Advantages of 4 Pin LED Connector, Pitch 2.55~3.49

High-reliability connection

4 pin LED connector designed by Johoty has excellent electrical connection stability and can maintain stable signal transfer in various environments. The precise contact point design reduces contact resistance and improves overall performance. This pogo pin connector has good durability, clients’ feedback it can withstand frequent connections without compromising performance. It is suitable for high vibration and can maintain connection even when moving or vibrating. This 4 pin connector can reduce failure rate and improve products’ reliability.

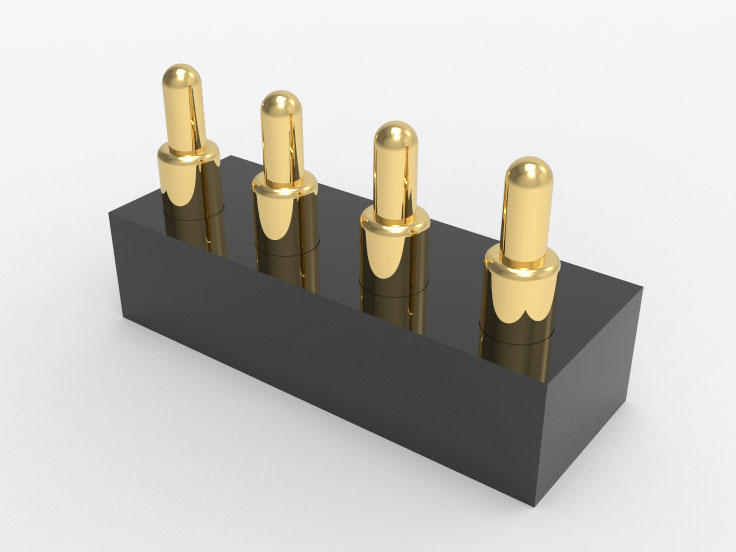

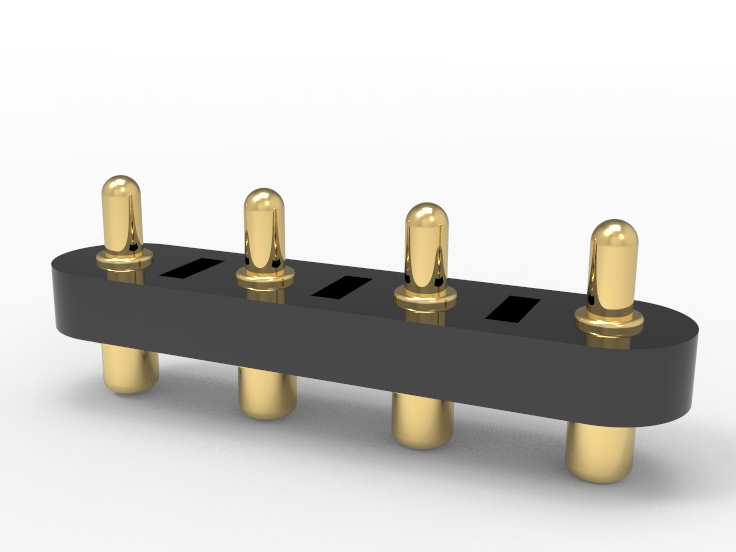

Compact and lightweight design

The 4 pin LED connector adopts pogo pin technology, achieving small volume and weight, suitable for limited space. With compact designs, Johoty’s 4 pin connector is easy to install in various small spaces. The lightweight structure of Johoty’s spring loaded connector reduces device’s overall weight, making it easy to carry and move. This design also optimizes equipment’s internal layout and improves space utilization. Compact and lightweight nature makes 4 pin LED connector popular in portable devices.

High speed data transfer

Configure pogo pins, 4 pin LED connector can transfer high-speed data, meeting device’s demand for fast signal processing. Low latency feature ensures real-time and accurate data transfer. This pogo pin connector can use for high bandwidth high-definition video transfer and high-speed data communication. This spring loaded connector reduces signal attenuation and keeps data integrity. The high-speed transfer gives it a significant advantage in high-performance devices.

Easy to install and maintain

The design of 4 pin LED connector simplifies installation process, reducing installation time and cost. Modular design makes maintenance more convenient and can replace without professional tools. This 4 pin connector connection method is more convenient for upgrades and maintenance devices. It can reduce the risk of malfunctions caused by installation errors. The easy to install and maintain features make this spring loaded connector more efficient in various applications.

