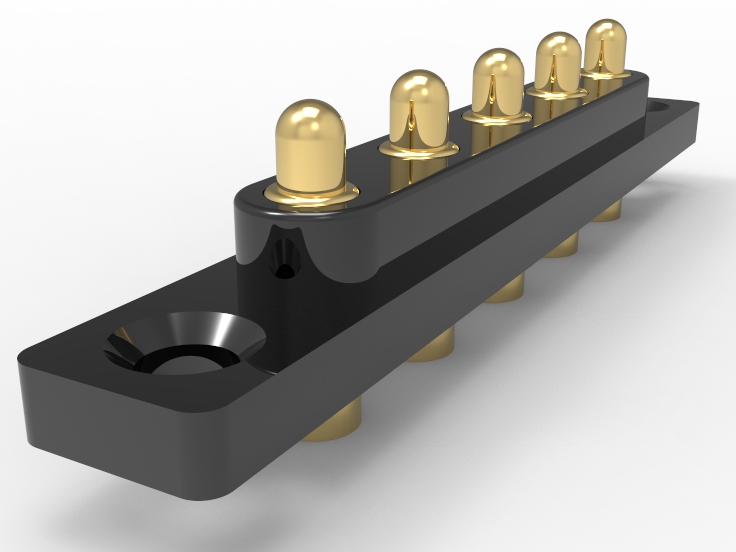

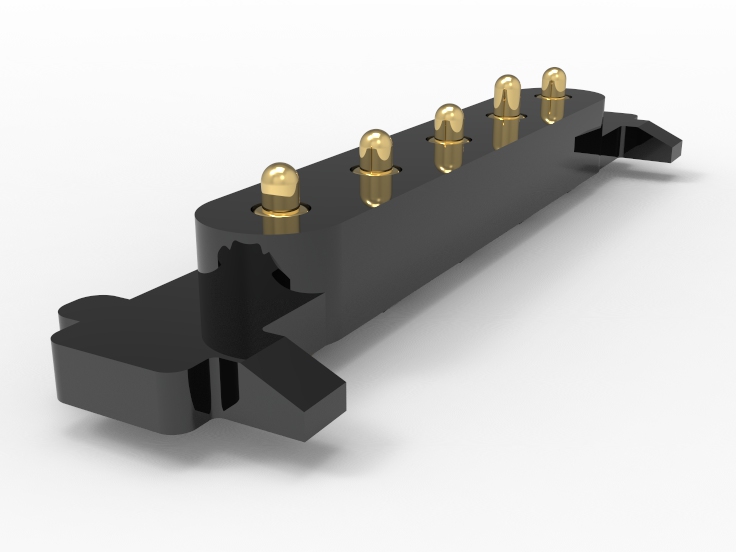

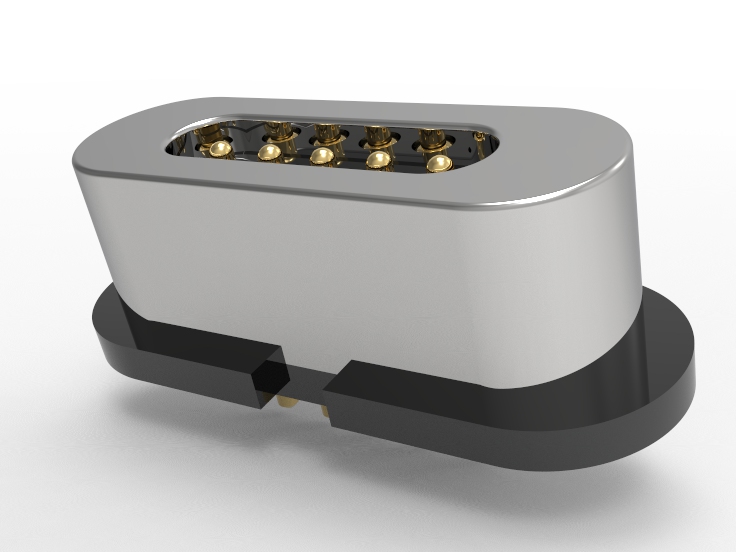

Advantages of 5 Pin Trailer Connector, Pitch 2.55~6.48

Ultra low contact impedance, no loss in signal transfer

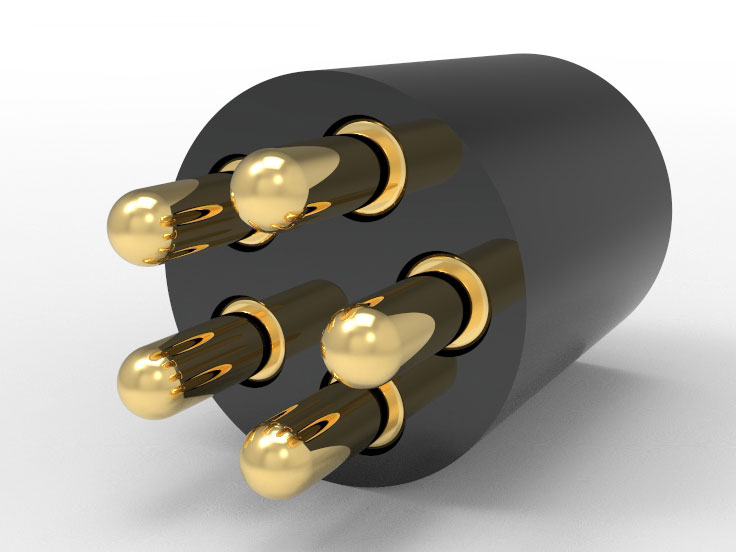

High-precision pogo pins technology enables 5 pin trailer connector to have low contact impedance. It ensures efficient transfer of current and signals. Engineers can enjoy minimal voltage drop and better signal integrity, suitable for high-speed data exchange or stable power supply. Its pogo pin adopts precision gold plating technology, and contact points maintain a low impedance state for a long time. Maintaining excellent conductivity in high-frequency connections ensures device’s long-term reliability.

Excellent wear-resistant design ensures long-term stability

The 5 pin trailer connector adopts a high-precision spring loaded pin structure. With excellent wear resistance, it can keep excellent contact performance after at least 10,000 connections. Johoty’s R&D precisely designs springs, and this pogo pin connector has a strong insertion force. It won’t cause additional pressure on the terminals and can effectively reduce mechanical fatigue. Meanwhile, based on special coating of pogo pins, plunger tip is corrosion & oxidation resistant. It can still provide sustained and stable current transfer in complex usage.

Adaptive tolerance compensation, accurately matching different devices

Precision pogo pins endow 5 pin trailer connector with strong adaptive docking. There are slight errors within assembly tolerance range, which can still ensure reliable contact. Unique spring loading effectively compensates for tolerance deviation, which can avoid poor contact caused by vibration, displacement, inaccurate installation. For devices that require precise signal transfer, this pogo pin connector adaptive compensation technology greatly improves connection stability. Your device can maintain excellent electronic performance in complex environments.

Ultra compact structure, maximizing optimized spatial layout

