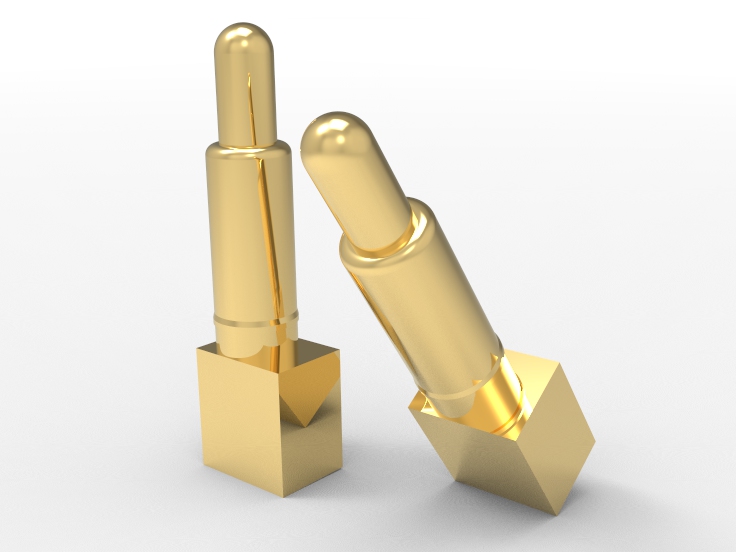

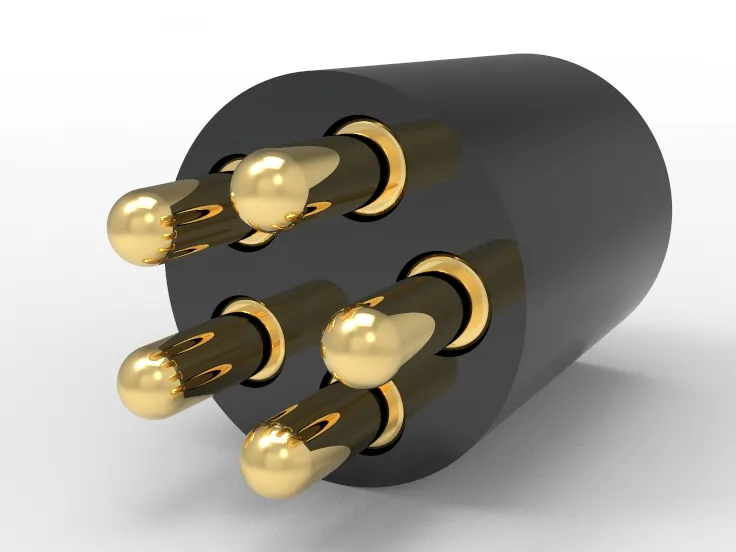

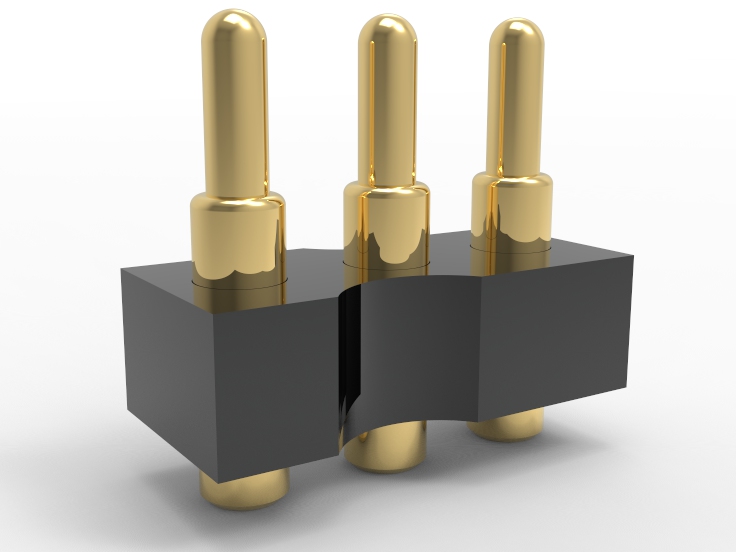

Advantages of Small Pogo Pins, L:3.00~5.99 mm,

Clever design, saves space

Small pogo pins are compact and can be installed along the edges of PCBs, saving valuable space for device design. Their unique right-angled structure optimizes layout, supports complex circuit board design, and provides higher flexibility. Suitable for high-density assembly, improving the utilization of produce’s internal space.

