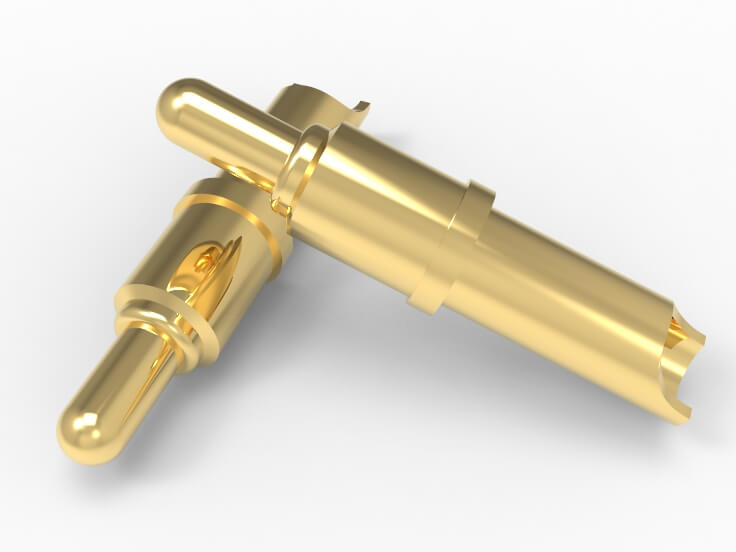

Best High Current Pogo Pins China Manufacturer Low Resistance

High current pogo pins have built-in or external springs to transmit <1,200A. Low contact resistance, long lifespan, and 7 installation methods. It uses gold-plated brass for high-power charging. Johoty offers flexible custom with safety and best price.

Features:

- Meet equipment stable current requirements.

- Low energy consumption, high-efficiency transfer.

- Less replacement, low maintenance, high reliability.

- Flexible design, and diverse installation methods.

- Stable and reliable operation in harsh environments.

- Customized solutions to meet specific usages.

High Current Pogo Pins Series

High current pogo pins handle currents from 3A to 1,200A, meeting diverse needs. They feature high conductivity and low resistance 1mΩ for long-lasting up to 500,000 cycles, 7 installation methods, Materials brass, beryllium/tellurium copper, stainless steel, gold-plated, platinum, or palladium. Used in charging and discharging, gigafactory, new energy, automobiles, and high-power. Johoty offers expert technical support, custom solutions, fast response, and safe delivery.

| Category | Detailed Information |

|---|---|

| Overview | High current pogo pins are spring-loaded precision design, low resistance, high reliability, sturdy and durable structure, excellent conductivity, and stable contact even during vibration or movement. |

| Customers | Electronic product manufacturers, automotive industry, power electronics companies, communication equipment manufacturers. Serving engineers, procurement managers, and technical teams for high-current connectors. |

| Applications | High-speed data transfer, charging system, signal connection, and multi-point contact testing. Electronic testing, communication equipment, medical instruments, high-end consumer electronics, automotive electronics, industrial automation. |

| Materials | Highly conductive brass, phosphor/beryllium/tellurium copper, gold/silver plated, excellent current conductivity and corrosion resistance. Gold-plated piano steel stainless steel spring, reliable for high current and high-frequency use. |

| Function | Stable and efficient electrical connections, maintaining low contact resistance, high reliability, stable current transfer, and safety under high current loads. |

| Specifications | Current<1,200A, contact resistance 1mΩ, standard and customized shapes/dimensions, 500,000 durability, spring force up to 100N, temperature -40 ℃~+125 ℃. |

| Brand | Johoty focuses on providing high-precision and highly reliable solutions for high current pogo pins. Provide customized services. |

| Price | $1 to $50, custom by batch, Johoty offers highest value at best price. |

| Quality | ISO 9001, RoHS, REACH, etc. |

| Where to buy | Johoty’s website (https://johotypro.com), E-mail (cft@johoty.com), WhatsApp (+86 18007608187), Skype (alfredyou2013), or WeChat (+86 18007608187). |

| Support | Support 24/7. |

| Feedback | Excellent stability! Under high precision requirements, performance remains consistent! Under high load conditions, can avoid overheating or poor contact. |

| Market | Excellent current carrying, wear resistance, corrosion resistance, and oxidation resistance. Stable signal and accurate data transfer. Customize different sizes, shapes, and current specs for medical equipment, industrial automation. |

Our high current pogo pins are gold-plated with beryllium copper and have a flexible design, with a maximum current of 1,200A and a minimum resistance of 1mΩ. For fast charging and high-power devices, they can operate stably and safely.

The contact pressure of each pogo pin can be customized to 100gf~100N, with high consistency. It can ensure stable electrical connection during different uses, avoid poor contact and overheating, and improve lifespan and reliability.

Johoty’s pogo pins undergo high current, high temperature, high humidity, and vibration testing during the production process to ensure that each factory pogo pin complies with ISO9001, RoHs, REACH, ensuring high safety and stability.

We provide 24/7 technical support to promptly answer international logistics, import customs clearance, and technical questions. Provide customized solutions. Even for your urgent needs, please contact the CFT team promptly.

Why Choose Johoty's High Current Pogo Pins?

