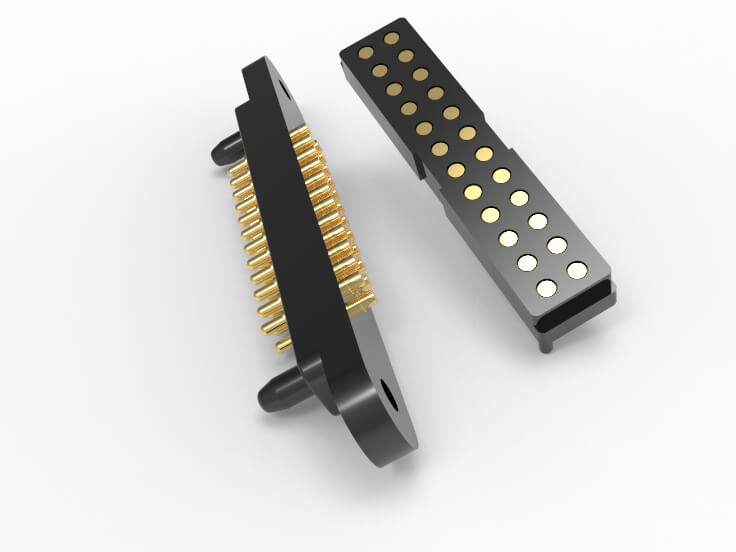

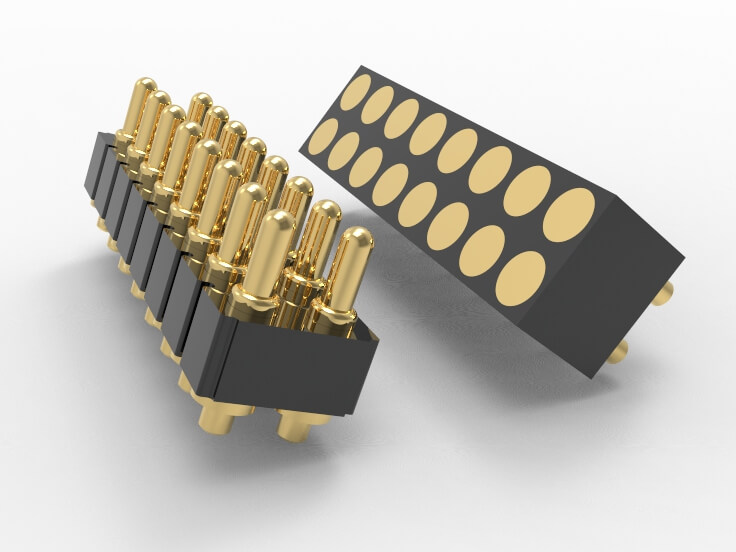

Best Pogo Pin Connectors China Manufacturer Multiple Pins

Features:

- High-precision pogo pins ensure stable electrical contact.

- Long-life design, supporting >10,000 operation cycles.

- Ultra-high-density layout for compact design requirements.

- High-temp, earthquake-resistance for extreme environments.

- Automatically clean plunger tip to keep high performance.

- High-speed signal transfer for high-frequency applications.

Pogo Pin Connectors Series

Pogo pin connectors series has 12 categories, Johoty’s clients often customize multiple functions in one connector:

- Ultra-high density: Pitch <1.27mm, supports precise arrangement of hundreds of pogo pins, designed specifically for multi-point connections in extremely small spaces. Used for high-frequency communication, micro-devices, smart wearable devices, and medical sensors.

- High-temperature durable type: Maintains stable electrical contact and spring compression performance at+250℃. Used for aerospace and military equipment that require high-temperature stability.

- High frequency and high-speed data transfer: low impedance, reducing signal loss and delay, used for high-performance computing, 5G communication, and high-definition image transfer.

- Self-cleaning type: Automatically cleans contact points to reduce oxidation and pollution, used for automated testing and medical equipment.