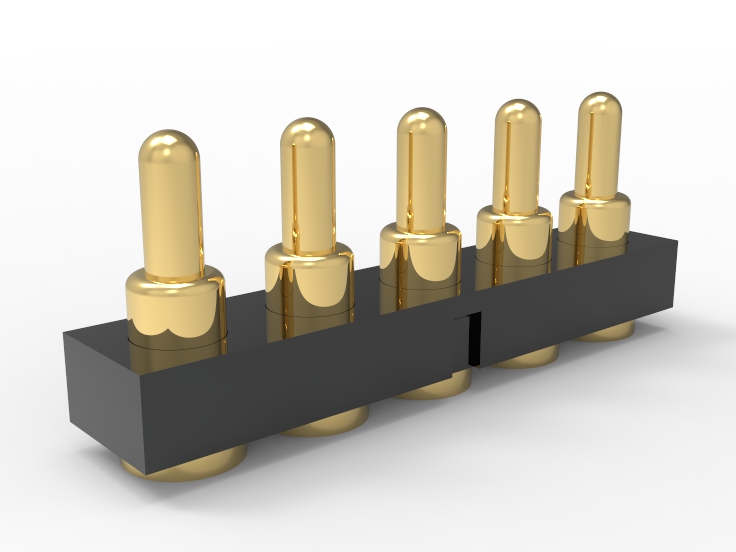

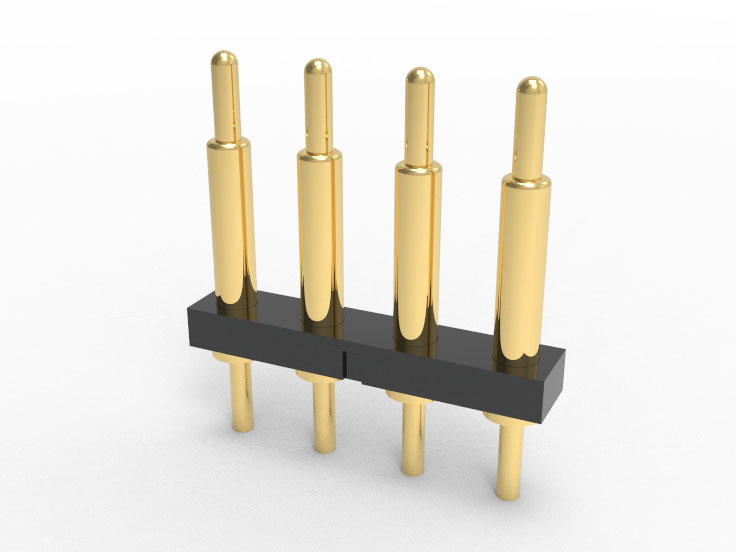

Efficient electrical performance

Small pogo pins have low resistance and high conductivity, ensuring stable transfer of signals and currents in circuits. They support multi-point contact optimization to reduce electrical losses. Simultaneously maintaining consistency, providing high-quality output, and adapting to high-demand electrical applications.

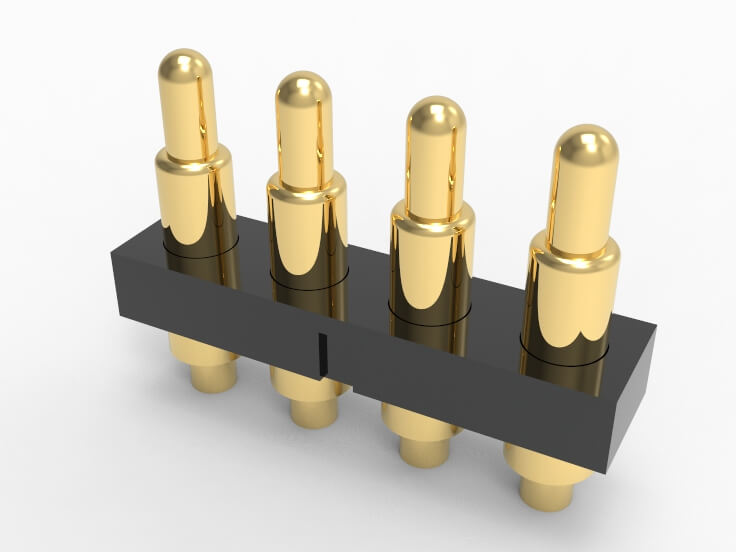

Durable mechanical structure

These small pogo pins are designed with precision, supported by high-strength materials, and can withstand multiple insertions and long-term use. They have a compact and stable structure, reduce wear, extend lifespan. At the same time, they can enhance overall reliability for high-frequency operations.

