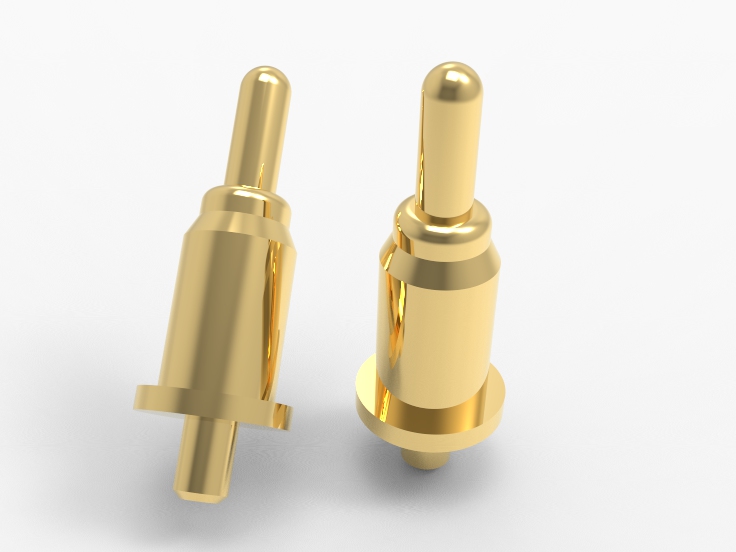

Advantages of Spring Pogo Pins, L 6.00-6.99 mm

Highly Precise Contact Reliability

Spring pogo pins are designed with precision to maintain excellent contact during high-frequency use, avoiding poor contact caused by prolonged use. Optimization of spring plunger tip design to ensure stable connection between different devices. Strong anti-vibration maintains stable connections in dynamic environments. Plug and play, reducing wear and tear during insertion and removal. The through-hole design enhances signal transfer accuracy and meets complex circuit requirements.

Optimized Spring Durability

Springs made of high-end music steel have excellent elastic recovery ability and aren’t easily deformed after long-term use. The lifespan can reach 200,000 or more compression cycles, meets high-frequency requirements. The spring tension has been rigorously designed to adapt to various usage. Spring pogo pins can withstand various compression depths with flexibility and applicability. Special processes ensure springs maintain good performance in harsh.

Outstanding Current Conduction Performance

The precise through-hole design ensures efficient current conduction and reduces transfer losses. Using high-quality conductive materials significantly improves conductivity. The plunger surface has been professionally treated to reduce contact resistance. Spring pogo pins have short and precise conductive paths, improving signal transfer efficiency. Optimized plunger and through-hole coordination achieve low interference and high-purity current conduction.

Adaptive Multi Angle Connection

Spring pogo pins can be flexibly adjusted at multiple angles to adapt to complex connection angles. The through-hole structure supports offset alignment, improving assembly flexibility. The plunger design meets various device interface and has strong universality. Multi angle compression is stable, and there is no need to worry about contact problems caused by offset. Easy and fast installation, reducing the difficulty of use.

High Strength Wear Resistance

Choose wear-resistant surface materials for extending their lifespan. The plunger has a special coating that significantly reduces surface friction. Sustainable response to high-frequency plugging without affecting performance. Spring pogo pins can enhance mechanical strength and reduce fracture risks. Excellent anti-corrosion, oxidation resistance and keeping highly stable performance in various environments.

Lean Size and Space Design

Spring pogo pins are compact and suitable for miniaturized devices. Precise optimization of pluger diameter and length ensures minimal space occupation. High matching degree of through holes improves overall assembly efficiency. Multiple sizes and specifications are available to meet different devices needs. The design is simple yet powerful, enhances overall product experience.

Excellent Resistance to Vibration and Impact

The combined design of the plunger and spring effectively absorbs external impact forces. Spring pogo pins contact surface optimization reduces signal interruption caused by vibration. Strong impact resistance, suitable for harsh environments. The through-hole reinforcement enhances overall structural stability. Keep high reliability in dynamic operation.

