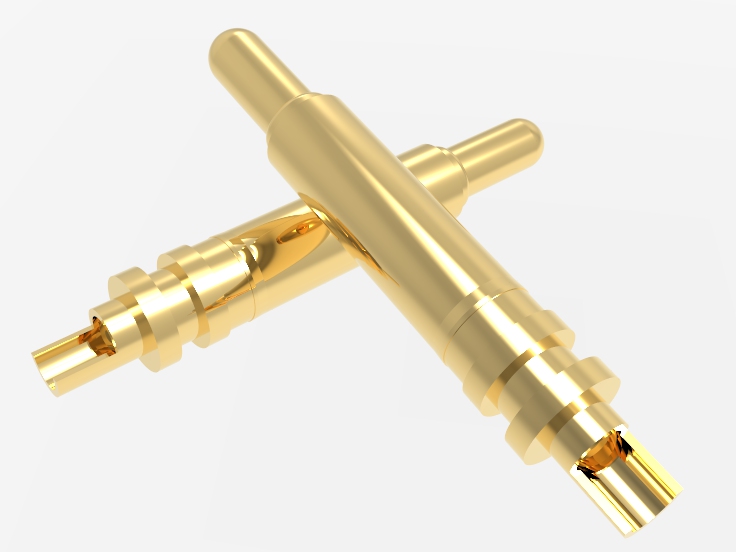

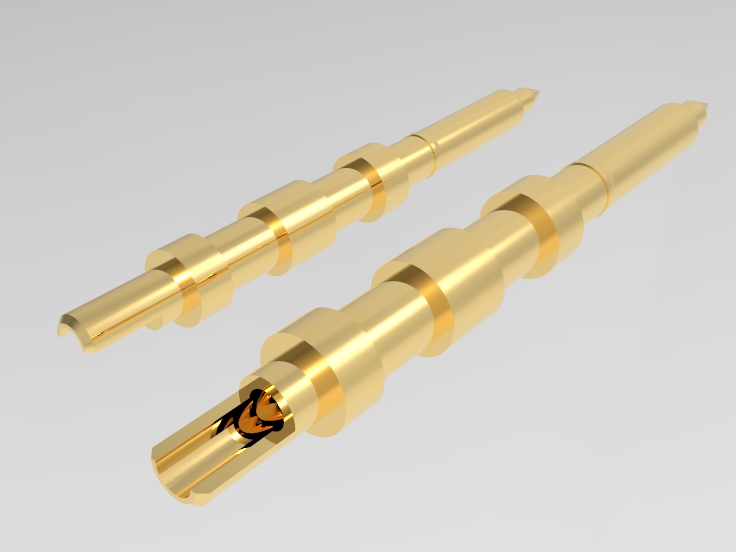

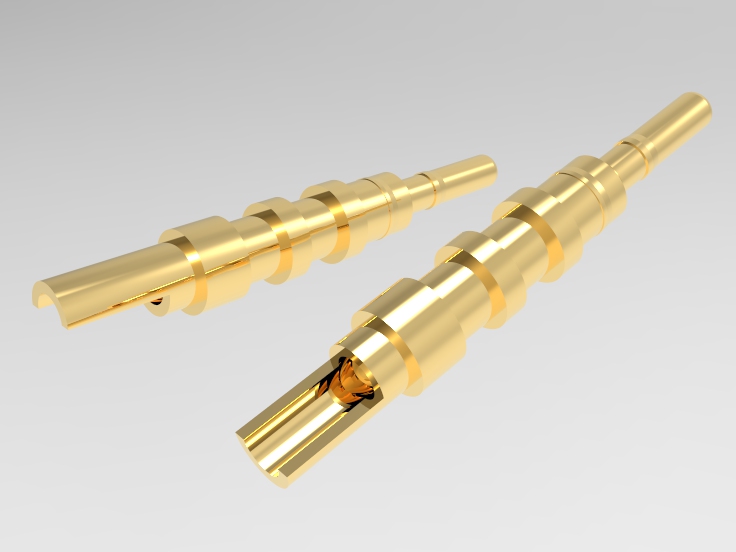

Advantages of Socket Pogo Pin, L:12.00~41.00 mm,

High precision connectivity performance

The accuracy of socket pogo pin is very high, which can ensure a very stable connection between devices. Its spring force is uniform and not easy to loosen. The resistance of the contact point is very low, and the signal transfer is fast. The design of plunger is meticulous and suitable for use in small spaces. Strict manufacturing tolerance control ensures more precise connections.

Excellent wear resistance

Johoty’s socket pogo pin is very durable and can withstand up to 200,000 insertions and removals. Its surface material is very hard and not easily damaged after friction. The spring part has undergone special treatment to maintain its high spring force for a long time. The contact point will not deform due to long-term use. Even in harsh environments, it can maintain stability.

