Johoty’s Service of 4 Pin Connectors

Sample 4 Pin connectors: Provides fast sample making service, with samples delivered within 14 working days. Meet clients’ urgent needs during the prototype design and validation phase. Support customized modifications to ensure that the final 4 Pin connectors fully meet project requirements.

Quality control: All 4 Pin connectors have passed ISO 9001 quality system. And 4 Pin connectors undergo 100% electrical testing before leaving the factory. The stability of contact impedance, elasticity, and electrical performance complies with RoHS, REACH, and industry standards.

Delivery time: The standard production cycle is 14 working days. We can provide expedited production options according to customer needs, which can be shortened to 10 working days. The time sensitive performance of the client’s project is fully satisfied by Johoty.

Minimum Order Quantity: MOQ for mass production is 3,000 pieces, meeting small and medium-sized production. For bulk orders, flexible adjustments can be provided to support larger scale production customization.

Logistics options: Multiple logistics options are available, including air freight, sea, truck, and express delivery. Select premium delivery based on customer’s location. For urgent orders, priority should be given to air freight to ensure delivery time of 3-5 days or 5-8 days.

Contact person qualification: Professional customer manager team, all contacts have at least 10 years of experience in 4 Pin connectors. Provide customers with end-to-end services from technical support to logistics follow-up, seamlessly connecting every link.

Supply chain transparency: A complete supply chain tracking system that allows clients to obtain real-time logistics information. Efficient communication and timely feedback to avoid any unnecessary delays.

After sales support: Provide comprehensive after-sales service, with a 30 day return and exchange guarantee for quality issues. Provide technical consultation to help customers solve any problems in practical applications.

Sample fees and payment: Sample fees are transparent and charged based on actual costs, with no profit allowed. Can be deducted from mass production orders to ensure maximum client’s ROI.

Technical docking and cooperation: The docking team includes senior R&D engineers and customer managers. Provide professional technical support and timely feedback in customized solutions. Drive customers’ products to quickly enter the mass production stage.

Customer certification and authentication of 4 Pin connectors: All 4 Pin connectors comply with CE, RoHS, etc. Customers can ensure compliance with market standards such as those in the European Union and the United States during procurement, helping to smoothly enter the target market.

Project management support: Provide project management support to assist clients in time planning and schedule control throughout the entire development cycle. Ensure 4 Pin connectors for each stage are achieved on time.

Click: More Catalog

Performance Test of 4 Pin Connectors

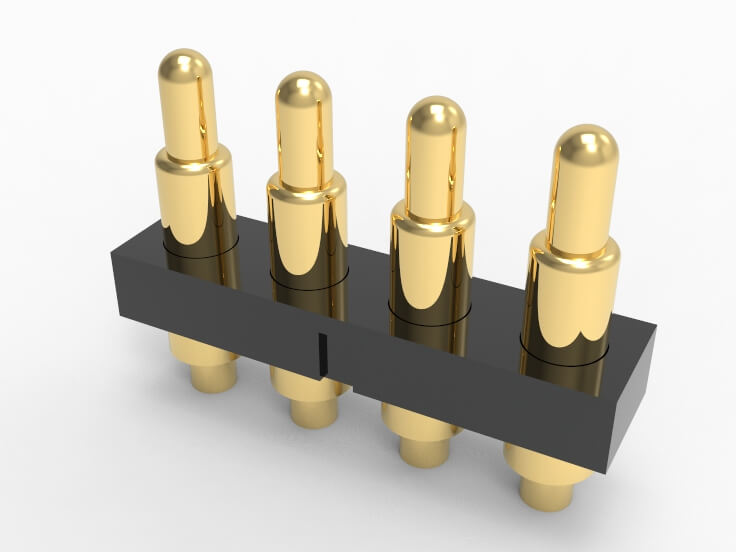

Contact impedance testing: high-precision instruments are used for contact impedance testing, and the contact impedance of 4 Pin connectors is as low as 10mΩ. It meets the requirements of high-frequency and high-speed transmission, ensuring stable signal transmission.

