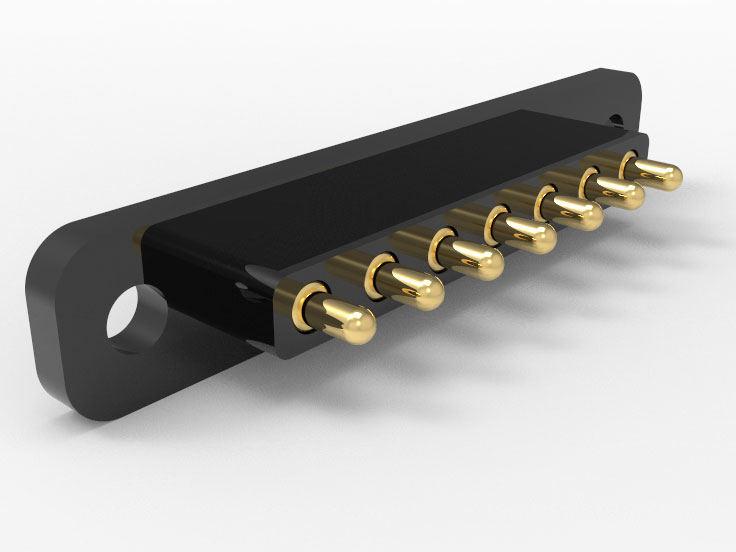

Advantages of 7 Pin Trailer Connector, Pitch 1.00~4.50

Ultra low contact resistance, reducing energy loss

Johoty’s 7 pin trailer connector uses high-precision pogo pins, with single point contact resistance as low as milliohms. Compared to traditional pin structures, the current transfer efficiency is higher. Precision coating technology reduces the oxidation risk of micro contact surfaces, ensuring stable signals and minimal energy loss. Maintain low temperature rise characteristics even under high-power load conditions. This pogo pin connector effectively improves the efficiency of the entire trailer power system. It avoids the risk of malfunction caused by additional heating.

High dynamic compensation, stable signal connection

Traditional connectors are prone to poor contact in vibration or shaking environments. Johoty’s 7 pin trailer connector adopts pogo pins dynamic compensation structure. Each contact point has independent elastic adjustment capability, which can provide stable and low-noise signal transfer even under high G-forces, bumps, or severe impacts. The independent floating contact design can effectively avoid transient disconnection and provide more accurate data signal guarantee for the intelligent trailer control system.

>50,000 plug and unplug cycles, ultimate durability

Ordinary trailer connectors have limited insertion and extraction times, and the pins are prone to poor contact due to friction and wear. Johoty’s 7 pin trailer connector adopts pogo pins technology, with a self-lubricating contact point structure and a plug-in life of >50,000 times. This pogo pin connector surface coating process can enhance its wear resistance. In high-frequency, it can keep long-term stable connections and reduce maintenance costs.

