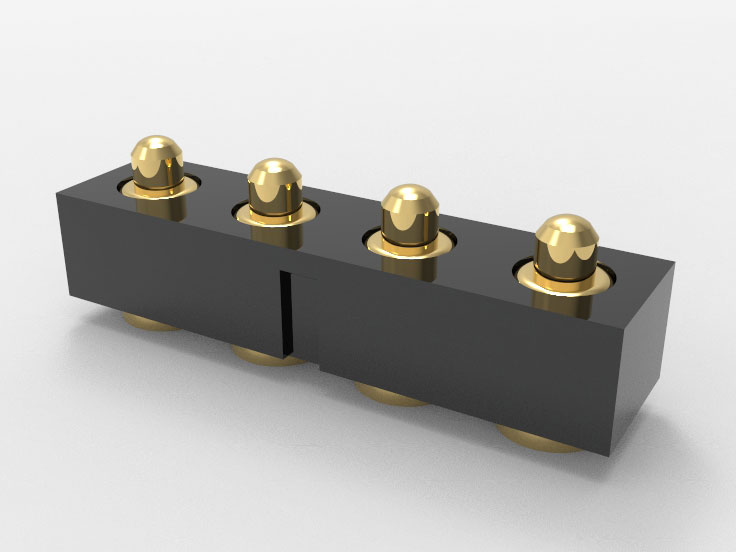

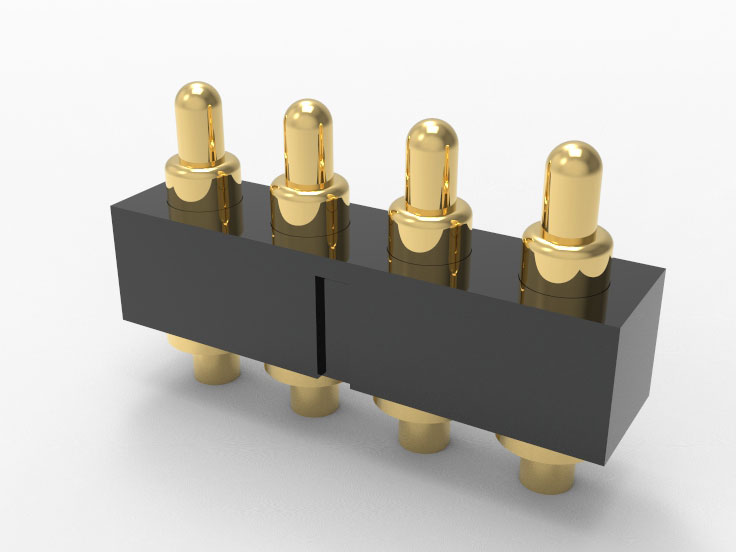

Advantages of 4 pin pogo connector, pitch: 1.27~1.99

High density design, saving space

2.0-2.53mm pitch of four pin connector can provide more electrical connections in limited space. In small devices, this 4 pin connector ensures efficient operation of multiple connection points, enhancing product design flexibility. High density pogo pin connector is highly suitable for consumer electronics, smart devices, and other compact design. Based on compact size of this spring loaded connector, device is easy to carry and more lightweight. By saving space, the device can accommodate more functions and improve device’s overall performance.

High plug-in life, reducing maintenance costs

The four pin connector has a plug-in life of >50,000 times, and Johoty can design to achieve 200,000 life cycles. So, it can maintain good electrical contact in frequently uses. In mobile devices and medical equipment, this pogo pin connector can always work stably. This greatly reduces damage and lowers maintenance costs. High plug-in life of 4 pin connector improves product reliability, reducing equipment failure and downtime.

High current carrying enhances performance

Johoty’s four pin connector supports 1A to 50A per pin, ensuring stable electrical contact at high power. This 4 pin connector can meet high demand for current transfer in battery management, electric vehicles, and industrial automation. Due to its excellent current carrying, it maintains low contact resistance when transferring electrical energy, avoiding energy loss and improving overall efficiency. Higher current means that device can operate more efficiently and perform better.

Anti environmental interference to ensure stability

Four pin connector has excellent EMI resistance, it can stably transfer signals in electromagnetic environments. This spring loaded connector has significant advantages in communication equipment, automotive electronics, etc. In high-frequency signal transfer or long-term use, this 4 pin connector can effectively isolate external interference and ensure signal is not distorted. This anti-interference is crucial in high precision and high data transfer.

Anti vibration & high temp resistance for extreme environments

The four pin connector is resistant to high temp & vibrations, and can operate very well in extreme vibrations & temperatures. This spring loaded connector is suitable for automobiles, aviation, and industrial equipmen. The excellent vibration resistance of 4 pin connector makes it difficult to loosen and maintains good contact force. Johoty’s pogo pin connector has high-temp resistant designs, it can ensure equipment can maintain excellent electrical performance at high temperatures. Our spring loaded connector is suitable for use in battery management and power systems.

