Top 5 Test Probe Solutions for Efficient Test Fixture! Boost Test Accuracy & Reduce Downtime With Johoty’s High-performance Spring Test Probes

Introduction: Why is choosing the right Test Probe crucial for Test Fixture?

In design and operation of test fixture, test probe is the core component that ensures testing accuracy and efficiency. However, many engineers often face signal distortion, poor contact, non test failures, and short probe lifespan. Resulting in inaccurate test results, increased equipment downtime, and affecting production efficiency.

Choosing a high-performance IC spring test probe can significantly improve the integrity of test signals, reduce maintenance costs, and extend equipment lifespan. In high-frequency signal testing, high current loads, and extreme environments, the correct test probe can bring a qualitative leap to your testing process.

In this article, Johoty will unveil 5 efficient and reliable test probe solutions for you. Help you optimize the performance of test fixture and improve production efficiency. If you are looking for high-quality ICT/FCT/ATE spring loaded test probe, Johoty’s professional solutions will be your ideal choice. Please continue reading our solutions to check how to find the best test probe for your testing projects!

Read: IC Spring Test Probes

How to choose a Test Probe suitable for Test Fixture?

Choosing a test probe is like selecting a capable assistant for your test fixture. If you choose the right one, testing will be fast and accurate; Wrong choice, there are a bunch of problems! Firstly, the electrical performance must be reliable, and the impedance must match the signal, otherwise the signal will be distorted. The current carrying also needs to be strong enough, don’t overheat and strike immediately after testing. High frequency testing also requires selecting test probe with low noise and low loss for stable signal transmission.

Secondly, the mechanical performance should not pull the hips, and the contact force should be just right. Too light for poor contact, too serious for testing points. Durability also needs to be strong, it can contact >100,000 times without breaking, which is worry free and cost-effective.

Moreover, environmental adaptability is crucial, as it must withstand high or low temperatures, corrosion, humidity. In automotive electronics or industrial environments, test probe must be of a tough guy grade. Finally, compatibility and cost-effectiveness also need to be considered. The test probe needs to be adapted to your testing point and cannot be too expensive, after all, saving money is also a hard principle! Choosing the right test probe, the testing efficiency will take off directly!

Read: ICT/FCT/ATE Spring Loaded Test Probes

How to choose a suitable test probe for test fixture?

Electrical performance: the key to testing accuracy

Electrical performance of test probe directly affects the transmission quality and accuracy of test signal. In order to ensure test signal is not distorted, test probe impedance must match the impedance of the circuit being tested. If the impedance can’t match with each, it’ll cause signal reflection, which in turn affects test results. Low contact resistance ensures stable current between test probe and circuit board, which is crucial for high-precision testing. The frequency response of test probe needs to cover your application requirements. If test signal frequency is high, you need to choose spring loaded probe that can support high-speed signals.

Mechanical properties: durability and precise contact

A good test probe has excellent mechanical strength, which directly affects durability and long-term effectiveness of test probe. Common test probe materials include stainless steel and beryllium copper alloy. Choosing materials that are wear & corrosion-resistant can effectively extend test probe lifespan. Elastic design of test probe directly affects its contact effect with test point. A hard test probe may cause damage to the circuit, while a too soft test probe may lead to poor contact. Frequent testing may lead to wear of test probe, so it is necessary to choose wear-resistant materials to avoid testing errors caused by probe wear.

Read: IC Spring Test Probes

Environmental adaptability: Adapt to various working conditions

Test probe often needs to work in high humidity, high or low temperature, complex working environments. Working temperature range of test probe needs to meet testing environment. In high temperature, it is necessary to select testing probe with high temperature tolerance. If humid or prone to dust accumulation, choose a testing probe with good sealing performance. This can effectively prevent liquid, moisture and dust from affecting test results. If there may be corrosive substances in testing environment, choose gold plating or stainless steel with strong corrosion resistance. This can effectively extend test probe lifespan.