Johoty’ 5 pin trailer connector adopts a highly integrated pogo pin design, making overall size compact. It can provide engineers with greater layout flexibility. The miniaturization of this pogo pin connector saves valuable PCB space and reduces overall component weight. It is highly suitable for precision electronic devices that have strict requirements for size and weight. Meanwhile, the highly optimized layout reduces parasitic capacitance and inductance. High frequency signals can still maintain excellent integrity in compact layout of pogo pins.

Excellent anti vibration ability, impeccable stability

Precise pogo pins endow 5 pin trailer connector with superior seismic performance. Unique spring-loaded design effectively absorbs impact force, maintains stable connection under severe vibrations or sudden impacts. In aerospace, automotive electronics, and high-end industrial equipment, excellent anti vibration ensures system’s normal operation in harsh. Compared to traditional fixed connectors, the floating contact scheme of spring loaded connector greatly reduces mechanical stress and improves overall lifespan.

Low insertion force and high extraction force, balancing convenience and firmness

Engineers often need to consider operation convenience and ensure connection firmness when designing electronic connections. 5 pin trailer connector is a perfect balance. Optimized pogo pin spring parameters maintain insertion force within a comfortable range for users. High pull-out force ensures that this pogo pin connector won’t detach due to slight external forces. High precision machining ensures equal and consistent force during each insertion and extraction. Users can enjoy a smooth and stable connection experience across different applications.

Low signal crosstalk to improve data transfer accuracy

Johoty’s 5 pin trailer connector based on high-precision pogo pins has been specifically optimized for signal path. It can significantly reduce crosstalk and EMI, and improve accuracy of data transfer. Shielding design combined with a reasonable pitch ensures excellent integrity of high-speed signals when passing through pogo pin connector. This can reduce bit error rate and improve system’s overall communication reliability. For high-speed data transfer and precision control signals, its low crosstalk ensures signal is clean and free of clutter.