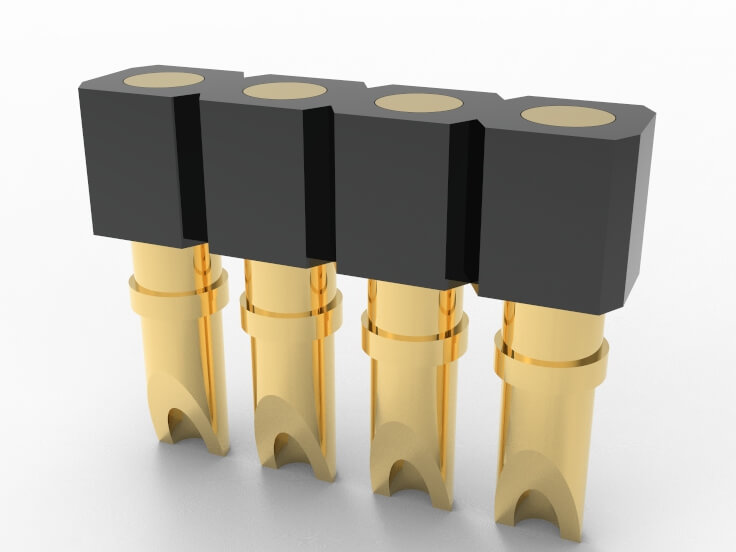

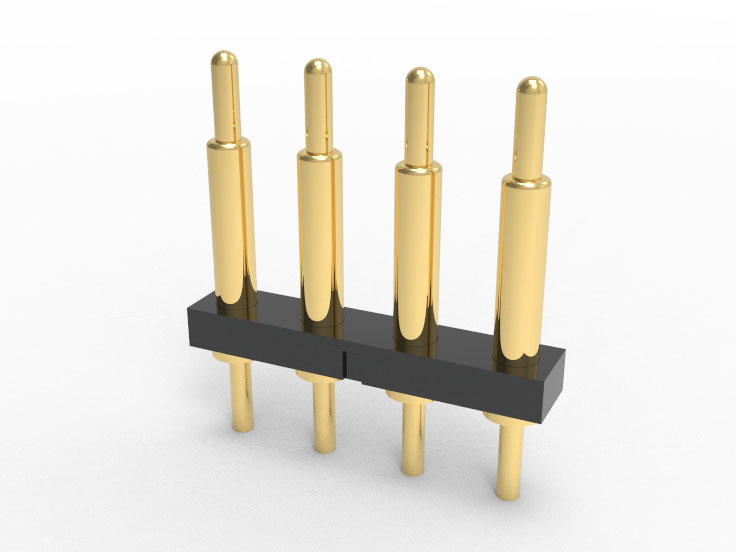

Durability test: Conduct 5,000 insertion and extraction tests to assess elasticity and stability under high-frequency usage. Each connector can withstand at least 5,000 operations to ensure long-term reliability.

Electrical performance testing: Conduct electrical testing under different current conditions to verify the rated current of 10A and rated voltage of 24V. All 4 Pin connectors pass 100% electrical performance testing to ensure fault free operation.

Mechanical strength test: Conduct a high tensile test to ensure that the 4 Pin connectors don’t suffer damage under high mechanical loads. The compressive strength of each pogo pin connector under tension meets the long-term usage requirements in the application.

Temperature and environmental adaptability test: Conduct the test within the extreme temperature range of -40℃ to +85℃. Stable performance in different working environments, adaptable to high/low temperature, and humid heat.

Surface gold plating thickness detection: Microscopic and electron beam analysis methods are used to check whether the gold plating thickness of each pogo pin meets the 5μm standard. Good contact and corrosion resistance.

Seismic testing: Vibration testing is conducted in a simulated vibration environment, and 4 pin connectors can withstand common vibration impacts. Used for high vibration industrial automation, drones, etc.

High frequency response test: Use a spectrum analyzer to measure the frequency response of 4 pin connectors. In high-speed data transmission, the signal is complete and meets the requirements of communication and data storage systems.

Insertion force test: Test the insertion and extraction force of the pogo pin connector, ensuring smooth and unobstructed insertion operations. Avoid unnecessary damage or malfunction during use.

Long term reliability testing: Conduct long-term continuous use testing in practical application environments. The reliability and stability of 4 Pin connectors under continuous load reduce maintenance costs.

Compatibility testing: Conduct compatibility testing with different types of equipment and electrical systems. Ensure that 4-pin connectors are suitable for industrial and consumer electronics.

