Advantages of Pogo Pins Connector, Pitch 2.54

Ultra-high durability

The 2.54mm pogo pins connector can withstand up to 200,000 insertion cycles, ensuring stable performance over long-term use. The precise design of the spring ensures long-term reliable contact and reduces poor contact. The gold plating or composite coating can reduce wear and provide customers with great surprises on antioxidation. High elasticity music steel ensures stable pressure after long-term use. It is suitable for high-frequency plugs without frequent replacement.

Extremely low contact resistance

Contact resistance below 30mΩ ensures stable current transfer and reduces energy loss. Pogo pins connector is made of high conductivity brass beryllium copper tellurium copper. this can enhance signal integrity and avoids performance degradation caused by voltage drop. It can optimize spring pressure to ensure tight contact can significantly improve conductivity efficiency. Precise manufacturing processes reduce micro motion interference and ensure long-term stable connections. Johoty’s spring loaded connector is suitable for precision equipment that requires high current stability.

High conductivity coating

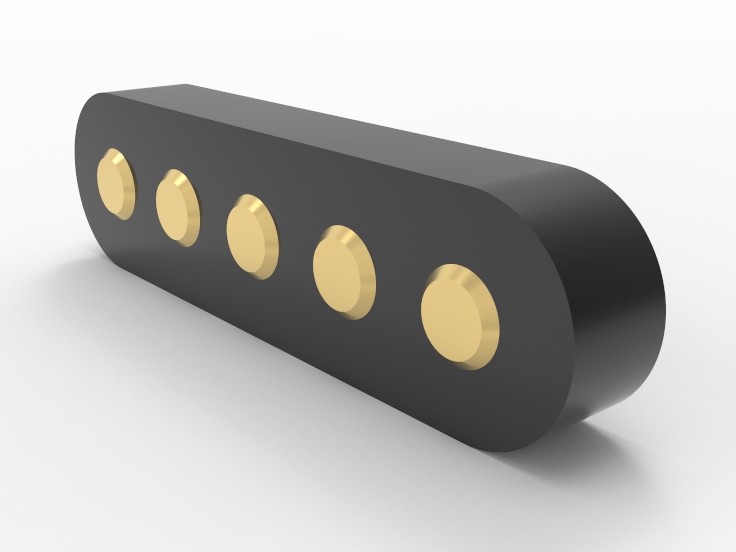

Gold plating thickness has been optimized to over 3 μm. Johoty’s pogo pins connector can achieve up to 200,000 connections, ensuring long-term reliable conductivity. Pogo pins inside have strong corrosion resistance and can maintain excellent performance. The uniform electroplating process ensures stable transfer at each pogo pin. The smooth surface of pogo pins reduces contact wear and extends their lifespan. This spring loaded connector is suitable for high-end electronic devices, ensuring efficient electrical signal transfer.

Strong error compensation

Spring-loaded structure allows for micrometer-level error compensation. On-assembly compatibility, it always gives customers peace of mind. The pogo pins connector can adapt to stable connections at different contact angles. Its elastic balance design can avoid excessive or insufficient pressure affecting performance. This spring loaded connector has adaptive adjustment capability, greatly improving success rate of device docking. For electronic devices with high-precision connectivity requirements, Johoty’s pogo pins are a perfect choice.

High vibration anti-interference

The spring-loaded design allows pogo pins connector to remain stable under severe vibrations. High elasticity materials can reduce the impact of external factors and prevent signal interruption. This spring loaded connector precise pressure control can maintain tight contact and improve reliability. Its optimized structure can reduce contact loss caused by vibration and is suitable for high dynamic vehicle and aviation.

Adapt to extreme temperatures

Our pogo pins connector can withstand high temperatures up to+85°C and -40°C. It operates stably in extreme environments. Based on thermal expansion matching optimization, it can prevent temperature differences from affecting connection performance. Pogo pins are based on gold plating or composite electroplating to resist oxidation, don’t deteriorate due to temperature changes. In high temperatures, this spring loaded connector maintains low contact resistance to ensure signal stability. After long-term verification by Johoty’s European and American customers, our pogo pins connector is suitable for industrial and military.