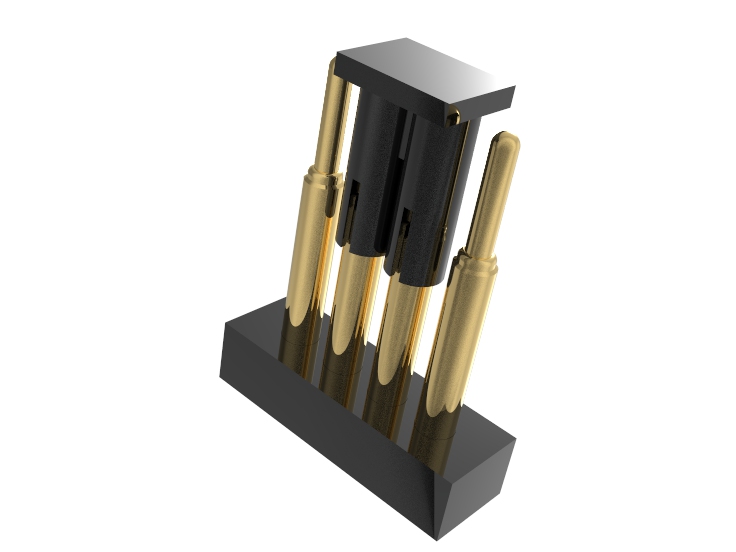

High durability and long lifespan

Johoty’s 4 pin LED connector is designed based on high-quality brass, which has excellent durability and long lifespan. The anti-corrosion can maintain stable operation in harsh environments. The wear-resistant reduces performance degradation of 4 pin connector. This pogo pin connector also has good anti-aging, it can greatly improve lifespan. Johoty’s pogo pins have significant advantages in long-term applications due to their high durability and long lifespan.

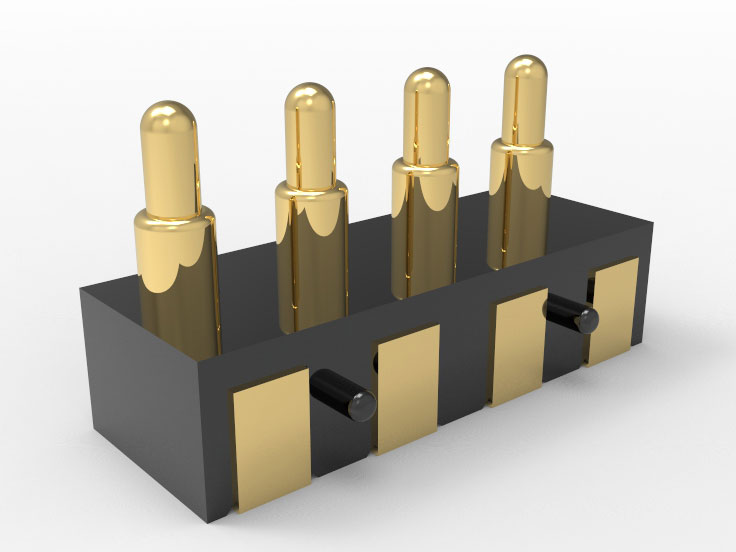

Excellent electrical performance

Our 4 pin LED connector has excellent low contact resistance and high insulation strength. This pogo pin connector can reduce EMI impact and ensure signal purity. It can fit high current based on low contact resistance and high voltage, meeting various electrical needs. This 4 pin connector also has good thermal stability and can maintain performance in high temperatures. Our 4 pin LED connector has excellent electrical performance and performs exceptionally well in high-demand applications.

Wide range of applications

Johoty’s 4 pin LED connector based on pogo pin technology. It is suitable for consumer electronics, military, communication, industrial automation, intelligent mobile devices, and medical equipment. Multi functional design can meet different applications. This pogo pin connector can fit high temperatures, high pressure, seawater, high humidity, and high vibration. This 4 pin connector also has good compatibility, can match multiple devices with seamlessly connection. Johoty’s spring loaded connector has wide applicability in the market.

High cost-effectiveness

Johoty’s 4 pin LED connector combines high performance and low cost perfectly, offering high cost performance ratio. Reduce material and production costs, and make prices more competitive. This pogo pin connector can reduce unit costs for mass production. This 4 pin connector reduces maintenance costs significantly, further improving economy. Its high cost-effectiveness often makes it popular among customers in projects with limited budgets.

