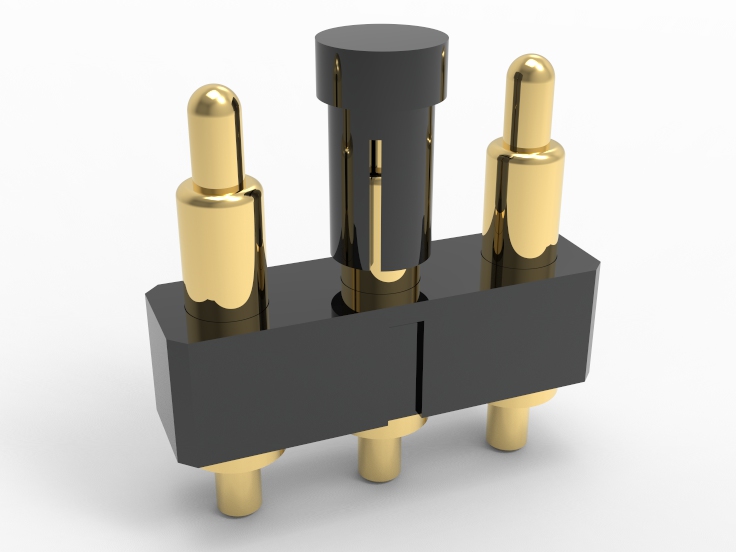

Advantages of 3 Pin Connectors, Pitch 2.54~2.99

High precision manufacturing

Johoty uses 5-axis CNC technology to ensure perfect matching of every detail of 3 pin connectors. The contact points of pogo pin are smooth and flawless, with extremely stable conductivity. The process error of this spring loaded pin is less than one tenth of a human hair. It can effectively reduce connection errors and ensure efficient current transfer.

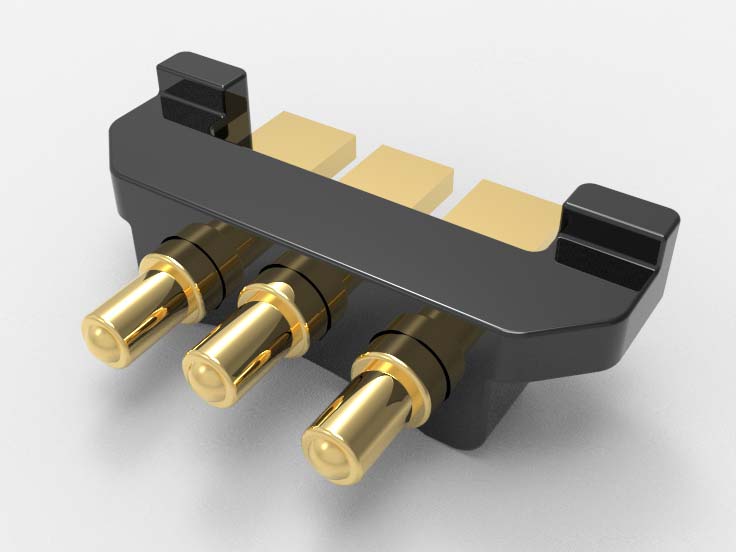

Excellent durability

Based on specialized materials and optimized design, 3 pin connectors can withstand 200,000 connections without compromising performance. Pogo pin coating is firmly bonded, with significant wear resistance, conductive parts are not easily aged and oxidized. This spring loaded pin remains as new after long-term use, meeting various complex working conditions.

Optimize thermal management

Our 3 pin connectors use special heat dissipation structures and materials to significantly reduce temperature rise under high load conditions. Their spring loaded pin has a unique thermal conductivity that quickly disperses heat, ensuring a stable connection. Excellent high temperature resistance, this spring loaded pin is suitable for extreme environments and enhances overall device safety.

High vibration resistance

3 pin connectors meet anti vibration of aviation and industrial standards, and can maintain reliable connections under harsh vibrations. Housing locking design avoids loosening, and pogo pins are stable without looseness, reducing performance fluctuations caused by vibration. This can safeguard the operation of complex equipment.

Advanced anti-interference capability

Exclusive shielding structure, 3 pin connectors can effectively isolate electromagnetic and radio frequency interference. This type of spring loaded pin is stable, external environment can’t affect it. Their data transfer speed is faster and more accurate, supporting multiple high-frequency signals. Regardless of the application, Johoty’s 3 pin connectors can provide reliable support.

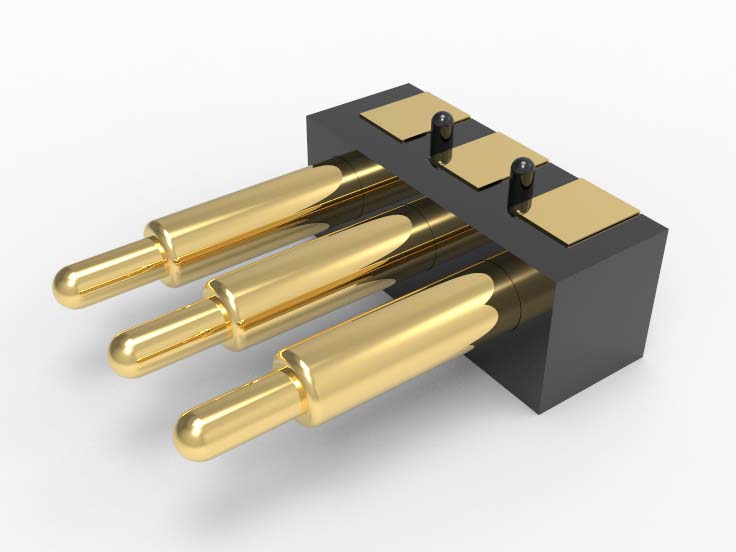

Compatibility between miniaturization and high power

Johoty’s breakthrough design of 3 pin connectors achieves high current carrying in small volume. This spring loaded pin can adapt to the requirements of compact devices, reduce device overall size, and improve space utilization. At the same time, the spring loaded pin inside can support strong current. It can achieve miniaturization with high performance.