Compatibility: Seamless connection with testing fixture

Compatibility determines whether test probe can use smoothly with various testing devices. If test probe isn’t compatible with target device, it may result in test failure or inability to obtain accurate test data. Different testing equipment may require BNC,SMB, or pogo pin. When selecting, ensure test probe interface is compatible with the device. The size of the test probe needs to match circuit size of UUT. A test probe is too large to reach precise test points, while a probe that is too small to be unstable. Some test probes adopt modular design, supporting the replacement of different probes and accessories. This design enables test probe to be used in various testing scenarios, increasing its versatility.

Read: Spring Test Probe for ICT/FCT/ATE

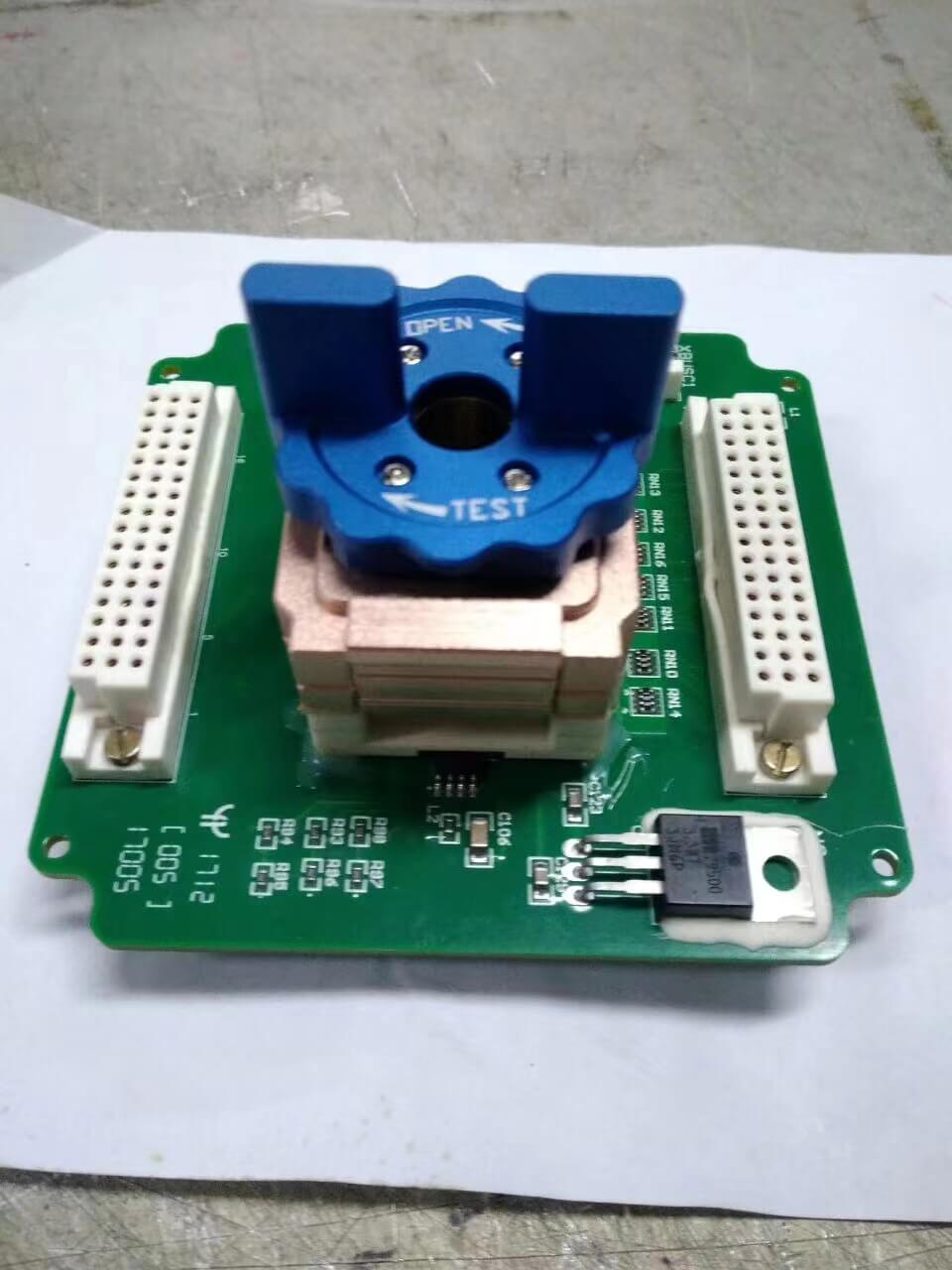

5 Best test probe Solutions for Efficient Test Fixture

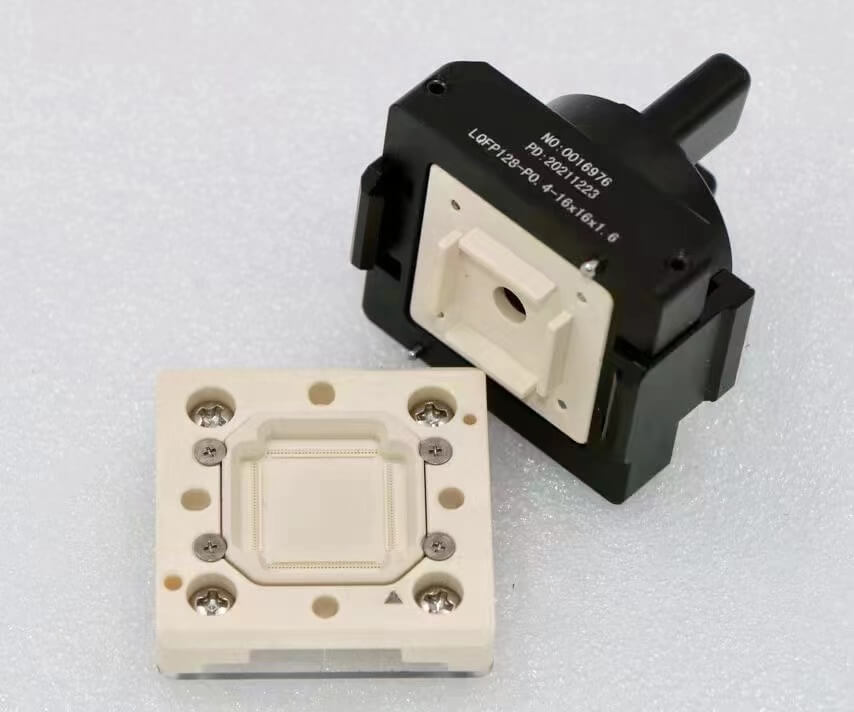

High-frequency test probe

A high performance solution designed for precision testing, supporting 5G, 6G, low insertion loss and high return loss. It utilizes advanced high-frequency technology to provide faster and more accurate signal measurements. Suitable for high-speed circuits and complex test environments. Low contact resistance, high temperature resistance, strong anti-interference ability, test results have high reliability and consistency.

Used in signal detection of high frequency communication equipment, performance testing of RF modules, and quality control of high-end electronic products.Johoty high frequency test probes have high sensitivity, low crosstalk, impedance matching, and stability. It reduces test errors, precise contact points and temperature stability, and improves test efficiency.

Johoty’s 5Gbps test probe was used during the testing of a 5G communication device. It successfully reduced signal interference and improved test accuracy. Engineers were able to quickly locate problems and optimize product design.

Heavy-duty test probe

Johoty’s professional tools are designed for high-load, high-intensity test environments. It is made of highly wear-resistant materials and optimized design to withstand high pressure and frequent use. It is suitable for testing of high-current and high-power equipment. With superb pressure resistance, long-lasting durability and precise contact performance, every test has efficient and stable performance.

Used in power equipment, power tools, automotive electronics, and industrial automation equipment. Heavy-duty test probes can withstand more mechanical shocks and higher current loads. It minimizes equipment damage and enhances the safety and reliability of the testing process.

