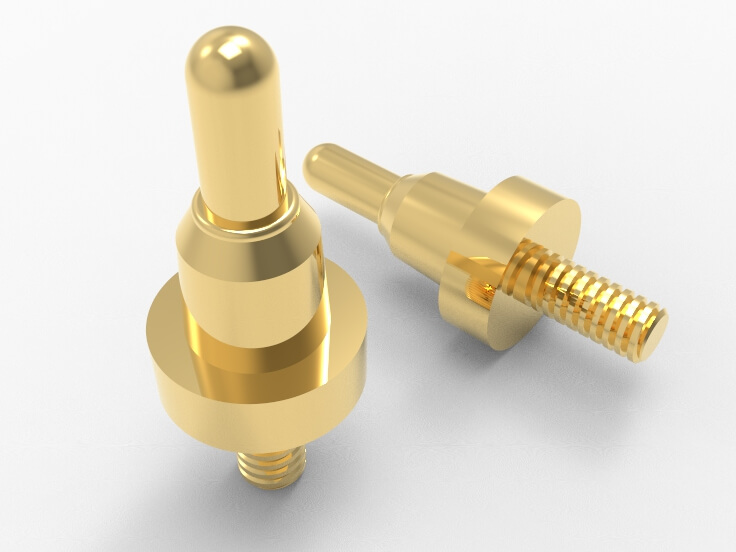

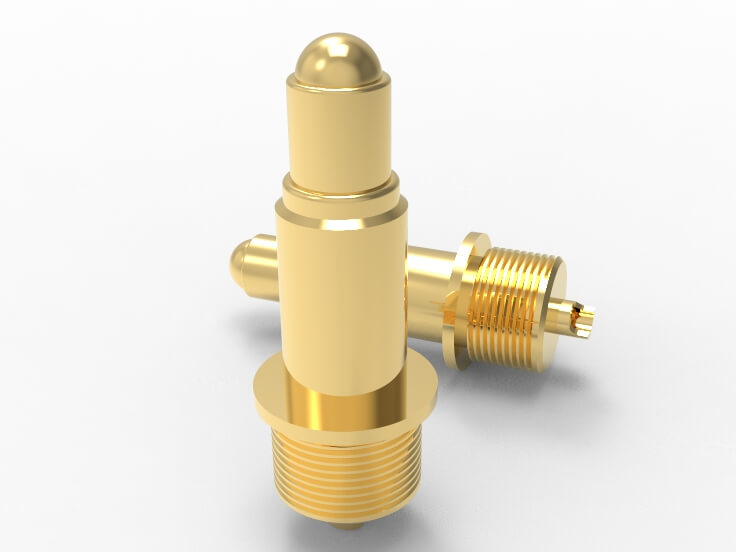

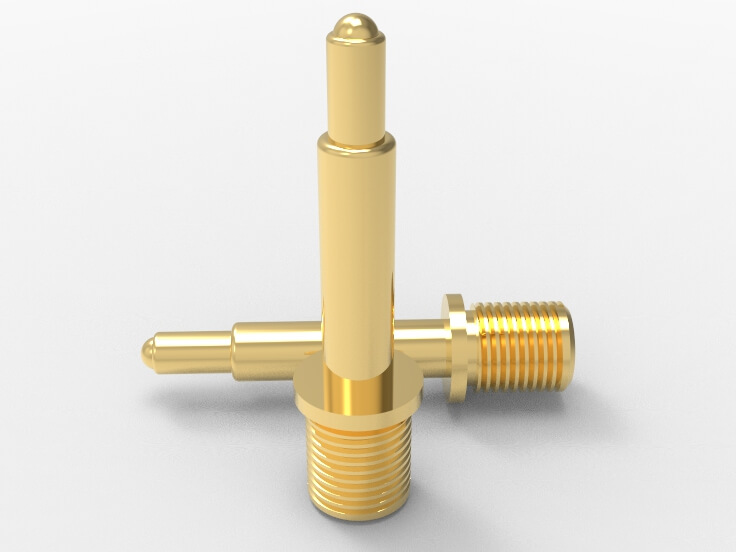

Advantages of Threaded Inserts, L: 6.00~70.00 mm

Efficient Connectivity Performance

Threaded inserts provide fast and stable electrical connections, reducing contact resistance and ensuring stable signal transfer. Support high-frequency applications to meet the needs of complex electronic devices. Compatible with various conductive materials, enhancing system adaptability. Durability testing shows a lifespan of over 50,000 connections, suitable for high-intensity uses. Optimize installation design, reduce engineering assembly difficulty, and improve production efficiency.