- Waterproof and dustproof: IP67, IP68 waterproof, Used for outdoor equipment, industrial control, and ocean exploration.

- Magnetic type: magnetic assisted docking, automatic engagement, precise docking, and stable connection, used for wireless charging, high-frequency electronics, medical equipment.

- Waterproof magnetic connector: Combination of waterproof and magnetic technology, used in automotive electronics, outdoor, industrial, and medical equipment.

- Ultra small: Extremely small size and compact design, used for wearable devices, portable electronic devices, sensor systems.

- Seismic resistant type: Maintains good electrical contact under severe vibration or impact, used for military, automobiles, and aerospace.

- Low resistance type: Designed with low contact resistance to ensure low power consumption during high current transfer, used for BMS, high-power equipment, and energy transfer systems.

- Multi-functional integrated type: Data transfer, power connection, signal detection, etc., reducing the number of connectors, used for high-end electronic products and intelligent hardware.

- Ultra-durable: Made of highly corrosion-resistant materials that maintain excellent performance for a long time, used in the oil and gas industry, chemical equipment, and medical instruments.

| Category | Description |

|---|---|

| Overview | Pogo pin connectors achieve high-density and high-precision electrical connections of 9-598 pins through a spring structure. Support more touchpoints and complex signal transfer. Addressing engineers’ concerns about small space design, vibration and impact resistance. |

| Target Customers | Customers require high-density & precision connectors to support complex circuit designs and stable transfer of high-frequency & speed signals. High-temp, vibration, impact resistance, reliable operation in harsh. High reliability, resistance to environmental interference, ultra-high density connection design. High current & voltage ensure reliability & safety of electrical connections. |

| Applications | Applied to micro connectors, ultra-small sizes, and flexible designs. High-frequency signal exchange and ultra-high density connection. High current/voltage supports safe and stable connection. High reliability, temperature resistance, anti-interference in extreme uses. High precision electrical connections, reliability and safety in harsh environments. Anti-vibration, shock resistant, high-speed data transfer. High precision and high-frequency signals ensure accuracy of test data. |

| Raw Materials | Spring steel SAE 1070/1074/1095, AISI301. Copper alloy: Beryllium copper C17200, phosphor copper C19400, oxygen-free copper C11000. Gold plating, silver, nickel, CoAu, Palladium, platinum, rhodium, ruthenium, Composite coating. Plastic shell: PBT, LCP, PP, PA, PI, PC, PEEK, etc. Stainless steel: AISI 304/316/316L, etc. Johoty can provide complete customization. |

| Function Specs | Ensure stable contact pressure and electrical connections, support more pogo pins, and provide higher signal channel density. Maintain stable contact pressure through repeated connections. Seismic and impact resistant, adaptable to extreme temperatures and humidity, support lossless transfer of high speed & definition signals. High-quality conductive materials and finishing can reduce contact resistance significantly, and greatly improve electrical performance. Flexible customization. Gold plating, silver, or composite electroplating enhance oxidation and corrosion resistance. Quick connection and disassembly, high load-bearing. |

| Brand Info | Johoty is a leading enterprise dedicated to researching and manufacturing high-precision pogo pin connectors. Committed to providing high-performance perfect solutions to global clients. High quality, the best quotation that matches the quality, professional customized services, fast and safe delivery are our core strengths. |

| Price Range | From $0.1 to $100, Different qualities, specifications, quantities, and delivery will have different prices. There will always be discounts for large quantities. |

| Quality Standards | Quality, environment, Safety, RoHS, REACH, IATF, CE, IEC, IPC, ASTM, etc. |

| Where to buy | Please find our E-mail (cft@johoty.com), WhatsApp (+86 18007608187) or Skype on Johoty website (https://johotypro.com). |

