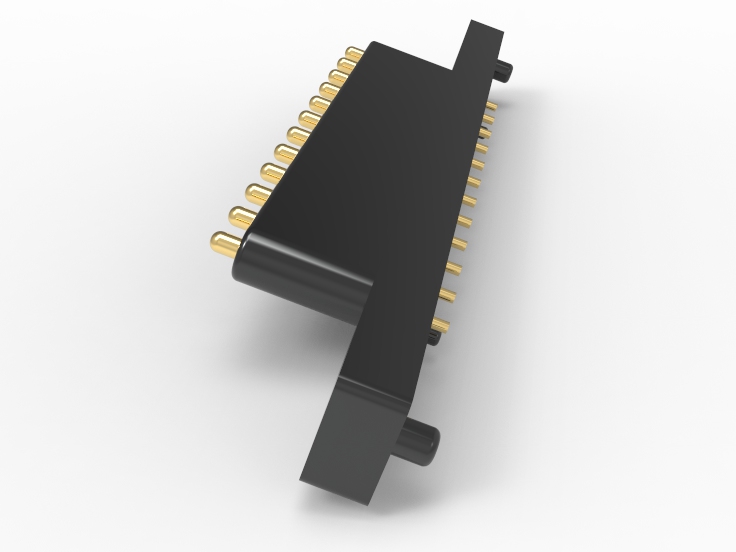

Advantages of 12 Pin Electrical Connector, Pitch: 1.50~3.50

High density design improves space utilization

High-density design means 12 pin electrical connector can provide more connection points in a limited space. This is suitable for very strict space requirements. Johoty’s pogo pin connector can help engineers save valuable space. The device can be more compact while improving its integration and efficiency. It greatly reduces wiring’s complexity and significantly improves product’s operability.

Excellent durability and stability

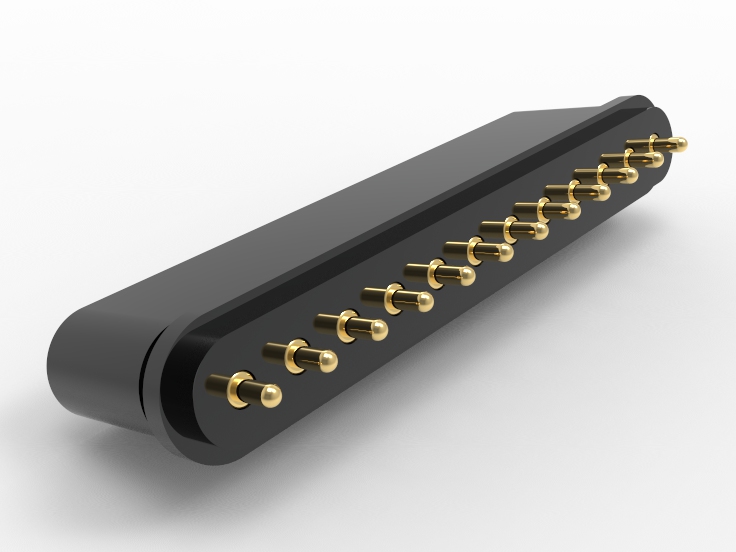

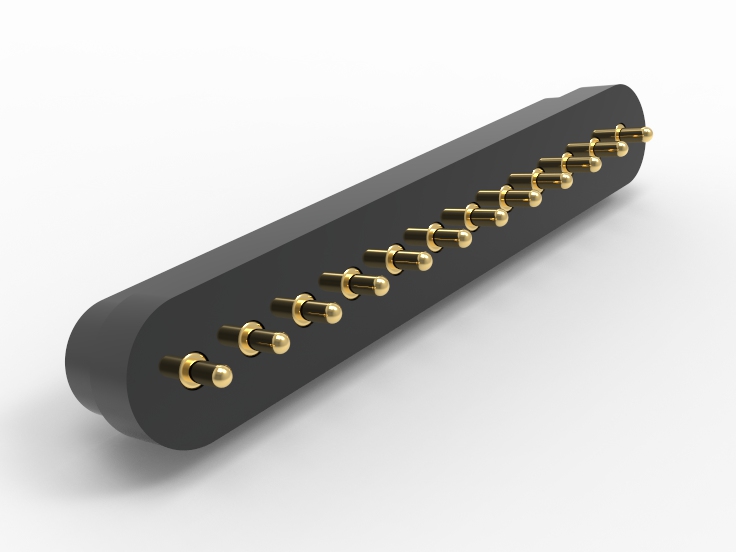

The 12 pin electrical connector uses high-quality brass or beryllium copper and advanced CNC technology, CMM. Its durability and stability can reach very high standards. In high load and high-frequency usage, this spring loaded connector can still maintain excellent performance. Long-term work won’t result in poor contact or performance degradation, system also runs very reliably.

Accurately match multiple connection requirements

Through 12 pin electrical connector, designers can accurately select appropriate connection configuration based on specific needs. Numerous engineers have provided feedback Johoty’s pogo pin connector can meet different engineering requirements. This high-precision spring loaded connector can adapt to various electrical signals and current loads. Engineers can find the best solution based on different requirements in practical applications.

Minimalist installation and maintenance process

The design of 12 pin electrical connector is very simple and clear, making it easy and quick to install. It can also be quickly installed in the most complex environments. The structure is very simple, and, it is also easy to operate, engineers can complete installation in a short time. This pogo pin connector can reduce faults or delays caused by complex connections, greatly improving maintenance convenience.

