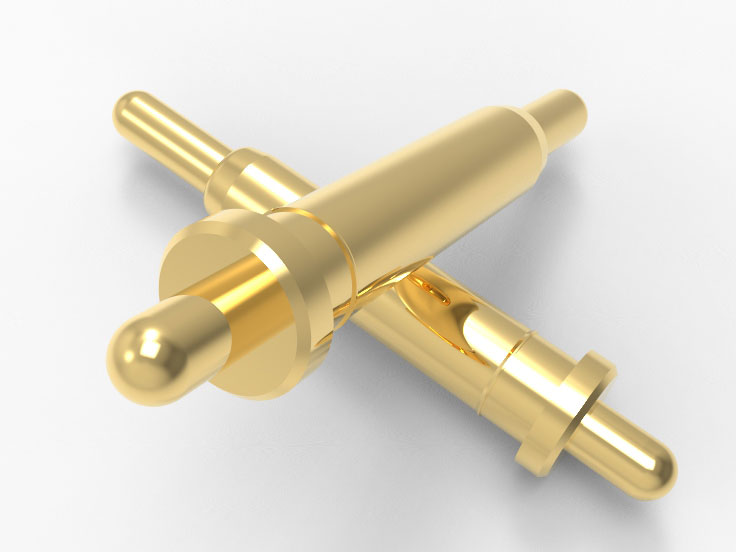

Advantages of Spring Contact Pins, L: 5.00~6.99 mm

High conductivity performance

Johoty’s spring contact pins are made of high-purity materials with excellent conductivity. This double ended pogo pin can significantly reduce power loss, improve efficiency, and maintain stable signal transfer. At high frequencies, they can maintain excellent performance and ensure reliable connections.

Ultra long lifespan design

The combination of precision structure and high-quality materials provides excellent wear resistance and fatigue resistance. Spring contact pins can maintain performance under high-intensity use. This can greatly extend product lifespan, reduce replacement frequency, and overall usage costs.

Accurate elasticity adjustment

Optimize spring design to ensure moderate contact pressure. Spring contact pins maintain efficient connections in both weak signal and high currents. They can avoid contact surface wear caused by excessive compression, perfectly balancing flexibility and stability.

Extremely small volume adaptability

Spring contact pins are compact and adaptable to high-density electronic devices, saving space. This pogo pin can provide more possibilities for complex circuit layouts. At the same time, they can maintain complete functionality and meet stringent requirements of precision instruments.

High temperature stability

Using special processing techniques, the dual headed spring contact pins maintain stable performance in high-temperatures. This spring loaded pin won’t cause material deformation or performance degradation for harsh usage.

Anti vibration reliability

The unique structural design of spring contact pins ensures stable connection under vibration and impact conditions This high-performance pogo pin can effectively avoid poor contact and improve the overall reliability of the system. Such pogo pins can fit high dynamic fields.

Multi layer electroplating reinforcement

The surface of Johoty’s spring contact pins adopts multi-layer electroplating or composite electroplating technology. This can increase corrosion resistance and ensure such double ended pogo pin keeps bright and new after long-term use. Meanwhile, they can enhance contact surface conductivity and further reduce connection resistance.

Flexible customization capability

Dual head spring contact pins support diverse design requirements. Flexible customization is available based on length, diameter, and contact force for different customers’ different devices. Meanwhile, spring contact pins ensure efficient mass production and enhance overall competitiveness.

FAQ:

Can dual head spring contact pins prevent arc?

The unique contact structure reduces instantaneous resistance during connection and minimizes the arc caused by current surge. Spring contact pins optimize material selection to minimize risk of spark ignition, and precise elasticity control ensures stable contact. Their special coating enhances resistance to current shock and effectively avoids equipment damage caused by electric arcs.

How do spring contact pins perform in weak signal transfer?

Spring contact pins can maintain stable connections based on high sensitivity under extremely low voltage. The improvement of surface smoothness reduces signal attenuation, optimization of contact pressure enhances ability to conduct weak currents. The oxidation resistant coating prevents signal interference, and this pogo pin supports high-precision transfer.

How can these spring contact pins avoid rapid wear and tear?

Selected high wear-resistant alloys significantly enhance wear resistance, while optimized spring contact pins contact surface design reduces contact stress. Enhanced spring life reduces the risk of fatigue fracture. Their surface electroplating reduces friction coefficient and extends service life. Precise machining process of this spring loaded pin avoids the exacerbation of wear caused by micro defects.

How can spring contact pins maintain performance under extreme temperature differences?

Johoty uses high-temperature alloy to ensure heat resistance, and low-temperature strengthening treatment to prevent embrittlement. The spring tension design of spring contact pins avoids loosening caused by temperature differences. And, contact surface remains stable without being affected by thermal expansion and contraction. Temperature changes.can’t reduce their performance based on special coating of Johoty’s pogo pin.

Can spring force of spring contact pins be precisely controlled?

Yes! Spring contact pins have high-precision springs and ensure consistency. Johoty uses advanced manufacturing to reduce elasticity deviation and optimizes material selection to provide ideal elastic modulus. Independent structure of this spring loaded pin prevents pressure changes. It strictly calibrates each pogo pin to ensure moderate pressure.

What applications with extremely small spacing can spring contact pins be adapted to?

The ultra micro structure design of spring contact pins supports high-density arrangement. Their dimensional tolerances are controlled at the micrometer level to ensure accuracy, and very thin-walled springs balance performance and compactness. The customized design of this pogo pin allows for flexible sizes to meet ultra small electronic products.

Why are spring contact pins still reliable in high vibrations?

Johoty adopts anti vibration spring to effectively absorb vibration energy, and the contact surface texture enhances anti slip performance. The fixed structure optimization of such pogo pins avoids looseness, and high-quality materials enhance impact resistance. Their elasticity quickly recovers and maintains stable connections

Can spring contact pins transfer high-speed signals?

Yes, it can satisfy! Spring contact pins are made of low resistance materials to ensure lossless signal transfer. Their high-frequency optimization can reduce impedance effects, and the polishing of the contact surface reduces EMI. The microstructureof this double ended pogo pin supports smooth high-speed data transfer and is compatible with various high-speed communications.