| Customer Support | Professional product selection advice and technical support, customized design of pogo pin quantity, size, material, etc. Samples for customer trial-running and verification, efficient production and delivery services, long-term quality assurance, and real-time support. |

| User Feedback | The customer is very satisfied with the consistency and high precision of Johoty’s pogo pin connectors, pointing out that the reliability and long-term stability of the connectors exceed expectations. Customers generally praise Johoty’s efficiency in delivery cycles, as customized orders can be delivered on time and meet urgent needs. Customers generally believe Johoty pogo pins have achieved a perfect balance between high quality and best price. In the application of high-precision and high-density pogo pin connectors, it has significant competitive advantages. |

| Market Edge | High reliability, high-density design, wide range of applications, adaptability to extreme environments, customized services, and compliance with international standards. It can effectively address the needs of engineers in high-end applications and complex engineering problems. Provide customers with solutions, production capacity, and quality in R&D and mass production. |

Johoty’s pogo pin connectors use advanced 6-axis 5-axis CNC machining and strict CMM to control quality. It can provide ultra-high precision multi pogo pin connectors to meet customers’ stringent requirements in high-end applications. Johoty’s pogo pin connectors can operate stably for high-frequency, high-speed signal transfer, and extreme environmental usage. Engineers can eliminate any worries during the designs and application process.

We have a strong R&D team of 45 people, dedicated to solving various complex technical problems for engineers. Johoty can provide customized solutions based on client needs, including small size, high-density designs, and selection of special materials. Through innovative technology and design, Johoty can help customers reduce risks and improve product performance. We will fully support our customers and ensure smooth progress of every project they undertake.

With large-scale CNC machining, efficient assembly and inspection, and efficient SCM, Johoty can significantly reduce production costs. Customers can obtain high-quality pogo pin connectors and their competitive prices. We can provide high-precision and quality pogo pins, and our pricing strategy ensures customers can enjoy tangible discounts. We always provide high-end technology while also controlling overall costs to achieve the best cost-effectiveness.

We have a partner who has been dealing with Chinese Customs for 20 years to ensure timely and safe delivery. At the same time, Johoty’s factory always optimize production process and logistics system. It is to ensure the completion of mass production orders timely or in advance. We can provide flexible delivery times for standard pogo pin connectors or customized pogo pins. Our goal is to help clients cope with rapid market changes and ensure clients project progress is smooth.

Why Choose Johoty's Pogo Pin Connectors?

Choose Johoty’s pogo pin connectors based on innovative technology, precise craftsmanship, and strong R&D capabilities. Can solve engineers’ difficult problems and meet high-end applications. Our pogo pins can provide excellent performance, and customers can also reduce costs and enhance project competitiveness.

Pogo Pin Connectors Applications

High speed data transfer field

Pogo pin connectors are crucial in design of electronic products and application of high-speed data transfer. They can transmit signals with high frequency and accuracy, ensuring smooth and interference free data. Engineers can greatly improve equipment’s efficiency and performance through this spring loaded connector. In high demand environment of 5G communication and cloud computing, the performance of our pogo pin connectors is irreplaceable.

High precision medical devices

Precision connections are crucial in development of high-end medical equipment. Based on high pin density and precise contact methods, pogo pin connectors can ensure stability and accuracy of internal circuits in medical devices. This spring loaded connector is applied in portable diagnostic instruments, imaging equipment, and vital sign monitoring devices. It can help healthcare workers improve diagnostic efficiency and equipment reliability, ensuring patient safety.

Autonomous driving and intelligent transportation systems

In autonomous driving technology, pogo pin connectors are applied to automotive electronics and sensor systems. High precision and high density, it can maintain good signal transfer in complex environments. It provides strong support for auto drive system. Connection between Lidar, cameras, and sensors can’t leave this spring loaded connector. It ensures system’s accuracy of data and real-time response, laying foundation for safety and reliability of intelligent transportation.