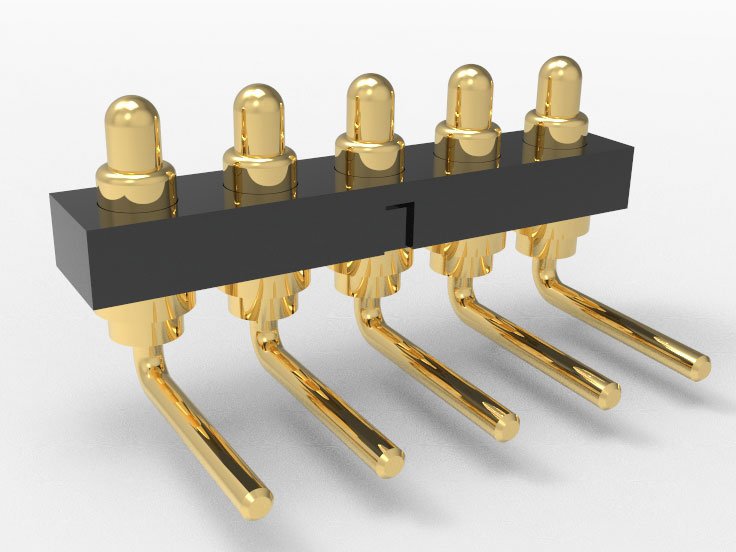

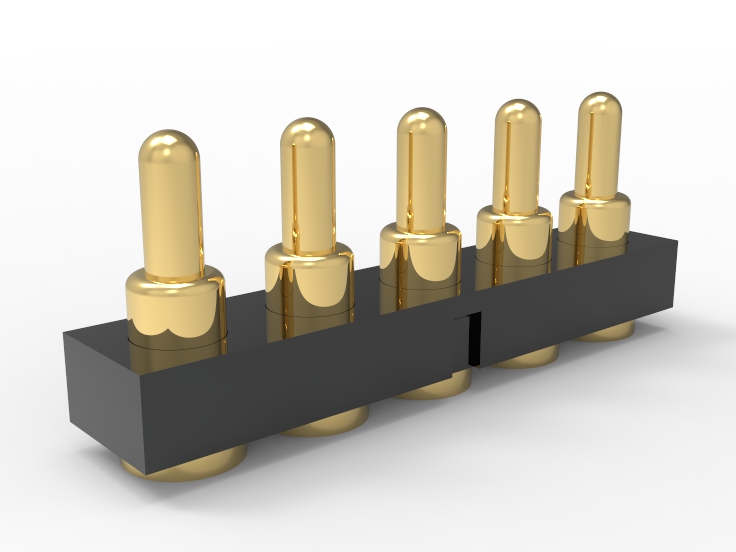

Small in size but strong in load-bearing

2.54mm pitch, pogo pins connector compact structure is suitable for high-density electronic layout. Its small size can carry high currents and meet high-power devices. The optimized spring of this spring loaded connector ensures stable connection while reducing space occupation. Johoty’s CNC manufacturing ensures efficient energy transfer and is suitable for compact devices. Our pogo pin connector is sure to enhance the design freedom of electronic products and achieve smaller and stronger system integration.

Optimization of high-speed signal transfer

Low loss brass beryllium copper can reduce signal attenuation, while pogo pins connector can ensure stable high-speed data transfer. CNC manufacturing process reduces signal reflection and improves signal integrity. This spring loaded connector optimizes contact point design to reduce EMI and ensure high-speed communication quality. The stable pressure control of spring loaded pin avoids contact jitter and ensures stable data transfer. Our pogo pins connector is suitable for communication and computer fields with high-speed data connections.

FAQ

Will the spring of pogo pins connector affect signal stability?