Click: More Catalog

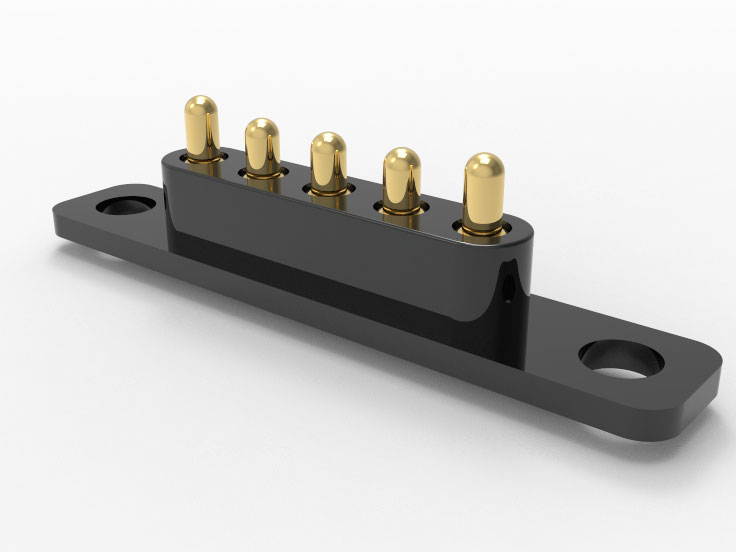

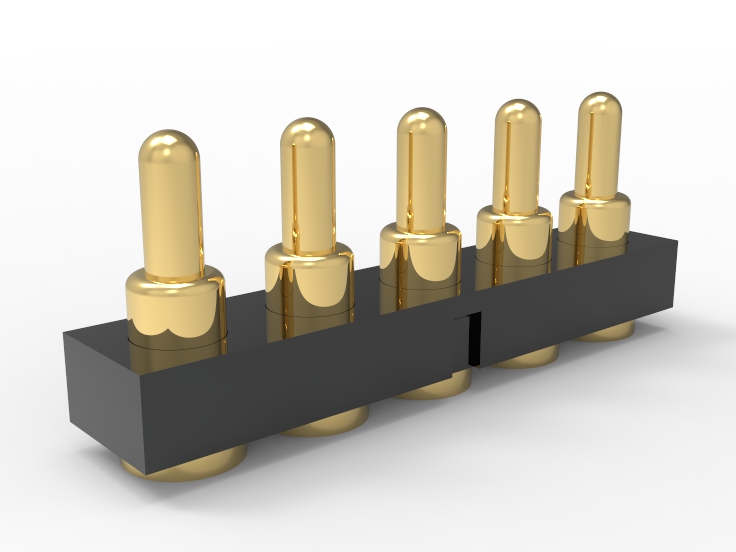

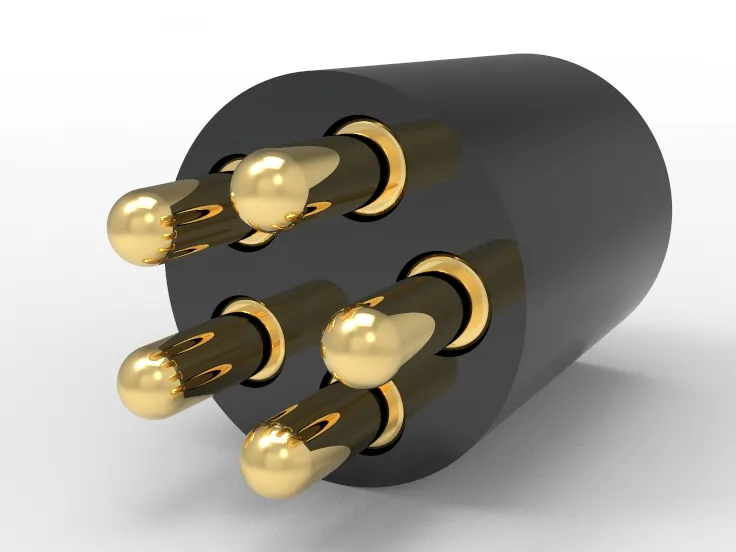

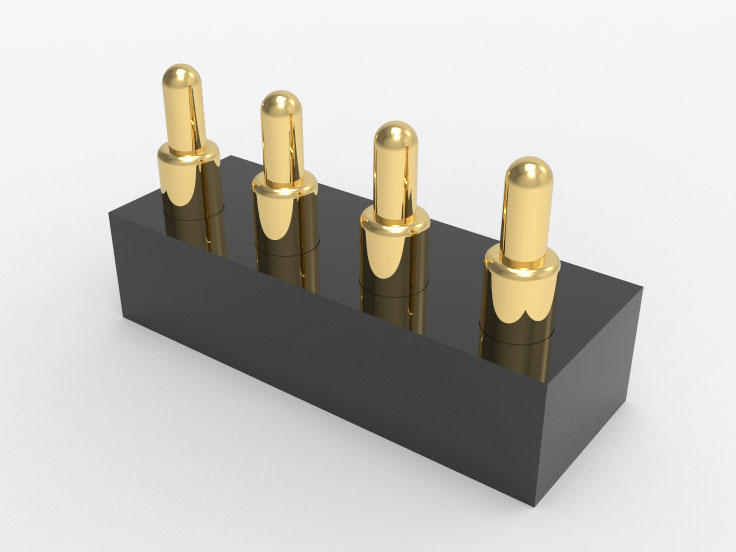

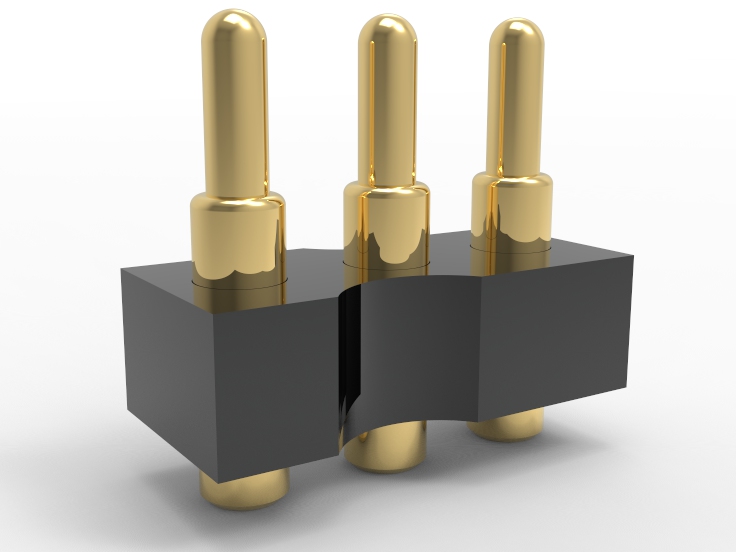

Customization of 4 Pin Connectors

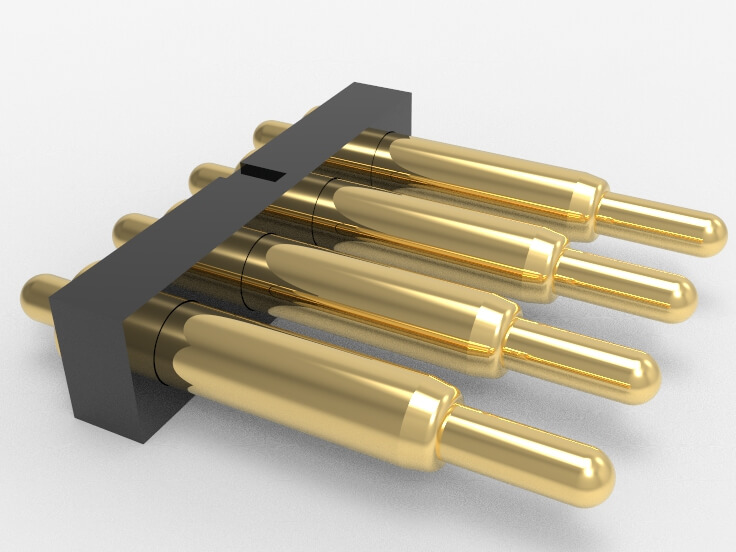

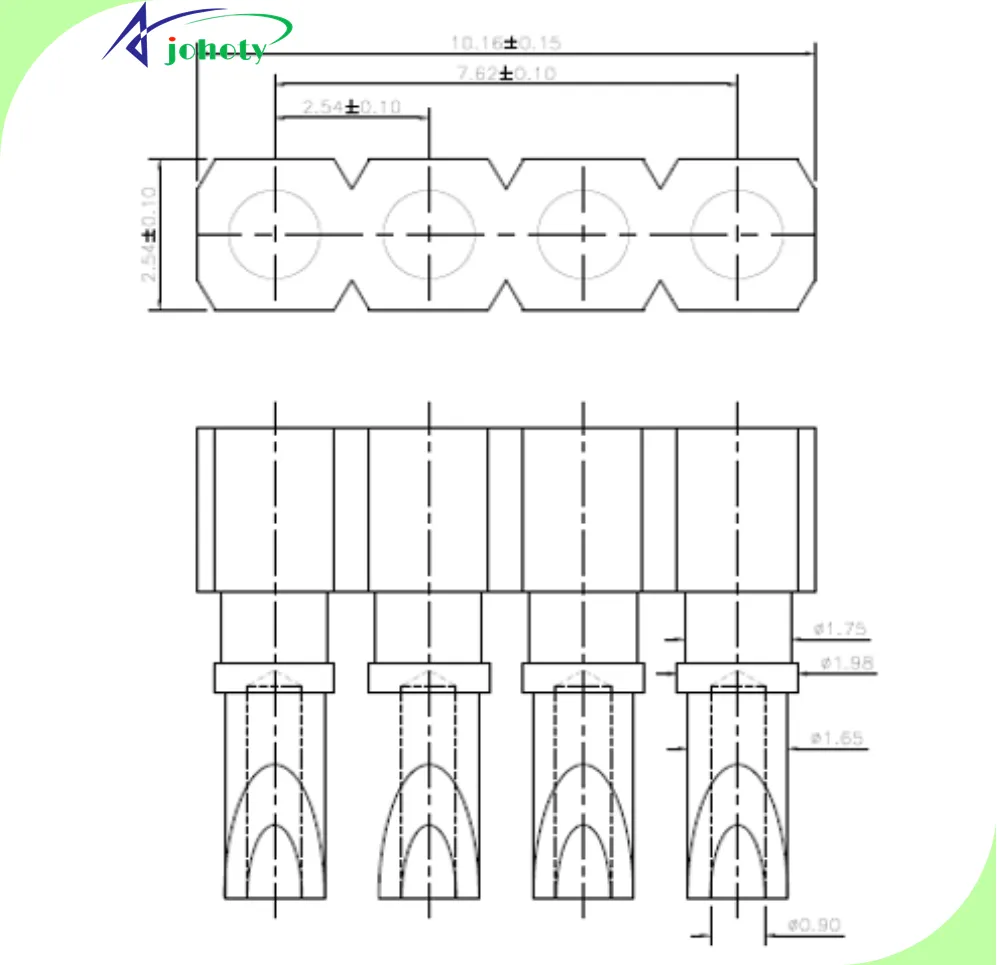

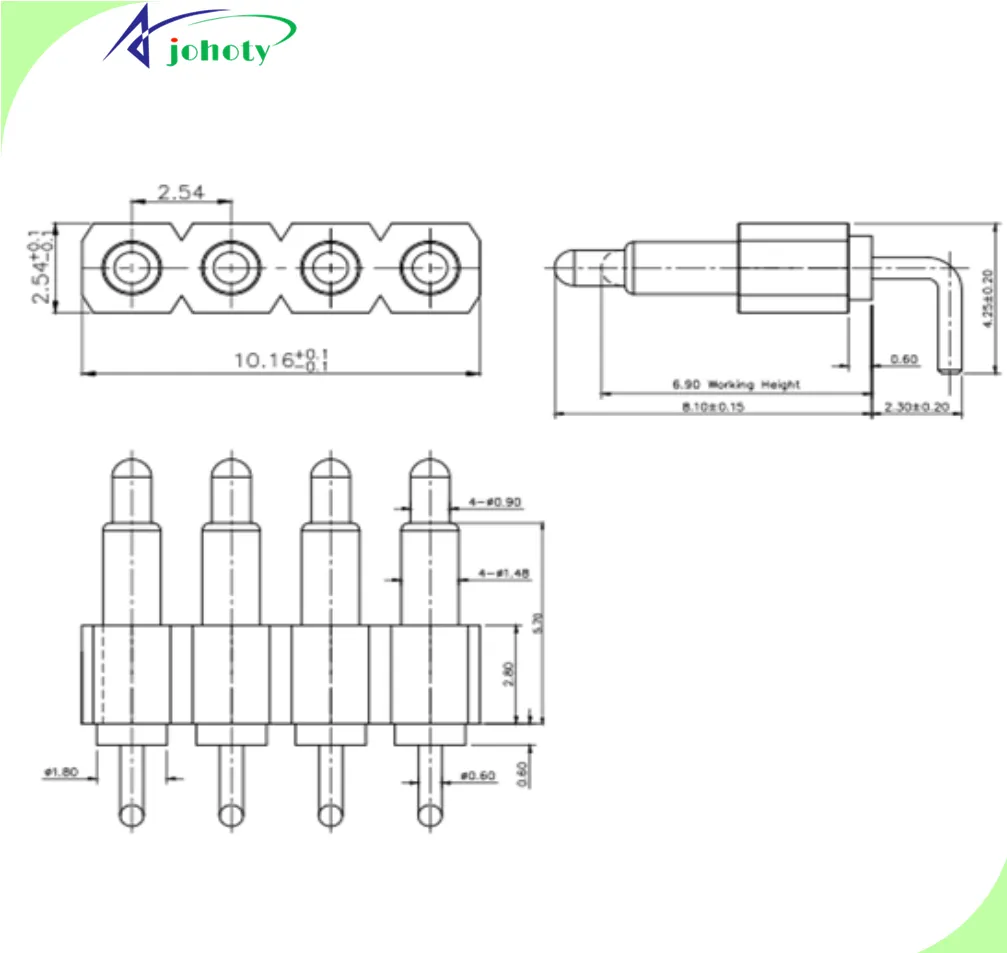

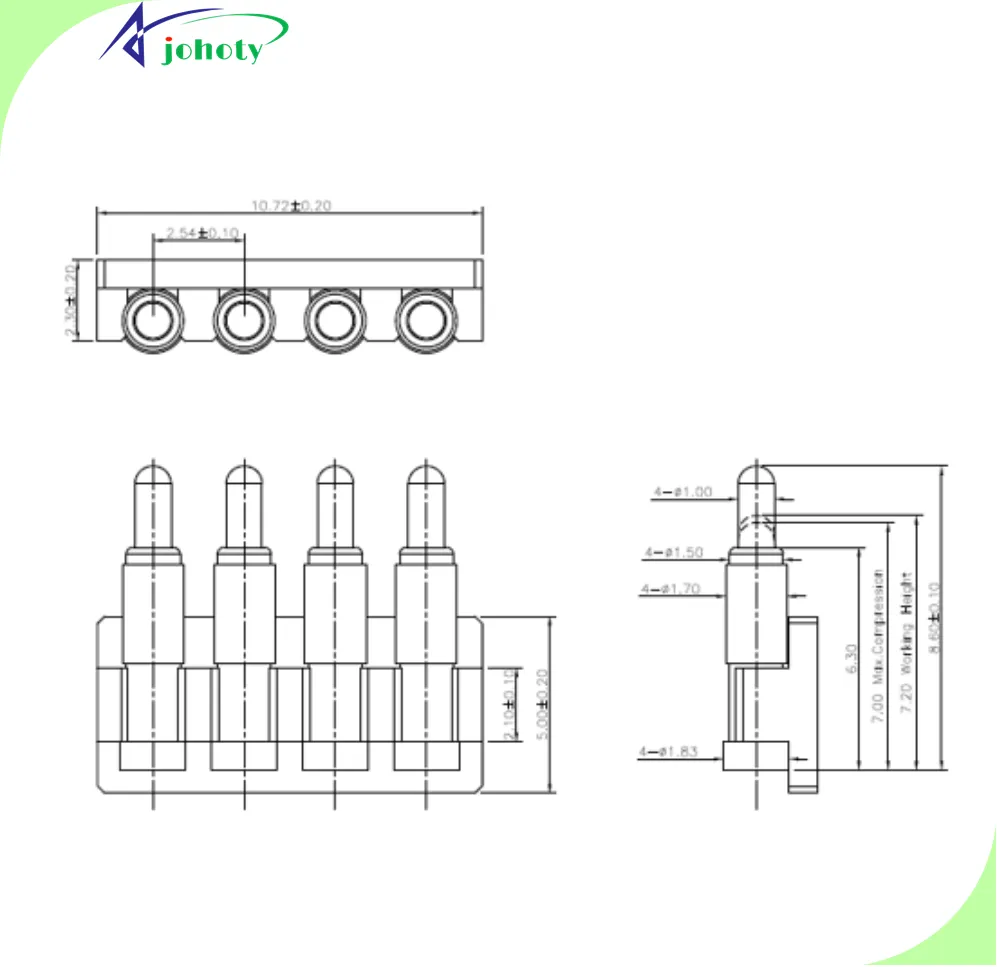

Customization of pin quantity and pitch: Provides customization from 4 Pins to up to 4,000 pins. Support adjustment for different pitches (from 2.54mm to a smaller pitch of 1.00mm), with stable electrical connections.

Customization of electrical performance: selection of different rated currents (customizable up to 50A) and rated voltages (customizable up to 250V). High power or low current devices suitable for specific applications.

