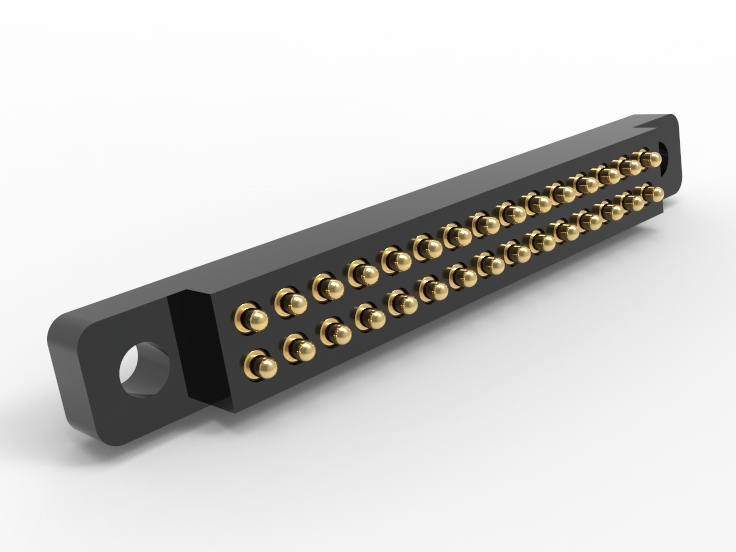

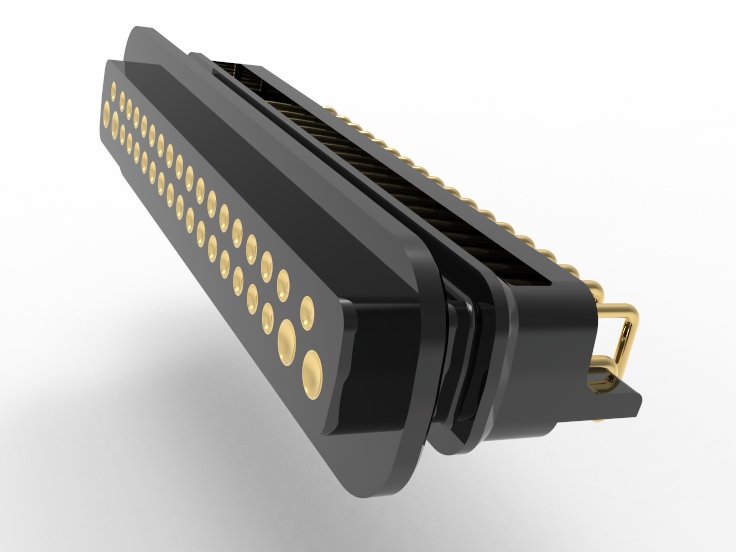

Advantages of Spring Loaded Connector, pitch: 1.00~2.54

High-density connection design improves space utilization

The high-density design of spring loaded connectors allows for more connections to be achieved in limited spaces. For engineers who need to save space, it is possible to achieve more functions on small-sized circuit boards. This undoubtedly improves the flexibility of design and system integration. This pogo pin connector can provide reliable power transfer in small spaces. It can also minimize physical space occupied and ensure more compact device design.

High anti-vibration capability ensures reliable connection

Unique structure our spring loaded connector enables it to maintain stable connection in vibration or impact. In high-intensity mechanical equipment or automotive fields, pogo pins can effectively resist external environmental interference. It can ensure stable operation without interrupting current due to external changes. Our pogo pin connector ensures device’s normal operation and long-term use.

Automatic docking function reduces manual errors

After configuring magnets, the spring loaded connector can automatically dock to avoid poor connection caused by manual operation. In engineering applications that require frequent plugging or multiple connections, automatic docking can greatly reduce the risks during operation process. In equipment maintenance with high frequency, it facilitates engineers to improve work efficiency. At the same time, it can reduce misoperation and improve overall productivity.

Adjustable pressure design improves connection quality

Spring loaded connector is equipped with adjustable pressure designs, ensuring connection quality in different usage. Engineers can adjust pressure of pogo pin connectors according to actual needs when dealing with different currents or signal transfers. This can ensure stable current and avoid equipment failure. This flexibility provides great convenience for complex circuit design.

