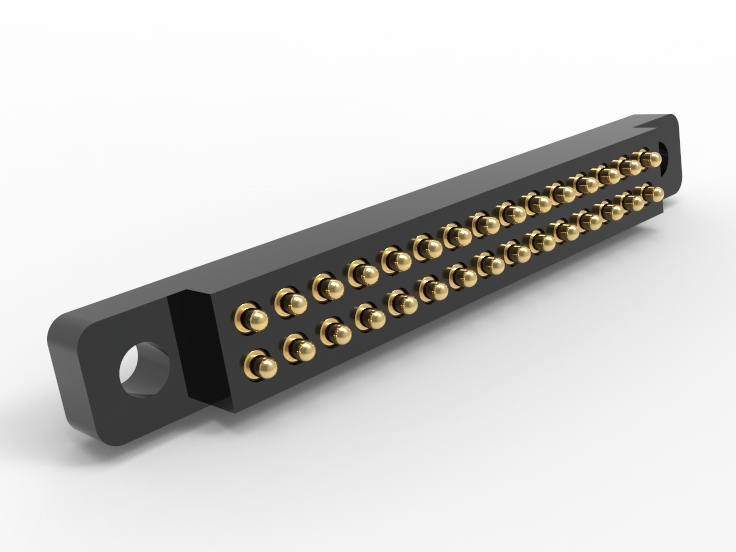

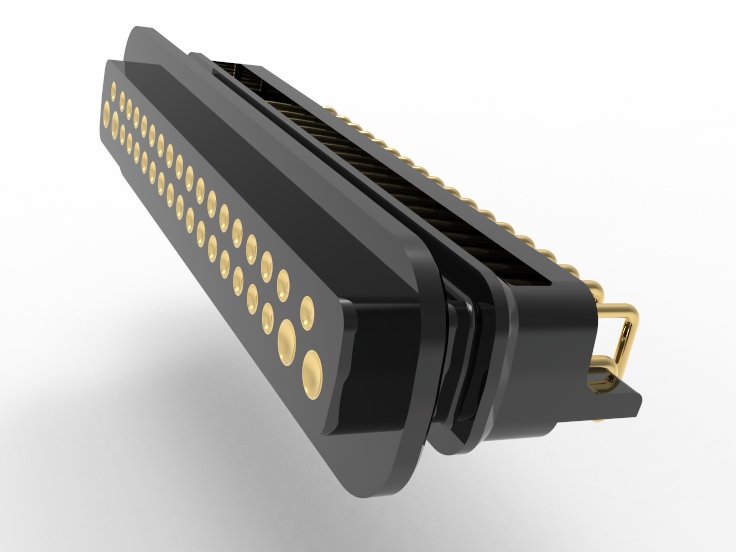

Advantages of Wire Connectors With Pogo Pins, pitch: 1.00~2.54

1. Exceptional Durability

Our Wire Connectors With Pogo Pins stay reliable even after extensive use. Each connector is tested for 10,000 plug-and-unplug cycles to ensure stable, wear-resistant contact points. This design greatly reduces failure rates from frequent use, making it perfect for high-frequency environments and extending its lifespan.

2. High Precision Contact

The contact points on our Wire Connectors With Pogo Pins are laser-processed for exact diameters, with a tolerance of just ±0.02 mm. This precision ensures stable signal transmission and minimizes the risk of data loss or errors due to poor contact.

3. Superior Electrical Performance

Our Wire Connectors With Pogo Pins can handle up to 5 amps of current and 24 volts of voltage. With an impedance as low as 15 milliohms, these connectors effectively reduce current loss and electromagnetic interference, ensuring efficient and stable operation.

4. Premium Material Selection

The pins on our Wire Connectors With Pogo Pins are coated with gold, palladium, or platinum to a thickness of 3 microns. This coating provides excellent conductivity and high resistance to heat and corrosion, extending the connector’s lifespan and reliability in tough conditions.

5. Excellent Compatibility

Our Wire Connectors With Pogo Pins come in various pin configurations, from 2 to 598 pins. They are compatible with a wide range of interface standards and design requirements, allowing seamless integration with various devices and systems for different applications.

