helps to wrap around the connection point, providing a larger contact area, and is particularly suitable for surface connections. There are depths and different edge shapes that help enhance the stability of the contact surface and soldering points. It can effectively reduce damage to contact points and improve the performance of device connections. Customers can achieve higher stability and accuracy when using it. When connecting large-area circuits, it can reduce errors and better absorb and distribute pressure. It can adapt to connection points of different shapes, providing higher flexibility and connecting irregularly shaped components.

Read: Solder Cup Pogo Pin

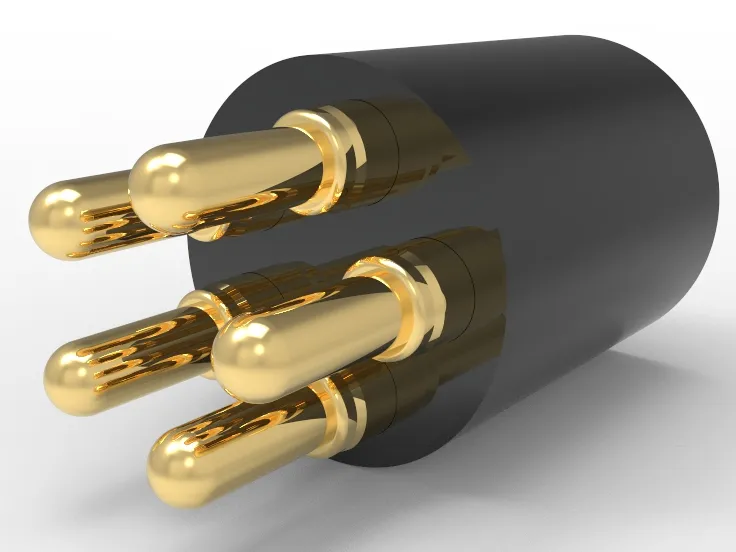

Ball head plunger tip:

The ball head design can adapt to lateral forces and is very suitable for connecting on uneven or sloping surfaces. Ball bearings can roll between the plunger tip and the contact point, reducing contact wear. Its design ensures that the contact point automatically adjusts its angle with changes in pressure, thereby maintaining stable contact force. Ball bearings can self adjust according to different pressure connections. It can maintain a continuous and stable connection in high dynamic contact. After using ball head plunger tips, the device can exhibit stable connection in constantly changing directions and force levels of movement. Customers achieve better reliability and accuracy in complex connections.

Customized head plunger tip:

Custom plunger tip is customized according to customer needs and can automatically adjust pressure or have built-in temperature sensors. Johoty can be specially designed for high temperature or ultra small size, suitable for connecting electronic components with unique requirements. Johoty’s customized plunger tip can provide the best solution for contact points with special shapes and specific environmental requirements. After using customized head plunger tip, customers can avoid the limitations encountered when using standard plunger tip, greatly improving connection efficiency.

Pogo pin multiple advantages for engineers

Efficient and reliable connection

Pogo Pin can quickly establish stable connections between different circuit boards. When engineers are conducting design and debugging, pogo pin can quickly make contact with the connection point. This can ensure smooth current transfer and avoid the complex welding connections. The design of pogo pin has more automatic docking function, which allows devices to connect and disconnect in very short time. In this way, engineers can save a lot of time, greatly reduce the complexity of manual operations, and improve work efficiency. At the same time, pogo pins help effectively reduce the possibility of connection issues during debugging.

Accurate contact and pressure control

Internally designed with springs, constant pressure can be applied at the contact points. Able to adapt to minor surface irregularities and ensure optimal performance with each contact. This design is crucial for maintaining the stability of the current and the reliability of the connection. For engineers, this precise contact control can effectively avoid interference in signal transfer. They don’t worry about poor contact when designing circuits. In high-frequency signal testing and sensitive circuits, it can reduce errors and improve accuracy.