Super durability to cope with harsh environments

In harsh, spring loaded connector often demonstrates excellent durability. Under extremely high, low temperature, humid, or corrosive gas conditions, this pogo pin connector can ensure connection doesn’t become loose or damaged. Faced with complex and ever-changing work environment, this high endurance characteristic can demonstrate a strong advantage. It can ensure that engineers’ designs can maintain long-term stability and high efficiency in any environment.

Precise contact design enhances electrical performance

Johoty always meticulously designs every contact of spring loaded connector. In this way, it can ensure stable electrical performance while transferring high current. During high-demand electrical transfer tasks, this design enables pogo pin connector to provide the lowest contact resistance. It can also maintain stable electrical performance during frequent use, avoiding power loss or signal interference.

Multiple specifications flexibly adapt to different needs

Our spring loaded connector comes in various specifications, sizes, function to fully meet engineers’ various expectitations. From precision electronic devices to large industrial machinery, Johoty always provides suitable pogo pin connectors. This flexible adaptation helps engineers easily tackle challenges of different projects. At the same time, it ensures efficient and reliable connections among various devices, equipment and systems.

Quick plug and unplug design saves time and cost

The quick plug and unplug of spring loaded connector make installation and maintenance more convenient. Engineers can connect or disconnect without tools or excessive manual operation. This greatly saves time and labor costs. In emergency repairs or equipment upgrades, it is possible to quickly complete connections and solve problems more efficiently. This is a practical advantage that engineers often pursue.

FAQ

Can you explain working principle of spring loaded connector?

Spring loaded connector utilizes spring pressure to keep stable connection and reduce contact resistance. It has one or two springs built into pogo pin connector to ensure tight contact between pogo pins and socket. In this way, it can adapt to different insertion and extraction forces, enhancing durability and reliability. Under vibration or frequent contacts, its connection quality won’t be affected, and it can often use in high-end engineering.

What is maximum current of spring loaded connector?

Maximum current of spring loaded connector depends on our designs and materials, the standard can withstand up to 5A. Specially designed pogo pin connector can often withstand 10A or even 50A. Its spring and conductor contact design can effectively conduct current. At the same time, it can maintain stability and low contact resistance. When selecting reasonably, ensuring current load doesn’t exceed the range, it’s to ensure long-term stability of pogo pins.

How to choose appropriate number and arrangement of pogo pins?

The number and arrangement of pogo pins should be selected according to customer’s circuit designs. Multiple pogo pins allows for more functions to be implemented simultaneously. The arrangement method should consider spatial layout, signal transfer, and engineer’s operating habits. Correct spring loaded connector can optimize space utilization and ensure efficient transfer of signals and currents.

Why is spring-loaded connector suitable for complex environments?

Spring loaded connector can work stably in complex vibrations, underwater, temperature changes, EMI, and mechanical pressures. It has strong adaptability and can ensure continuous and stable contact under harsh external conditions. This pogo pin connector fits aerospace, automation equipment, high demand engineering applications.

How to ensure contact stability of spring loaded connector?

The contact stability mainly depends on designs and spring material to ensure good contact. The precision spring pressure of the spring loaded connector can prevent poor contact or looseness. It can maintain low contact resistance, ensuring equipment’s long-term stability. Your regular inspection and maintenance can also improve its long-term stability.

What is anti-interference of spring loaded connector?

Becuase the springs ensure good contact and conductivity, and super low resistance, spring loaded connector have certain anti-interference capabilities. By precise pogo pin arrangement and conductive paths, it can reduce signal interference. In high-speed signal transfer, this pogo pin connector performs exceptionally well. Many Johoty’s clients are from high-frequency communication and sensitive electronic devices, we always receive clients possitive feedback.

How do ensure performance of spring loaded connector in high temperatures?

The spring and contact materials of spring loaded connector should be perfect from strong high-temperature resistance. In this way, it can maintain normal function in high temperatures. By optimizing materials and design, this pogo pin can maintain stable electrical connections at extreme temperatures. With this characteristic, engineers in industrial equipment and automotive electronics often contact CFT team for pogo pins.

How to optimize space utilization of spring loaded connector?

Johoty often achieves spatial optimization of spring loaded connector through reasonable pogo pin arrangement and compact design. Choosing appropriate number and layout of pogo pins based on device’s size and functional requirements is crucial. This can avoid redundant connections and improve space utilization efficiency. Through design flexibility, spring loaded connector is sure to achieve more functionality within limited space.