Customized gold plating thickness: Customize the gold plating thickness from 0.1μm to 5μm. 4 Pin connectors have high corrosion resistance and excellent contact properties in long-term use.

Customization of elasticity and insertion force: Adjust the elasticity and insertion force of 4 Pin connectors to provide solutions suitable for precision operation or high-frequency connections. 4 Pin connectors can meet customer requirements in different usage scenarios.

Customized working temperature range: Customize the working temperature range (-40℃ to+125℃) to adapt to extreme environments. Ensure the reliability of 4 Pin connectors under various harsh conditions.

Material customization: Choose different materials such as copper alloy, metal alloy, plastic shell, etc. Corrosion resistance, oxidation resistance can meet customer’s requirements together with mechanical strength in different applications.

Spring force customization: Seismic enhanced customization ensures stable electrical performance of 4 pin connectors under high vibration conditions. Drones and automotive electronics are commonly used.

Customization of packaging methods: Multiple packaging forms are available, including T&R, ESD bags, plastic tubes, and customized paper boxes. Transportation and storage security are achievable based on different industries and customers.

Customized contact resistance: The maximum adjustable resistance is below 10mΩ, ensuring lossless signal transmission and suitable for high-speed communication and data storage systems.

Testing and Verification Services: Customized electrical and mechanical performance testing, 4 Pin connectors meet strict technical requirements. Satisfy customers’ special applications.

Pre-production sample verification: Provide pre-production samples to ensure the feasibility and stability of customized 4 Pin connectors in practical use. Customers can conduct functional validation before their mass production.