Lightweight Innovation

The innovative materials and structural design of our 3 pin connectors make them lightweight yet extremely strong. This spring loaded pin effectively reduces overall system weight and improves device portability. Johoty’s pogo pin connector is suitable for portable devices and high-altitude applications. It can seamlessly combine performance and lightweight.

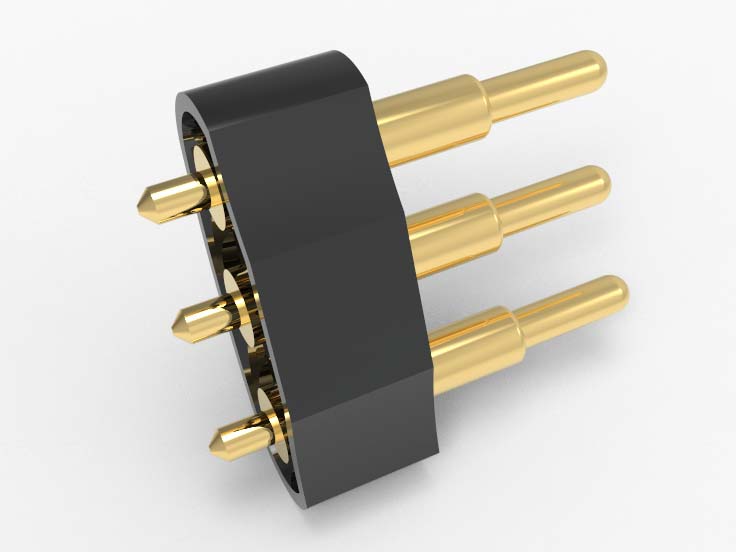

Flexible compatibility

We adopt modular design of 3 pin connectors, which can easily adapt to various specifications and applications. This spring loaded pin is simple and easy to install, and it can meet the requirements. Johoty’s 3 pin connector does not require additional complex configurations and can quickly integrate into existing systems. This can bring great convenience to various devices.

FAQ

Do 3 pin connectors support long-term stability in extreme temperature differences?

Yes, 3 pin connectors support reliable operation at extreme temperatures. The spring loaded pin has strong heat and cold resistance, and contact point remains stable. This pogo pin connector can prevent deformation caused by temperature differences, and its unique structure avoids thermal expansion and contraction. Johoty’s 3 pin connectors ensure device operates properly in changing environments.

Are 3 pin connectors suitable for high-speed dynamic connections?

Special 3 pin connectors can adapt to high-speed mobile connections. They have excellent impact resistance and stable contact points that don’t fall off. This pogo pin connector supports quick connection without affecting performance. Pogo pins have stable conductivity and ensure reliable connection. There is no distortion in signal transfer under dynamic conditions.

Can 3 pin connectors transfer weak signals and high-power signals?

Yes, 3 pin connectors can transfer both weak signals and high-power current simultaneously. This pogo pin connector shielding structure isolates interference and ensures clear signals. The contact impedance of pogo pin inside is extremely low, ensuring stable current. Their special design supports dual requirements and efficiently adapts to complex circuits.

Can 3 pin connectors keep long-term performance in high humidity?

Of course, special moisture-proof design is IP67, IP68 waterproof, Capable of handling high humidity. This pogo pin connector has an internal coating for isolating water vapor effectively. The contact surface also has strong anti-oxidation and corrosion. The connection components of 3 pin connectors have strong sealing, ensuring worry-free operation in humid.

Are 3 pin connectors flexible for adjustable installation angles?

Johoty’s 3 pin connectors can support multi angle installation and adapt to complex installation. This pogo pin connector is flexible on structure design, and users can freely adjust connection angle. Our 3 pin connectors are easy and stable to install, reducing installation limitations. They can easily meet different scenarios.

Can 3 pin connectors meet special requirements of lightweight drones?

Yes, 3 pin connectors are lightweight but strong, meeting the needs of drones. The special material of their pogo pins can reduce equipment burden, contact points have high strength and are not easily damaged. This pogo pin connector has a small size and saves space, supporting a perfect combination of high efficiency and lightweight.

Do 3 pin connectors have ultra long lifespan in slight vibration?

Under slight vibration, 3 pin connectors can maintain long-term operation. Contact surface of spring loaded pin is precisely adhered to prevent performance degradation caused by slight vibrations. Wear resistant materials can extend service life, and locking design of this pogo pin connector can enhance connection stability. Johoto can ensure our 3 pin connectors remain reliable for long-term operation.

Do 3 pin connectors support embedded installation in narrow spaces?

Johoty designed 3 pin connectors for efficient embedding in extremely narrow spaces. This pogo pin connector has an ultra small size that doesn’t take up extra space. And its flexible interface can adapt to multiple installation. Our 3 pin connectors are easy to plug and unplug without affecting performance. Their high compatibility ensures strong adaptability and enhances device design freedom.