Industrial Automation and Robotics Technology

In industrial automation and robotics technology, pogo pin connectors have become important connecting components for robots based on high precision and density. This spring loaded connector can withstand high-frequency operations, ensuring machine’s stability in extreme environments. Pogo pin connectors can effectively reduce failure rate in high precision assembly and material handling requirements. It can improve production efficiency and provide critical support for intelligent manufacturing.

FAQ

Are pogo pin connectors reliable in the long term?

Pogo pin connectors maintain good contact performance over time through spring design and precision CNC manufacturing. Spring pressure and material selection of pogo pins can ensure that they aren’t easily worn or loose after 10,000 uses. In addition, precise dimensions and fit effectively prevent poor contact caused by pressure changes or vibration. This spring loaded connector can handle high-frequency and maintain long-term stable electrical connections in various environments. Excellent materials and design help pogo pins adapt to complex environments and avoid failure.

How much current can pogo pin connectors support?

The current carrying capacity of pogo pin connectors depends on diameter, material, and design of pogo pins. Usually, pogo pins can support currents ranging from 0.01A~50A. Larger pins and high conductivity copper alloy gold plating can support higher currents. During design, current requirements will directly affect the selected pogo pin specifications. By precisely controlling the pitch and contact force, pogo pin connectors can maintain stable electrical performance under current loads. It won’t overheat or damage due to excessive current.

How to solve poor contact of pogo pin connectors?

Poor contact is usually caused by pogo pin contamination, damage, or insufficient pressure. Firstly, ensure that surface of pogo pin pins is free of stains or oxides to prevent contamination from affecting conductivity. Secondly, check if contact pressure is appropriate during insertion and removal, as excessive or insufficient pressure can lead to poor contact. Precisely tuned pogo pin connectors can effectively avoid these issues and ensure connection stability. In addition, using more durable materials and optimized designs, including appropriate electroplating, are effective solutions. In this way, it can enhance wear resistance of contact points, thereby extending their service life.

What are pogo pin connectors life cycles?

Standard pogo pin connectors can support >10,000 insertions and removals. Johoty’s specially designed pogo pin connector can achieve 200,000 or more connections. The lifespan is closely related to raw materials, spring design, and contact force. High quality pogo pins are based on wear-resistant alloy and precise spring design, which can significantly extend their lifespan. Choosing durable pogo pins is crucial for high-frequency automation equipment or consumer electronics. In frequently, it’s used automated testing, it can also ensure stable connections and avoid performance degradation caused by repeated connections.

What is temp-range of pogo pin connectors?

Temperature resistance range of pogo pin connectors is usually between -40°C and+85°C. Johoty can achieve high temperature pogo pin connectors up to +250°C. They can maintain stable performance from extremely cold Arctic to high-temperature industrial sites. It often uses in industrial control, automobiles, etc. with large temperature differences. By selecting high-temperature alloys or special coating, this spring loaded connector can maintain high efficiency at extreme temperatures. It can effectively avoid material expansion or contraction caused by temperature changes, ensuring stable electrical connections.

How to choose pogo pin connectors that are suitable for your product?

The selection of suitable pogo pin connectors depends on the current, size, space, shape, and usage conditions of the application. Firstly, it is necessary to confirm required current carrying and pogo pin pitch. Secondly, considering the temperature, pH, and humidity of the working environment, choose materials and coating designs that are resistant to high temperatures and corrosion. Finally, pay attention to the size, stroke, contact resistance, function distribution of pogo pin to ensure that it can adapt to device’s space. After reasonable selection, the stability, aesthetics, and durability of this spring loaded connector can ensure its good performance.

Can pogo pin connectors improve signal transfer stability?