Low contact resistance to improve signal transfer quality

The contact resistance of our four pin connector is usually less than 50m Ω, which ensures efficient transfer of electrical signals. 4 pin connector with low contact resistance has less energy loss as well as higher transfer efficiency. It fits high-speed signals and high-precision. Pogo pins can provide stable and clear signals in audio, video transfer, and communication systems. The low contact resistance of Johoty’s pogo pin connector ensures equipment long-term reliability and high-quality operation.

Compact design, flexible adaptation to various applications

Compact design of four pin connector is suitable for small electronic devices, including smartphones, smartwatches, wireless headphones, etc. Based on its small size, engineers can design more flexibly and accommodate more functions without increasing equipment sizes. Despite its small size, 4 pin connector can provide efficient and reliable electrical connections, fitting various complex applications. The high-density and compact nature of this pogo pin connector allows customers to enhance functionality and performance while maintaining product portability.

Easy installation, improve production efficiency

Four pin connector supports surface mount, solding cup, through hole, right angle, and double ended. Automated production lines is very simply to use such pogo pin connector. Due to its simple design, fast and accurate installation, this 4 pin connector can reduce manual operation and installation time, and improve production efficiency. It is suitable for mass production of consumer electronics, automotive electronics, etc. And its simple installation can significantly reduce production costs. Fast assembly process of pogo pin connector shortens production cycle and helps customers improve market response speed.

FAQ

Why choose four pin connector instead of traditional plug?

It has high-frequency plugging capability and four pin connector is suitable for frequent use. This 4 pin connector has compact design and can achieve multiple connection points in small space. Compared to traditional plugs, Johoty’s spring loaded pin can provide more stable electrical contact and lower contact resistance. This pogo pin connector has strong durability and fits various high-strength applications. For efficient transfer and long lifespan, pogo pins are a more ideal choice.

What extreme temperatures can four pin connector use for?

Johoty considered high and low temperatures when designing four pin connector, which operates stably within -40°C to+85°C. The temperature of this pogo pin connector makes it suitable for high temperature or severe cold environments, such as automobiles, aviation, etc. Whether starting at low temp or working at high temp, Johoty’s 4 pin connector can maintain stable electrical features. The temperature adaptability of Johoty’s spring loaded pin greatly increases device lifespan. This feature is very suitable for industrial or military equipment with strict temperature requirements.

How to avoid plunger tip wear of four pin connector?

To avoid the wear of plunger tip, ensure smooth operations, and avoid strong pulling. We always choose pogo pins with high wear resistance and gold plating when designing four pin connectors. Reasonable installation pressure can also reduce excessive wear of contact points. Keep 4 pin connector clean and avoid dust and grease from interfering with contact surface. This can effectively extend service life based on regular inspecting equipment status and timely replacement of severely worn pogo pin connector.

How much current can four pin connector withstand?

Four pin connector support currents of 1A to 50A per pogo pin, making pogo pin connector suitable for low to medium power applications. When transferring high current, the current can be improved through improved contact materials and structures. In high-power battery management and smart cars, pogo pins can stably transfer high currents without overheating. The stability of Johoty’s 4 pin connector ensures device operates normally under high current loads. To ensure long-term efficient operation, each spring loaded pin needs to avoid excessive current overload.

Does four pin connector support IP68 waterproof?

Of course, some four pin connector can adopt IP67, IP68 waterproof, suitable for outdoor or humid environments. By sealing and special waterproof coating, it can effectively prevent moisture from entering interior of pogo pin connector. The IP67 waterproof makes 4 pin connector suitable for smart homes and medical devices. This design ensures spring Loaed connector stability in rainy or humid. When choosing a waterproof four pin connector, it is important to confirm its protection level and applicable environment.

How does four pin connector cope with vibration?

The four pin connector has excellent spring force and fitts high vibration environments. Its unique spring structure helps maintain stable electrical contact and ensures signa isn’t affected in equipment vibration or collision. In industries, automotive electronics, 4 pin connector can effectively reduce vibration impact on connections. To enhance its anti vibrations, Johoty optimizes contact material and design of pogo pins. For equipment with strong vibration, it is recommended to choose a seismic resistant four pin connector.

Is four pin connector susceptible to EMI?

The four pin connector has strong EMI resistance. This 4 pin connector has good contact and can reduce signal distortion caused by poor contact. By using shielding materials and high-quality contact materials, Johoty’s pogo pin connector can effectively isolate external electromagnetic noise. This spring loaded connector is suitable for wireless communication, medical equipment, etc. that require high signal quality. EMI resistance of this four pin connector ensures stable operation in electromagnetic environments.

Can four pin connector be customized?

Yes, Johoty can customize four pin connector based on customer needs when designing it. Whether it’s pogo pin pitch, materials, dimensions, etc. Johoty can fine tune it according to actual applications. Customized four pin connector can meet higher currents or smaller volumes for special applications. Through customized design, it is possible to better adapt to specific needs of different fields. For engineers in specific fields, customized four pin connectors can provide higher product adaptability.