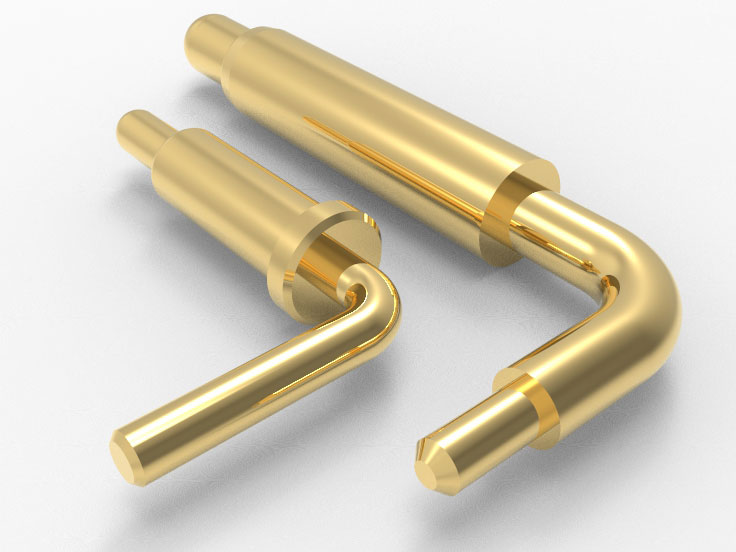

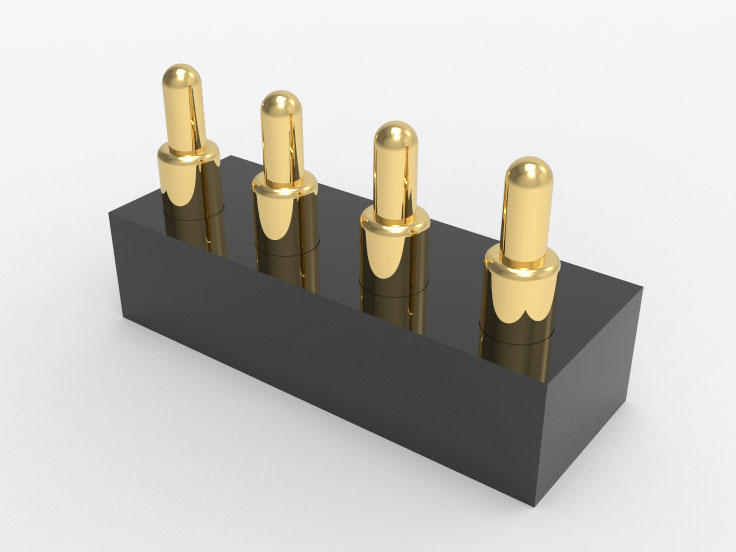

Easy integrated installation

Johoty’s small pogo pins feature a right angled design, easy to solder onto PCB pads for quick and efficient installation. They support multiple installation forms and have high compatibility with other components. Suitable for rapid production, significantly improving assembly efficiency and reducing manufacturing complexity.

Excellent contact reliability

Small pogo pins have a spring design that provides stable and reliable contact pressure. They adapt to different surface irregularities to ensure continuous electrical contact. At the same time, it has excellent anti vibration effect, ensuring connection stability and meeting various complex applications.

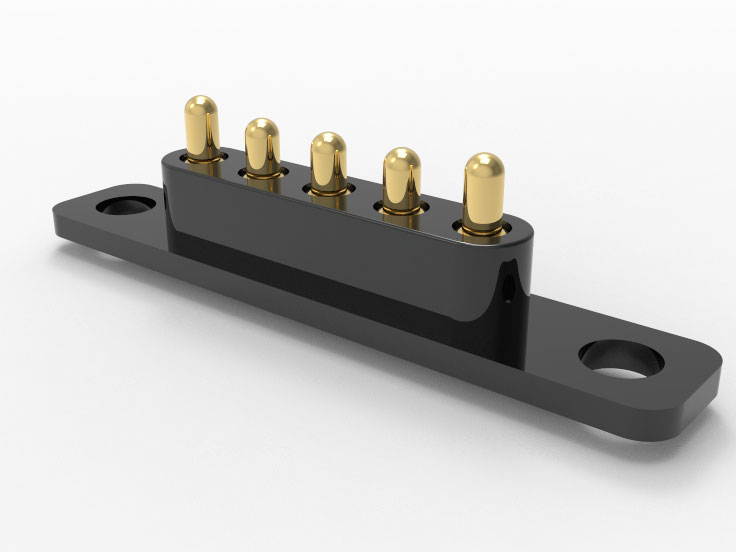

Accurate multi-purpose design

Small pogo pins support multiple uses and adapt to different circuit connections. Their design is flexible and customizable, meeting specific module requirements while supporting high-density design. Excellent performance in precision electronic devices with strong expandability.