FAQ

Will spring force of 4 pin LED connector affect LED brightness?

Yes, excessive spring pressure can cause an increase in contact impedance, a decrease in current passing ability, and thus affect LED brightness. Appropriate pressure can ensure stable contact, and excessive or insufficient pressure may cause LED flickering or uneven brightness. Different applications require different spring force, and excessive force may accelerate mechanical fatigue of spring loaded pin, reducing service life of 4 pin LED connector. Choosing the appropriate pogo pin pressure requires consideration of PCB pad design and LED driver circuit parameters.

What are 4 pin LED connector effects in extreme temperatures?

High temperature may cause spring to soften, reduce contact pressure, and thus affect conductivity stability. While low temperature may cause material brittleness, causing the spring to lose elasticity or fracture. Expansion coefficients of different materials are different, which may cause slight contact displacement during temperature changes, affecting LED lighting effect. If temperature changes is dramatical, condensation may occur inside 4 pin LED connector, increasing the risk of short circuit or poor contact. In low-temperature, the coating may develop small cracks due to material shrinkage, which can affect electrical performance of pogo pin connector over long-term use.

Why does coating thickness of 4 pin LED connector affect durability?

The thicker the coating, the more effective it is in reducing wear caused by friction and improving the lifespan of pogo pin connector. However, excessive coating may affect spring force and reduce contact pressure. When gold coating is thin, it is easy to be scratched, exposing underlying material, resulting in increased contact resistance and even corrosion. Reasonable coating thickness of 4 pin connector can provide clients with >10,000 life cycles and very good conductivity. Different usage require different thicknesses, we can’t simply pursue the thickest coating, but should optimize it according to actual applications.

Can 4 pin LED connector withstand vibration and impact?

Sure, but it depends on specific design. High elasticity pogo pins can enhance seismic resistance, but excessive spring force may increase mechanical stress and affect the structural lifespan. Barrel’s design is also important, a reasonable structure can reduce the looseness and displacement caused by vibration. The installation method of 4 pin LED connector also affects their spring force. The soldering-cup or through hole connections can enhance their impact resistance. Different frequencies of vibration have varying effects on 4 pin connector. And, Johoty always optimizes perfect structure for specific applications based on clients’s requirements.

Will the LED flicker due to unstable contact of 4 pin LED connector?

Yes, changes in contact resistance can cause unstable LED current, leading to flickering, which is more pronounced at low currents. Insufficient spring pressure, worn or oxidized coating of 4 pin connector may cause poor contact. Then, the LED may turn on and off intermittently. Transient resistance changes may cause protection of power supply to malfunction, affecting circuit stability. High frequency vibrations or impacts may cause brief separation of contact points, further exacerbating flickering. Using Johoty’s high-quality pogo pin connector and optimizing designs can effectively reduce such problems.

Will signal transfer of 4 pin LED connector be affected by magnetic fields?

4 pin LED connector powered by DC is usually not affected by magnetic fields, but if PWM dimming is used, magnetic field may interfere with signal integrity. If there is a strong magnetic field around 4 pin connector, it may have small impact on current path, causing resistance change of pogo pins and causing brightness fluctuations. The pogo pins of magnetic materials may be affected by forces under strong magnetic fields, which can affect contact stability. During high-speed signal transfer, magnetic field interference may affect signal integrity, but its impact is limited for ordinary LED power supply.

Does pogo pin length of 4 pin LED connector affect its electrical performance?

Yes, the longer the pogo pin, the slightly increased resistance and the increased spring deformation may affect long-term stability. An excessively long pogo pin can lead to a decrease in mechanical stability and increase displacement or deformation. Although shorter pogo pins have high stability, they may not meet equipment assembly requirements in complex structures. Long pogo pins may cause additional voltage drop under high current, and optimization design will reduce the impact. Choosing Johoty’s 4 pin LED connector with appropriate plunger length is key to balancing mechanical and electrical performance.

Can 4 pin LED connector use for rotating or sliding connections?

Limited, pogo pins are used for point contact. If used during rotation or sliding, it may lead to increased wear, rapid coating consumption, and affect contact stability. Sliding friction may cause arcing effects, further exacerbating damage to contact surface. The specially designed 4 pin LED connector can work in small rotation or sliding status, but can’t sustain large-scale movement. If long-term sliding or rotating connections are required, additional conductive slip rings or 4 pin LED connector with ball plunger are usually needed.