The spring pressure has been precisely calculated, and after 23 quality tests, the pogo pins connector ensures stable contact. Its highly conductive coating can reach up to 80u “, reducing signal loss and improving transfer quality. Optimizing smooth travel can reduce micro motion interference and effectively prevent signal jitter. The precision machining of the plunger tip of the pogo pin can maintain long-term low resistance after gold plating or composite electroplating. After verification by Johoty customers in multiple DP signal projects, our pogo pins are suitable for electronic devices with high-speed data and low interference requirements.

How can pogo pins connector reduce insertion and removal wear?

The gold plating layer enhances wear resistance, while palladium, platinum, rhodium, and ruthenium plating can effectively solve specific problems and reduce performance degradation caused by long-term use. The spring of pogo pins connector can always control the pressure within optimal range. Our 5-axis and 6-axis CNC manufacturing ensures the smoothness of pogo pins and reduces wear from small particles. High strength stainless steel 304 is fatigue resistant, extending the lifespan of this spring loaded connector.

Is pogo pins connector suitable for non-standard docking angles?

The spring-loaded design allows for slight angular deviations, and pogo pins connector can maintain a stable connection within ±3°. Optimized arrangement of pogo pins can reduce resistance fluctuations caused by angle errors. The adaptive force and distance adjustment of the spring enable spring loaded connector to adapt to different device interfaces. With high elasticity structure, when docking is not precise, pogo pins can still reliably conduct for complex structures or mobile devices.

Is pogo pins connector reliable in severe vibration?

Of course! Spring structure has working stroke and full stroke, which can ensure reliable continuous contact and prevent power failure due to vibration. High elasticity material of pogo pins connector can absorb external impacts and reduce transient changes in resistance. Optimize contact surface shape, improve anti vibration ability, and control the tolerance of pogo pin precision manufacturing. It is to ensure long-term stable connection. This spring loaded connector is based on high-performance piano steel springs and can fit automotive and aviation.

Will pogo pins connector reduce conductivity in high humidity?

Ordinary products will definitely be affected. But Johoty’s pogo pins connector’s high-quality gold plating layer can prevent oxidation and maintain long-term stable conductivity. It has special moisture-proof materials to reduce moisture impact on spring. The precise injection molding process can significantly improve moisture resistance and avoid short circuit. Electroplating processes or composite electroplating can reduce resistance fluctuations caused by humidity changes. Johoty’s pogo pins connector is suitable for electronic devices in outdoor and high humidity.

How does pogo pins connector ensure stable transfer of high current?

Low resistance plunger tip, gold-plated with palladium, platinum, rhodium, and ruthenium, can greatly optimize energy transfer and reduce power loss. The high elasticity spring of pogo pins connector ensures stable pressure and prevents current fluctuations. The gold plating layer can also reduce current heating, improve connection safety and stability. The high current design maximizes contact area, which can improve load-bearing capacity for high-power electronic devices.

Will reliability of pogo pins connector decrease after long-term use?

High strength stainless steel 304/316 spring is fatigue resistant, and piano steel can easily achieve 200,000 cycles. Optimized mechanical structure, pogo pins connector can reduce resistance changes caused by wear. Gold plating, palladium, and platinum can ensure improved corrosion resistance and prevent performance degradation caused by oxidation. Precision CNC machining control tolerance ± 0.01mm, stable connection after insertion and removal. For pogo pins designed with a lifespan of 200,000 cycles, they can easily adapt to industrial and consumer electronics with high durability.

Can pogo pins connector support high-speed signal transfer?

Of course, pogo pins connector with low loss materials can significantly reduce signal attenuation and ensure data integrity. Its optimized spring stroke reduces signal reflection and improves transfer efficiency. Precise CNC manufacturing can reduce micro motion interference and improve signal stability. The pogo pins connector has great power in reducing signal loss due to its low contact resistance, which enables high-speed data without delay. Our pogo pins connector is suitable for high-speed communication, computers, and data transfer devices.