Advantages of 6 Pin Connectors, pitch 2.55~5.00

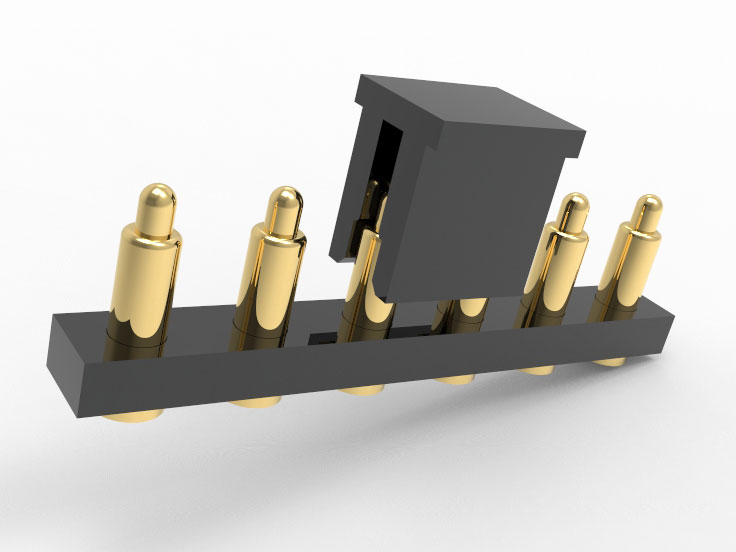

Low contact resistance ensures signal integrity

High precision pogo pins endow 6 pin connectors with extremely low contact resistance, reducing signal transfer loss to almost imperceptible levels. Engineers can handle high-frequency signals and low-voltage applications with peace of mind, without worrying about data attenuation or increased power consumption. The gold-plated contact surface of the plunger tip provides excellent oxidation resistance and can operate efficiently for a long time without being affected by the environment. This optimized current path design allows pogo pin connectors to maintain stable electrical performance in high-density circuits.

Excellent mechanical durability, long lifespan and high stability

The 6 pin connectors are designed with precision springs, and each pogo pin has been optimized. This can withstand over 10,000 contacts without any performance degradation. With high elasticity materials and strict manufacturing tolerance control, pogo pin connectors can maintain precise contact pressure without compromising reliability. Engineers can rely on the stable mechanical lifespan of this spring loaded connector when designing devices that require high-frequency connections. It ensures product’s durability, reduces maintenance and replacement, and enhances reliability.

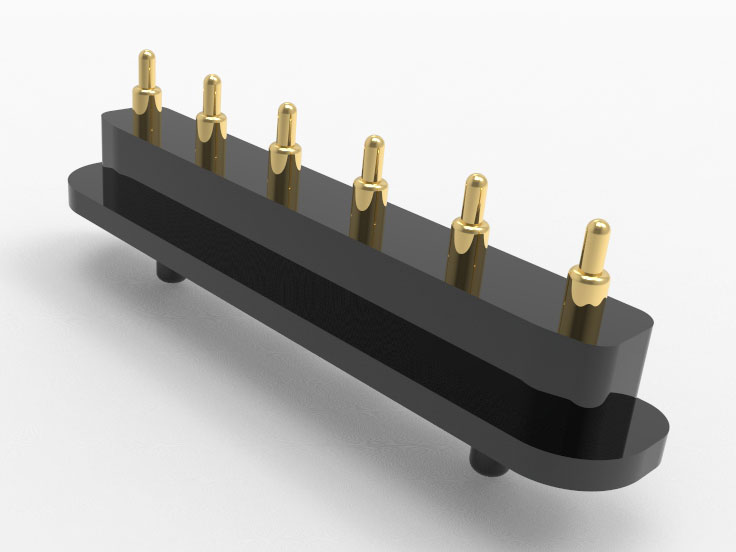

Compact structure, achieving maximum space utilization

Pursuing the ultimate miniaturization of modern electronic devices, 6 pin connectors take up less space to meet the needs. With its ultra short stroke pogo pin technology, this pogo pin connector can significantly reduce the overall height. Fine pitch ensures the possibility of high-density layout and provides stable and reliable connections on extremely small PCBs. Engineers can benefit from this optimized volume design without sacrificing electrical performance. It has become an ideal choice for portable devices, wearable devices, etc. that require extremely high space.