Durability and long lifespan

The material and design of pogo pin ensure its durability and effectively reduce wear and friction between connectors. The standard lifespan is greater than 10,000 cycles, and special designs can reach 200,000 cycles. After repeated plugging, it can maintain good contact performance. Compared to other connectors, pogo pin can withstand more insertions without being easily damaged. For engineers who require frequent circuit testing and debugging, this is very helpful. The long lifespan of pogo pin can effectively reduce replacement, saving costs and time.

Read: Right Angle Pogo Pins

Strong adaptability, easy to customize

Johoty can customize according to different needs, and we support multiple sizes, shapes, and contact methods. Very compact and flexible, able to adapt to various design needs. Small size and high adaptability, suitable for compact devices and circuits that require high-density connections. This provides engineers with a high degree of flexibility to select the most suitable pogo pin based on circuit design and testing requirements. Precise micro devices, larger circuit boards, and Johoty’s pogo pins can all be easily adapted.

Improve work efficiency and reduce errors

The use of pogo pin can reduce the potential for weak welding and short circuits that may occur during traditional welding processes. It can effectively reduce signal interference caused by poor contact and provide more stable performance. When conducting testing or debugging, pogo pin can quickly connect through simple contact. Design and use more intelligent, without manual intervention. Avoiding hardware damage or errors caused by improper operation. This undoubtedly improves the work efficiency of engineers and reduces debugging costs.

Simplify the production process

In the mass production of products, pogo pin can reduce manual welding steps and minimize human errors in the production process. Its design makes the product easier to use and reduces connection errors caused by manual contact. For engineers, this means simplifying and accelerating production process, and this intelligent design makes work more reliable. It can improve production efficiency, enhance product consistency and quality.

Read: Threaded Pogo Pins

Case study: Why do engineers favor Johoty’s Pogo Pin?

Quick Connection in Electronic Devices

Pogo Pin is used as a tool for quick connection on smartphones, laptops, and smart wristbands. Johoty’s Pogo Pin provides stable electrical connections, ensuring efficient signal transmission even when the contact surface of the device is very limited. Engineers favor it because this Pogo Pin can quickly and accurately transmit current or signals without excessive physical contact. In this way, it reduces the risk of poor contact, thereby improving the reliability of the product.

Application in Automated Production

In industrial automation, Pogo Pin is used for interface connection between robots and automation equipment. Compared to traditional connection methods, the flexibility and efficiency of Pogo Pin greatly reduce maintenance costs and improve the intelligence level of the production line. In highly automated production lines, ensuring the stability and reliability of connections is key to ensuring production efficiency. Due to its high durability and adaptability, Johoty’s Pogo Pin can maintain stable connectivity in environments with prolonged high-frequency use. This is very important for engineers in Europe and America,

Accurate interface design in wearable devices

Wearable smartwatches, health monitoring instruments, etc. require very precise and stable electrical interfaces. The application of Johoty’s Pogo Pin in these small devices greatly optimizes space utilization and ensures stability during long-term use. Engineers prefer this design because it not only saves valuable internal space. At the same time, the device still has accurate power supply and data transmission functions during long-term wearing. This is crucial for wearable devices’ performance improvement and continuous development.

Read: Bending Pogo Pin

Conclusion: Why Johoty is your best choice

Engineers often face many challenges when choosing a pogo pin that is suitable for your project’s plum tip. Johoty stands out as the preferred choice for engineers due to its profound technical accumulation and high-quality pogo pins.

Firstly, Johoty’s pogo pin’s plunger tip is designed with precision and reliability in mind, ensuring stable operation in high-frequency and complex circuits. Secondly, our customization allows engineers to choose the appropriate size, shape, and material according to specific needs, meeting the strict requirements of different applications. We have 23 strictly controlled production processes to provide high-quality and long-lasting pogo pin connectors. We can ensure that every pogo pin can minimize system failures and improve engineering efficiency to the greatest extent possible.

By choosing Johoty, you can receive top-notch technical support and enjoy fast response and flexible delivery services. Choosing Johoty means you have chosen a precise, stable, and efficient solution to take your project to the next level. Contact Johoty immediately to experience the advantages of the preferred brand for engineers and ensure the success of your project!

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656