Flexible MOQ: Supports small batch customization to large-scale production, ensuring that customers can also receive high-quality 4 Pin connectors during the initial research and development stage.

Click: More Catalog

FAQ

Is the performance of 4 pin connectors stable in high vibration environments? The pogo pin connector has undergone high vibration testing and can withstand prolonged mechanical vibrations. Suitable for high vibration drones, robots, and automation equipment, with long-term stability.

What is the corrosion resistance and durability of 4 pin connectors? Use copper alloy material and apply 0.5μm~5μm gold plating treatment. 4 pin connectors have excellent corrosion and wear resistance when face harsh environments. Industrial equipment, outdoor environments, and even seawater can maintain their performance unchanged.

What is the plug-in life of 4 pin connectors? The plug-in life of each spring loaded connector is at least 10,000 times. Johoty’s specially designed pogo pins can achieve a stable lifespan of 500,000. It uses in industrial automation and consumer electronics devices for frequent connections.

Are 4 pin connectors reliable in humid or hot conditions? This pogo pin connector can pass simulated testing in humid and hot environments. Stable electrical performance can still be maintained at 90% relative humidity and high temperature. Under extreme weather conditions, such as in medical laboratories and chemical chambers, Johoty’s 4 pin connectors are commonly used.

Do 4 pin connectors support charging devices with high current and low contact resistance? After Johoty’s special design, our 4 pin connectors support a maximum current of 50A. That is to say, this pogo pin connector can support up to 200A high current and has a contact resistance as low as 10mΩ. Battery management systems and power tools that require low resistance and high power transmission cannot do without this pogo pin.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656