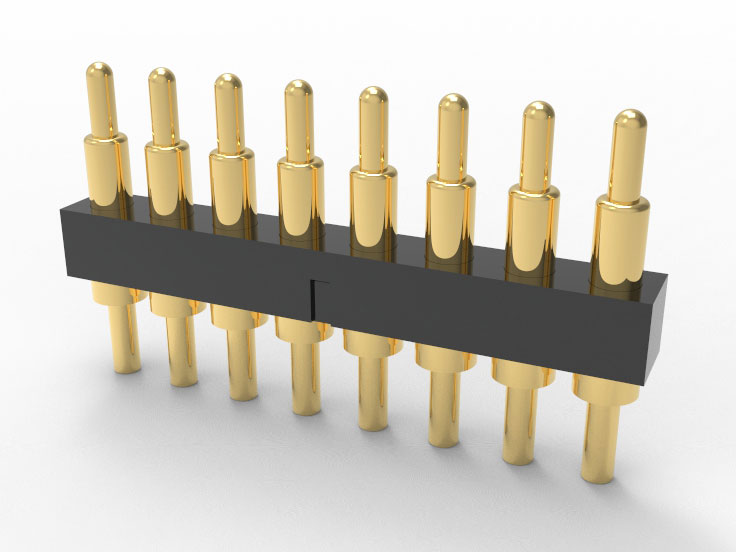

Advantages of 8 Pin Power Connector, Pitch: 2.55~5.50

High density current carrying

One advantage of this 8 pin power connector is to carry high currents, meeting high-power devices. Each contact is very precise, ensuring stable current transfer under high load conditions. In industrial equipment or high-performance computers, it can rely on this pogo pin connector to transmit sufficient current. In this way, the equipment can avoid system failures caused by unstable voltage. Compact design, the device can save space while receiving strong power support.

Strong resistance to vibration and durability

Another major advantage of an 8 pin power connector is its shock resistance and durability. This 8 pin connector can maintain stable power transfer in strong vibrations. It is suitable for robots or drones. The high-precision connection design allows pogo pin connector to maintain good contact during frequent connections. This can greatly improve long-term reliability and product’s lifespan. In extreme environments, Johoty’s spring loaded connector can work stably without causing device power outages or malfunctions.

Accurate contact pressure design

The contact pressure of 8 pin power connector is very precise, ensuring the stability of power transfer. The contact resistance of each contact has been optimized to reduce current loss. The regulation of contact pressure ensures consistent current transfer during each contact. This is important for devices with high-precision control. In robot control systems and high-end instruments, our pogo pin connectors can hold long-term stable operation.

Ultra small size and high efficiency

The 8 pin power connector is very compact and can also transmit high currents. It can use in wearable devices, precision instruments, etc. with limited space. Although this pogo pin connector is compact, its power transfer is not compromised at all. Perfectly balancing volume and performance for high requirements for space and power.

High frequency connection capability

For frequent contact, this 8 pin power connector is very suitable. Each pogo pin can maintain long-term stability and transmit stable power after repeated plugging. This type of 8 pin connector is favored in various production lines and industrial automation. It can significantly improve production efficiency, system stability as well.

Adaptability to high temperatures

The 8 pin power connector can maintain stable power transfer in high temperatures. It is suitable for automotive BMS and high-temperature industrial equipment. The material and structure of this pogo pin connector can operate reliably under severe temperature fluctuations. It can ensure equipment’s continuous and stable operation. This is an essential key advantage for engineers.

Low contact resistance

Another significant advantage of 8 pin power connector is low contact resistance. Impedance as low as 15mΩ makes power transfer more efficient and avoids power waste. In high-power applications, the smaller the resistance, the less current loss. This pogo pin connector ensures that power is transmitted more accurately and quickly to device’s each part. For high-speed and precise power, low contact resistance can significantly improve overall system efficiency and response speed.

High-density space utilization

Johoty designed 8 pin power connector with space constraints in mind, as it can provide high-density power transfer. In the case of very compact equipment space, it can also ensure efficient and stable power connection. This pogo pin connector is very suitable for drones and precision instruments with limited space. Through this design, Johoty’s clients can achieve more functions in limited space and improve devices’ overall performance.

FAQ

How long is plug-in life of 8 pin power connector?

This 8 pin power connector has a very long plug-in life, exceeding 10,000 times. After Johoty’s special design, it can also achieve lifespan of 200,000. Each insertion can maintain stable contact and isn’t easily worn out. Even with frequent use, this pogo pin connector can transfer stable current. High precision contact design will make it more durable. For a long time, 8 pin connector can significantly reduce maintenance costs.

What temperature range is 8 pin power connector suitable for?

The 8 pin power connector can operate stably from -40°C to+85°C. After special design, it can withstand extreme temperature changes and up to 250℃. It can keep efficient power transfer at high or low temperatures. Based on high-temperature resistant materials and Johoty’s careful design, our pogo pin connector doesn’t malfunction in harshs. Engineers can use it with confidence in various industries.

How many contact points are there for 8 pin power connector?

It is 8 contact points, each point undergoes precise gold plating process, 8 pin power connector can stably transmit power. We adopt a single and double row in design, making the connection very compact and efficient. Each contact point can carry up to 50A of current, ensuring device’s table operation. The high-density design of pogo pin connector maximizes space savings. The contact resistance of each point is low, 8 pin power connector can reduce energy loss significantly.

What industries are suitable for 8 pin power connector?

Johoty’s 8 pin power connector can use in robots, drones, electric vehicles, etc. It can carry high current and the equipment is stable and safe. This 8 pin connector can fit high-end devices with high-precision power connections. It is also commonly seen in industrial automation, precision instruments, and data centers. Our pogo pin connector can work stably in various high-load & frequency applications.

How does 8 pin power connector ensure stability?

Adopting high-precision design, contact resistance is very small, and 8 pin power connector can effectively reduce power loss. After precise tuning of contact points, it ensures stability after each insertion. Compact and sturdy in structure, this pogo pin connector can withstand high currents and frequent contact. Our spring loaded connector can offer high durability and reliability based on unique materials and manufacturing processes. It can ensure that power transfer is not affected under high loads.

How much current 8 pin power connector withstand?

An 8 pin power connector can withstand 5-10A of current, which is sufficient for most industrial applications. Johoty’s customized rated current can reach 50A per pin. The high current transfer design ensures stable operation of high-power equipment. We will precisely calibrate each contact to ensure no power loss. The high current carrying of this pogo pin connector can improve devices’ working efficiency. You or engineers can use it with confidence in high load devices.

What is protection of 8 pin power connector?

Based on strong protective performance, 8 pin power connector can effectively resist dust, moisture, and corrosion. Its sealing design and corrosion-resistant materials can work stably in harsh. with IP67, IP68 waterproof, this pogo pin connector can maintain good performance in outdoors or in industries. It is suitable to work in dust fields and underwater. With excellent environmental resistance, 8 pin power connector is preferred choice for heavy-duty equipment.

Is it difficult for 8 pin power connector to install?

Very simple, installing 8 pin power connector can be quickly completed by someone without professional experience. It adopts standardized interfaces, and both plugs and sockets are easy to connect. When plugging Johoty’s 8 pin power connector, there will be no jamming due to unreasonable design. In small devices, it can quickly complete connections. It can provide great convenience for the demand of fast wiring.