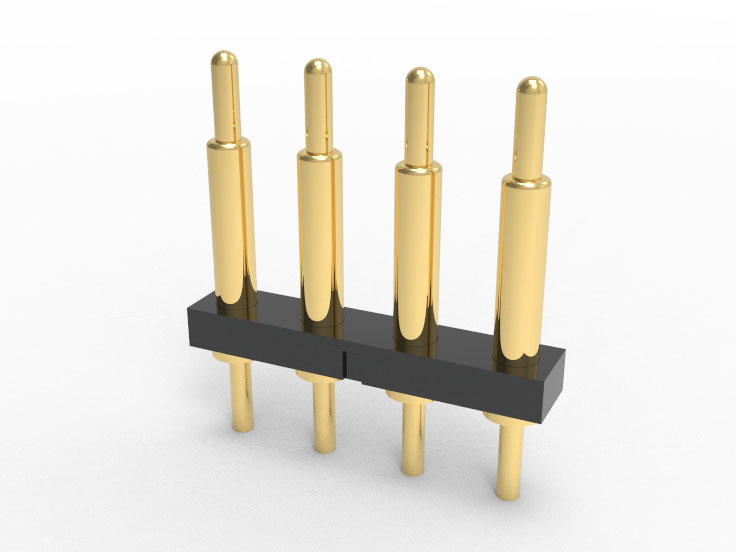

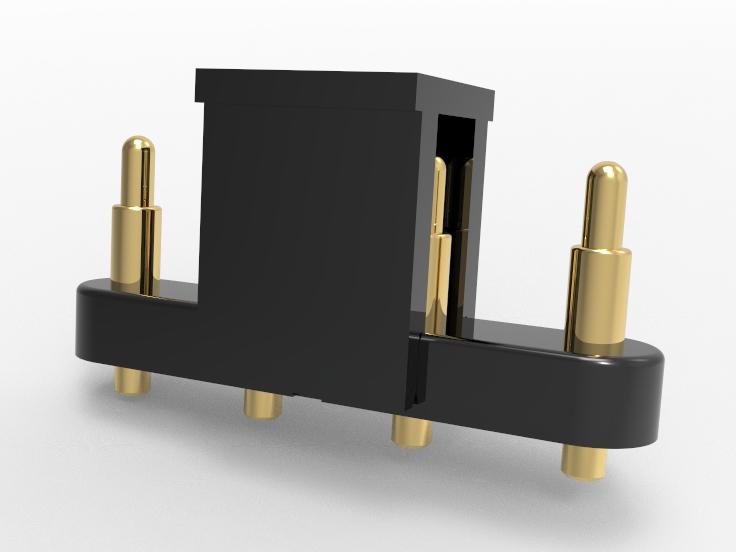

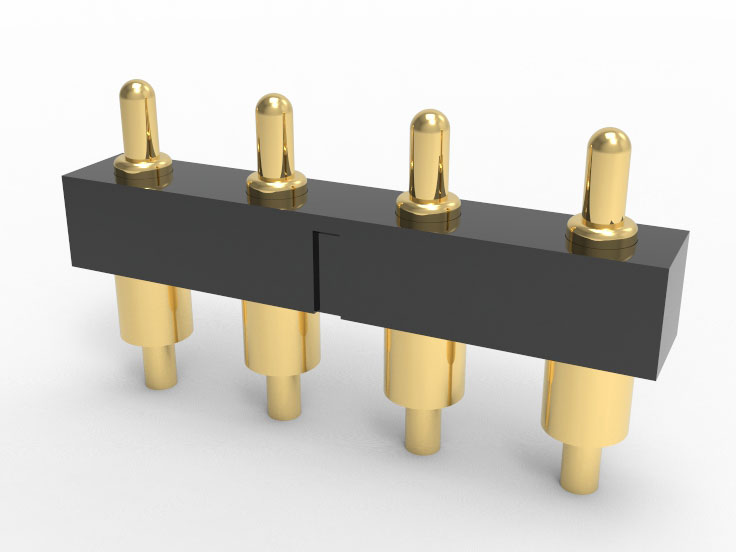

Advantages of 4 Pin LED Connector, Pitch 2.55~3.49,

Super strong anti vibration ability

On rough and uneven roads, this 4 pin trailer connector utilizes pogo pin structure to make the connection more stable, even in the face of severe bumps, it will not loosen. The core characteristics are stability, precision, impact resistance, sustainability, and efficiency, which can cope with various complex road conditions and ensure stable current transfer. Whether on highways or off-road environments, reliable connections can be maintained, significantly reducing signal loss or poor contact, ensuring driving safety, making vehicle systems operate more smoothly, and easily coping with various extreme driving conditions.

