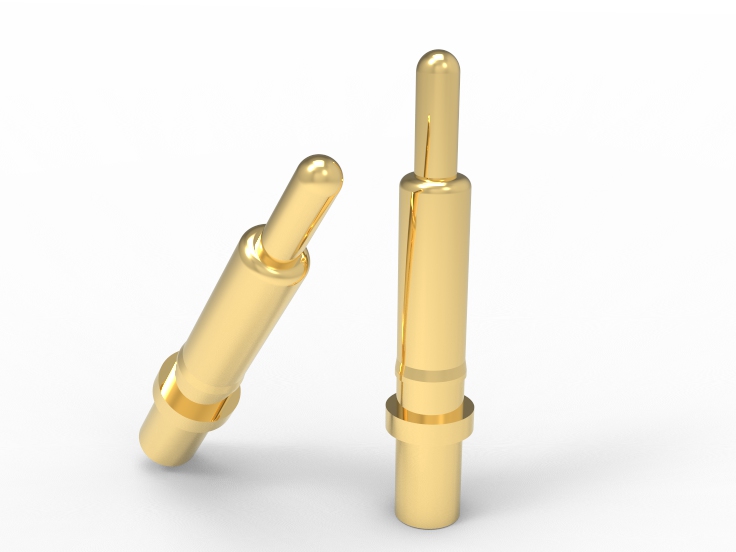

Advantages of Spring Loaded Pin, L: 5.00~5.99 mm,

High Conductivity and Stability Performance

The through-hole spring loaded pin is made of high-precision conductive brass beryllium copper, which has extremely low resistance and super strong conductivity. Spring design ensures conductivity stability and maintains performance even in high-frequency vibration. The optimized contact point structure minimizes contact resistance to the greatest extent possible. Can still work reliably under high or low temperatures. Spring loaded pin has a long lifespan and repeated uses without performance degradation.

Precision Design Achieves High Durability

Spring loaded pin is meticulously designed with superior bending resistance and fatigue performance for frequent uses. The spring pressure is evenly distributed to ensure contact points are not easily worn out. The surface adopts special coating to enhance corrosion resistance. The structural components have undergone strengthening treatment, and spring loaded pin is suitable for complex conditions. Maintain precise contact after long-term work.

Miniaturization and High Integration

Johoty’s through-hole spring loaded pin adopts a micro design, which can be easily installed in small spaces. Highly integrated structure saves equipment space and reduces component usage. The multifunctional module design enables the product to have both conductive and fixed functions. Combining optimized size with high efficiency, Spring loaded pin is suitable for various high-density circuit boards. Innovative design enables compatibility with complex devices.

Ultra Low Contact Resistance

The contact points of Johoty’s spring loaded pin have undergone special treatment, resulting in extremely low conductivity loss, ensuring the integrity and high precision of signal transfer. The material selection and processing technology of spring loaded pin significantly reduce electrical energy dissipation. Optimize spring structure design to ensure constant contact resistance. Maintain a low resistance regardless of frequent use or prolonged contact.

Anti Impact and Vibration Performance

Specially designed to cope with complex environments, Johoty’s spring loaded pin high elasticity spring effectively absorbs impacts. The precise structure ensures electrical contact can be maintained under vibrations. The anti deformation allows the spring loaded pin to reset under heavy pressure. The material is made of high-quality metal, which has a significant impact resistance effect. After long-term use, the spring has excellent elasticity and resilience.

Easy Installation and Strong Adaptability

Adopting modular design, spring loaded pin can quickly achieve compatibility with multiple devices. The through-hole design makes installation easier and does not require special tools. The standardized specifications of spring loaded pin are easily to combine with other components. The flexible installation method is suitable for vertical and horizontal multi angle operation. The unique structure allows for efficient connections within a limited space.

Excellent High-frequency Performance

Spring loaded pin performs excellently in high-frequency signal transfer. The spring ensures tight contact and reduces signal loss. The contact material has been optimized to reduce high-frequency interference. Spring loaded pin reduces reflection and crosstalk, ensuring clear signal transfer. Suitable for high-performance communication and high-speed data transfers.

High-temp resistance & adaptability to Extreme Environments

Using high-quality materials, the through-hole spring loaded pin still performs excellently in high temp as well as extreme environments. The heat-resistant design ensures stable operation at high temperatures. Surface technology enhances antioxidant capacity and adapts to harsh environments. Spring elasticity remains unchanged under low temperature conditions. Spring loaded pin is suitable for aerospace and industrial automation.

