Pogo Pin Cable Optimizes Your Connections. 5 Top Solutions for Reliability, Durability, Efficiency. Choose Johoty for Quality Custom Options

Introduction: Uncovering Technical Appeal of Pogo Pin Cable

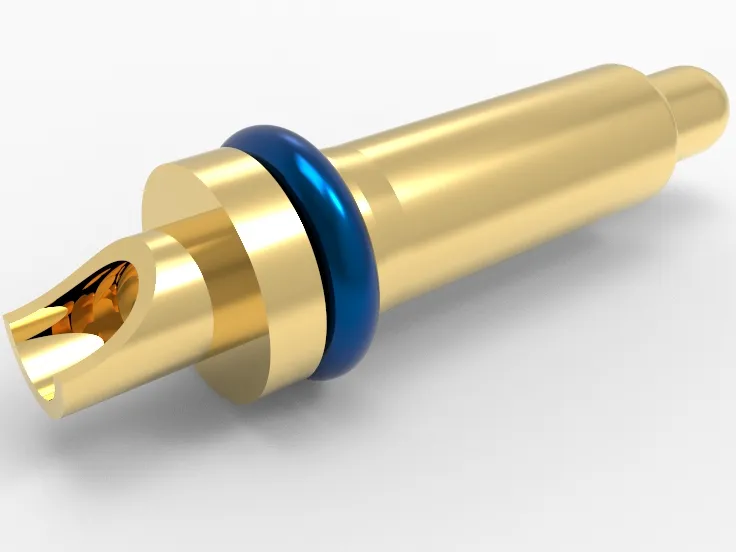

In electronics and precision engineering, engineers often ask Johoty for reliable connection solutions. Pogo pin cable, an innovative connector, has become engineers’ preferred choice because of its excellent contact stability and durability. It is suitable for high precision, high frequency and stable connections in consumer electronics, medical devices, automation equipment and more.

So what makes pogo pin cable so unique and compelling? First, it utilizes a spring-loaded contact design that ensures a stable electrical connection under vibration and tension. Secondly, pogo pin cable is customized to meet different needs, providing engineers with a high flexibility. It is in terms of interface shape, number of pins, rated current, spring force, and environmental adaptability.

Here Johoty will discuss 5 optimized connection solutions of pogo pin cable. It will help engineers to better understand how to improve connection efficiency and solve practical problems in engineering. More and more engineers are choosing Johoty’s pogo pin cable as core connection component in their projects. Let’s show you how to maximize value of these innovative technology solutions in engineering. Improve the performance and stability of your entire project.

Johoty can flexibly custom pogo pin cable to connector USB Connector, magnetic connector, board-to-board, FPC, wire-to-board, coaxial, docking station, battery. RF, waterproof, HDMI, RJ45, audio jack, power, sensor, LED, smartwatch, DIN, SMA, modular, JST, Molex, banana plug, alligator clip. BNC, micro-USB, type-c, lightning, barrel, terminal block, mini-USB, displayport, VGA, D-sub, RJ11, XLR, TRS/TRRS. SPEAKON, M12, M8, Anderson, Phoenix, MC4, Deutsch, circular, mini-DIN, SCSI, PCIe, Edge connector.

Read: Waterproof Magnetic Connector + Cable

Five solutions for optimizing Pogo Pin Cable connections

Optimization of contact force and contact life for improved connection reliability

Material selection and surface treatment

High-quality contact materials and surface finishing are key to improving contact force and contact life. The selection of highly conductive gold, silver or nickel plating can effectively reduce contact resistance and improve signal transfer quality. PVD or chemical gold plating in surface finishing can enhance wear and oxidation resistance of contact point, prolong service life.

Precise contact force control

Contact force directly affects connection effect of pogo pin cable. Precise spring design and mechanical optimization ensure pogo pins maintain proper contact force during insertion and removal. This precise control prevents contact points from becoming too loose or tight, thus reducing wear and prolonging product’s effective working life.

High Temperature & Frequency Adaptability

In high temperature & frequency, contact force and contact life of pogo pins may be significantly reduced. Therefore, high-temperature materials and optimized design ensure connection maintains good contact performance under extreme conditions. This is an effective means of improving connection reliability. Thermally stable springs and conductive materials with good high-frequency characteristics significantly improves system stability at high temperatures and high frequencies.

Vibration and shock resistant design

In industry, pogo pin cable is often exposed to frequent vibration and shock. To ensure connection stability, pogo pins are designed to be vibration-resistant. Pogo pins are secured by increasing springs’ compression resistance or by using a special structural design. Yes, it can avoid vibration-induced contact failures and thus increases connection reliability.

