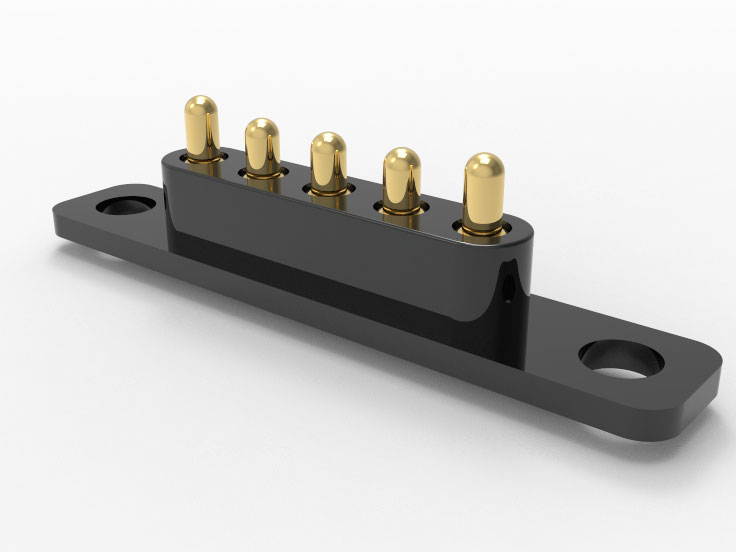

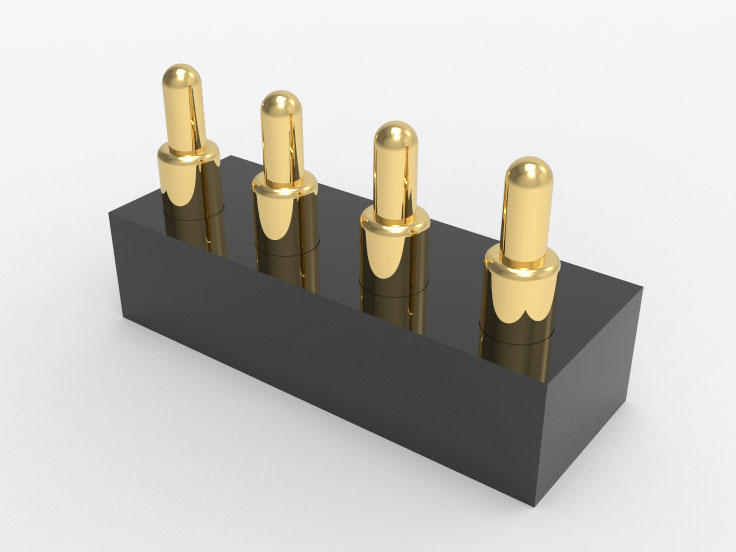

Advantages of PCB Pogo Pins, L: 11.00~60.00 mm

Micro design improves space utilization efficiency

The miniaturized design of PCB pogo pins enables efficient connections in a very small space. Suitable for high-density PCB layout and optimized internal structure. Save space and leave more design space for complex circuits. Support the development of smaller devices to enhance portability. Meet the demand for compact design in modern electronic devices. Enhance the integration of device appearance and achieve more aesthetically pleasing product design.

Signal integrity in high-frequency transmission

High frequency devices often require precise signal transmission, and Johoty’s PCB pogo pins ensure stable data transmission. Low contact resistance reduces signal loss. Optimize the structure to reduce electromagnetic interference. Support high-frequency signal transmission to meet the requirements of high-speed equipment. Enhance data consistency and improve device accuracy. Suitable for communication and sensing devices that require high-quality signal connections.

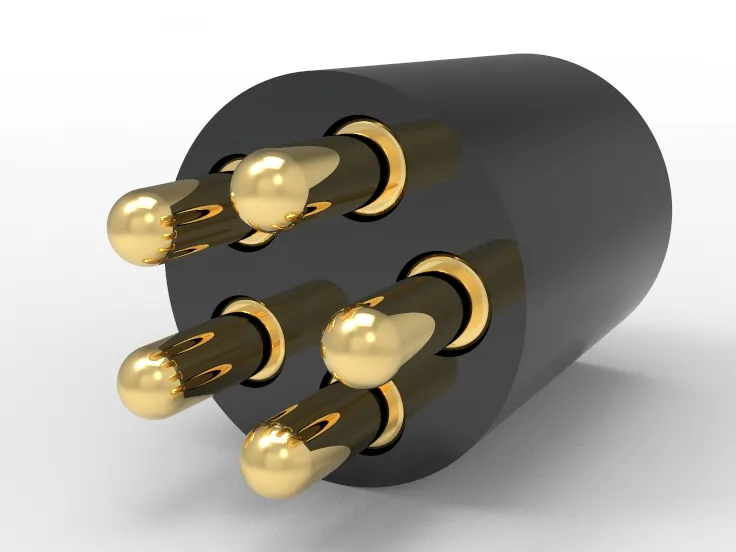

Connection stability in dynamic environments

Johoty’s PCB pogo pins perform well in vibration or movement, making them suitable for complex usage scenarios. The internal spring structure provides stable contact pressure. Support long-term use in vibration and impact environments. Adapt to frequent plugging and unplugging to maintain stable connection. High strength materials have strong durability and are not easily deformed. Suitable for industrial or mobile devices with frequent dynamic operations.