Excellent anti vibration ensures stable connection in harsh

6 pin connectors have an optimized elastic structure with high-precision pogo pins. They can effectively absorb small mechanical vibrations and prevent poor contact caused by vibrations. Its high rebound force ensures stable contact pressure and provides stable signal transfer under continuous vibration conditions. Engineers can use it with confidence in industrial equipment, aerospace electronics, or automotive electronic systems that require resistance to impact and vibration. Meanwhile, engineers do not need to design additional seismic resistant structures to compensate for connection issues.

Low insertion force and high retention force coexist, optimizing user experience

The common problem of high insertion force in traditional shrapnel connectors is cleverly avoided on 6 pin connectors. High precision pogo pins achieve extremely low insertion force through optimized spring stiffness and structural design, making assembly and operation easier. At the same time as low insertion force, its high retention force ensures the firmness of the connection, avoiding connection failure caused by external pulling or micro movement. This balanced design provides engineers with a better assembly experience while ensuring long-term reliability of connections without affecting equipment performance.

Adaptive tolerance compensation matches more assembly

In high-precision electronics, small assembly errors always generate connection failures. Johoty’s 6 pin connectors, with adaptive spring travel of pogo pins, can effectively compensate for small tolerances in manufacturing, assembly. Although slight deviations in PCB or contact pad, pogo pins can still provide stable contact pressure for connection stability. Johoty’s pogo pin connector can greatly enhance the flexibility of engineers in product design and production processes. It reduces reliance on strict tolerance control and improves E2E manufacturing yield.

High current carrying to meet high-power requirements

6 pin connectors are not only suitable for signal transfer, but also have superior performance in power applications. High precision pogo pins use low impedance conductive materials and optimized current distribution design. This makes the current carrying capacity of a single pogo pin far exceed that of traditional patch connectors. Engineers can use it with confidence in circuits with high power demands, without the need to add multiple pins to share the current load. This efficient current management allows devices to operate on a limited number of connection points. The equipment can obtain stronger power supply capability and reduce the design complexity of engineers.

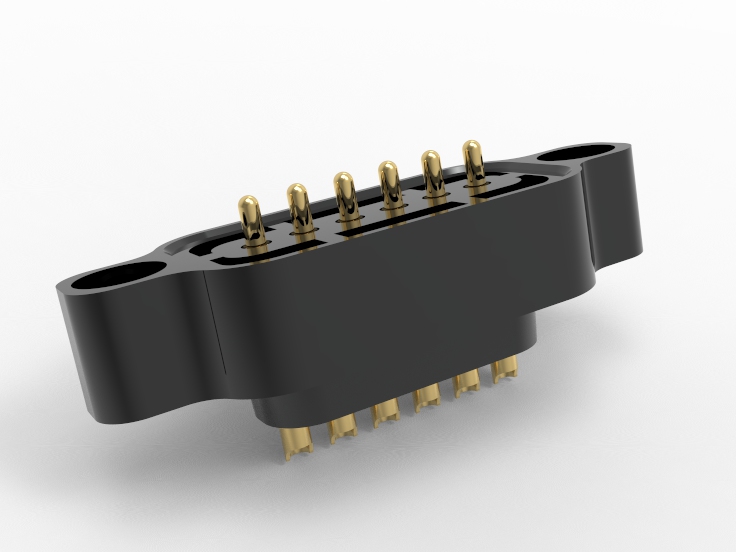

Modular custom design, compatible with multiple applications

The pogo pin technology of 6 pin connectors supports multiple spring force and stroke configurations. Engineers can customize suitable contact force, spacing, and arrangement based on different applications. High speed data transfer, low-voltage power supply, and complex signal interfaces can all be easily adapted through modular structures, reducing unnecessary design iterations. Based on this flexible customization capability, it has become an ideal choice for intelligent devices, industrial automation, and medical instruments in high demand fields. Pogo pin connectors can help engineers achieve product innovation, iteration, and production more efficiently.