Environmental encapsulation and protection

To minimize external contaminants impact on contact points, Johoty often employs environmental encapsulation techniques. Sophisticated encapsulation design prevents dust, moisture, other corrosive substances from entering connection system. ip67 waterproof can effectively prolong contact life and increase reliability. Waterproof and dustproof design enhances connection durability and protects system in harsh environments.

Read: 2 Pin Connector + Cable

Choosing high-quality insulation: Reducing signal interference

Insulation materials

Pogo pin cable, as precision connecting components, needs to work stably in high frequency, low impedance environments. Reduce dielectric loss, reduce energy loss in high frequency signal transmission, improve signal integrity. Enhance anti-interference, shielding external EMI, prevent signal attenuation. Improve durability, high temperature and aging resistance for long-term stability.

High Quality Insulation

Johoty designs pogo pin cable with high-performance insulating materials: PTFE, which has a low dielectric constant and extremely low signal loss for high frequency applications. FEP, which is highly flexible and chemically resistant and is commonly used in medical and high end industrial equipment. PFA, which is more resistant to high temperatures than PTFE and is suitable for harsh environments. LCP is low hygroscopic and suitable for miniaturization and precision connection needs. LCP, extremely low moisture absorption, suitable for miniaturization and precision connection needs.

Key Parameters for Insulating Materials

Dielectric constant Dk, the lower the value, the better to reduce signal delay and improve signal stability. Loss Factor Df, which determines the amount of signal loss. Low Df materials are suitable for high-speed data transmission. Thermal stability determines the material’s resistance to deformation in high temperature environments, ensuring stable connections. If mechanical strength is high, material can resist bending, wear and tear, and adapt to complex application environments.

Optimization of insulation materials for pogo pin cable

A U.S. engineering company was using conventional PVC insulation for high-speed data transfer, which resulted in EMI interference and degradation of signal integrity. Replacing the insulation with Johoty’s PTFE insulation reduced signal degradation, increased transfer rates and improved durability by 30%. For subsequent projects, client requested Johoty’s pogo pin cable to be miniaturized with lower loss, higher temperature resistant insulation. We also continue to research high performance LCP, PFA, and PEEK to optimize connection performance and extend equipment life.

Read: 3 Pin Connector + Cable

Customized Designs: Meeting Different Engineering Needs

Why Customized Pogo Pin Cable?

Standard pogo pin cable has limitations in size, contact pressure, spring life, etc. Johoty optimizes signal transfer by requiring different resistance for different frequencies, reducing signal degradation. Enhanced durability with materials and coatings to increase resistance to wear and tear and longevity. Improved structural fit, precisely matched to equipment interfaces, reducing connection losses and improving assembly efficiency.

Key Factors in Customizing Pogo Pin Cable

Designing pogo pin, adjusting its diameter, pitch, length, spring force, stroke, rated current, optimizing contact performance. Gold plating, palladium-nickel, rhodium-ruthenium, composite plating enhance electrical conductivity, high temperature resistance, seawater resistance, corrosion resistance. Optimized spring force and customized spring stiffness ensure stable contact pressure and avoid signal interruption. For cable material, Johoty usually chooses high quality silver-plated copper wires to reduce resistance and improve data transfer efficiency. PTFE, PEEK, LCP are used for high temperature resistance and low loss to improve environmental adaptability.

Customized Case

A German medical device company uses pogo pin cable for high-precision diagnostic instruments. Standard solution couldn’t meet low signal noise and high durability. Therefore, client contacted Johoty to customize pogo pin with palladium-nickel plating to reduce signal loss. FEP improves chemical resistance, and Johoty designed 50gf spring force pogo pin to reduce contact wear and increase durability by 40%. The result is to dramatically improve signal stability and extend device lifespan.

In subsequent pogo pin cable customization, client often used pogo pin connector to solder cable, then connect to Molex or Amphenol’s high end connectors. Johoty fully supported our client to realize modular pogo pin cable solutions to adapt to different device interfaces. Most of them are miniaturized high-density connectors for precision electronics and wearable devices. Meanwhile, we also optimize the connection parameters through AI to improve the efficiency of data transfer.

Read: 4 Pin Connector + Cable

Environmental Adaptability: Enhanced Water, Dust and Shock Resistance

Challenges:

Wet environments, underwater, around seawater, water vapor infiltration can lead to short circuits, corrosion and affect signal transfer. Dust accumulation will increase contact resistance, leading to signal attenuation and even connection interruption. Frequent vibration will lead to connector loosening and poor contact, affecting normal operation of the equipment.