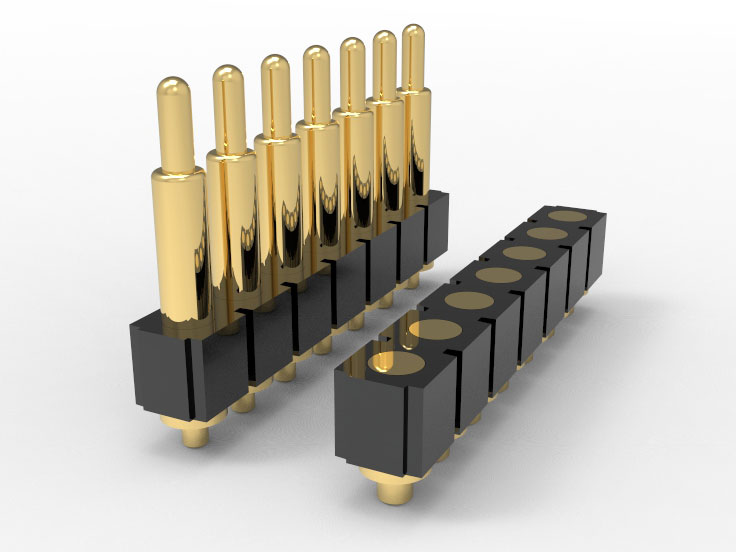

Adaptive compression design, precise contact matching

There may be slight tolerances between the male and female ports of different devices. This leads to uneven contact pressure of ordinary pin connectors, affecting the efficiency of current and signal transfer. Johoty’s 7 pin trailer connector uses pogo pins adaptive compression technology. Each spring-loaded contact point can self adjust within the micrometer range, ensuring uniform distribution of contact pressure at all times. Whether there is a slight error in the size of the male or female end, stable and reliable electrical connections can be ensured.

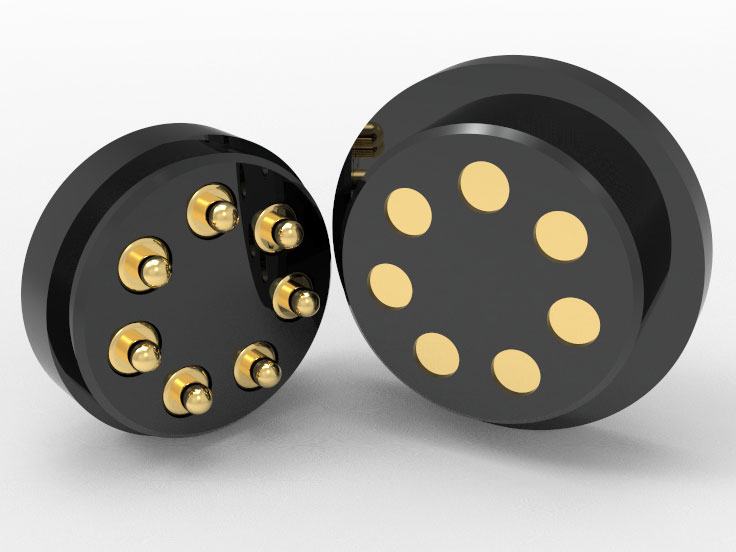

Super strong impact resistance and adaptability to harsh environments

Severe impact can cause instantaneous displacement of ordinary pin structures, thereby affecting electrical connections. The pogo pins of Johoty’s 7 pin trailer connector have high rebound characteristics and can maintain stable contact under large vibrations or impacts. Its independent spring reduces stress concentration caused by rigid connections. In high-intensity applications of construction machinery and military vehicles, this pogo pin connector ensures the continuous and reliable operation of critical systems.

Low wear coating technology extends the lifespan of connectors

Ordinary gold-plated or silver plated connectors are prone to contact point wear or oxidation after long-term use, which affects connection stability. Johoty’s 7 pin trailer connector adopts a high wear-resistant coating process, and each pogo pin has self-healing characteristics. This can effectively reduce coating damage caused by frequent contact. Long term high-intensity use can maintain low impedance and high conductivity. This pogo pin connector can significantly improve device reliability and lifespan.

Automatic calibration docking to improve installation compatibility

There is an assembly error in the connection between the trailer and the main vehicle, and ordinary connectors need to be precisely aligned to ensure stable contact. Johoty’s 7 pin trailer connector achieves automatic alignment and contact compensation through the independent floating design of pogo pins. There is a slight deviation during the towing process, and the contact point loaded by the spring can quickly adapt. This pogo pin connector achieves efficient docking. It can greatly enhance the compatibility and installation convenience between devices of different brands and specifications.

Super antioxidant capacity, maintaining high performance for a long time

Traditional trailer connectors are exposed to outdoor environments for a long time and are affected by moisture, rain, or air pollution. In this way, its contact points are prone to oxidation, leading to increased resistance and even signal loss. Johoty’s 7 pin trailer connector uses pogo pins high-density coating technology. Each contact point has a self-cleaning function, which can effectively prevent the accumulation of oxides. This pogo pin connector can maintain excellent conductivity even after prolonged use. After years of high humidity and high salt environment, it can still ensure stable and reliable connection.

