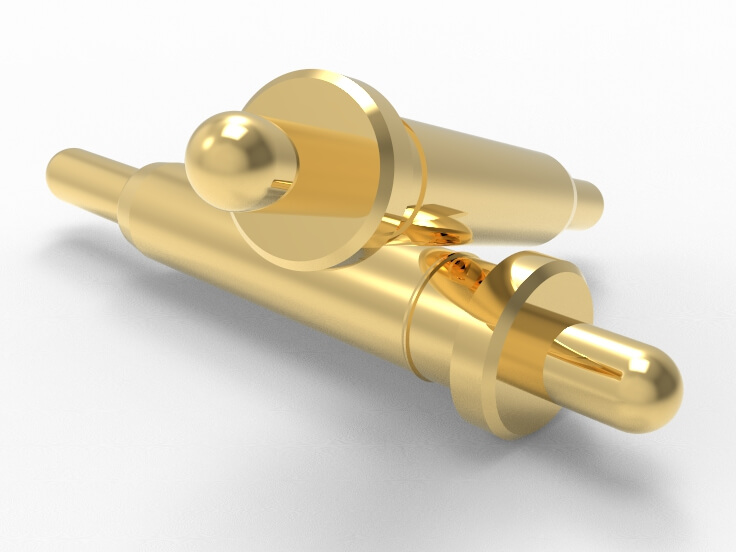

Advantages of Pogo Pin, Length: 1.39~4.99 mm,

Ultra-small Size Designs:

Pogo pin can adapt to extremely narrow device spaces and is suitable for electronic products that pursue miniaturization. The spring loaded pin design is lightweight and compact, while ensuring stable connection. Can optimize device’s internal layout and support more complex functions. High installation flexibility, suitable for diverse design needs.

High Precision Manufacturing:

Made with precision CNC to ensure consistent size and reliable performance of each spring loaded pin. The contact points have undergone strict processing, resulting in excellent conductivity. Precise spring provides stable pressure. High standard testing process ensures excellent spring loaded pin quality. Equipment that can meet extremely high connection accuracy.

Excellent Conductivity Performance:

Pogo pins have stable conductivity, ensure interference-free signal transfer. Low contact resistance and minimal energy loss. Adapt to high-frequency usages and have strong reliability. The multi-point contact provides excellent contact effect, and spring loaded pin supports high-speed power and signal transfer, improves device performance.

Excellent Anti Vibration:

Pogo pins have strong anti-vibration and are suitable for dynamic applications. The spring loaded pin structure effectively reduces vibration and ensures that the contact points are not loose. High impact resistance, suitable for mobile or outdoor. Elastic stability, able to maintain efficient connection for a long time. Strong reliability and adaptability to complex applications.

Extremely Long Service Life:

Through hole pogo pins have undergone special finishing and have a much longer lifespan than regular connectors. The contact points are wear-resistant for frequent operations. The spring rebound performance is stable and maintains long-term reliability. The spring loaded pin material is of high quality and has strong antioxidant freatures. Suitable for high durability requirements.

Flexible Customization:

Support flexible customization according to device requirements to meet diverse applications. Can adjust the sizes, spring forces, and contact point designs. Pogo pins can meet device compatibility and special environmental requirements. Johoty quickly responds to customer needs and provides solutions. Assist devices in achieving optimal matching.

Low Installation Complexity:

Spring loaded pin installation is simple for mass production processes. The through-hole design facilitates quick positioning and fixation. Component design optimization to improve assembly efficiency. Pogo pins are suitable for automated production lines, saving costs and time. The installation is firm and reliable, reducing the risk of equipment failure.

Superior Material Performance:

Pogo pin is made of stainless steel with excellent conductivity and durability. Material selection ensures stable corrosion & temperature resistance and adaptability for complex environments. The surface finishing of pogo pins is fine, ensuring good contact point quality. Support long-term reliable operation of high-performance devices.

FAQ

What Devices Is Pogo Pin Suitable For?

Through hole pogo pins are suitable for smart wearables, wireless headphones, medical devices, etc., which require small connectors. Spring loaded pin can provide stable connections, occupy small spaces, adapt to complex structures, support multiple power and signal transfers, and meet high precisions.

Is It Difficult to Install Pogo Pin?

Through hole pogo pins are easy to install and suitable for quick assembly. The spring loaded pin design is easy to locate, firmly installed without looseness, supports automated production lines, improves assembly efficiency, reduces operational complexity, and adapts to assembling various devices.

Can Pogo Pin Fit High-frequency Connection?

The spring loaded pin design is durable and supports high-frequency operations. Elastic and stable, not easily fatigued, contact points resistant to wear, long-term use to maintain stability, suitable for frequently used customer products, spring loaded pin meets high usages.

How Long is Pogo Pin Lifepan?

Our spring loaded pin has been treated with special materials and processes, resulting in long uses. Pogo pin has strong antioxidation, long-lasting spring rebound force, high temperature resistance without deformation, good contact point durability, and can maintain efficient operation for a long time.

Does Pogo Pin Support Customized Designs?

Johoty’s pogo pin supports flexible customization to meet diverse needs. Adjustable size, spring force, contact point meets special requirements, supports rapid development and personalized configuration for complex or unique applications.

Can Pogo Pin Withstand Vibrations?

Pogo pin has strong anti vibration for dynamic environments. The pogo pin structure is stable and has good shock absorption effect, without loose contact points for mobile devices and outdoor, and can maintain efficient connection for a long time, provid reliable user experiences.

Is Pogo Pin Conductivity Stable?

Johoty’s pogo pin has superior conductivity and stable signal transfer. Low contact resistance, low energy loss for high-speed transfer, multi-point contacts improves conductivity, and Johoty’s pogo pin ensures equipment reliability during operation.

Can Pogo Pin be Worked in High-temperature?

Pogo pin uses high-strength & temperature resistant materials, which can work stably in high temperatures. Pogo pin structure is not easily deformed, the contact point is durable and reliable, and it can adapt to complex temperatures. Pogo pin supports long-term use of various devices.