FAQ

Will short pogo pin stroke of 6 pin connectors affect contact?

No, precision pogo pin structure can provide high rebound force, ensuring sufficient contact pressure and reliable connection with small strokes. The spring has been optimized, and even slight compression deviations won’t affect signal or current transfer. Gold plated contact surface reduces micro motion wear and improves long-term stability. This pogo pin connector can maintain stable contact even in high vibration or high-frequency connection environments. Engineers don’t need to worry about stroke and can be flexibly applied to various devices.

Can 6 pin connectors transfer high-speed data?

Of course, high-precision pogo pins have low impedance paths to ensure signal integrity and reduce data attenuation. Optimized contact point design reduces crosstalk, improves signal quality, and is suitable for high-speed data applications. The spring loaded structure reduces micro contact noise, and 6 pin connectors are suitable for high-speed communication interfaces. Stable contact pressure ensures long-term signal consistency and is not affected by the number of insertions and removals. This pogo pin connector can be used for high-speed serial communication, storage devices, or micro data interfaces.

How can 6 pin connectors maintain reliability under different assembly tolerances?

The adaptive spring stroke of pogo pin can automatically compensate for assembly tolerances, ensuring stable contact points. High precision manufacturing controls pogo pin’s pitch, providing precise docking even with small deviations. The optimized contact area enables 6 pin connectors to be compatible with different board thicknesses or housing tolerances. The spring force curve design prevents performance degradation caused by excessive compression. This pogo pin connector does not require strict adjustment of component positions and can improve assembly tolerances.

Can 6 pin connectors use for high current power supply?

Sure, the pogo pin uses low impedance materials to optimize current distribution and can support high-power loads. The short path design of 6 pin connectors reduces current loss and improves energy efficiency. The high elasticity contact structure ensures stable conductivity and prevents poor contact due to temperature changes. The gold plating layer is resistant to oxidation and long-term use does not affect its conductivity. It can be used for low-voltage high current power modules, mobile device fast charging, or industrial power connections.

How do 6 pin connectors cope with micro vibrations?

The spring-loaded pogo pin design can absorb slight vibrations and prevent poor contact caused by mechanical disturbances. High rebound force provides stable contact pressure, avoiding signal loss caused by long-term vibration. Gold plated contacts reduce the impact of micro corrosion and enhance vibration resistance reliability. The optimized mechanical structure can adapt to aerospace, automotive, or industrial vibration environments. 6 pin connectors do not require additional shock-absorbing design and can operate stably for a long time.

How do 6 pin connectors perform in high humidity?

Gold plated contact points provide excellent oxidation resistance and prevent humidity from affecting conductivity. 6 pin connectors packaging process reduces internal corrosion risks and adapts to humid environments. The high elasticity material ensures that water vapor does not affect the spring’s rebound force and maintains reliable contact for a long time. The optimized layout design of this pogo pin connector reduces water vapor accumulation and improves environmental tolerance. It can be used in outdoor electronics, seawater, medical equipment, ocean fleets, or high-humidity environments.

Can 6 pin connectors use for devices with rotatable connections?

Yes, the 6 pin connectors structure allows for slight changes in rotation angle, ensuring unrestricted connections. High elastic contact pressure maintains stable conductivity, and even rotation does not affect signal or current transfer. Optimized mechanical design prevents contact wear and improves long-term durability. Our 6 pin connectors are suitable for rotating screens, smart wearables, or automatic docking systems. This spring loaded connector can easily achieve high reliability rotary connection solutions.

Can 6 pin connectors stably work in high voltage?

Typically, 6 pin connectors are used for low voltage connections, and their optimized design can be adapted to medium or even high voltage applications. The spacing between pogo pins should be at least 1.50mm to avoid the risk of breakdown and improve electrical safety. The multi-point contact of this pogo pin connector reduces local hotspots and decreases the probability of electrical breakdown. High flame retardant materials enhance pressure resistance and are suitable for specific industrial and medical equipment. 6 pin connectors can be safely applied to precision power supplies or control systems within an appropriate voltage range.