Screw Thread in threaded Pogo Pins: Johoty Provides Detailed Specs, Solutions, Best Quality at the Most Competitive Prices for Your Projects

Introduction

The details make the difference between success and failure. Johoty understands this well, which is why we pay close attention to every detail in our Threaded Pogo Pins, especially in the design and application of the Screw Thread. Our Screw Thread design not only delivers outstanding mechanical connection performance but also ensures exceptional durability and reliability while maintaining high precision.

No matter what your project requirements are, Johoty’s Threaded Pogo Pins offer the ideal solution with advanced technology, the best prices, and unmatched quality. Our detailed specifications and high manufacturing standards guarantee that each Pogo Pin meets strict industry standards, providing strong support for your designs and engineering.

In this blog, we’ll explore how Johoty’s Screw Thread design in Threaded Pogo Pins helps you optimize your projects, achieving a perfect balance of performance and cost-effectiveness. Discover how our technological innovations are setting industry trends, delivering more efficient and reliable connection solutions.

What are Threaded Pogo Pins with high-precision screw thread?

1. Definition:

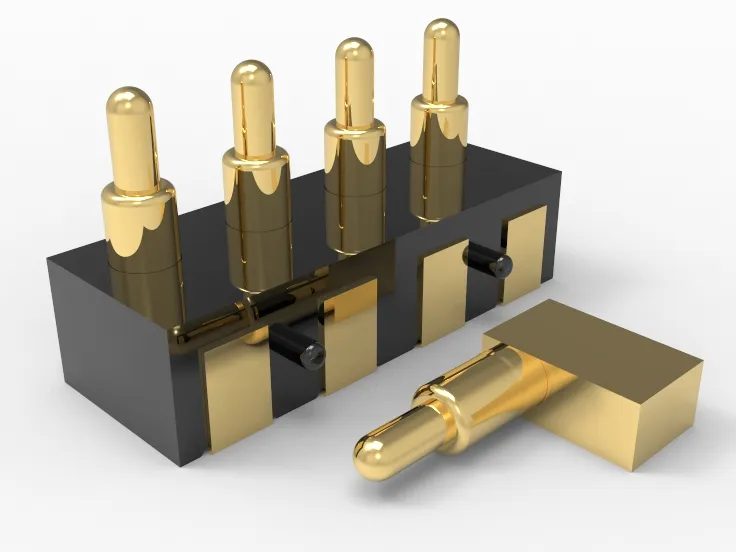

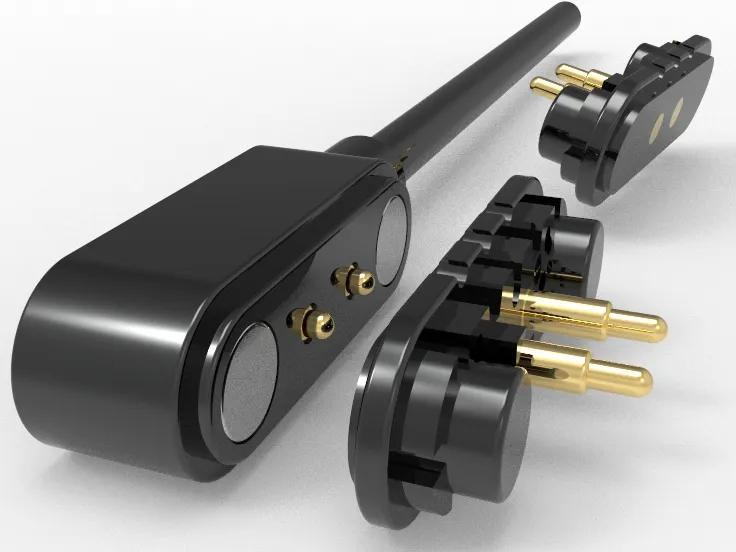

- Johoty’s Threaded Pogo Pins are high-precision electronic connectors featuring a threaded structure to ensure reliable mechanical fixation and electrical connection when inserted. Designed for demanding connection applications, these pins typically include a screw thread shaft that allows for a secure connection through a screwing and locking mechanism.

2. Function:

- Stable Electrical Connection: The threaded pogo pins provide stable electrical contact when inserted, reducing the risk of poor connections.

- Reliable Mechanical Fixation: The threaded design ensures that the connection remains secure even under high vibration or external forces.

- High Durability: Thanks to precise manufacturing and material choices, these pogo pins are built to last with their great durability and resistance to rust.

3. Applications:

- Electronic Devices: Used for electrical connections in various electronic devices like computer hardware, mobile devices, and consumer electronics.

- Automotive Industry: Acts as a crucial component for connections and signal transmission in automotive electronics, ensuring the stability and safety of vehicle systems.

- Medical Equipment: Provides high precision and reliable connections in medical instruments and equipment, ensuring proper operation and accurate data transmission.

- Communication Equipment: Ensures stable signal transmission and reliable connections between devices in communication infrastructure.