To ensure stable signal transfer, pogo pin connectors typically use highly conductive gold and copper alloys to produce pogo pins. Johoty precisely controls contact force of pogo pins for reliability of electrical contact. In addition, contact surface can be polished or coated to reduce signal loss and noise interference. During design, the pitch, contact impedance, rated current, pressure, and conductive materials of pogo pins all affect signal quality. Johoty’s pogo pin connectors can effectively avoid communication errors caused by poor contact or signal attenuation. They can ensure stable transfer of high-frequency or speed signals, at the same time, their appearance is very exquisite and beautiful.

Does appearance design of pogo pin connectors have an impact on usage?

Appearance design of pogo pin connectors has a direct impact on their performance and user experience. The shape, stroke, impedance, length, pitch, and spring design of pogo pins all determine their contact force and stability. A suitable exterior design can reduce friction during insertion and removal. The operation will be smoother, reducing wear and extending lifespan of this spring loaded connector. In high-density connectivity applications, precise design ensures that each spring loaded pin has sufficient contact surface and pressure. This can effectively prevent poor contact caused by inappropriate appearance. Therefore, optimizing exterior design is critical to improve connection stability and reliability.

Benefits to Clients:

Precise design ensures high-frequency insertion and removal stability

Our pogo pin connectors are designed with precision, and their performance remains unaffected after 10,000 frequent contacts. This is crucial for smart devices, automated testing, and automotive electronics that require frequent uses. Precision design can provide superior contact stability, effectively prevents poor contact or plunger tip wear caused by frequent operation. Customers can use it with confidence without worrying about spring loaded connector failure due to excessive usage. It can ensure ltable electrical connection of customer equipment.

High load-bearing capacity to meet requirements of high current applications

Pogo pin connectors can support currents of 10A or higher, making them suitable for applications with high current requirements. For some high-power equipment or industrial automation systems, we have specially designed optimized contact surfaces and thickened pogo pins. It is to stably withstand larger current loads. This ensures that no faults occur during current transfer process due to overheating or poor contact. In high current, customers can use Johoty’s pogo pin connectors with confidence. Don’t worry about damage or failure of pogo pins due to excessive current, ensuring system’s safety, smoothness, and stability.

Adapt to extreme environments, superior temperature and corrosion resistance

Johoty’s pogo pin connectors can operate stably in extreme temperatures, adapting to temperature fluctuations from -40°C to+85°C. Our pogo pin connectors can maintain good performance in both high-temperature industrial environments and low-temperature cold conditions. In addition, we have coated pogo pin surface with corrosion-resistant coating to enhance its durability in damp and salt spray conditions. Customers don’t need to worry about the impact of extreme environments on performance of spring loaded connector. You can use it with peace of mind in various environments, and the device can operate stably for a long time.

High precision manufacturing ensures contact stability and low resistance

We use high-precision CNC, CMM and assembly process, each plunger tip of pogo pin connectors can achieve ultimate stability. The precision contact surface and spring effectively avoid the increasement of contact resistance, improving speed and stability of signal transfer. Low resistance design ensures stable and clear signals in high-frequency. In medical instruments, data communication, etc. customers can use them with confidence without worrying about signal interference or loss.

Optimize costs and provide cost-effective solutions

Johoty focuses on optimizing production processes, significantly reducing production costs through automated production, refined management, and large-scale procurement. Despite providing high-precision and high-quality pogo pin connectors, we are still able to maintain highly competitive prices. In this way, customers can receive high-quality and high-performance pogo pin connectors, as well as enjoy high cost-effectiveness. Both small, medium or large-scale enterprises or producers can find suitable economic solutions in our pogo pins. Johoty can help clients various achieve perfect situations on value, cost, or benefit.

Customized services to meet various complex application needs

Johoty provides standard pogo pin connectors and support customization according to customers’ needs. We can precisely adjust the quantity, pitch, shape design, and material selection of pogo pins. We can provide perfect customized solutions for high-density design in special spaces and special electrical performance. Customers can obtain precise and adaptable pogo pin connectors in complex engineering applications. Our pogo pins can help you maximize work efficiency and reduce unnecessary technical adjustments.