Advantages of 2 Pin Waterproof Connector, pitch: 2.55~3.99

Excellent waterproof performance

2 pin waterproof connector has strong waterproof capabilities and isn’t afraid of rain, sweat, and liquid splashes, making it suitable for various applications. Sealed design of this pogo pin connector can effectively protect internal circuit. It is highly suitable for outdoor equipment to withstand harsh environments and can maintain its waterproof effect after prolonged use. This pogo pin has precision craftsmanship to ensure stable performance and provides comprehensive protection for equipment.

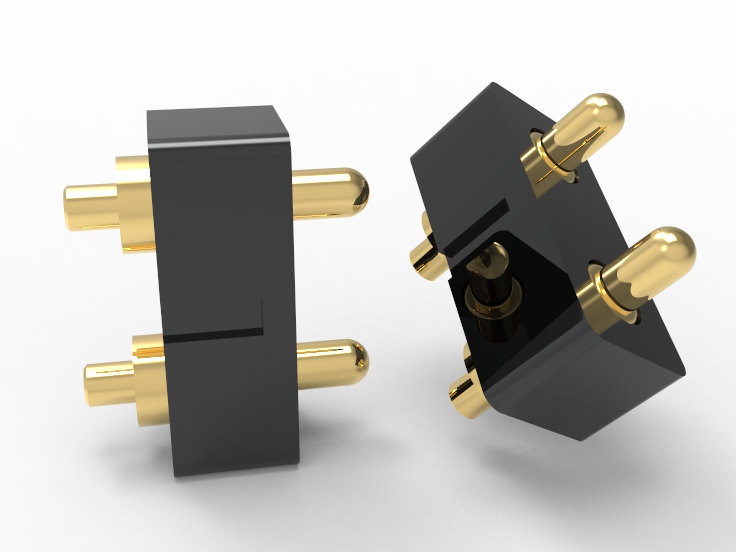

Compact and exquisite design

2 pin waterproof connector is designed in a small size to meet high-end devices. You can easily integrate such pogo pin connector into compact space without any pressure. Lightweight design of this precise pogo pin connector can reduce product total weight. It fits complex internal structures, and its exquisite appearance enhances product high-end feel. Johoty can help you save space and improve design flexibility, seamlessly matching with various devices.

Stable and reliable connection

Our 2 pin waterproof connector remains stable during plugging and unplugging, providing reliable support for device operation. This pogo pin connector ensures good contact for data and power transfer, reduces looseness, avoids interruptions in use. The high-precision pogo pins ensure secure connection, improve operational convenience, and aren’t easily worn out after long-term use.

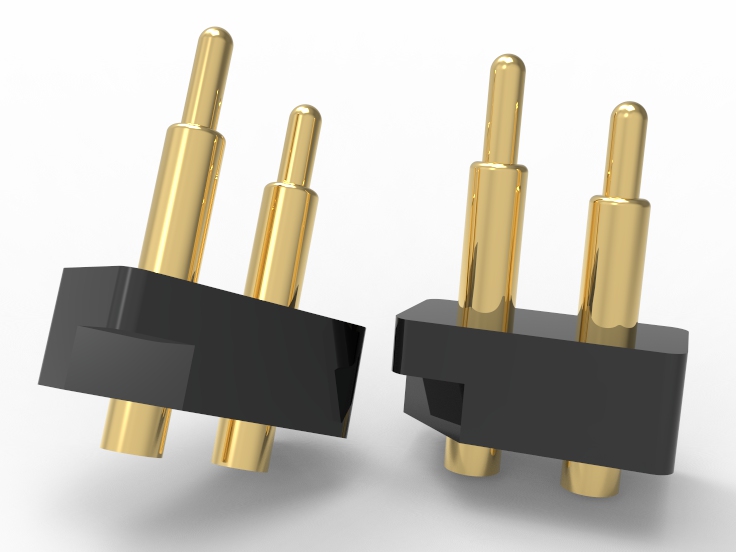

High end and durable materials

2 pin waterproof connector is made of brass, tellurium copper, beryllium copper, stainless steel, and has high durability and stability. This spring loaded pin is corrosion-resistant and adaptable to various applications, with high strength to resist physical impacts. Gold plating, silver, palladium, platinum, rhodium ruthenium ensure wear resistance for long-term use. Its high-tempe stability ensures long-lasting performance, excellent materials highlights product’s high-end feel.

Fast and efficient transfer

2 pin waterproof connector transfer efficient power and signals, suitable for modern high-end devices. Its pogo pins are plated with gold, silver, and have an impedance as low as 15mΩ, which can improve current conduction efficiency. It can reduce energy loss and improve user experience, compatible with multiple powers and signals. This high-quality spring loaded pin is suitable for high demand devices without delay transfer. And, the connection process is smooth and natural.