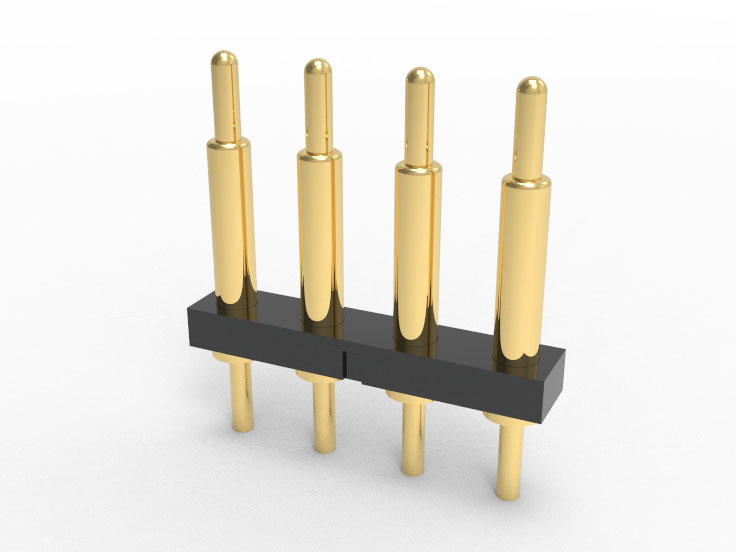

Seamless adaptation of automated assembly processes

The surface mount design allows Pogo Pins to perfectly adapt to automated production processes. Compatible with SMT reflow soldering to improve production efficiency. Reduce manual intervention and minimize production errors. Simplify the PCB design process and shorten the development cycle. Support mass production, suitable for efficient industrial manufacturing. Optimize manufacturing costs to meet the rapid iteration demands of the market.

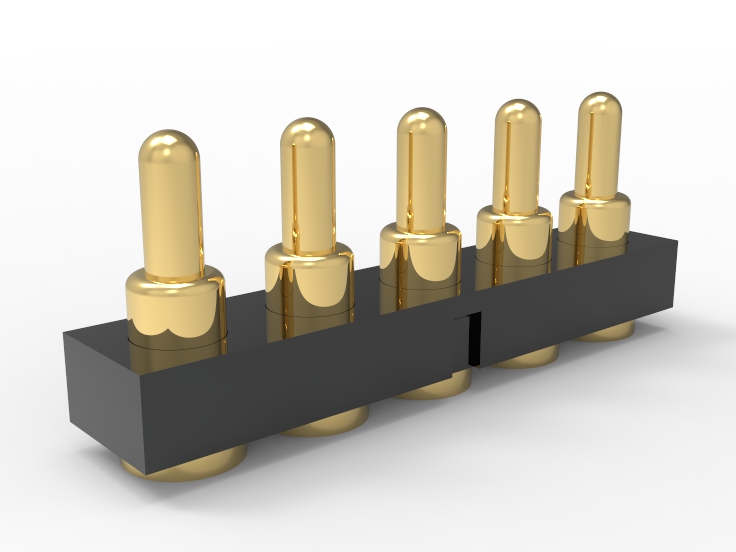

High current carrying capacity enhances performance

High current devices require stable electrical connections, and Johoty’s PCB pogo pins can provide optimal support. A large-diameter needle improves the efficiency of current transmission. Low contact resistance reduces heat accumulation. Adapt to high-power device requirements. Provide stable power supply and improve equipment performance. Suitable for high-power demand in automotive and industrial applications.

