Advantages of 8 Pin Connectors, Pitch 2.00~2.54

High-density design, compact space optimization

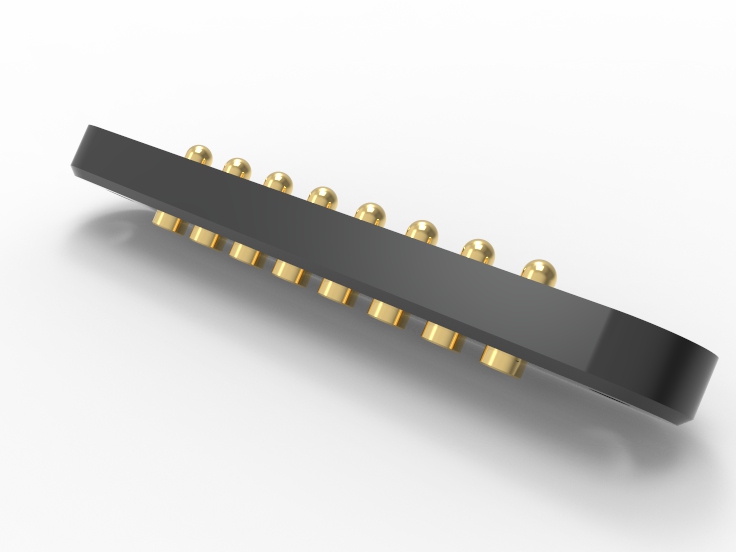

High-density design, compact space optimization Johoty’s 8 pin connectors are very compact, they help our clients achieve efficient connections in limited spaces. Their pitch is ≤2.54mm, which can effectively route wires on very narrow circuit boards. Through Johoty’s high-density design, they can significantly reduce the area of circuit boards and optimize system’s overall layout. In addition, dense pogo pin arrangement can also effectively improve connection stability, ensuring clarity and reliability of signal transfer.

Multiple configuration options, flexible application

Single and double row pogo pins, with 8 pin connectors for male and female ends, provide high flexibility to meet various applications. For electronic devices with high-frequency signals and low-power intelligent hardware, the most suitable pogo pin connector can be found. Pogo pins with different configurations can adapt to different electrical specifications and meet the challenges of different electrical connections. This spring loaded connector has stronger adaptability and adjustability in engineering projects.

Precise conductivity ensures signal integrity

Johoty pays attention to conductivity when designing 8 pin connectors, using high-quality brass and gold plating. This ensures that every pogo pin has ultra-high conductivity. It can maintain signal integrity and avoid transfer errors in both high-speed data transfer and low current connections. By optimizing metal contacts and conductive surfaces, long-lasting electrical performance can ensure long-term stability of spring loaded connector.

Precise coordination to enhance connection reliability

The design of 8 pin connectors is very precise, achieving high alignment accuracy when connecting pins and connectors. This precise fit ensures there won’t be poor contact caused by physical wear during use. By using finely processed pogo pin connector, mechanical friction has been reduced. The connection stability is stronger and less prone to loosening, which improves devices’ overall efficiency.

Strong durability to withstand harsh environmental challenges

Our 8 pin connectors feature brass and rigorous design, capable of withstanding high temperatures, vibrations, low temperatures, and moisture. For industrial grade equipment, it is very important because these devices are often in unstable environments. They require connectors to have stronger pressure resistance and durability. In extreme temperatures and heavy humidity, Johoty’s pogo pin connector can keep stable performance, ensuring equipment’s reliable operation.

High speed data transfer to meet modern communication

Pogo pins design of 8 pin connectors enables high-speed signal transfer. They are suitable for stable work in communication equipment and electronic systems. Low impedance can effectively reduce signal delay and loss, achieving fast electronic signal exchange. This pogo pin connector has superior performance in high demand and can easily transmit high-speed data. Johoty’s clients feedback, they can ensure efficient interaction between devices.

High anti-interference ability and stable performance

Johoty’s 8 pin connectors have strong anti EMI and signal stability through carefully selected conductive materials. In high-frequency applications, EMI is very prominent, and our pogo pin connector can effectively suppress noise impact. It can reduce signal errors, maintain good conditions of equipment, and improve system’s overall reliability.

Quick installation and simplified engineering debugging

The installation of Johoty’s 8 pin connector is very simple. Each pogo pin connector has precise docking, and there is no need for excessive complex operations during installation. This can save engineers a lot of debugging time. The pogo pins with automatic positioning can ensure error-free operation during contacts. They can improve engineers’ work efficiency, significantly increase production cycles and development progress.

FAQ

Why can pogo pins provide reliable connections in small spaces?

Pogo pins are spring-loaded contact points that can achieve precise connections in very limited spaces. Through the action of tiny metal springs, they can generate a certain pressure when in contact, ensuring stable signal transfer. In 8 pin connectors, this design makes connection more flexible and suitable for devices that require frequent connection.

Why is metal materials for 8 pin connectors important?

When choosing 8 pin connectors, metal materials directly affects connection quality and durability. The conductivity, corrosion resistance, and elastic properties of different metals are different each other. For pogo pin design, high-quality metal ensures precise and error-free connections every time, ensuring stable signal transfer without premature wear.

How are the male and female of 8 pin connectors designed to avoid poor contact?

The male and female terminals can ensure that each pogo pin can accurately touch the other’s contact point. This can avoide poor contact caused by misalignment. Through precise manufacturing, each pogo pin contact of 8 pin connectors is very precise. It can effectively reduce poor contact during the connections.

Why do 8 pin connectors sometimes require special finishing?

Surface treatment is crucial for 8 pin connectors in high-frequency. Special surface coatings can greatly reduce signal loss and improve connection quality. For example, some special coatings can prevent oxidation or reduce contact resistance. Then, pogo pins can work stably for a long time, thereby improving connection performance.

Can 8 pin connectors work properly in high temperatures?

In fact, the pogo pins design of 8 pin connectors is very adaptable to temperature changes. In high or extremely cold, pogo pins can still maintain stable elasticity and electrical performance. This is because it uses specially designed spring materials inside, which can adapt to wide temperature fluctuations without losing function.

Why do 8 pin connectors sometimes generate EMI after connection?

In some high-frequency applications, 8 pin connectors may experience EMI. This is usually related to contact area, cable shielding, and the elasticity of pogo pins in the design. To solve this problem, some shielding measures are usually added or the design is adjusted. It’s to reduce the interference generated by contact points and improve the stability of the connection.

How to determine if 8 pin connectors can handle high current loads?

We always evaluate the ability of 8 pin connectors to withstand high current loads through their internal design and selected materials. As we know, pogo pins need to have good conductivity and sufficient load-bearing capacity. This can ensure they don’t overheat or damage when high currents pass through. By carefully analyzing its structure and materials, engineers can predict its working effect.

Why is pitch 2.54mm of 8 pin connectors so important?

Pitch 2.54mm is the industry standard and is suitable for most electronic devices. This standard ensures pogo pin connector stability. It also allows for easy matching with other common components. When designing 8 pin connectors, we can ensure precise docking of each pogo pin based on reasonable pitch. It also facilitates equipment assembly and maintenance.