Automated assembly is friendly and improves production efficiency

The 5 pin trailer connector adopts high-precision CNC manufacturing and has high compatibility in automated assembly processes. Accurate dimensional & tolerance control and standardized design enable quick and efficient installation during automatic welding or plug-in assembly. This pogo pin connector greatly reduces manual intervention and improves production consistency. Meanwhile, self-cleaning feature of pogo pins ensures that there is no oxide accumulation on plunger tip surface. It reduces poor contact and improves overall production yield of customer products.

FAQ

What is effect of 5 pin trailer connector on contact pressure?

When designing 5 pin trailer connector, contact pressure of each pogo pin must be accurately calculated. This is because contact pressure directly affects the quality of signal transfer. If contact force is too small, connection may be unstable, leading to transfer errors. If contact force is too strong, it may damage the metal surface and contact surface of the plunger tip. Engineers typically choose appropriate materials and designs to maintain pressure within the optimal range and ensure long-term stability. Under high load conditions, the choice of contact surface material for pogo pin connectors is important. Gold plating on stainless steel or copper alloy can reduce contact resistance and improve efficiency.

How to avoid current fluctuations in 5 pin trailer connector?

When using 5 pin trailer connector in high current, current fluctuations may become a problem. To reduce such fluctuations, Johoty often carefully selects suitable materials and precision. The elasticity and conductivity of pogo pins are key factors determining current stability. Different metal finishing, such as copper or gold plating, can effectively enhance corrosion resistance and current surge resistance of pogo pin connector. In addition, the arrangement of pogo pins can also affect current uniform distribution. It affects signal stability and equipment reliability.

What are performance changes of 5 pin trailer connector at extreme temperatures?

At extreme temperatures, the performance of 5 pin trailer connector will be greatly affected. At low temperatures, the shrinkage of certain materials can lead to loose connections, affecting current transfer. However, high temperatures may cause material’s thermal expansion in contact, thereby increasing contact resistance and affecting performance. Therefore, choosing suitable extreme temperature resistant materials is crucial. By using high-temperature gold-plated pogo pins, it can keep high stability under extreme conditions. This can ensure equipment’s long-term reliability. Engineers will often use optimized temperature compensation design to solve this problem.

Is 5 pin trailer connector flexible and durable?

The flexibility and durability of pogo pins are important considerations during designing 5 pin trailer connector. As usage frequency increases, pogo pins in pogo pin connector will gradually wear out, affecting signal transfer. In order to improve durability, high-quality alloy materials and optimized design of springs can extend their lifespan. In addition, the number of connections designed by Johoty can also affect the reliability. Therefore, reasonable control of force and frequency can effectively prevent metal fatigue and aging, and maintain stable connection effect.

How to design 5 pin trailer connector to improve vibration resistance?

In long-term operation or vibration, the anti vibration ability of 5 pin trailer connector is very important. Johoty often designs pogo pins that meet high-frequency vibrations. These pogo pin connectors can effectively reduce poor contact caused by vibration. By using materials with high elasticity and special finishing, the stability of spring loaded pin can be significantly improved. Furthermore, optimizing contact pressure and pogo pin materials can also enhance anti vibration performance, ensuring 5 pin trailer connector won’t fail.

Does 5 pin trailer connector have good electrical performance in humid?

The electrical performance in humid is a challenge for 5 pin trailer connector. Moisture may cause electrical corrosion in connectors, in high humidity where metal parts inside connector are prone to rusting. In order to improve corrosion resistance, the surface of pogo pins is usually gold plating, which can enhance conductivity and effectively prevent corrosion. Johoty will also add waterproof designs to ensure that 5 pin trailer connector can maintain good contact and signal transfer in rainy or humid.

What is optimal solution for contact resistance of 5 pin trailer connector?

The contact resistance has a direct impact of 5 pin trailer connector on performance. If contact resistance is too high, it may cause signal attenuation or heating problems, affecting the normal operation. To optimize contact resistance, Johoty usually chooses gold-plated beryllium copper and precisely designs geometric shape of contact surface. It is to reduce the resistance between contact surfaces. The spring force and material of pogo pins directly determine the magnitude of contact resistance. Common optimization solutions include using gold and silver plating to enhance the conductivity of 5 pin trailer connector.

Is the size and application compatibility of 5 pin trailer connector high?

The size design of 5 pin trailer connector is very important, and of course, Johoty can use 6-axis CNC machining without worrying about precision. We choose appropriate pogo pin size and pitch based on space requirements. If size is too large, it may cause interface incompatibility. If it is too small, it may not provide sufficient current and signal transfer capability. To ensure compatibility, Johoty often customizes dedicated sockets and 5 pin trailer connector for different devices. In addition, installation and plugging methods of 5 pin trailer connector should also be considered. This will ensure it can be easily installed in a small space.