FAQ

What is Spring Loaded Pin?

A through-hole spring loaded pin is specially designed connector used in various electronic products. It provides stable contact pressure through springs. During installation, insert circuit board through through hole to ensure effective connections with contact points on the circuit board. Pogo pin is used for high-frequency signal transfer or applications that require high contact pressure. Its working principle is based on spring compression and release, which keep the contact points tight at all times.

How to Choose Spring Loaded Pin?

When selecting a through hole pogo pins, please consider: first, choose appropriate contact materials based on current and signal type. Secondly, spring pressure should meet usage environment requirements. Pay attention to pogo pin length and diameter to fit circuit board. Also, pay attention to working temperature to ensure stable work or operation in different environments. Finally, consider equipment installation methods and choose appropriate installation sizes.

What is Spring Loaded Pin Working Principle?

Spring loaded pin relies on internal springs to provide stable pressure and achieve good electrical contact. The spring ensures a tight connection with PCB contact point during plunger compression and release. The pogo pin ensures efficient conductivity, while the spring absorbs external vibrations or impacts, reducing the impact on contact points. This design ensures stable electrical performance in frequent connection.

What are Spring Loaded Pin Applications?

Through hole spring loaded pin is applied in electronic products, communication equipment, automotive electronics, aerospace, and other fields. It is used for fixed connections on circuit boards or to provide stable electrical contacts in high-speed signal transfer. Pogo pins is excellent for frequent connections and disconnections. It can maintain stable operation in high vibration and strong impact environments, making it suitable for industrial automation and medical equipment.

How can Through-hole Spring Loaded Pin Improve Durability?

Spring loaded pin uses high-strength materials and precision manufacturing to enhance durability. High quality metal materials ensure pogo pin fatigue resistance and wear resistance. The internal spring is specially designed to withstand multiple connection without losing its elasticity. Adopting special finishing can effectively prevent corrosion and oxidation. The precise production process ensures each component accuracy, avoiding malfunctions caused by looseness or wear during use.

How can Spring Loaded Pin Ensure Electrical Contact Reliability?

Spring loaded pin ensures electrical contact reliability through various means. Firstly, the contact points are made of highly conductive brass to ensure low contact resistance. The spring design ensures stable pressure at contact point, reducing the risk of poor contact. The plug-in part between pogo pins and circuit board is precisely processed to matches conductive surface perfectly. Secondly, plunger and barrel surface has been specially treated for strong oxidation and corrosion resistance, which extends its service life. The overall design ensures reliable contact after prolonged use.

Does Spring Loaded Pin Transmit High-frequency Signals?

Yes, through-hole spring loaded pin is very suitable for high-frequency signal transfer. Its contact point optimization can effectively reduce signal loss and reflection. Using low resistance materials to ensure stable signal transfer. Spring design ensures uniform distribution of contact pressure, thereby reducing the risk of poor contact. Uder high-frequency working conditions, pogo pins can provide excellent electrical performance and are applied in communication equipment and RF circuits.

How does Spring Loaded Pin Ensure Connection Stability?

Through various design optimizations, through-hole spring loaded pin ensures connection stability. Firstly, spring constant pressure ensures a tight contact at the contact point. Secondly, the connection surface between pogo pins and circuit board is precision machined to ensure reliable conductivity. In terms of material selection, metals with good conductivity were used to reduce resistance. The contact points have undergone special finishing to increase wear & oxidation resistance. Ultimately, spring anti fatigue design ensures plunger can maintain good contact for long time.

How Should Spring Loaded Pin Cope With Vibration and Impact?

Excellent resistance to vibration and impact. The spring loaded pin can effectively absorb external vibrations and impact forces, preventing poor contact. The pogo pin and spring are both made of brass or stainless steel, which can withstand large impacts without deformation. The contact point structure is precise and can ensure stable electrical contact under severe vibrations. Pogo pin has excellent durability and impact resistance, and is used in demanding industrial equipment and transportation vehicles.

Are Spring Loaded Pin Suitable for High Temperatures?

Spring loaded pin is made of special materials that are resistant to extreme temp and can work stably in high-temperatures. The spring loaded pin maintains its elasticity at high temperatures and won’t experience poor contact due to temperature changes. Material selection of contact point can resist oxidation and corrosion which always caused by high temperature. The overall design ensures that it can provide reliable electrical connections in high temperatures. Spring loaded pin performs exceptionally well in automotive electronics, aerospace, as well as high-temperature environments.