Johoty Heavy Duty test probes are used to successfully perform stability tests with high power currents during periodic inspections of industrial equipment. It helps engineers to quickly troubleshoot potential faults in the power system and improves overall productivity.

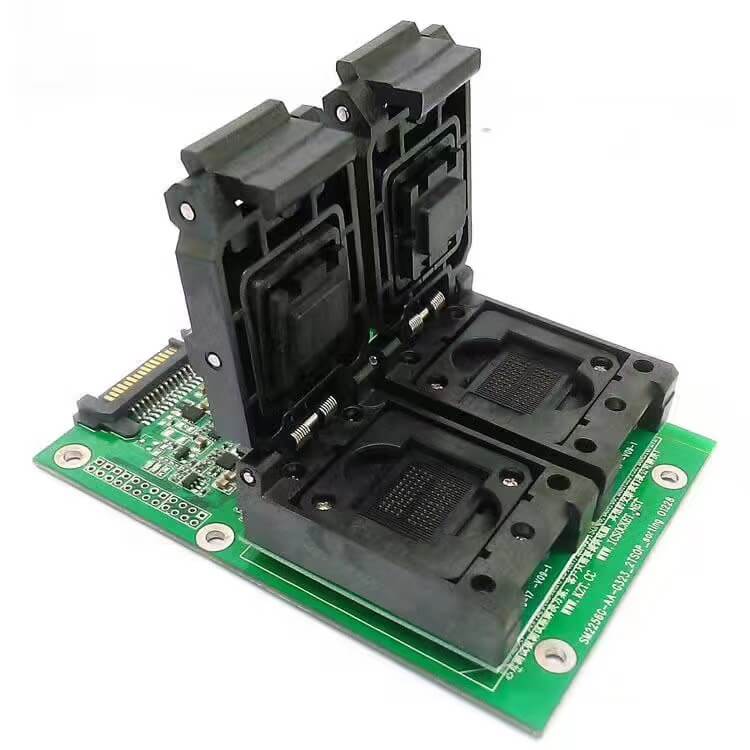

Micro-miniature test probe

Designed as a top-of-the-line solution for efficient test fixtures for high-density PCBs and micro-components, Johoty specializes in delivering superior test performance for electronics that require precise, high-density connections. The miniaturized design provides stable and reliable signal transfer in a very small space. At the same time, Johoty’s spring test probe can keep high accuracy and speed during testing.

The applications are very wide, suitable for high frequency circuits, PCB testing, precision instruments and advanced semiconductor testing.Johoty test probe is made of stainless steel or beryllium copper, which have long lifespan. It also has low contact impedance to keep test result accuracy. It has excellent anti-interference capability and continuous stable performance in electromagnetic environments.

An Italian electronics company uses Johoty miniature test probes for circuit board testing of its new smartphones. The customer was able to increase test efficiency, reduce failure rates, and significantly lower development costs. For engineers, choosing Johoty miniature test probes can effectively improve work efficiency. It also ensures high quality test results, leading to higher levels of design and production.

High-temperature test probe

Designed for precision testing in high-temperature environments, these probes are designed to withstand operating temperatures up to 200°C or more without deformation or oxidization. We utilize high-temperature resistant nickel-based alloys, stainless steel, ceramics, and advanced designs to maintain electrical and mechanical properties at extreme temperatures.

Our goal is to maintain excellent electrical performance even in harsh thermal environments. These spring test probes are used in high temperature testing of automotive electronics, aerospace, and industrial equipment. They excel in battery testing and power electronics, semiconductor testing, automotive electronics, aerospace, solar and fuel cell testing.Johoty high temperature test probes are extremely temperature resistant and maintain good contact stability and low contact impedance.

We can customize probes for higher or wider temperature ranges to obtain accurate test data at high temperatures. Internationally recognized automobile manufacturers in the United States use Johoty high temperature test probes for high temperature environmental testing of battery modules. The customer successfully avoided the test error and equipment damage or intermittent caused by high temperature.

It effectively improves the testing efficiency and product reliability. For engineers, choosing Johoty high-temperature test probes can greatly improve test accuracy and safety in high-temperature environments. Stable test results can be obtained under severe conditions.

