Advantages of Multi Pin Connector, Pitch 2.55~12.00

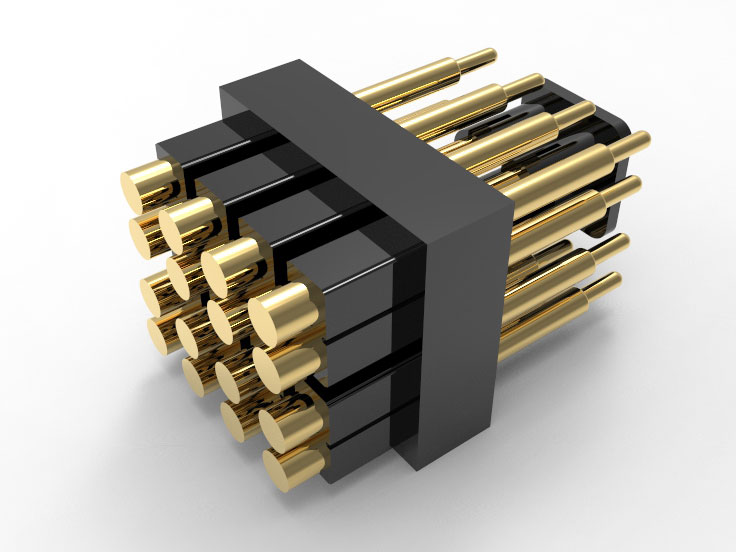

Precise contact, super stability

A high-precision multi pin connector based on pogo pin technology can provide unparalleled contact accuracy. It can maintain stable connections for a long time in complex environments. Each pogo pin is precision machined to achieve reliable electrical contact under high-speed data transfer and high-frequency current. For highly demanding engineers, pogo pins are an extremely attractive technology. According to customer feedback, it can meet requirements of engineering projects that require high stability and performance.

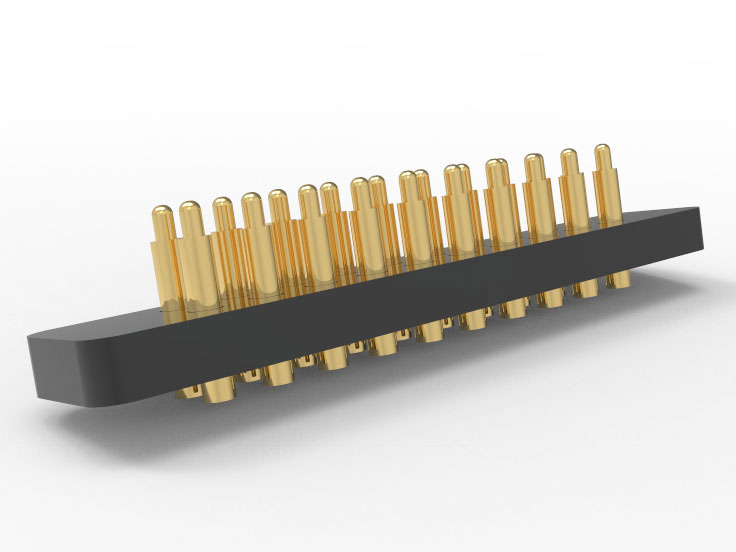

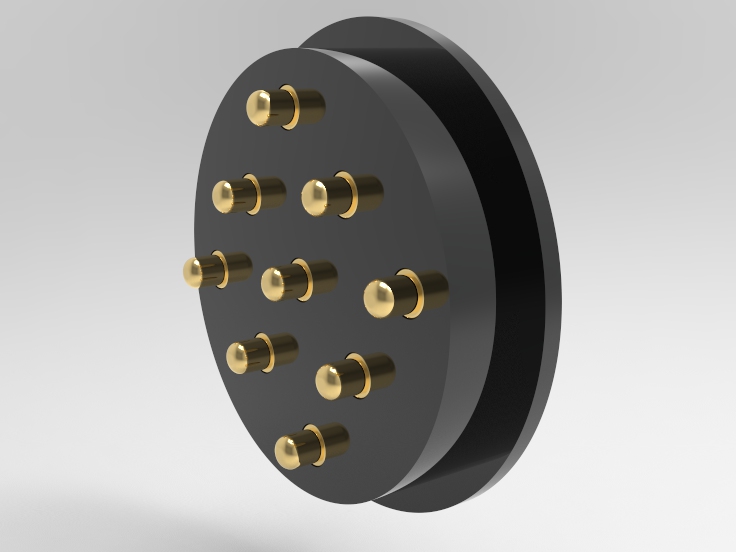

High density connectivity solves spatial problems

Johoty considered ultimate optimization of space utilization when designing this multi pin connector. It can provide high-density electrical connections within a limited space. For engineers designing miniaturized and compact devices, our pogo pin connector can provide significant advantages. In smart hardware, consumer electronics, it can demonstrate complete functionality under automatic compensation and size limitations that traditional connectors cann’t provide. Each pogo pin can be precisely docked, helping engineers solve insufficient space but huge connection requirements.

Efficient data transfer without delay

Multi pin connector often adopt innovative designs that support 5G high-speed data transfer without any delay. It can ensure smooth signal transfer between devices and use for video signal data transfer. It is commonly used in high-end computing devices, real-time communication systems, and high-frequency processing systems. After using this pogo pin connector, engineers can more easily handle rapid exchange of large-scale data. Its accuracy and transfer speed far exceed traditional connection methods, and engineers will have significant breakthroughs in technology.