Excellent seismic resistance

Johoty’s 2 pin waterproof connector is designed for earthquake resistance and can operate stably during movement and vibration. The structural optimization of this spring loaded pin reduces vibration interference, high-strength contact points ensure secure connection. Each pogo pin remains secure during complex movements, protects device interior from vibrations. It can provide secure support for portable devices.

Flexible design compatibility

2 pin waterproof connector can smoothly match various devices and applications, providing a high design freedom. This pogo pin connector has lots of specifications to meet different needs. It is suitable for various device interface and can be easily integrated without affecting overall design. It can help engineers with strong scalability, support future upgrades, and flexibly optimize device performance.

Ultimate operational convenience

2 pin waterproof connector is simple, allowing users to quickly complete connection and disassembly, making it convenient and efficient. This simple pogo pin connector has an intuitive design that requires no additional learning. Its smooth connection saves time and effort, with clear labeling to avoid incorrect operations. You can complete its connection with one hand, making your high-end devices closer to users’ daily use.

FAQ

How does 2 pin waterproof connector ensure its waterproof performance?

The waterproof performance of 2 pin waterproof connector is achieved through high-precision sealing design. The housing uses waterproof materials and special sealing rings between the contacts to prevent moisture infiltration. The pogo pin contacts are designed with great precision, ensuring tight contact every time, avoiding any gaps. In underwater or high humidity, this pogo pin connector can ensure stable current transfer. The guarantee of waterproof performance enables it reliably uses in outdoor, automotive, and other humid environments.

How much current can 2 pin waterproof connector withstand?

2 pin waterproof connector can withstand high current loads. The internal pogo pin contacts are made of low resistance and high conductivity gold-plated brass. This can effectively carry up to 50A high current which won’t generate excessive heat. Johoty can design a large contact area for each pogo pin, which can reduce resistance and improve transfer efficiency. This pogo pin connector housing also has a heat dissipation function, which helps to release excess heat when current passes through. Under high loads, the connector can maintain stable operation and won’t be damaged due to overheating or excessive current.

What applications is 2 pin waterproof connector suitable for?

2 pin waterproof connector is highly suitable for automotive electronics, industrial machinery, outdoor equipment, and precision instruments. This pogo pin connector can work stably in extreme humidity and temperatures. The small and compact design of its pogo pin is also suitable for limited volume, ensuring flexible installation. They are suitable for power and signal connections, ensuring long-term stability in harsh.

Why can 2 pin waterproof connector work in vibration?

This pogo pin connector can face challenges in vibrations, using a high-strength housing and optimized internal contact structure. Pogo pin contacts have precise spring design, which can maintain stable contact force during vibration and avoid loosening. Tight combination of outer housing and internal contacts reduces poor contact and minimizes the impacts from vibration. Under high-frequency vibration, 2 pin waterproof connector can maintain high stability, ensuring normal operation.

How does 2 pin waterproof connector cope with low temperatures?

2 pin waterproof connector is suitable for low temperatures, using low temperature resistant materials and special design. It can maintain good performance in colds. The design of pogo pin contacts and springs ensures stable contact pressure and prevents poor contact caused by material shrinkage at low temperatures. The housing material has anti freezing and anti cracking, avoiding cracking at low temperatures. Sealing ring can also withstand low temperatures, preventing water vapor from entering. This ensures stable operation of this pogo pin connector under cold conditions.

Can 2 pin waterproof connector transfer high-frequency signal?

2 pin waterproof connector can transfer high-frequency signals, its contacts are made of high conductivity gold and silver plating. It has a large contact area, reducing losses in signal transfer. Optimized design of built-in pogo pin reduces obstacles in signal path and avoids signal attenuation. Precision machining of pogo pin contacts ensures stable signal transfer and isn’t affected by interference in high-frequency. The housing has electromagnetic shielding, effectively preventing external EMI from affecting signal quality, ensuring clear and stable signals.

How long is the plug and unplug lifespan of 2 pin waterproof connector?

Johoty considered long-term use and long lifespan when designing 2 pin waterproof connector. The pogo pin contacts are produced of high-strength springs and wear-resistant palladium and platinum plating. They can withstand 200,000 insertions without failure. The housing of this pogo pin connector has been reinforced to prevent damage. Every time it is plugged or unplugged, the contact force of its spring loaded pin remains stable. It is to avoid affecting the connection quality due to wear and tear. Even after 10,000 operations, the connector can still maintain good performance.

How to ensure reliability of 2 pin waterproof connector?

2 pin waterproof connector is made of brass, stainless steel, tellurium copper, etc. to ensure stable performance during long-term use. Pogo pin contacts are finely processed, with smooth and uniform contact surfaces, avoiding performance degradation. Its housing is sturdy and durable, preventing damage to internal components from external environments. The sealing design inside this pogo pin connector effectively isolates water, water vapor and dust outside. It can ensure 2 pin waterproof connector is in optimal status for a long time. All designs and materials have been rigorously optimized to ensure long-term reliability.