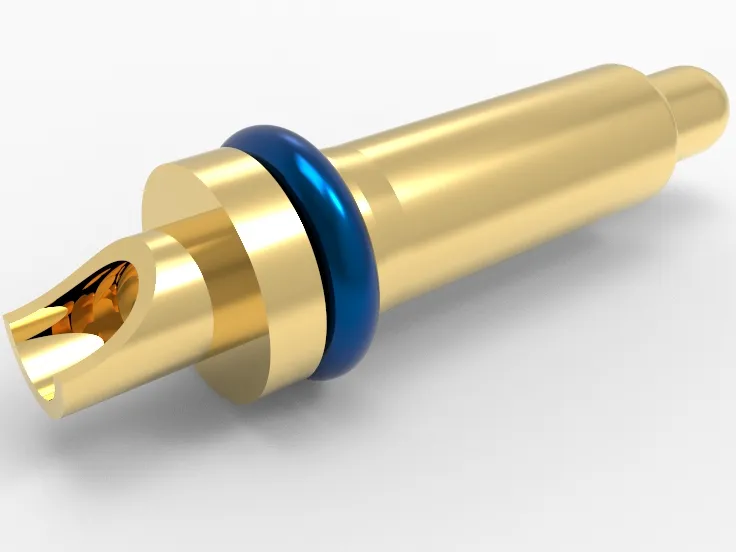

Multi-purpose test probe

Johoty multi-purpose test probe is a solution that engineers can’t afford to ignore when it comes to test fixtures. This series of test probes is designed for efficient testing with ultra-low contact impedance and highly durable spring construction. It supports high-speed signal transfer and is compatible with a wide range of PCB testing, functional testing, ICT testing, and high-frequency signal analysis, Johoty provides a stable and reliable connection.

It adopts precision gold-plated tip, pointed tip, flat tip, crowned tip, tungsten carbide, beryllium copper alloy as raw material, which significantly reduces signal loss. Its special alloy spring ensures an ultra-high life span of 200,000 active connections. Johoty’s spring test probes have high contact accuracy and wear resistance, maintaining excellent performance in high temperature, high humidity or corrosive environments.

In the application of a French automotive electronics manufacturer, Johoty solved the problem of poor contact caused by vibration of traditional probes. It helped the customer to significantly improve test stability, reduce maintenance time, and improve production efficiency. For engineers who want to improve test accuracy and accelerate the R&D cycle, this probe is undoubtedly the ideal choice to improve the performance of test fixtures.

How to maximize the performance of Test Probe in Test Fixture?

Choosing the right test probe material

A high quality beryllium copper or stainless steel will directly improve the contact performance and durability of test probe. johoty typically uses a high quality gold or gold plating, which significantly improves the stability of the contact and the speed of the signal transfer. When selecting a material, we often consider the current carrying capacity, oxidation resistance and stability of the contact with the surface being tested. The right material extends the service life of test probe and also improves the accuracy of the measurement.

Optimizing contact pressure

The amount of pressure at which test probe comes into contact with the object under test is critical. Too much contact pressure can damage the UUT and may leave scratches on the surface of the DUT. Too little contact pressure will result in poor signal contact and affect the measurement results. Therefore, adjusting the contact pressure to ensure that it is within the optimal range is one of the keys to improving the performance of test probe. It’s critical to maintain high stability of test fixture. In order to obtain the optimum pressure, a test probe with a pressure regulator can be selected.

Precise selection of test probe design

Different testing purposes require different types of test probes; for high frequency signal testing, choose a test probe with low inductance and high frequency response; for high current testing, choose a test probe that can carry high current and has a large contact area; and according to the testing requirements, choose the appropriate test probe design, which is very critical. Choosing the right test probe design according to the test requirements is very critical and a common challenge for engineers. You can contact Johoty, we can help you to improve your test performance and ensure the accuracy and safety of your tests.