6. Reliable Mechanical Structure

The connectors feature a high-temperature aluminum alloy shell, heat-treated to operate within a temperature range of -40°C to +125°C. The sturdy design enhances pressure resistance and reduces deformation or damage under heavy loads.

7. Easy Installation and Maintenance

Our Wire Connectors With Pogo Pins are designed with standardized mounting holes and screw interfaces for straightforward installation. Each connector includes a detailed installation guide, helping engineers complete the process quickly and accurately, saving time and costs.

8. Strict Quality Control

Every batch of Wire Connectors With Pogo Pins undergoes rigorous quality checks, including 100% electrical and mechanical testing. They meet quality standards like ISO 9001 and ROHS certification, ensuring each connector’s reliability and consistency to meet high-quality demands.

FAQ

1. What are the height requirements for Wire Connectors With Pogo Pins?

The working height of Wire Connectors With Pogo Pins is crucial for stable and reliable electrical connections. Our connectors are designed with a height adjustment range of ≥15mm to meet various needs. We use advanced CNC machines to ensure height precision within ±0.01mm, improving compatibility and stability. Choosing our connectors means strict quality control and consistent performance, enhancing your equipment’s reliability and user experience.

2. How do Wire Connectors With Pogo Pins perform in high-frequency applications?

For high-frequency applications, Wire Connectors With Pogo Pins are designed with gold-plated contacts and advanced springs to minimize signal loss and interference. We’ve rigorously tested our connectors at frequencies up to 10GHz to ensure excellent signal transmission. We provide detailed test reports for thorough evaluation. With our connectors, you’ll get top performance and meticulous attention to detail.

3. How durable are Wire Connectors? How many insertions can they handle?

Durability is key for Wire Connectors With Pogo Pins. Our connectors withstand up to 10,000 insertions without performance degradation. Made from high-quality stainless steel and springs, they maintain elasticity and wear resistance over time. Certified by ISO9001, our connectors are rigorously tested for quality. Opt for our connectors if you want dependable performance and longevity, cutting down on maintenance and minimizing downtime.

4. How to choose the right Wire Connectors With Pogo Pins for my project?

Choosing the right connectors involves considering factors like voltage, load capacity, and precision. Our Wire Connectors With Pogo Pins handle up to 3A current and 50V voltage, with various protection levels available. For tailored advice and custom options, consult our CFT team. Choose our Wire Connectors With Pogo Pins for customized service and precise solutions.

5. What is the rated current of Wire Connectors With Pogo Pins, and how to select the appropriate rating?

Our Wire Connectors With Pogo Pins have a wide rated current range from 0.5A to 5A or more, suitable for different applications. For signal transmission, 0.5A is usually sufficient; for high-power devices, choose models rated above 3A. Our engineering team provides top-notch guidance to help you choose the perfect pogo pin connector for your project.

6. How to ensure the stability and safety of Wire Connectors With Pogo Pins at rated currents?

Johoty uses cutting-edge techniques and materials to guarantee stability and safety even at maximum currents. Our Wire Connectors With Pogo Pins feature high-conductivity gold-plated pogo pins and quality springs to reduce contact resistance and overheating. Each pogo pin connector undergoes strict current-carrying tests to ensure stable performance. Our connectors meet safety standards, ensuring reliable and long-lasting use.

7. What factors affect the rated current of Wire Connectors With Pogo Pins?

Factors include contact materials, current path design, and environmental conditions. We use high-conductivity gold-plated materials and optimized springs to reduce resistance and heat buildup. Temperature and humidity impact current-carrying capacity too. We provide detailed specs and adaptability data to help you choose the best Wire Connectors With Pogo Pins.

8. Does the rated current affect the long-term lifespan of Wire Connectors With Pogo Pins?

Yes, higher rated currents can lead to greater heat accumulation, affecting lifespan. We use high-thermal-conductivity materials and optimized designs to maintain stability even at rated currents. Our Wire Connectors With Pogo Pins are tested to last over 10,000 insertions and up to 50,000. Opt for Johoty’s Wire Connectors if you want products built to last and perform consistently.