FAQ

Can 7 pin trailer connector use in zero gravity?

Johoty’s 7 pin trailer connector uses spring-loaded technology to provide stable contact in weightless environments. Low contact impedance ensures no fluctuation in current transfer, and the independent spring structure can adapt to small positional deviations. Coating materials can prevent electron migration issues in aerospace environments and maintain long-term stability. Reliable connection can still be maintained without gravity inside spacecraft. This pogo pin connector ensures interference free signal and power transfer.

Will 7 pin trailer connector experience poor contact due to severe acceleration?

The 7 pin trailer connector adopts a high-precision spring loading design, and each contact point can independently absorb impact. The structural design ensures uniform contact pressure during high-speed movement or sudden braking. This pogo pin connector low impedance material reduces contact transient fluctuations and avoids signal interference caused by impact forces. The dynamic compensation mechanism enables 7 pin trailer connector to adapt to high G-force changes. This pogo pin connector remains stable in high-speed racing or aerospace equipment.

Will 7 pin trailer connector disconnect under extreme high-frequency vibration?

The adaptive structure of Johoty’s 7 pin trailer connector can maintain contact stability at micrometer level amplitudes. The high elasticity support system can effectively reduce the problem of poor contact caused by micro vibrations. The low-noise connection design of this pogo pin connector ensures signal integrity. The anti fatigue spring structure enables it to maintain consistent rebound force under high-frequency vibration. It is suitable for high vibration unmanned aerial vehicles and military equipment.

Can 7 pin trailer connector use in ultra-high voltage power systems?

Johoty’s 7 pin trailer connector optimizes the pogo pins contact surface for larger current transfer. Special coating reduces the generation of high-voltage arcs and avoids the impact of electrical corrosion on contact life. Low resistance structure can reduce electrical energy loss and improve the overall efficiency of high-power systems. Under high pressure conditions, this pogo pin connector still maintains stable plugging and unplugging characteristics. It is suitable for the special connection requirements between new energy vehicles and industrial power grid systems.

Can 7 pin trailer connector function properly under strong EMI?

Johoty’s pogo pins are designed with shielding optimization to reduce the interference of electromagnetic waves on signal transfer. Contact point optimization ensures low inductance characteristics and reduces electromagnetic noise. Spring loaded structures can reduce transient signal loss caused by vibration. This pogo pin connector can also maintain stability in strong EMI environments. Highly conductive materials reduce impedance mismatch issues and make data transfer more reliable. It is suitable for radar and high-power radio systems.

Is 7 pin trailer connector suitable for low-temperature superconducting?

Johoty’s 7 pin trailer connector can maintain high elastic contact characteristics in extremely low temperature environments. Low temperature materials ensure that there will be no micro cracks on the contact surface due to extreme temperature differences. Coating technology optimizes low-temperature conductivity and reduces electron scattering problems in superconducting environments. Pogo pins can maintain stable contact pressure in extreme cooling environments. This pogo pin connector is suitable for the connection requirements of deep space exploration or superconducting magnet systems.

Can 7 pin trailer connector use underwater?

Johoty’s 7 pin trailer connector adopts a water-resistant coating process to maintain stable connection in damp or short-term immersion. The spring loading characteristic allows the water film to self clear, reducing contact failure caused by water particles. The 7 pin trailer connector made of corrosion-resistant materials ensures long-term underwater use without compromising performance. Sealed optimization structure reduces the impact of water vapor intrusion and is suitable for critical electrical connections of marine equipment or submersibles.

Can 7 pin trailer connector use for autonomous driving systems?

Johoty’s pogo pin connector features an adaptive docking design. There is a slight error in automatic connection, but it can still make precise contact. Low latency signal transfer ensures that real-time data communication is not affected. The extra long plugging life reduces maintenance requirements and improves reliability of auto drive system. Anti vibration optimization enables 7 pin trailer connector to connect stably in complex road conditions. It is suitable for unmanned trucks or automated logistics systems.