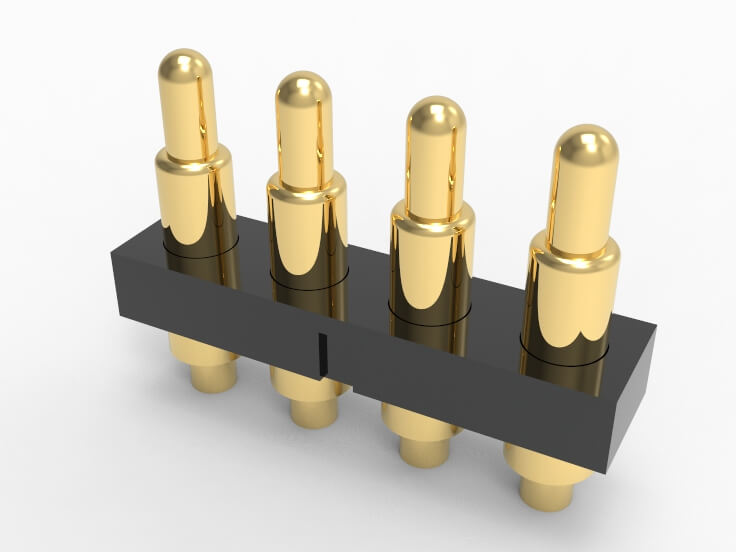

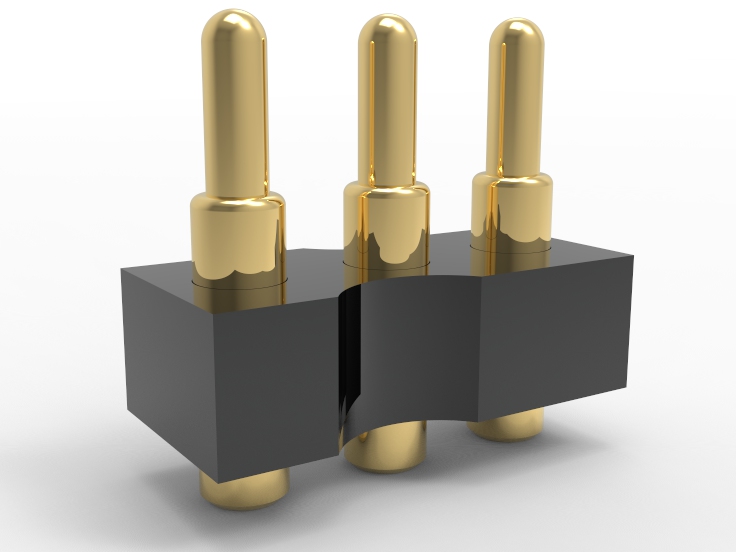

Flexible connections in modular design

Modular devices require flexible connection solutions, and PCB pogo pins are perfectly suited for such needs. Support free combination and disassembly of multiple modules. Provide stable electrical connections and simplify module layout. Save assembly time and improve overall efficiency. Enhance device scalability to facilitate functional upgrades. Suitable for rapid iteration of modular electronic products.

Long life design reduces maintenance costs

Johoty’s PCB pogo pins have a long lifespan and are suitable for high-frequency usage scenarios. Wear resistant materials extend the product’s lifespan. The spring has a high lifespan and supports multiple dynamic operations. Reduce the frequency of connector replacement and lower maintenance costs. Long term stable performance reduces equipment failure rate. Suitable for medical, industrial and other equipment that requires long-term stable operation.

Customized options to meet individual needs

Pogo Pins offers a variety of customized specifications to meet the needs of different devices. Adjustable pogo pin height to accommodate various designs. The stroke and spring pressure can be adjusted to meet special requirements. Various material and coating options are available to enhance performance. Unique design suitable for specific environmental requirements. Meet personalized applications in industries such as communication, healthcare, and automotive.

FAQ

Are PCB pogo pins suitable for module connections on mobile devices?

Yes, PCB pogo pins are very suitable for mobile devices. They provide stable connections, withstand vibrations and impacts. Support multiple dynamic plugging and unplugging without compromising performance. Optimize the structure to make equipment disassembly and assembly more convenient. Suitable for high-density layout without taking up extra space. Reliable connection improves module performance consistency.

What current and voltage can PCB pogo pins support?

Johoty’s PCB pogo pins can support devices ranging from low power to high current. Wide rated current range, suitable for various equipment. Low contact resistance reduces power consumption. Supports stable current of up to 50 amperes. Suitable for up to 500V voltage and high safety performance. Suitable for continuous operation of high-power modules.

How can spring life of PCB pogo pins fit long-term use?

The spring life design of PCB pogo pins is excellent, supporting up to 200,000 connections. The spring material is often musi steel wire or stainless steel. Optimize mechanical structure to reduce wear and tear. Improved fatigue strength through precision processing. The gold-plated surface enhances corrosion resistance. Suitable for long-term and frequent connections.

Does PCB pogo pins support flexible design of modular products?

Pogo pins are very suitable for modular design. Support stable connections between multiple modules. Fine-tune stroke and height to accommodate various designs. PCB pogo pins can reduce module assembly complexity. Support flexible layout and improve space utilization. Convenient module disassembly and assembly, enhancing product scalability.

What is performance of PCB pogo pins in high temperatures?

Johoty’s PCB pogo pins exhibit stability in high-temperatures. The working temperature range is wide, from -40°C to+125°C. The material has strong heat resistance and is not easily deformed. Low contact resistance reduces heat accumulation. Structural design to avoid failure caused by high temperatures. Suitable for automobiles and industrial equipment in high temperatures.

How can PCB pogo pins improve automation production efficiency?

Pogo pins are designed and optimized to adapt to automated production. Flat bottom design supports SMT process. Easy installation, reducing manual operation. Compatible with automated surface mount equipment. Improve production speed and shorten development cycle. Suitable for large-scale mass production, reducing production costs.

Does PCB pogo pins support high-frequency signal?

Yes, Johoty’s PCB pogo pins support high-frequency signal transdwe. Low contact resistance ensures signal integrity. Optimize design to reduce EMI. Supports high frequency up to 6GHz. Suitable for high-speed data demand. Widely used in communication and network devices.

How to maintain stable connection of PCB pogo pins in harsh?

PCB pogo pins are specially customized by Johoty for harsh environments. Resistant to high vibration, high impact, the connection is not loose. The spring structure is stable and suitable for dynamic use. The coating has strong corrosion resistance and extends its lifespan. The material has high strength and is not easily affected by external forces. Suitable for industrial and outdoor.