High current carrying capacity

The socket pogo pin can pass up to 50A of current and is suitable for various devices. The material of plunger has strong conductivity and can transmit stable current. Internal structure optimization reduces current loss. The spring force design is reasonable and will not loosen due to high current. Good high temperature resistance and low temperature rise when current passes through.

Small scale design adaptability

The solder cup socket pogo pin is very compact and suitable for use in precision equipment. The plunger design is compact and can save internal space. The spring part is small yet powerful, never compromise its performance. The barrel has a small volume, makes device thinner and lighter. It can be embedded into complex modules, making it convenient to use flexibly.

Excellent conductivity stability

The socket pogo pin can maintain stable conductivity for a long time. The contact point material is excellent and the resistance change is small. The spring force is uniform and the connection will not disconnect. The surface coating is smooth, reducing current interference. Strong sealing design to prevent external factors from affecting performance. Capable of adapting to high-frequency signal transfer requirements during connection.

Superior anti vibration performance

Johoty’s socket pogo pin remains stable in a vibrating environment. The spring force design is scientific and can absorb vibration and impact. The connection between plunger and barrel is tight and not easy to loosen. The shell material is sturdy and can withstand equipment movement. Compact structure, even in bumpy environments, it will not affect the connection. Suitable for use on mobile devices.

Easy and fast assembly

The installation of socket pogo pin is very simple and greatly saves time. The plug-in part is seamlessly integrated with the module. Modular design that does not require complex tool assembly. The spring is very simple on structure and also easy to disassemble. Uniform size, able to quickly match with other components. Users can easily complete device assembly work.

Excellent temperature adaptability

The solder cup socket pogo pin can adapt to various temperature conditions and has stable performance. It can maintain conductivity in high temperature environments. The spring force will not decrease at low temperatures, and the connection remains reliable. The material has been processed and has strong temperature resistance. Temperature changes will not cause deformation or poor contact. Suitable for equipment usage needs in complex environments.

FAQ:

Why is socket pogo pin suitable for high-frequency signals?

The contact resistance of socket pogo pin is very low, as low as 15mΩ, and the signal transfer loss is small. The internal spring force is stable and can be customized to 800gf or even 3,000gf, ensuring continuous and reliable contact points. Coating material has good conductivity and can reduce signal interference. Plunger design optimization reduces the reflection of high-frequency signals. Compact structure effectively reduces signal delay and interference.

How to maintain efficient connection of socket pogo pin in micro devices?

Its plunger and barrel designs are very small, suitable for small spaces. The spring part has been optimized to be both compact and strong. Strict tolerance control ensures stable operation in micro devices. It has very flexible installation methods and can embed with various precision modules. Even in small devices, socket pogo pin conductivity is still excellent.

Why can socket pogo pin withstand high currents?

It can reduce current loss based on high quality brass with gold-plated. Spring and plunger design can evenly distribute pressure and prevent overheating. Plunger coating is resistant to high temperatures, ensuring that it is not damaged when passing high currents. Optimize internal structure of socket pogo pin to effectively improve its current carrying. Contact area between plunger and barrel has been scientifically designed to improve conductivity efficiency.

How to avoid socket pogo pin loosening after long-term use?

Spring materials have high resilience and can maintain stable pressure. The precise fit between plunger and spring prevents looseness. Barrel design protects its internal structure and reduces vibration impact. Contact point coating has good wear resistance and is stable for long-term frequent insertion and removal. Internal components in socket pogo pin have been optimized and designed to extend their lifespan.

How to ensure compatibility of socket pogo pin among multiple interfaces?

Its size design is uniform and can adapt to multiple interfaces. Easily adjust spring pressure for different contact requirements. Plunger has diverse shapes and supports various connection methods. Socket pogo pin is flexible on installation method and can be embedded into different device modules. Modular design, socket pogo pin can easily combine with other components.

Why can socket pogo pin maintain long-term conductivity stability?

Contact point coating is excellent, reducing the resistance increase caused by oxidation. Spring force is uniform and will not weaken due to prolonged use. Plunger material is wear-resistant, ensuring a stable contact area at all times. Socket pogo pin structure has strong sealing performance to prevent environmental interference. The contact point resistance is small, and current transfer is more continuous and stable.

Can socket pogo pin meet high-frequency connections?

The spring design of Johoty’s socket pogo pin is fatigue resistant and can withstand multiple uses. Plunger material is wear-resistant and remains reliable after frequent contact. Spring pressure has been optimized and the contact is always tight. The coating is durable and conductivity won’t decrease after uses. Barrel design protects internal components from damage caused by frequent uses.

How can socket pogo pin adapt to different device shapes?

The solder-cup of socket pogo pin are diverse and can be customized for design. Circular, flat, and pointed plummers are suitable for different needs. Spring pressure is adjusted according to plunger shape, making the connection more secure. Plunger length can be flexibly adjusted to match device height. Surface finishing of socket pogo pin is excellent, and various plnugers can conduct electricity stably.