Advantages of Spring Loaded Pins, L: 7.00~11.99 mm

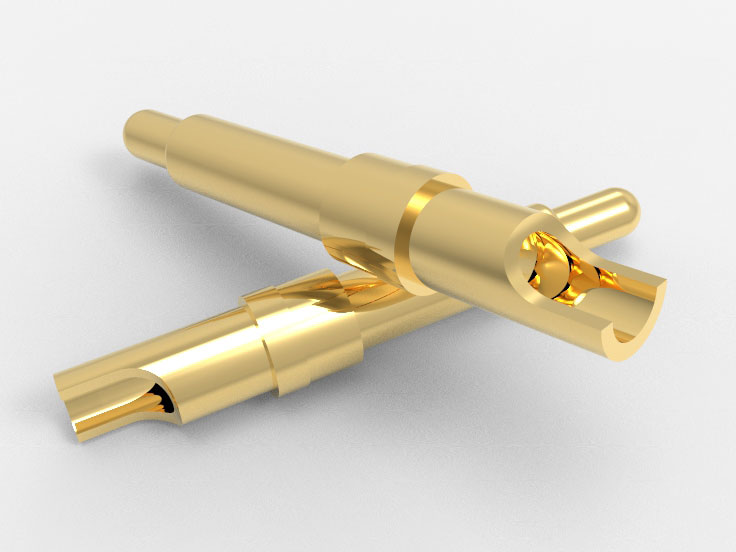

High precision design

Spring loaded pins use high-precision machining technology to ensure seamless connection at each contact point. Stable structure, minimal error, suitable for various micro devices, they provide high conductivity and mechanical stability, possess excellent wear resistance.

High durability

Johoty’s spring loaded pins can withstand up to 200,000 to 300,000 repeated presses, maintain their performance without degradation. Their material selection is strict, resistant to high and low temperatures, not easily deformed after long-term use. At the same time, spring loaded pins have excellent oxidation resistance for super-long life cycles.

Rapid response capability

The solder-cup spring loaded pins are designed to be compact and have precise elasticity, enabling instant response electrical connections. The spring structure provides stable pressure, signal transfer is completed in milliseconds, and supports high-speed transfer between multiple modules.

Strong flexibility

Suitable for complex circuit layouts, it can easily meet various shape and size requirements. Spring loaded pins support multi angle contact, easy and flexible installation. No need for complex tools, and have strong compatibility for modular design of different devices.

Small size, high performance

It can still provide powerful performance in an ultra small volume for modern miniaturized products. Spring loaded pins have a compact structure but excellent conductivity, supporting high-frequency signal transfer. They can provide stable connection strength and save device internal space.

Excellent anti vibration

Spring loaded pins for soldering cable can effectively absorb vibrations and impact forces, ensure connection is not loose. The spring structure provides continuous pressure, strong resistance to mechanical fatigue. They can adapts to various dynamic environments, with extremely high operational stability.

Ultra high reliability

Exhibits high reliability in critical applications, unaffected by environmental changes. The contact surface design is scientific, with long-lasting and stable conductivity, no performance degradation during long-term operation. At the same time, the connection strength remains consistent after installation.

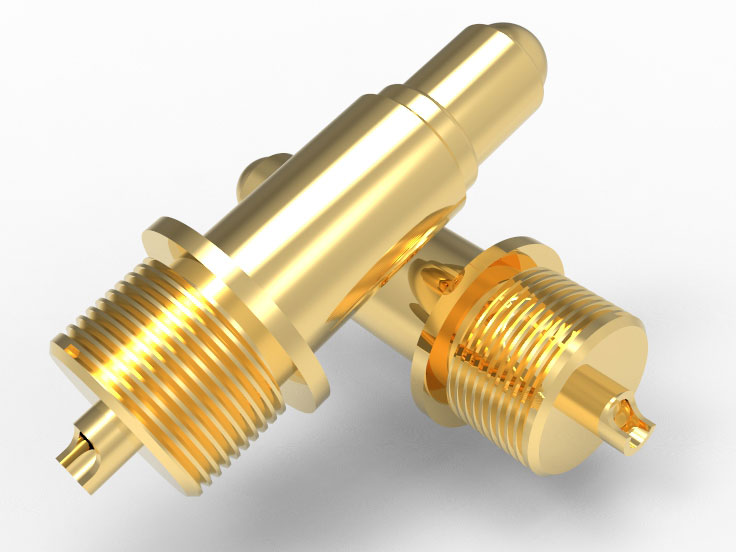

Easy installation

The design simplifies installation steps, saving time and labor costs. Fixed without complex tools, reducing assembly error rates, while adapting to multiple interface requirements. They can easily achieve fast connections between devices.

FAQ:

In which extreme environments can spring loaded pins be applied?

They are suitable for industrial sites with high temperature and pressure, and can maintain stable performance in very cold environments. Corrosion resistant materials can resist chemical erosion, and spring loaded pins still conduct electricity reliably under high humidity Meanwhile, Johoty’s spring loaded pins are highly adaptable to vacuum or low-pressure environments and perform exceptionally well.

How is the lifespan of spring loaded pins calculated?

According to the test of mechanical pressing cycles, Johoty can work out more than 200,000 times of life cycles. High quality springs and conductive materials extend their lifespan, connection stability is not affected by time. Spring loaded pins can improve environmental adaptability and reduce replacement frequency.

How to ensure long-term stability of spring loaded pins for soldering cable?

Using high-purity materials to reduce resistance fluctuations, contact surface is designed with precision to prevent oxidation. Spring pressure of spring loaded pins remains stable at all times. They have strong seismic resistance and will not loosen. Their structural avoids signal transfer interruptions, and their performance is long-lasting and reliable.

What current or voltage ranges can spring loaded pins support?

Johoty’s spring loaded pins are suitable for various applications, from low voltage and low current to high voltage and high current. The conductor material has high conductivity. Such pogo pin structure always supports multi specs with high current efficiency, which can avoid overheating or arcing.

Is spring loaded pins suitable for dynamic sports environments?

They are suitable for frequent movement or vibration, with spring design absorbing impact forces and maintaining stable connections. Anti mechanical fatigue of spring loaded pins is excellent. And, they are not easy to loosen or break, ensure signal transfer is not disturbed.

How can spring loaded pins meet miniaturized devices?

Johoty’s spring loaded pins are compact yet powerful for compact layouts. Precise design of Johoty’s pogo pin saves space, moderate spring pressure ensures conductivity. They support complex connectivity without affecting overall device performance.

Can spring loaded pins withstand multi-point connections?

of course! Johoty’s spring loaded pins support multi-point simultaneous connection, with uniform spring pressure and stable contact surface. The modular structure of spring loaded pins makes installation simple for connecting multiple devices. This won’t affect signal and power transfer quality.

Is spring loaded pins high-maintenance?

They almost don’t require special maintenance, and raw material is wear-resistant and won’t show any performance degradation after long-term use. Based on our customer feedback, other parts in equipment are broken, but Johoty’s spring loaded pins are still in good. Their antioxidant design prevents contact surface failure and keeps very stable installation with no easy loosening. Meanwhile, Spring loaded pins are simple and easy to clean structure and extremely durable.