Self cleaning contact point

This 4 pin trailer connector features a special pogo pin design that gently scrapes away dirt from the contact points every time it is plugged in or unplugged, ensuring stable conductivity at all times. The core advantages are cleanliness, smoothness, unobstructed, high lifespan, and maintenance-free. Whether it is dust, oil stains, or humid environments, they will not affect the connection effect. Even with long-term use, it can maintain low contact resistance, reduce signal attenuation, keep the headlights, brakes, and other systems in optimal condition, say goodbye to frequent cleaning troubles, and use more worry-free.

Extremely low contact resistance

Using high-precision pogo pin technology, the 4 pin trailer connector has extremely low contact resistance, ensuring maximum energy transfer efficiency and reducing energy loss. Its characteristics include low resistance, high efficiency, stable current, precision, and reliability, making current transfer smoother and preventing voltage drop due to high resistance. In this way, the car lights are brighter, the signal response is faster, the vehicle circuit system is more stable, and there will be no overheating or other problems during long-term operation, bringing a better driving experience and higher energy efficiency.

Durable and long-lasting spring structure

The unique spring in pogo pin can withstand >10,000 cycles of insertions and removals, maintaining a stable connection even under high-frequency use. The core characteristics are wear resistance, durability, stability, fast rebound, no deformation, and no poor contact due to long-term use, greatly extending the service life. Compared to traditional plug-in connectors, 4 pin trailer connector can reduce replacement frequency, avoid contact failure due to metal fatigue. It can ensure long-term reliability of trailer systems, reduce maintenance costs, and improve work efficiency.

Adapt to extreme temperature changes

Whether in severe cold, ice, or hot deserts, the 4 pin trailer connector can maintain stable performance and is not affected by temperature. Its characteristics are cold resistance, heat resistance, stable voltage, high adaptability, and long-lasting. Even with drastic temperature changes, pogo pins can still ensure reliable contact and will not loosen or lose power due to thermal expansion and contraction. Whether it’s the cold winter of minus tens of degrees Celsius or the scorching heat on the highway, the car lights and signal system can operate stably without being restricted by the environment.

Quick installation and disassembly

The design of a 4 pin trailer connector eliminates the need for complex operations, making installation and disassembly easier and more efficient. The advantages include convenience, instant connection, stability, tool free, and time-saving. With just a gentle press, precise docking can be achieved, and smooth insertion and removal without lagging. No additional adjustments or welding are required, reducing installation difficulty and significantly shortening assembly time. This 4 pin connector is suitable for vehicle applications that require large-scale production and frequent replacement, improving operational efficiency, reducing labor costs, and making it easy to use.

Highly compatible with multiple vehicle models

Whether it’s heavy-duty trucks, RVs, freight trailers, or agricultural equipment, the 4 pin trailer connector can be perfectly adapted and has strong versatility. The main features are universality, wide compatibility, stability, high compatibility, easy integration, suitable for various vehicle systems, and compatible with different electrical interfaces. This pogo pin connector can easily connect to various lighting and signal devices without the need for additional conversion interfaces, making the towing system more flexible. Regardless of the vehicle model, the connection is simple and reliable, truly achieving a 4 pin connector that can adapt to various needs.

Strong waterproof and dustproof design

Specially designed for harsh outdoor environments, the 4 pin trailer connector has excellent waterproof and dustproof capabilities, ensuring stable operation even in harsh weather conditions. The core features are sealing, corrosion resistance, moisture resistance, fearlessness of rain and snow, and high reliability. Even in heavy rain, mud, or dust, it will not affect the circuit connection. Pogo pins come with anti pollution design, ensuring smooth and unobstructed use for extended periods of time, avoiding short circuits or malfunctions, and keeping the trailer system in optimal working condition, improving overall safety and reliability.