9. How to test the rated current capacity of Wire Connectors With Pogo Pins?

We use various tests, including temperature rise, load, overcurrent, and high-temperature tests, to verify current capacity. Each batch goes through thorough testing to ensure it delivers stable performance. We provide detailed test reports and data to validate the connectors’ performance. Our testing meets international standards for high performance.

10. How does Johoty assist customers in choosing the right current rating?

Johoty provides expert technical support to help customers select the best Wire Connectors With Pogo Pins. Our CFT team offers tailored advice based on your current load, environment, and equipment needs. We provide samples for testing and analyze results to ensure the Wire Connectors With Pogo Pins meet your requirements. Choose Johoty for expert support and efficient solutions.

11. What is the spring force of Wire Connectors With Pogo Pins? How to choose the right spring force?

We offer various spring force specifications, ranging from 15gf upwards. The right force depends on your application, such as connection stability and durability. Higher forces provide stable connections in high-vibration environments, while moderate forces are suitable for lighter loads. Our engineers can recommend the best spring force for your needs.

12. How does spring force affect the stability of Wire Connectors With Pogo Pins?

Spring force impacts connection stability. Proper force ensures stable contact pressure during insertion and removal, preventing poor contact or signal interruption. Our Wire Connectors With Pogo Pins use precision stainless steel springs for optimal stability. We conduct multiple tests to confirm stable performance in different environments.

13. How to ensure consistency in the spring force of Wire Connectors With Pogo Pins?

We rely on cutting-edge equipment and rigorous quality checks to guarantee steady spring force. The manufacturing process includes precise spring compression and testing. Each pogo pin connector undergoes rigorous spring force testing before shipment. Our quality control ensures each pogo pin connector meets consistent standards.

14. How does spring force affect the lifespan of Wire Connectors With Pogo Pins?

Spring force significantly affects lifespan. Excessive force can cause wear, while insufficient force can lead to instability. Our design balances spring force and wear resistance to maintain performance over time. Our Wire Connectors With Pogo Pins last up to 10,000 insertions at rated force. Choose our connectors for durability and stable performance.

15. How to test the spring force of Wire Connectors With Pogo Pins?

We use advanced equipment to test spring force, including force testers, load tests, and insertion cycles. Each pogo pin connector undergoes rigorous testing to ensure it meets design specifications. We provide detailed test reports and data to help you assess performance. Our testing follows strict standards for reliability.

16. What is the contact resistance of Wire Connectors With Pogo Pins? How to choose the right contact resistance?

Our Wire Connectors With Pogo Pins have contact resistance as low as 15 milliohms, ensuring efficient signal transmission. The right contact resistance depends on your application, such as high-frequency signals or current requirements. We offer options as low as 15 milliohms for stable applications. Our CFT team can provide expert recommendations to optimize performance.

17. How does contact resistance affect signal transmission in Wire Connectors With Pogo Pins?

Lower contact resistance improves signal quality by reducing signal loss and interference. Our Wire Connectors With Pogo Pins use high-conductivity gold-plated pogo pins and precise manufacturing to keep contact resistance as low as 15 milliohms. With thorough testing and quality control, our Wire Connectors With Pogo Pins deliver excellent signal transmission and minimize signal loss and interference.

18. How do we ensure the stability of contact resistance in Wire Connectors With Pogo Pins?

Our quality control and meticulous production methods guarantee that contact resistance remains consistent. Factors like material choice, pogo pin design, and production processes all contribute. We use high-conductivity gold-plated materials and advanced equipment to keep contact resistance consistent. Every batch undergoes detailed impedance testing and verification to meet standards, ensuring reliable performance.

19. Does contact resistance change over time and with use?

Yes, contact resistance can change over time and with frequent use due to wear or contamination. Our Wire Connectors With Pogo Pins use durable materials and high-quality plating to slow down changes in contact resistance. We conduct long-term durability tests to ensure stable resistance even with frequent use. Johoty also provides maintenance tips to effectively help extend connector life. Choosing our Wire Connectors With Pogo Pins means consistent performance and reduced maintenance.