Excellent Long-term Reliability

Material selection focuses on long-term stability and isn’t prone to fatigue or failure. Rigorous design ensures that performance doesn’t deteriorate after long-term use. Precise combination of plunger and spring prevents wear and tear from causing failure. The through-hole connection is stable and meets long-term connections. Spring pogo pins have excellent resistance to environmental changes for various applications.

FAQ

What are Spring Pogo Pins?

Spring pogo pins are electronic connectors for electrical connections between circuit boards and devices. It is composed of springs and metal plunger, inserted into through holes of circuit board. The spring function is to ensure good contact between pogo pin and circuit board, providing a stable electrical connection. It has higher reliability and durability than traditional connectors, withstands multiple insertions and removals. Compared to other types of connectors, pogo pins have a simple structure, lower cost, and high cost-effectiveness.

How do Spring Pogo Pins work?

Spring pogo pins adjust the contact between pogo pins and the circuit board through built-in springs. When inserting circuit board, the spring compresses and maintains a certain pressure to ensure stable electrical contact. If there is poor contact, the spring will automatically adjust to ensure a stable connection. Compared to regular connectors, spring loaded pins can withstand more insertions and removals, adapting to different contact conditions. It can effectively reduce the risk of poor contact, ensure reliable connection, reduce maintenance costs.

What are Spring Pogo Pins Applications?

Through hole spring pogo pins are used in electronic devices, SOS, industrial automation, small smart devices, consumer electronics, testing equipment. They are used for connecting circuit boards for fast plugging and unplugging. Pogo pins are used as testing tools and temporary connectors in automated production lines. They are also commonly used to connect consumer electronic products, smartphones, cameras, televisions, etc. Due to its affordable price, many designers and engineers choose Johoty’s spring pogo pins to save costs and improve production efficiency.

What is Difference Between Spring Pogo Pins and Traditional Connectors?

Compared with traditional connectors, the biggest feature of spring pogo pins is the built-in spring that can automatically adjust the contact pressure to ensure stable connection. Traditional connectors rely on physical contact and are prone to poor contact or wear issues. The spring plunger can adapt to different contact surfaces, reduces faults or poor contact. Spring pogo pins are more durable and have longer lifespan in use. Its simple design reduces production costs while providing higher connection accuracy.

How to Choose Spring Pogo Pins?

When selecting through-hole spring pogo pins, better to choose appropriate model based on circuit board sizes, pogo pin length and diameter. The spring hardness is also very important, too hard or too soft can affect electrical connection quality. We also need to consider temperature, humidity, and electrical load to ensure suitable material and specifications. High quality pogo pins can provide stable electrical connections and reduce maintenance costs. When choosing, considering Johoty is also an important competitive advantage.

What are Competition of Spring Pogo Pins?

Spring pogo pins have several significant competitive advantages. Firstly, it has high cost-effectiveness, simple production process, and low material cost. Secondly, the design of Spring pogo pins allows it to withstand frequent connection, with strong durability and reduced replacement frequency. Thirdly, the spring can automatically adjust their contact, ensuring stability during use. Fourth, Spring pogo pins can also provide stable connections and save space with limited space. Finally, Johoty’s precise manufacturing process enables it to provide high-precision electrical connections.

How can Spring Pogo Pins Improve Connection Stability?

Through spring adaptive mechanism, through-hole spring pogo pins improve electrical connection stability. The spring can automatically adjust in case of poor contact and maintain stable pressure. Compared to traditional connectors, Spring pogo pins have stronger plug-in performance and can maintain contact quality. The spring compression ensure connection reliability and minimize contact wear risk. High precision manufacturing ensures the consistency and stability of spring pogo pins in various environments.

How to Extend Lifespan of Spring Pogo Pins?

In order to extend the lifespan of Spring pogo pins, avoid excessive use and frequent plugging and unplugging first. Keep the contact surface between plunger and the circuit board clean to avoid dust and oil stains affecting the connection quality. Secondly, regularly check spring elasticity to avoid performance degradation caused by long-term compression. When using, avoid overloading and ensure working voltage and current are in spec. Finally, choosing high-quality and competitively branded, Johoty’s spring pogo pins can greatly improve their lifespan and performance stability.