FAQ

Will 4 pin trailer connector loosen due to long-term vibration?

No, pogo pins in 4 pin trailer connector adopts high-precision spring, which can maintain stable contact under long-term vibration. It has high rebound, impact resistance, firmness, durability, and fatigue resistance, won’t loosen or fail whether driving on bumpy mountain roads or at high speeds. The unique design ensures continuous and stable current transfer, avoiding signal loss. This 4 pin connector enables trailer system to operate reliably in various environments without power outages or poor contacts caused by vibrations.

much current may 4 pin trailer connector withstand?

Pogo pin design of this 4 pin trailer connector supports high current and won’t cause malfunctions due to overload. It has high power, high efficiency, high temperature resistance, low impedance, and stable current. This can meet high-power requirements of heavy trucks, RVs, freight trailers. Even after long-term high loading, it can maintain stable current output and avoid heating or power loss. The pogo pin connector can make power system of trailer vehicles safer and more efficient, adapting to various power consumption.

Will contact points of 4 pin trailer connector fail due to dirt?

No, pogo pin self-cleaning function can automatically clean contact points every time it is plugged in and out, keeping connection smooth. Anti fouling, corrosion-resistant, stable, smooth, and long-lasting, ensuring stable conductivity in dusty, humid, or oil. 4 pin connector doesn’t require frequent manual cleaning, reducing maintenance burden and allowing trailer system to operate stably in harsh. The pogo pin connector is not affected by dirt, ensuring the reliability of lighting, braking, and signal systems.

Will 4 pin trailer connector fail in extreme low temperatures?

No, pogo pins are made of special materials that can maintain good elasticity and conductivity in cool. It is always cold resistant, low temperature resistant, non shrinking, stable, and able to work continuously. In several tens of degrees below zero, 4 pin condenser can ensure stable current transfer without poor contact caused by metal shrinkage. Whether in snow covered mountainous areas or cold Arctic regions, pogo pin connector can ensure normal operation of trailer systems. It will not affect the lighting and signal functions due to low temperature.

Can 4 pin trailer connector adapt to high salt environments by seaside?

Yes, 4 pin trailer connector is made of corrosion-resistant materials and won’t rust or have poor contact in high salt environments. Pogo pins are salt spray resistant, antioxidant, moisture resistant, highly durable, and have stable connections. In coastal areas and port terminals, spring loaded pin can still work stably. Special coating can effectively prevent metal surface oxidation and ensure low contact resistance after long-term use. 4 pin trailer connector ensures reliable operation of trailer circuit system in humid and high salinity air.

Will the spring of 4 pin trailer connector reduce force after prolonged use?

No, pogo pin is made of high-strength alloy spring material, ensuring good resilience. It is fatigue resistant, highly elastic, stable, non deformable, and has a long lifespan. It can withstand 10,000 cycles without affecting performance. Despite frequent connections, it still maintains precise contact and won’t loosen or fail. 4 pin trailer connector ensures long-term stability of trailer’s electrical system and reduces contact issues caused by spring aging.

Will too many connections of 4 pin trailer connector affect its performance?

No, the pogo pin of 4 pin trailer connector is coated with wear-resistant material, which can maintain good conductivity. It always has high wear resistance, oxidation resistance, long-lasting stability, precise contact, and zero loss. After 10,000 connections, contact resistance of pogo pin remains low and doesn’t affect current transfer. 4 pin connector is suitable for logistics vehicles, emergency trailers, etc. that require frequent disassembly and assembly. This ensures power system remains in optimal condition for a long time.

Is 4 pin trailer connector suitable for continuous high-frequency vibration?

Sure, 4 pin trailer connector adopts a high-precision pogo pins, which can maintain stable connection under long-term high-frequency vibration. It is earthquake resistant, impact resistant, durable, zero loosening, and highly reliable. This can ensure its use on transportation vehicles that experience frequent vibrations. Always maintain stable contact in freight trailers, off-road vehicles, etc., unaffected by vibration. Continuous vibrations on highways, extreme bumps on off-road terrain, and 4 pin trailer connector won’t affect current transfer and signal stability of the trailer system.