Low contact resistance can effectively improve product lifespan

Johoty’s multi pin connector has ultra-low contact resistance and won’t experience signal attenuation or current instability. In this way, engineers can avoid common contact problems in high-precision applications. It can strongly support high-speed data transfer and significantly improve device’s lifespan. Through such innovative design, engineers can reduce maintenance and component replacement, greatly reducing operating costs.

Flexibly adapt to complex application scenarios

This multi pin connector can perfectly adapt to high-pressure, high-temperature, and high-frequency environments. Its design can meet conventional industrial requirements and work normally in extreme environments. Engineers can confidently apply pogo pin connector to various complex systems. It is based on high-precision spring loaded pin, so you don’t have to worry about connection failures or performance degradation. After verification by many customers, our multi pin connector is the ideal choice for solving high-end application problems.

Quick assembly to reduce production cycle

Our multi pin connector adopts convenient assembly method, all of which are modular and installed using solder wires, through holes, or SMT. Engineers can quickly connect and disassemble during installation without specialized tools, greatly reducing assembly time. In complex equipment production, this pogo pin connector can significantly improve efficiency and reduce production cycles. For engineers, this is not only a technological advancement, but also an increase in productivity, reducing working hours and costs.

High anti-interference ability to ensure system stability

Electromagnetic interference has always been a headache for engineers in modern high-tech products. The multi pin connector adopts unique design and has high anti-interference performance. It can effectively prevent external EMI from entering device, ensuring stable system operation. It is suitable for precision instruments and medical equipment. After using Johoty’s pogo pins, engineers can save a lot of interference caused problems and truly achieve equipment’s stable operation.

Exquisite appearance, meeting design requirements of high-end products

This multi pin connector based on pogo pins has powerful functions and modern appearance design. It meets aesthetic requirements of today’s high-end products. With its compact, luxury, and exquisite appearance, it can seamlessly integrate with any high-end device. Engineers don’t have to sacrifice appearance and aesthetic design while pursuing technical performance. Designers and engineers can achieve win-win situations between functionality and appearance through Johoty’s pogo pin connector.

FAQ

Why are multi pin connector more advantageous in high-precision applications?

The advantage of a multi pin connector is that it can provide stable electrical connections in very small spaces. Due to its spring-loaded design, the connector can automatically adjust the contact pressure. It can maintain good contact effect in high-frequency signal transfer or high vibration environment. For engineers, pogo pin connectors can provide excellent reliability and flexibility. In devices that require extremely high space and precision, it solves complex electrical problems that traditional connectors cannot adapt to.

How to prevent poor contact of multi pin connector?

The design of multi pin connector places great emphasis on pressure distribution and balance at the contact points. Each pogo pin ensures sufficient contact pressure through a spring to avoid poor contact. In order to further improve reliability, the materials and manufacturing processes of Johoty’s pogo pin connector have been rigorously optimized. We can ensure that each pogo pin can work stably for a long time in actual use. Each pogo pin can independently adjust its contact state is key to preventing poor contact in complex applications.

Can multi pin connector effectively reduce signal attenuation during high-frequency transfer?

Yes, Johoty’s multi pin connector can work well in high-frequency applications. The reason is that we can reduce its’ contact resistance and current interference when we designed it. High-precision manufacturing of pogo pins ensures the smoothness and conductivity of contact points. This design and process can minimize signal attenuation and reflection. When transferring at high frequencies, it’s ideal choice for requiring high signal quality and stability. And, It’s based on the reliability and low contact resistance of pogo pins.

How to handle inconsistent contact forces in multi pin connector?

Inconsistent contact force usually leads to unstable signals or connection failures. High-precision spring of multi pin connector can maintain consistent contact force under different working conditions. In environments with significant equipment vibration or temperature changes, each pogo pin can automatically adjust pressure as needed. Johoty’s pogo pin connector ensures uniform contact force across all pogo pins, avoiding inconsistent contact force in traditional connectors.

What are challenges of using multi pin connector in small space?

The application in confined spaces imposes strict requirements on the design, reliability, and space utilization of connectors. Compact design and spring contact of multi pin connector provide stable electrical connections in limited spaces. This pogo pin connector has a compact appearance and high-precision manufacturing, which ensures contact integrity in dense arrangements. Please trust Johoty, we can solve the space limitation that traditional connectors can’t cope with.

How can multi pin connector reduce connection instability caused by environmental changes?

The spring structure and conductive material of multi pin connector have excellent temperature adaptability. It can maintain stable electrical connections in extreme temperature and humidity changes. This design can automatically adjust contact pressure, avoiding unstable contact caused by environmental changes in traditional connectors. For engineers, using pogo pin connector can ensure devices’ stable operation in harsh environments. It can reduce system failures caused by environmental changes.

Can multi pin connector achieve fast and stable automatic connections?

Yes, the design of multi pin connector ensures fast and stable contact during insertion and removal. Each pogo pin has a spring device that can automatically adjust contact pressure during insertion. This ensures fast and stable electrical connections. This automated design can improve connection efficiency and effectively reduce problems caused by human errors. Multi pin connector can effectively ensure system’s efficiency and reliability.

How to reduce problems caused by small errors in high-precision docking of multi pin connector?

The high-precision manufacturing of multi pin connector can effectively reduce small errors during contact. Johoty always strictly controls machining tolerance of each pogo pin to ensure precise docking during connection process. This high-precision design can effectively avoid electrical contact problems or signal loss caused by small errors. Multi pin connector is highly suitable for high-end devices that require high precision, ensuring system’s stable operation.