Pay attention to test probe cleaning and maintenance

Contamination of test probe’s contact surface can seriously affect its performance, resulting in unstable signals or even measurement failure. text fixtures are available for both automated and non-automated testing, and regardless of the type of test, a clean working environment needs to be maintained. Regular cleaning of test probes inside the text fixture to ensure that the contact surfaces are free of dust, oxidized layers or other contaminants is a daily task to improve their performance. Using professional cleaning tools and detergents to keep the contact surface clean can greatly improve the test accuracy and service life of test probe.

Reasonable configuration of the installation angle and position of test probe

During the testing process, the installation angle and position of test probe will directly affect the stability and accuracy of the measurement. Optimizing the angle of test probe ensures more uniform contact with the object under test and reduces signal errors caused by poor contact. By adjusting the position and angle of test probe, the performance of the text fixture can be maximized, ensuring the accuracy of the test results.

Why Choose Johoty’s Test Probe Solution?

Accurate test performance for efficient testing

Accurate test performance is a fundamental requirement for engineers when designing and manufacturing test fixture, and Johoty’s test probe solutions use advanced technology to ensure that each test probe is extremely accurate and consistent. Johoty’s test probe provides extremely accurate contact in the testing of circuit boards and more complex industrial products. We always believe that we can make your text fixture give you highly accurate test data. This enables engineers to quickly verify the correctness of a design during the design phase, reducing the time for rework and modifications.

Highly Compatible, Easily Adaptable to Different Designs

Each test fixture has its own unique design requirements, and Johoty’s test probe series is highly compatible with a variety of designs and working environments. When you need to test a complex circuit board, or a large piece of machinery, Johoty has a solution that fits the bill. With their versatile design, engineers have more flexibility to choose test probe when designing and producing test fixture. You won’t waste time and effort on compatibility issues in your projects.

Innovative design concepts for increased productivity

Johoty’s test probe is more than just test consumables, they are designed with a strong focus on productivity. some of Johoty’s test probe features an innovative auto-calibration technology that adapts to different environments. This greatly reduces manual intervention and calibration time for ICT or FCT engineers. Meanwhile, for engineers who are involved in high-precision IC chip testing or test development, it is also a great help to save time and improve efficiency. johoty’s test probe adopts modular design, which allows engineers to quickly change and combine different test probes when producing test fixture, which can greatly improve the efficiency of engineers and test fixture. This can obviously improve working efficiency of engineers and test fixture.

Superior durability reduces maintenance costs

Engineers attach great importance to the durability, stability, and consistency of the tools, and in the long term, can reduce the unnecessary frequent replacement, maintenance and cost. johoty’s test probe is made of high-quality beryllium copper, stainless steel gold-plated, and have a super durable. Designed to withstand up to 200,000 or 300,000 cycles, they are capable of withstanding frequent test operations. You will be able to design, manufacture, commission and maintain test fixture with less tool maintenance and replacement. You can see the significant benefits of reducing TCO over time.

Recommended by engineers worldwide for broad industry applications

Johoty’s test probe uses in a wide range of industries. It becomes preferred choice of engineers worldwide based on its excellent reputation and high performance. From semiconductors to medical devices, from automotive to aerospace, Johoty’s test probe has excelled in a variety of fields. These wide range of industry applications and recommendations from engineers make Johoty the ideal choice when designing and manufacturing test fixture.

Conclusion: Improve Test Fixture Efficiency, Start with Johoty

Choosing right test probe is the key to improving overall test efficiency in the design and use of efficient test fixture, Johoty provides engineers with a series of high-quality test probe solutions based on superior technical strength and innovative spring test probes. We can minimize test errors, increase test speed and extend test fixture lifespan. For precision testing of small quantities and efficient testing of large production lines, Johoty’s test probe can bring you performance that exceeds your expectations.

With Johoty, you are choosing professionalism and innovation to make your test fixture more efficient and accurate. Experience Johoty’s test probe today and make your test fixture more competitive and your projects more achievable. Buy now and let’s move towards a more efficient future together!

Read: IC Spring Test Probes