Ability to resist environmental interference

These right-angle small pogo pins exhibit stability in harsh, are resistant to corrosion, temperatures, humidity. They ensure that electrical connections are not affected by external environments. Suitable for various industrial and consumer applications. This ensures reliable function and performance under extreme conditions.

Precision manufacturing process

Right angle small pogo pins are produced in high-precision processes for consistency and high quality. They have precise dimensions and perfect contact, reduce errors, and improve assembly success rates. They showcase outstanding performance of precision craftsmanship, endow the product with more competitive advantages.

FAQ:

What special applications are small pogo pins suitable for?

Small pogo pins with right angle design are suitable for devices with limited space or requiring vertical insertion and removal. They can place connection points at PCB edge, saving internal space and are suitable for compact electronic devices. For densely arranged components, right angle installation makes wiring more flexible. At the same time, this design is more convenient in product assembly process and improves assembly efficiency. For complex circuit board layouts, right angle design can also simplify the connection method.

Can small pogo pins work stably in high temperatures?

The high temperature resistance of small pogo pins depends on their designs and raw materials. High-temperature resistant metal makes such pogo pins, which can keep normal under extreme temperature. They have undergone special treatment to enhance thermal expansion and corrosion resistance. They can maintain good electrical contact in high temperatures. Even if exposed to a heat source for a long time, it can still maintain stable performance and won’t cause poor contact or damage due to excessive heat.

Does small pogo pins support waterproof?

Some models of small pogo pins have waterproof design and can continue to function normally in humid. Their protection level is achieved through special sealing technology, and some products also add anti-corrosion coatings to prevent moisture infiltration. Waterproof pogo pins are suitable for medical equipment, outdoor electronic products, etc. They can ensure that they are not affected in humid and maintain stable electrical connections.

Can small pogo pins adapt to PCBs of different thicknesses?

Yes, small pogo pins can be customized according to different PCB thicknesses. Their spring design enables them to automatically adjust contact pressure, ensuring stable contact with thickness changes. Johoty offers multiple specifications to accommodate PCB designs of different thicknesses. By adjusting pogo pin length or shape, engineers can ensure their compatibility with various types of circuit boards and ensure good connections.

How to ensure stability of small pogo pins in vibration?

Small pogo pins adopt a spring-loaded structure, which can maintain stable contact pressure in vibration. Their design takes into account high quality seismic, ensuring that they will not loosen or fail under severe vibrations. The special metal material and surface finishing enhance its fatigue resistance, allowing pogo pins to withstand long-term vibrations without damage. In addition, stability can be further improved during installation by reinforcing connections or using shock-absorbing devices.

Is the installation of small pogo pins prone to errors?

Installing small pogo pins is relatively simple, but take care of some details. The correct welding method can avoid poor contact or loose solder joints. Due to its right angled design, PCB pads can be more accurately aligned during installation, reducing misalignment. Engineers should ensure welding surface is very smooth and very clean for good contact. If operation is standardized, the installation process is smooth and efficient.

Can small pogo pins support high-frequency signals?

The electrical performance designed by small pogo pins can support high-frequency signals. They adopt a low contact resistance to reduce signal loss and ensure data stability and clarity. In high-frequency signals, communication devices, RF applications, etc., small pogo pins can provide stable connections to ensure signal quality is not affected by interference. Through precise design and material optimization, small pogo pins can perform well in high-frequency

Can small pogo pins be applied to 3D printing equipment?

The elasticity and compact design of small pogo pins make them suitable for 3D printing equipment, electrical connections, and modular design. 3D printing equipment requires quick connection of different modules, and small pogo pins can provide a simple and secure connection method. Due to its easy installation and support for repeated use, small pogo pins can effectively reduce assembly time and improve equipment efficiency. They can be seen on control panel, sensor interface, and other places of 3D printers.