Solutions:

To enhance waterproof performance, Johoty uses high grade IP67 or IP68 waterproof connectors to prevent water vapor penetration. Use waterproof sealing rings and sealant, add sealing rings and sealant at the connector interface to further block water vapor intrusion. Optimize cable jacketing material, choose TPU or silicone with excellent waterproof performance to prevent water vapor from penetrating through cable jackets.

Enhance dustproof capability, choose dustproof connectors with dustproof cover or sealing structure to effectively block dust entry. Optimize contact structure, using self-cleaning contacts or dustproof design to reduce dust impact on the contact. Regularly clean dust on connector surface to keep connector clean.

Strengthen anti-vibration performance, choose connectors with locking structure or anti-vibration design, to ensure that pogo pin connector maintains stable connections in vibration environment. Optimize pogo pin cable fixing method, use strain relief devices or fixing clips to prevent cable from loosening due to vibration. Johoty always conduct vibration tests, simulate actual use environment, conduct vibration tests to ensure connector’s performance is stable under vibration environments.

Advantage:

Improve connection reliability and environmental adaptability. Reduces connection failures due to moisture, dust and vibration, ensuring stable equipment operation. Extends the service life and protects the connector from environmental factors. Extends connector life and reduces maintenance costs. Expand application areas of pogo pin cable by meeting extreme environments.

Read: 5 Pin Connector + Cable

Integration and Automation Design: Improving Productivity

Seamless Integration of Pogo Pin into Automated Equipment

Tightly integrated into automated production lines, pogo pin cable can be connected multiple times at high frequencies without human intervention. Using advanced sensors and control systems, the automation equipment monitors connection status in real time. This ensures stable and accurate connections and greatly increases productivity.

Reduced manual operation and human error

In traditional manual connection methods, operators may cause connection problems due to operational errors or fatigue. This affects performance and reliability of clients’ products. With automated design, pogo pin cable won’t rely on manual operation in connection process. It reduces human error and ensures every connection can meet high standards.

Improve system reliability and consistency

Automated design can improve productivity and enable consistency from connection to connection. Guests feedback that it avoids variables due to manual operation. In high frequency testing, data transfer, and precision assembly, pogo pin cable connection stability and reliability have been dramatically improved. This significantly enhances system overall performance.

Shorter Production Cycles

Automated machines perform connection tasks quickly and precisely, significantly reducing production cycle times. By optimizing connection design of pogo pin cable, engineers can achieve higher production speeds. At the same time, product quality won’t be compromised. With increased productivity, overall production costs are reduced.

Flexible multi-device compatibility

Modern automated production lines often need to support various devices and connectors. pogo pin cable is highly flexible and perfectly compatible with diverse connection systems. It can easily use for various applications. This compatibility makes it ideal for multiple automation scenarios.

Read: 12 Pin Connector + Cable

Why choose Johoty for customized pogo pin cable?

High Precision Engineering

Johoty is committed to providing customers with high precision pogo pin cable solutions. Each cable is carefully engineered to work stably under high frequency, high voltage and prolonged usage. Our pogo pin cable is suitable for various engineering applications with high precision and reliability.

Versatile customization options

Unlike typical connection solutions, Johoty offers flexible and perfect customization. Whether specific length, performance, material or connection form, Johoty can create suitable pogo pin cable for you. It’s to ensure perfect alignment with your engineering design, your factory’s mass production, and your customer’s pleasure.

Quality Materials and Manufacturing Process

Johoty utilizes the most appropriate high performance materials and advanced manufacturing processes. Each pogo pin cable is highly durable and resistant to interference. These cables are able to maintain efficient transfer in harsh environments and adapt to diverse industrial applications.

Strict Quality Control

Johoty has complete quality control where each pogo pin cable undergoes rigorous 23-step testing and quality inspection. These measures ensure the stability, durability and efficiency of the connection to meet your precision equipment.

Fast Response and Technical Support

With Johoty, you will enjoy prompt technical support from professional CFT team. Whether it’s during prototype, design phase or the use of pogo pin cable, Johoty provides fast and professional service. We follow strict contract and quality standard to ensure your project goes smoothly.

Read: 7 Pin Connector + Cable

Conclusion: The Key to Improved Connectivity, Choose Johoty’s Pogo Pin Cable

Choosing Johoty’s pogo pin cable is not just a decision to improve connection performance, it’s the key to ensuring efficient, stable, and long-lasting operation. From precision design to superior durability, our pogo pin cable provides the ideal solution for your project. Whether you’re working with high frequency circuits, complex signaling, or harsh operation, Johoty has you covered with reliable connections.

Purchase Johoty’s pogo pin cable today to optimize your connections and enhance overall performance of your project. Add reliability and precision to your engineering designs and choose Johoty for excellence.