Johoty’s Threaded Pogo Pins are a leading choice in the industry for providing high-reliability and high-stability connection solutions due to their excellent design and quality manufacturing. These products not only meet the demands of various applications but also continually innovate to improve performance and adaptability, supporting a wide range of high-end uses.

What are Screw Thread Specifications?

A screw thread is a corkscrew-like ridge that winds around a cylindrical or cone-shaped item. It is used to connect or secure parts, usually in conjunction with screws or nuts. The shape and size of the thread can impact its strength and suitability:

1. Screw Thread Specifications:

- Major Diameter: The largest diameter of the screw thread.

- Minor Diameter: The smallest diameter of a screw thread is the width at the bottom of the grooves.

- Pitch Diameter: The diameter between the major and minor diameters, representing the effective working diameter of the thread.

- Pitch: The distance between adjacent threads, or the spacing of the threads.

2. Screw Thread Types:

- External Thread: The threads on a screw.

- Internal Thread: The threads inside a nut.

3. Screw Thread Shapes:

- Straight Thread: Uniform helical threads.

- Thread Profile: Shapes such as triangular, square, or round.

4. Screw Thread Standards:

- Metric Thread: Measured in millimeters. For instance, M6x1.0 indicates a screw with a 6mm diameter and a thread distance of 1.0mm.

- Unified Thread Standard (UTS): For example, 1/4-20 UNC means a diameter of 1/4 inch with 20 threads per inch.

5. Screw Thread Applications:

- Connecting: Screw Threads are commonly used to secure and connect various mechanical parts.

- Adjusting: Used to adjust the position or tightness of components.

Johoty’s Screw Thread Technology

Screw Thread Types and Design: Different types of threads (like internal, external, and fine threads) and their design parameters, such as pitch, diameter, and shape. These design elements affect the strength and stability of the connection.

- Screw Thread Tolerance and Fit: Definitions and standards for screw thread tolerance to ensure precise fitting in actual use, avoiding poor contact or mechanical failures due to tolerance issues.

- Material Properties: Mechanical properties of materials used for threads, such as hardness, tensile strength, and corrosion resistance. These elements influence how durable and effective the screw thread will be in various settings.

- Screw Thread Manufacturing Processes: Main methods for creating threads, such as turning, milling, and rolling. Different processes affect the thread’s surface finish and accuracy.

- Assembly and Testing: Key considerations for assembling threads, including assembly order, torque requirements, and testing methods to ensure the reliability and performance of the connection.

- Screw Thread Lubrication and Protection: Types of screw thread lubricants and their effects on thread connections, including how to choose and apply lubricants to extend the life of threads and reduce wear.

Why Choose Johoty’s Threaded Pogo Pins?

Johoty’s Threaded Pogo Pins use advanced Screw Thread technology to offer top-notch solutions. The precise screw thread design ensures excellent contact performance and stable connections, greatly enhancing the reliability of electrical connections.

- Competitive Pricing: Because of effective manufacturing techniques and the ability to produce in bulk, Johoty offers market-competitive prices. This allows customers to get high-performance Threaded Pogo Pins within their budget without sacrificing quality, helping to manage project costs effectively.

- Outstanding Quality: Johoty guarantees excellence by monitoring quality at each step of production. The use of Screw Thread technology makes our Threaded Pogo Pins more durable and stable, ensuring long-term reliable electrical connections while reducing failure rates and maintenance costs.

- Detailed Screw Thread Specifications: Johoty provides comprehensive Screw Thread specifications so you can choose the best Pogo Pins for your specific application. Whether it’s screw thread diameter, pitch, or type, Johoty offers detailed technical parameters to perfectly match various design needs.

- High-Precision Threaded Pogo Pins: Manufactured with precision machining technology, our Threaded Pogo Pins feature high-precision screw thread structures that ensure strong mechanical connections and excellent electrical performance. The precise screw thread design enhances contact stability and increases resistance to vibration and impact, making them ideal for demanding engineering applications.

Johoty’s Threaded Pogo Pins deliver exceptional electrical connection solutions with competitive pricing, outstanding quality, precise Screw Thread specifications, and manufacturing craftsmanship, excelling in a range of complex applications.

Advantages of Johoty’s Threaded Pogo Pins in Applications

Stable Electrical Connections:

- Johoty’s high-precision Threaded Pogo Pins excel in providing stable electrical connections. Designed with precision and made from high-quality materials using advanced manufacturing processes, these Pogo Pins ensure consistent electrical contact during connections. Unlike traditional Pogo Pins, which may suffer from signal loss or current interruption due to poor contact, Johoty’s precise design minimizes these issues.

- The screw thread structure enhances the mechanical locking force between the Pogo Pins and the connector, ensuring stability even with long-term use. This stable electrical connection is crucial for high-frequency and high-speed data transmission applications, such as in computer motherboards, electronic device test interfaces, and communication equipment, ensuring accurate and reliable data transfer while reducing the risk of system failures or performance drops due to poor contact.