Excellent Mechanical Strength

The unique thread and spring structure provide strong mechanical locking force to prevent loosening or detachment. Threaded inserts can withstand up to 10 kg of tension and are suitable for vibration use. Improved torque resistance performance by 20%, suitable for precision assembly. The material hardness reaches HV500 or above, with better wear resistance. After high-temp aging testing, it has excellent sustained stability performance.

Accurate Conductivity

Johoty uses low resistance high-quality conductor materials to improve conductivity efficiency. The contact impedance of threaded inserts is ≥15 milliohms, meeting the requirements of high-precision electronic devices. Optimize structural design to avoid current concentration effects. Coating finishing enhances surface conductivity and has strong antioxidant capacity. Suitable for multiple current ranges, stable operation from microampere to 120A.

Excellent Environmental Adaptability

Excellent temp resistance in -40°C ~120°C. The anti moisture design effectively avoids water vapor erosion and is suitable for outdoor equipment. The chemical corrosion resistance has passed the salt spray test and reached over 500 hours. Threaded inserts have excellent resistance to vibration and impact, making them suitable for complex industrial environments. The dustproof and waterproof ability reaches IP68, meeting the requirements of harsh environments.

Flexible Customization Capability

Support multi spec customization from micro to large sizes. Design can be adjusted according to different thread requirements to enhance compatibility. Supports multiple electroplating treatments, including nickel, gold, and silver coatings. Threaded inserts offer different spring hardness options to meet special application requirements. The processing accuracy is as high as ± 0.02mm, ensuring product consistency.

Durable and Reliable Lifespan

The special spring steel material provides excellent elasticity and fatigue resistance. The docking number can reach 10,000 times, suitable for long-term repeated use. Threaded inserts have strong weather resistance and stable performance in extreme environments. After >96 hours of salt spray corrosion testing, the lifespan is longer. The spring relaxation rate is <5%, and it maintains strong contact for a long time.

Installation Convenience

Threaded inserts are designed to be compact and easy to operate, without the need for additional complex tools to assist with installation. The screw in structure reduces installation time and efficiently adapts to industrial assembly lines. Compatible with multiple substrates, including plastic, metal, and composite materials. The thread self-locking function avoids secondary adjustment and improves installation efficiency. Support automated equipment assembly to improve production line efficiency.

Used in Various Industries

Threaded inserts are suitable for high-end precision automotive, medical, and aviation. Meet consumer electronics needs and enhance device connectivity stability. Excellent performance in industrial automation equipment, durable and reliable. Provide high-frequency connection solutions for 5G base stations, supporting high data transmission rates. Threaded pogo pins are applied in the field of new energy to help stabilize the connection between charging piles and energy storage devices.

FAQ:

What are Electronic Threaded Inserts?

Threaded inserts are high-precision threaded pogo pins used to create reliable threaded connections. They combine threaded fixation, spring conductivity, high-temperature resistance, stability and reliability, and easy installation, exhibiting outstanding performance in complex equipment.

What Advantages Do Threaded Inserts Have?

Threaded inserts have high conductivity, excellent anti-corrosion performance, flexible installation, long service life, and strong seismic resistance. These features make threaded pogo pins very popular in ensuring device performance and reducing maintenance costs.

How to Customize Threaded Inserts?

Johoty can customize dimensions, thread specifications, working stroke, material selection, conductivity, and special packaging according to specific equipment and complex applications.

What Industries Are Threaded Inserts Suitable For?

Johoty’s threaded inserts are applied in aerospace, wireless equipment, medical equipment, industrial automation, intelligent healthcare devices, mobile smart wristbands, automotive manufacturing, and consumer electronics, providing professional solutions for high-precision electrical connections.

What Are Threaded Inserts Materials?

Threaded inserts often use brass, beryllium copper, tellurium copper, stainless steel 304, 316, composite materials, etc., which can provide stable fixation and reliable conductivity during installation.

How do Threaded Inserts Ensure Reliable Electrical Connections?

Through high-quality materials, spring contact design, anti loosening structure, uniform force distribution, and high conductivity, threaded inserts can ensure safe, stable, and long-lasting electrical connections.

What Are Installations for Threaded Inserts?

Supports hot melt, ultrasonic, cold pressing, spiral screw-in, and injection molding, meet different equipment and applications flexibly.

What Working Environments Can Threaded Inserts Withstand?

Threaded inserts support up to 120 A of current, withstand temperatures up to 125℃, withstand high impacts and vibrations, and have reliable performance to meet harsh environments.