Strong anti-interference ability

When designing 12 pin electrical connectors, Johoty often uses special beryllium copper or phosphorus copper and optimizes the design. It can effectively isolate external EMI. In high-frequency & voltage environments, this pogo pin connector can also ensure that signal transfer isn’t interfered with. It can greatly improve system’s stability and anti-interference ability, providing reliable support for high-end applications.

Excellent thermal management performance

Based on excellent thermal management, 12 pin electrical connector can effectively dissipate heat in high temperatures. This can keep long-term stable and safe operation of pogo pin connector and device. This advantage is important for equipment that requires long-term high-load operation. Because it can minimize equipment failure effectively and avoid overheating causing performance degradation.

High-precision contact structure ensures electrical performance

Contact structure of 12 pin electrical connector has been precisely designed, ensuring each pin can make perfect contact. It can minimize losses and instability in electrical contacts significantly. With its high-precision contact, the transfer of signals and power is error-free. This pogo pin connector can perfectly adapt to high-precision industrial applications.

Flexible adaptation to various industry applications

Due to multifunctional of 12 pin electrical connector, it can flexibly apply in various industries. You can find its presence in aerospace, automotive electronics, and communication equipment. With high-precision connection and high reliability, pogo pin connector is preferred choice for engineers in various high-end projects. Products designed by engineers have a range of adaptability too.

FAQ

Can 12 pin electrical connector improve integration of high-density circuit boards?

The high-density design of 12 pin electrical connector can provide more connection points in limited space. This can allow circuit board to integrate more functions. Engineers can reduce the number of components, optimize spatial layout, reduce weight, and improve overall system performance. Compact design can save board space and improves wiring efficiency. Through this approach, more complex electrical configurations can be achieved while reducing system complexity. High density connectors provide perfect solution for designing efficient and highly integrated circuit boards.

How can 12 pin electrical connector optimize thermal management?

Our 12 pin electrical connector adopts advanced heat dissipation technology, which can effectively reduce pogo pin’s temperature, maintain their stability. Thermal conductivity efficiency of each pogo pin has been optimized. It is to ensure even distribution of heat during high-power operation, avoiding local overheating. Material and structural selection of this pogo pin connector also enhances overall heat dissipation effect. This thermal management advantage enables stable operation in high temperatures. Through better thermal management, lifespan and reliability of pogo pin connector have been significantly improved.

Can 12 pin electrical connector ensure vibration resistance?

The 12 pin electrical connector uses high-precision pogo pins and a sturdy housing design. It can effectively enhance anti vibration of this pogo pin connector. Johoty’s 12 pin electrical connector can maintain stable electrical contact in frequent vibration or impact environments. We will specially design its contact points to resist poor contact caused by vibration. Under extreme conditions, it can also maintain electrical signal transfer’s reliability. This spring loaded connector is suitable for high vibration applications in aviation, automotive,etc. At the same time, it can ensure equipment’s high stability in various extreme environments.

How can 12 pin electrical connector prevent poor contact?

Johoty used high-precision pogo pins when designing 12 pin electrical connector. This ensures that each connection point has uniform pressure distribution. In long-term use, poor contact can be effectively prevented. Precise contact structures can reduce electrical problems from wear or aging. The reliable contact performance of this pogo pin connector ensures high stability of system operation. In high-frequency and long-term applications, it can ensure connection accuracy and stability.

Is 12 pin electrical connector safe in high voltage?

The 12 pin electrical connector adopts a pressure resistant design and uses high-strength materials to effectively cope with high pressure. In systems with large voltage fluctuations, it can also operate stably to prevent short circuits or poor contacts. The unique insulation layer design of this pogo pin connector avoids leakage during voltage anomalies. Its contact point material has compressive strength and can maintain electrical contact continuously in high-pressure. With this feature, it can meet high-voltage applications, such as power equipment.

How can 12 pin electrical connector quickly install?

Emphasizing simplicity, the installation and removal process of 12 pin electrical connector is highly efficient. With self alignment function, this pogo pin connector can be quickly and accurately inserted and securely connected. No special tools or additional adjustments are required, reducing the complexity of installation. The structural optimization of this spring loaded connector avoids card lag or damage. Engineers can complete the operation cycles in short time, greatly improving production efficiency and maintenance convenience.

How can 12 pin electrical connector improve signal transfer accuracy?

Plunger tip of 12 pin electrical connector is precision machined to ensure error-free signal transfer for each pogo pin. Its optimized design can effectively reduce interference and loss in signal transfer. Through precise contact design, this pogo pin connector can avoid signal distortion or noise interference. High quality materials can further improve signal transfer stability. It can maintain efficient and accurate signal transfer in complex signal or high-speed transfer.

Does 12 pin electrical connector support high-end applications in multiple industries?

Johoty’s 12 pin electrical connector has strong adaptability and can meet multiple industries. It is critical in aerospace, automotive electronics, and industrial automation. This pogo pin connector has high-precision and reliability, it can cope with various extreme environments. Faced with complex electrical configurations, Johoty’s 12 pin electrical connector can also provide precise and stable support. Its versatility makes Johoty pogo pins preferred choice for multidisciplinary engineers in high-end applications.