Increased Durability and Reliability:

- High-precision Threaded Pogo Pins offer significant advantages in terms of durability and reliability. Johoty uses high-strength, wear-resistant materials to manufacture these Pogo Pins, and the screw thread structure not only increases mechanical locking strength but also reduces wear caused by frequent insertion and removal.

- Traditional Pogo Pins may experience contact point damage or material fatigue from frequent use, but Johoty’s precise screw thread design effectively distributes the insertion and removal forces, extending the product’s lifespan.

- This high durability is particularly suitable for applications that require frequent connecting and disconnecting, such as in portable devices, testing instruments, and automation equipment. Improved durability not only lowers maintenance costs but also ensures stable performance over long-term use, enhancing the overall reliability and safety of the system.

Enhanced Mechanical Stability

- Johoty’s high-precision Threaded Pogo Pins offer superior mechanical stability. The screw thread design provides a tight mechanical lock, making the connection more secure and reliable. In real-world applications, vibrations, impacts, or movements can cause traditional connectors to loosen, but the unique design of threaded Pogo Pins effectively prevents this issue.

- Improved mechanical stability is crucial for devices that need exact precision and reliability, like high-tech instruments, factory automation systems, and medical tools. In these scenarios, ensuring stable connections can significantly improve system efficiency, reduce equipment failures, and ensure accurate and safe operations.

Successful Cases:

1. Success in the Medical Device Sector

- In the medical device field, Johoty’s high-precision Threaded Pogo Pins have successfully addressed issues of poor contact and durability. Traditional medical device connectors often suffer from poor contact due to frequent insertion and removal, impacting device accuracy and stability.

- Johoty’s Threaded Pogo Pins, with their precise screw thread design, not only ensure stable connections every time but also greatly enhance durability. These Pogo Pins can withstand high-frequency insertions and removals without significant wear or contact problems. For example, a leading medical device manufacturer used Johoty’s Threaded Pogo Pins in their high-end diagnostic instruments, improving device reliability and diagnostic accuracy.

- Additionally, the high precision of the design makes maintenance and replacement easier, further reducing operational costs. This successful application highlights Johoty’s technological advantages in demanding medical fields and its key role in enhancing device performance.

2. Success in Consumer Electronics

- In the consumer electronics sector, Johoty’s high-precision Threaded Pogo Pins have achieved notable success in the design of smartphones and laptops. As consumer demands for electronic device performance increase, particularly regarding connectivity and durability,

- Johoty’s Pogo Pins stand out with their unique screw thread design that enhances connection stability and addresses issues of loosening and poor contact common with traditional connectors. For instance, a well-known smartphone manufacturer used Johoty’s high-precision Threaded Pogo Pins in the charging port of its latest flagship phone.

- This design not only supports higher current capacity but also improves connection durability, solving previous issues with unstable charging. By improving this feature, we’ve not only made the product easier to use but also cut down on returns related to charging problems, enhancing the brand’s edge in the market.

3. Success in Automotive Electronics

- In the automotive electronics sector, Johoty’s high-precision Threaded Pogo Pins have demonstrated outstanding performance in high-vibration environments. Automotive electronics require connectors to maintain stable electrical performance under harsh conditions, including high vibration, temperature, and humidity.

- Johoty’s Threaded Pogo Pins, with their precise screw thread design, ensure firm and reliable connections, even in intense vibrations. A car manufacturer implemented Johoty’s Threaded Pogo Pins in control modules for high-performance vehicles, where stable signal transmission during operation is crucial.

- After rigorous testing, these Pogo Pins proved to deliver excellent performance, enhancing the stability of automotive electronic systems and extending their lifespan. This successful case highlights Johoty’s technological edge in handling complex automotive environments, providing reliable solutions for the automotive electronics industry.

What’s the Best Way to Pick the Right Threaded Pogo Pins?

- Understand Your Needs: Identify your application to determine the type, size, and contact pressure required for the pogo pins. This will help you select pins with the right specifications.

Precision Standards: Johoty’s threaded pogo pins are known for their exceptional precision. Ensure the pogo pins you choose meet strict manufacturing standards to guarantee stable connections and long-term reliability. - Material and Durability: Opt for materials that are wear-resistant and corrosion-resistant, such as high-quality stainless steel or nickel-plated materials, to enhance lifespan and performance.

Specification Match: Check that the size, length, and screw thread specifications of the pogo pins match your equipment’s design requirements. Johoty offers a variety of specifications to suit different needs.

Vendor Reputation: Opt for a reliable company such as Johoty to make sure you get top-quality products and excellent customer service. Review customer comments and case studies to gauge their performance and feedback. - Technical Support: A good supplier will provide expert technical support and advice to help you make the best choice. You can count on Johoty’s CFT team to answer your queries and give you professional guidance.

Conclusion:

Johoty’s threaded pogo pins, with their superior screw thread technology, offer the best solution for your project through unmatched quality and competitive pricing. Whether you have high-demand electronic applications or standard connection needs, Johoty can meet your expectations. Contact Johoty for the latest information and custom solutions that will guarantee your project exceeds expectations.