Choose Johoty’s high current pogo pins to enjoy a long lifespan, stable electrical performance, and fast connection. High-demand applications, high efficiency and reliability. Enhance your product performance as well as market competitiveness. Choose Johoty now to create huge value for you!

Current Transfer in Electric Vehicle Charging System

Car Battery Management Systems

Electric vehicle charging systems often use high current pogo pins to provide efficient and reliable current transfer. They can ensure good contact under high current loads, reduce resistance and heat loss, and improve charging efficiency. These Pogo Pins can work stably during repeated plugging and unplugging, extending device life cycles and meeting the demand for fast EV charging.

Power and Signal Transfer in Communication Equipment

In the communication industry, high current pogo pins are for power and signal transfer of various devices. They can withstand high current loads and ensure stable operation. With excellent electrical performance, pogo pins become the perfect precision parts for 5G base stations, routers, and other communication devices. They ensure the reliability and efficiency of data transfer and help customers reduce equipment failure rates and maintenance costs.

Stable Power Support in Medical Equipment

High current pogo pins are for various medical devices, life support systems, surgical robots, and wearable devices. They can provide stable power support and ensur efficient operation at critical moments. Due to the extremely high precision and reliability of medical equipment, these pogo pins have passed tests on functionality, performance, dimensional accuracy, film thickness, etc. They can provide stable power transfer, reduce failure risks, and ensure the safety of patients and equipment.

Power Support in Industrial Automation

In the field of industrial automation, high current pogo pins are used in robots, motor drives, and industrial control systems. Due to their durability and high current carrying capacity, they can operate continuously and stably in harsh industrial and provid strong power support. These pogo pins can ensure long-term equipment efficiency, minimizes downtime and maintenance based on their high reliability. And, they bring clients high production efficiency and equipment reliability.

FAQ

What is the Maximum Current of Johoty’s High Current Pogo pins?

Johoty’s high current pogo pins are designed to support a maximum current of 1200A. By using beryllium copper gold plating and precision CNC machining, we ensure that each Pogo Pin operates continuously at 120 ℃ for 4 hours with a temperature rise not exceeding 25 ℃. They have long-term reliable electrical connectivity to meet high load current transmission.

How Long is the Lifespan of High Current Pogo Pins?

Johoty’s high current pogo pins have undergone strict testing for current and spring force, lifespan is up to 500,000 cycles. We use wear-resistant materials, gold plating, and optimized contact surfaces. It can minimize wear and ensure excellent electrical performance and long-term stability.

How to Ensure Electrical Stability of High Current Pogo Pins?

Johoty conducted rigorous resistance, conductivity, and anti-interference tests for each high current pogo pin. Through these tests, we ensure that the electrical connection is stable and will not cause electrical faults due to overheating, vibration, or external factors, thereby providing high-quality current transfer.

What is Material Selection for High Current Pogo Pins?

Our high current pogo pins are gold-plated beryllium copper or stainless steel, which can withstand high current loads and reduce heat generation. The coating uses corrosion-resistant gold and palladium, which can resist moisture and oxidation, and is stable and reliable. Meanwhile, our materials comply with RoHS, REACH too.

How can High Current Pogo Pins Solve the Challenges in High Temperatures?

For high temperature, we have used thermal diffusion technology in the design, which can effectively dissipate heat and avoid the decrease in current carrying capacity. We also use high-temperature resistant insulation materials to ensure stable operation in large temperature fluctuations.

How to Customize High Current Pogo Pins?

Johoty can provide personalized customization and design suitable high current pogo pins based on customer needs. We can provide customized solutions in terms of size, shape, impedance, material, and current to ensure each pogo pin fully meets your requirements.

Benefits to Clients

Improve Equipment Reliability and Safety

By choosing our high current pogo pins, you will greatly enhance your device’s reliability and safety. Our pogo pin design ensures stable carrying of high currents, reduces faults caused by poor contact or current fluctuations, and ensures long-term safe operation. They can reduce your maintenance and replacement costs, and make your product more competitive.

Reduce Long-term Usage Costs

Due to the long lifespan and durability of our high current pogo pins, you will significantly reduce the long-term operating costs. Each pogo pin has undergone 500,000 lifespan tests and can work stably after high-frequency use, reducing frequent replacement times. Lower maintenance costs, and improve your ROI.

Improve Product Overall Performance

Johoty’s high current pogo pins reduce current losses and improve electrical transfer efficiency through optimized design, enabling your products to work more efficiently. Their stable, fast, and efficient transfer enhances overall performance, ensures smooth operation under high load, and improve user experience.

Customization to Meet Specific Needs

We provide customized pogo pin solutions to meet your needs. We can provide flexible customization according to your application in terms of size, material, and current carrying capacity. Customized services can help you achieve unique designs and enhance your product’s competitiveness.

Environmental, Sustainability Guarantee

Johoty uses RoHS compliant materials to ensure stable operation under high current transfer, following environmental principles. By choosing Johoty’s high current pogo pins, you can provide customers with green and eco-friendly solutions, while also complying with environmental regulations. This can enhance your brand’s sense of social responsibility.

Ensure Fast Delivery and Service

We provide efficient production and delivery cycles to ensure you receive high current pogo pins on time. Johoty delivers your orders quickly through precise production planning and logistics management, and we provide professional technical support so that you can receive professional assistance at any time.